Professional Documents

Culture Documents

H-10207 00 0ea00-001f DB-CSCS KKS Identification Rule For Variables - A

Uploaded by

nguyen rinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

H-10207 00 0ea00-001f DB-CSCS KKS Identification Rule For Variables - A

Uploaded by

nguyen rinCopyright:

Available Formats

Dates : Name : Reference :

Approval Return Status

Comments

SigN Date

SigN.

SigN.

SigN.

SigN.

SigN.

SigN.

A SigN. 2016/05/14 First Issue GFE

HXN LPH LPH

REV ESTABLISHED CHECKED APPROVED DATE MODIFICATIONS STAT.

VIETNAM ELECTRICITY

TRI AN HYDROPOWER COMPANY

LOT NO.5:“DESIGN,MATERIAL,EQUIPMENT SUPPLY AND

TECHNICAL SERVICES”

CONTRANT NO:99/HD-TDTA/ALSTOM

PURCHASER: SUPPLIER:

ALSTOM-HYDRO

CSCS KKS IDENTIFICATION RULE FOR VARIABLES

SCALE SIZE

SUBSUPPLIER:

A4

REV. SH/SH END N of S

H-10207 00 0EA00-001F DB 1/24 24

A

MODIFICATIONS TABLE

REV ESTABLISHED CHECKED APPROVED DATE MODIFICATIONS Status.

A HUANG XIN LI PENGHAI LI PENGHAI 2016/05/14 FIRST ISSUE GFE

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .2/A

SUMMARY

1 PURPOSE ............................................................................................................... 4

2 REFERENCE DOCUMENTS ................................................................................... 4

3 ABBREVIATION ...................................................................................................... 4

4 KKS STRUCTURE .................................................................................................. 5

4.1 BASIC STRUCTURE ............................................................................................... 5

4.2 KKS STRUCTURE FOR CSCS VARIABLES ........................................................... 5

5 LEVEL1 SYSTEM CODE ........................................................................................ 6

5.1 PROJECT WORK UNIT CODE---G F0 ............................................................................. 6

5.2 FUNCTION CODE ----- F1 F2 F3 ................................................................................... 7

6 LEVEL2 EQUIPMENT CODE ................................................................................ 13

6.1 CODE--- A1 A2 ........................................................................................................ 13

7 LEVEL3 COMPONENT CODE FOR VARIABLES ................................................ 17

7.1 “B1B2” .................................................................................................................. 18

7.1.1 Input signals (from field to C&M system) ........................................................... 18

7.1.2 Output signals (from C&M system to field) ........................................................ 18

7.1.3 Calculated (output) signals (from C&M system to field).................................... 19

7.1.4 Controller Automatically generating Internal Variables .................................... 20

7.2 “BN” ...................................................................................................................... 20

7.2.1 Analogue signals ................................................................................................. 20

7.2.2 Binary signals....................................................................................................... 20

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .3/A

1 PURPOSE

KKS (Kraftwerk-Kennzeichensystem) is an internationally used designation system for power

stations. For its structure and system of codification, KKS corresponds with international standards

as IEC and ISO.

This document details System (function) KKS Code to define the KKS signal identification rules

and its application in the ALSPA Controplant System.

2 REFERENCE DOCUMENTS

This document is valid for ALSTOM Hydro. (P&S).

Document Name Document Number

Alstom Hydro Numbering System for Products and P&S HEM7.03.1005 rev B

Engineering General Rules

3 ABBREVIATION

NA

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .4/A

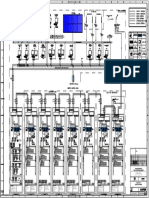

4 KKS STRUCTURE

4.1 BASIC STRUCTURE

Breakdown level 0 1 2 3

Title of

Block Function Equipment unit Component

breakdown level

Designation of

G F0 F1 F2 F3 FN FN A1 A2 AN AN AN A3 B1 B2 BN BN BN

data character

Type of data

(N) (N) A A A N N A A N N N (A) A A N N N

character

A : Alpha-numerical

N : Numerical

4.2 KKS STRUCTURE FOR CSCS VARIABLES

The codification of CSCS variables, following the KKS basic structure, We defined 3 levels,

System level, Equipment level, Component level, Between each level,

There is a underline(_) to link them.

