Professional Documents

Culture Documents

Head Ropes: Mine Hoisting Solutions®

Uploaded by

JORGE0 ratings0% found this document useful (0 votes)

12 views1 pageCable para Huinches

Original Title

NSnonRotatingRopes

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCable para Huinches

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views1 pageHead Ropes: Mine Hoisting Solutions®

Uploaded by

JORGECable para Huinches

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

HEAD ROPES ROTATION

N.R.H.D. Construction RESISTANT

CONSTRUCTION

Our Design Engineers have been

Head-Ropes

looking for a winding rope that

concentrated most of the qualities Drum Winding

of a Lock Coil Rope and that of a Friction Winding

N.R.H.D. 7 Series

Flattened Strand Rope, IE: resistance

12 x 7 Langs Lay

to rotation under tension, smooth Metallic Core: (4x17) + (4x7) + (4x7)

outer surface, maximum steel content

in the cross section and high wire NOMINAL APPROPRIATE BREAKING

tensile in order to obtain the highest DIAMETER MASS STRENGTH

possible breaking strength for an (MINIMUM)

equal size, maximum flexibility and

resistance to crushing. mm Inch kg/m lb/ft kN lbs

19 3/4 1.50 1.01 268 60,200

The result of this research is a wire 22 7/8 2.00 1.34 360 81,000

rope family call N.R.H.D. for Non- 26 1 2.80 1.88 500 112,400

Rotating High Density. 29 1 1/8 3.50 2.35 625 140,400

The smooth outer surface is achieved 32 1 1/4 4.37 2.94 781 175,600

by an outer layer of 12 langs lay 35 1 3/8 5.40 3.63 940 211,300

38 1 1/2 6.25 4.20 1,110 249,500

strands. This is very efficient for

42 1 5/8 7.45 5.01 1,332 299,400

wear resistance.

45 1 3/4 8.55 5.75 1,532 344,300

Having the Independent Wire Rope 48 1 7/8 9.85 6.63 1,754 394,200

Core laid up in an opposite direction 51 2 11.10 7.47 1,998 449,100

to the outer layer, give s resistance to 54 2 1/8 12.40 8.34 2,242 504,000

rotation. The tension, when applied

to the rope, induces opposite and

balanced torque.

Steel content into the cress section area

is improved through a Warrington Lay

construction (4/4) + 4 strands. Such an

arrangement for the strands in a rope

is an extension of the arrangement of

the wires in the strand. It improves

fatigue and crushing resistance by

avoiding sharp contacts between the

strands as they are parallel to each

other.

The total number of wires in the

rope, 208 for N.R.H.D.7 and 312 for

N.R.H.D.19, gives good flexibility

and allows high tensile wires to be

used.

Mine Hoisting Solutions®

You might also like

- Sucker Rod Couplings PDFDocument3 pagesSucker Rod Couplings PDFParag PadoleNo ratings yet

- DCP Product DatasheetDocument16 pagesDCP Product Datasheetsandip0002No ratings yet

- ALS7501 01 Sucker Rods Brochure PDFDocument8 pagesALS7501 01 Sucker Rods Brochure PDFedinson saenzNo ratings yet

- All Metal Lock Nuts: Earnest Technical Bulletin Stover StyleDocument3 pagesAll Metal Lock Nuts: Earnest Technical Bulletin Stover StyleDavid Lay IINo ratings yet

- Wire Rope Oil-And-Gas-Drilling-User-GuideDocument16 pagesWire Rope Oil-And-Gas-Drilling-User-GuideJhon Fabio ParraNo ratings yet

- Wire Rope Design: C0NtentDocument20 pagesWire Rope Design: C0NtentVisweswaran RangasamyNo ratings yet

- Belting Correia de BorrachaDocument54 pagesBelting Correia de BorrachaFilype NascimentoNo ratings yet

- Tapered Equipment: Secoroc Rock Drilling ToolsDocument12 pagesTapered Equipment: Secoroc Rock Drilling Toolsedin saquilNo ratings yet

- Properties: Navigation 1/4" (6.55 MM) Monoconductor Corrosion ResistantDocument1 pageProperties: Navigation 1/4" (6.55 MM) Monoconductor Corrosion ResistantRaed fouadNo ratings yet

- SD II PDF - OCRDocument18 pagesSD II PDF - OCRSuraj KumarNo ratings yet

- 199 Imi EkoguardDocument2 pages199 Imi EkoguardEngr KamalNo ratings yet

- Irjet V5i5220Document4 pagesIrjet V5i5220afaq AhmadNo ratings yet

- Wire Rope Specifications: Design FactorDocument46 pagesWire Rope Specifications: Design FactorjackNo ratings yet

- Rebar Works: VCDLSJ2020Document56 pagesRebar Works: VCDLSJ2020Abelost ZenithNo ratings yet

- 9 MiningDocument12 pages9 MiningSuelen BarbosaNo ratings yet

- Oil & Gas Drilling User's GuideDocument16 pagesOil & Gas Drilling User's GuideDavid OrtegaNo ratings yet

- Timber Construction: Connection Design According To Nzs 3603 Using Spax ScrewsDocument12 pagesTimber Construction: Connection Design According To Nzs 3603 Using Spax Screwstimur sibaevNo ratings yet

- Section 5 - Material - StrengthsDocument32 pagesSection 5 - Material - StrengthsChris MedeirosNo ratings yet

- Analysis, Design and Construction of Tie-Back Anchor For Coffer DamDocument7 pagesAnalysis, Design and Construction of Tie-Back Anchor For Coffer DamThanh Bình HuỳnhNo ratings yet

- Basic Cable&Cable CareDocument39 pagesBasic Cable&Cable CareDivyansh Singh ChauhanNo ratings yet

- Mohawk Riserlite Indoor Outdoor Fiber CableDocument2 pagesMohawk Riserlite Indoor Outdoor Fiber CablecolinyNo ratings yet

- Cabillas Convencionales PDFDocument12 pagesCabillas Convencionales PDFgenesisNo ratings yet

- Leader Cable - 132kVDocument8 pagesLeader Cable - 132kVTeo Yi LinNo ratings yet

- Rope IIIDocument20 pagesRope IIIDhruv ShindeNo ratings yet

- Catalog Shear ConnectorDocument16 pagesCatalog Shear ConnectordedeNo ratings yet

- Design and Development of Hydraulically Operated Slag Remover For Steel FurnaceDocument12 pagesDesign and Development of Hydraulically Operated Slag Remover For Steel FurnaceTJPRC PublicationsNo ratings yet

- Sucker Rods Brochure 851 06Document12 pagesSucker Rods Brochure 851 06Ronald LlerenaNo ratings yet

- Design Guide To AS1720Document12 pagesDesign Guide To AS1720Adam DawsonNo ratings yet

- Wire & Cable 202312261659586681900588413Document24 pagesWire & Cable 202312261659586681900588413Amir IqbalNo ratings yet

- TEC BrochureDocument6 pagesTEC Brochurejose05olivera96No ratings yet

- EMPHASER EX10-12-15T3 DatenblattDocument2 pagesEMPHASER EX10-12-15T3 DatenblattDaniel BivolaruNo ratings yet

- Rotor of Separator SF 600Document2 pagesRotor of Separator SF 600Fareed EngineeringNo ratings yet

- Endurance of Compacted Steel Wire Ropes: ObjectivesDocument7 pagesEndurance of Compacted Steel Wire Ropes: ObjectivesYadi KusmayadiNo ratings yet

- Ijert Ijert: Strength Study On Castellated BeamDocument7 pagesIjert Ijert: Strength Study On Castellated BeamAdnan NajemNo ratings yet

- Water Cooled Cable For Electric FurnaceDocument4 pagesWater Cooled Cable For Electric FurnaceWAWANNo ratings yet

- Development of Elevator Ropes: Tech Tip 15Document2 pagesDevelopment of Elevator Ropes: Tech Tip 15أحمد دعبسNo ratings yet

- Reinforcedself SupportDocument2 pagesReinforcedself SupportTREE OF LIFENo ratings yet

- Adp NmsDocument1 pageAdp NmsTREE OF LIFENo ratings yet

- Join HW 3 BBDocument3 pagesJoin HW 3 BBYuanjing Xu100% (1)

- Flux Cored Wires (Elga)Document15 pagesFlux Cored Wires (Elga)DarkoPerićNo ratings yet

- Power ScrewsDocument17 pagesPower Screwsxttyzz03No ratings yet

- Steel Wire RopesDocument34 pagesSteel Wire RopesMarius GrigorasNo ratings yet

- Care Lifting CatalougeDocument28 pagesCare Lifting CatalougeHari KrishnaNo ratings yet

- Wire Jacketing Nylon FirestoneDocument14 pagesWire Jacketing Nylon FirestoneAndres Valencia MiraNo ratings yet

- Presented By:: Introduction To Accumulative Roll Bonding Process (Arb)Document106 pagesPresented By:: Introduction To Accumulative Roll Bonding Process (Arb)amelNo ratings yet

- Tapcon: Storm Guard AnchorsDocument2 pagesTapcon: Storm Guard Anchorsblessed cccNo ratings yet

- HammacatalogueDocument20 pagesHammacataloguegilea stefanNo ratings yet

- SteelccreteDocument4 pagesSteelccreteOSE0597No ratings yet

- Chapter 3: Casing Design & Selection: By: Mutia KharunisaDocument7 pagesChapter 3: Casing Design & Selection: By: Mutia KharunisaKader BakourNo ratings yet

- Technical-Documentation (Casar)Document32 pagesTechnical-Documentation (Casar)Caio AraujoNo ratings yet

- Corod SWR High Strength 29feb12Document3 pagesCorod SWR High Strength 29feb12Ronald LlerenaNo ratings yet

- 11 SS Type Hydrophone CableDocument2 pages11 SS Type Hydrophone CableMathew Manoj ThyvelikakathNo ratings yet

- MD - Chapter 1Document5 pagesMD - Chapter 1Delia GantiaNo ratings yet

- Multi Rib Metal Roofing TileDocument1 pageMulti Rib Metal Roofing Tilevadivel415No ratings yet

- Aluminum HoneycombDocument8 pagesAluminum HoneycombManoj ManoharanNo ratings yet

- CablesDocument20 pagesCablesalejotoroNo ratings yet

- Composite Light Poles: Hoop HelixDocument2 pagesComposite Light Poles: Hoop Helixfadzlee zainalNo ratings yet

- Overhead Conductors: ACAR (Aluminium Conductor, Aluminium Reinforce)Document21 pagesOverhead Conductors: ACAR (Aluminium Conductor, Aluminium Reinforce)Malik Shahzeb AliNo ratings yet

- LOT 4 - Technical Specs - 132 KV Transmission Line AccessoriesDocument13 pagesLOT 4 - Technical Specs - 132 KV Transmission Line AccessoriesPeters Clever OkelloNo ratings yet

- Secadores KaeserDocument13 pagesSecadores KaeserDiego Laya PicadoNo ratings yet

- General Electric - Inlet Air RecommendationDocument28 pagesGeneral Electric - Inlet Air Recommendationhussain mominNo ratings yet

- ACI 304R Guide For Meas., Mix., Transp., & Placing ConcDocument41 pagesACI 304R Guide For Meas., Mix., Transp., & Placing ConcVasanth KumarNo ratings yet

- 6-Absorption Stripping Pt1Document18 pages6-Absorption Stripping Pt1Naufal FasaNo ratings yet

- ST014 Sod - MetasilicateDocument1 pageST014 Sod - MetasilicateAreIf Cron BmxStreetNo ratings yet

- Technical Paper SiC Ceramic MembranesDocument5 pagesTechnical Paper SiC Ceramic MembranesEman El DsoukyNo ratings yet

- Bouwpaco Powder Dosing & PackingDocument33 pagesBouwpaco Powder Dosing & PackingAlexander AeromodelistaNo ratings yet

- Bill of QuantitiesDocument18 pagesBill of QuantitiesMohd ShahrizanNo ratings yet

- Materials For High Temperature High Pressure Applications andDocument28 pagesMaterials For High Temperature High Pressure Applications andDrVRKNo ratings yet

- Z&J Technologies GMBH: Conversion Table of EN - Materials vs. US Materials (Assorted by ASTM No.)Document1 pageZ&J Technologies GMBH: Conversion Table of EN - Materials vs. US Materials (Assorted by ASTM No.)Nattapong PongbootNo ratings yet

- D 3633 - 98 - RDM2MZMDocument3 pagesD 3633 - 98 - RDM2MZMluisandrade100% (1)

- Argillon ICA DeNOx EnglishDocument2 pagesArgillon ICA DeNOx Englishukhfulajif;gNo ratings yet

- RF Series-Catalog 3800 - SectionADocument3 pagesRF Series-Catalog 3800 - SectionAStefan DinuNo ratings yet

- HC15 Manual PDFDocument24 pagesHC15 Manual PDFnstefosNo ratings yet

- Lab Report#01: Safety Guidelines and Introduction To Manufacturing Processes LabDocument3 pagesLab Report#01: Safety Guidelines and Introduction To Manufacturing Processes LabMuhammad Owais AwanNo ratings yet

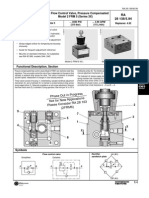

- 2-Way Flow Control Valve, Pressure Compensated Model 2 FRM 5 (Series 3X)Document4 pages2-Way Flow Control Valve, Pressure Compensated Model 2 FRM 5 (Series 3X)Dias EliNo ratings yet

- Carrier FCUDocument140 pagesCarrier FCUInventor SolidworksNo ratings yet

- Location Planning and AnalysisDocument42 pagesLocation Planning and AnalysisSobhit Gupta100% (2)

- Megadoor S1500 Brochure - HB 290Document28 pagesMegadoor S1500 Brochure - HB 290Shamsul Bahrin SulaimanNo ratings yet

- NPCP Chapter 2 PDFDocument12 pagesNPCP Chapter 2 PDFbenNo ratings yet

- Flowserve Durco CatalogDocument36 pagesFlowserve Durco CatalogbryandownNo ratings yet

- C-23 Life Cycle of Process Plants PDFDocument9 pagesC-23 Life Cycle of Process Plants PDFnike_y2k100% (1)

- SMAC LCR16 Linear Rotary Actuator BrochureDocument2 pagesSMAC LCR16 Linear Rotary Actuator BrochureElectromateNo ratings yet

- Epoxy CuringDocument8 pagesEpoxy CuringUrban Renewal Development100% (1)

- RUD Industrial ChainsDocument12 pagesRUD Industrial ChainsBenjamin ČakićNo ratings yet

- 2016good and ImportantDocument4 pages2016good and ImportantMahdi koolivandNo ratings yet

- Sea Water Intake SystemDocument17 pagesSea Water Intake SystemJayne Mawusi Siaw-Botchway100% (1)

- Welding TechnologyDocument26 pagesWelding TechnologyHiren Kumar100% (1)

- A22009BDocument162 pagesA22009BInstalatii CivileNo ratings yet

- Nitrogen N2 - Data Class 1Document2 pagesNitrogen N2 - Data Class 1neyzaNo ratings yet