For example : 01PAC10_AP001_XG01 , It means “pump1 started”

Note : For Level1 and Level 2 , It is the same as Alstom Hydro Numbering System for Products

and P&S Engineering General Rules: HEM7.03.1005 rev B

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .5/A

5 LEVEL1 SYSTEM CODE

This level is consist of Working unit key and Function Key :

Working unit key:

It is composed of 2 numerical digits :

the breakdown level “0” : block (G)

the breakdown level “1” : function (F0)

Function Key:

It is composed with 3 letters(F1,F2,F3) and 2 (FN, FN )numerical digits

5.1 PROJECT WORK UNIT CODE---G F0

Breakdown level 0 1 2 3

Title Block Function Equipment key Component key

Designation of

G F0 F1 F2 F3 FN FN A1 A2 AN AN AN A3 B1 B2 BN BN (BN)

data character

Type of data

(N) (N) A A A N N A A N N N (A) A A N N N

character

Equipment unit

Apparatus,

Total

Signal code Part of plant C&I range Signal

Plant

Manufacturing

Installation

Table5.1 Identification of signals in level 1

G F0 Work unit

0 0 General power plant (all area)

0 * Common part of the whole part of the unit *

1 * Common part of the whole part of the unit *

2 0 Common part in the power house

2 * Common part for more than one unit

3 0 Common part for penstock

3 * Free for use

4 0 Common part of the Lower reservoir

4 * Free for use

5 0 Common part of the Upper reservoir

5 * Free for use

6 0 Common part of the transformer area

6 * Free for use

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .6/A

7 0 Tunnel

7 * Free for use

8 0 Switchyard

8 * Free for use

9 0 Outdoor building

9 * Outdoor building

Table 5.2

NOTE : * = 1 to 9

5.2 FUNCTION CODE ----- F1 F2 F3

0 : Overall Plant engineering

0AA : Technical Project Coordination

0AB : Technical Project Management

0AQ : Quality Assurance Aspects (if cannot be related directly to a KKS item)

0BA : General single line diagram

0BB : Cabling and cable trays system,

0BC : Electrical installation

0BD : Grounding system

0BE : Electrical special studies (Insulation coordination, Short Circuit calculation, Stability

of HV network…)

0CA : Piping system

0CE : Mechanical special studies

0DA : Civil Work / General Arrangement

0EA : General control system

A : Grid and distribution system

A*D : HV switchyard

Where * is replaced by a letter below according to the voltage level :

* Voltage level

B >420kV system

C 380kV to 420kV

D 220kV to 359kV

E 110kv to 219kV

F 60kV to 109kV

G 45 to 59kV

H 30 to 44kV

J 20 to 29kV

K 10 to 19kV

L 6 to 9 kV

M 1 to 5kV

N <1kV

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .7/A

Table 5.3

ATA : Transformer equipment HV / HV

B : Power transmission and auxiliary power supply

BAA : Generator leads (MV main busbars and cells)

BAB : Surge and measurement cabinets

BAC : Generator circuit breaker

BAT : Power transformer, including cooling system

BAW : Generator neutral point system

BBA : 6,3kV – Main distribution board

BBT : MV transformer

BFA : 400V AC distribution board

BFL : 220V AC distribution board

BFT : Auxiliary transformer

BRA : UPS - 400V AC distribution board

BRU : UPS Converter, inverter

BRV : Emergency power generating equipment (diesel)

BTA : 220 V DC batteries

BTB : 125 V DC batteries

BTC : 48 V DC batteries

BTD : 48 V CD batteries (telecommunication)

BTE : 24 V DC batteries

BTL : 220 V DC batteries charger

BTM : 125 V DC batteries charger

BTN : 48 V DC batteries charger

BTQ : 24 V DC batteries charger

BUA : 220 V DC distribution board

BUB : 125 V DC distribution board

BUC : 48 V DC distribution board

BUD : 48 V CD distribution board (telecommunication)

BUE : 24 V DC distribution board

C : Instrumentation and control equipment

CBA : Common auxiliaries control

CBB : Turbine governor control

CBC : Switchyard

CBD : Water intake / tail-race / Spillway control

CBE : Dispatching RTU

CFA : Measurement and recording cabinets (if not incl. in CJA)

CHA : Generator protection system / Generator-transformer protection system

CHB : Busbar protection system

CHC : Line protection system

CHD : Transformer protection system (if separated from CHA)

CHE : Block protection system

CHX : Common protection system

CJA : Unit control / synchronisation cabinets

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .8/A

CJD : Transformer control system

CKA : Plant Operator Stations, Supervisory & Joint Control

CKB : Simulator system

CKC : CMMS (computerized maintenance management systems)

CMA : Vibration monitoring

CMB : Air gap monitoring

CMC : Partial discharge monitoring

CMD : Temperature monitoring

CMX : Other monitoring or common

CVA : Marshalling cabinets (if not included in system/function)

CWA : Main control console

CWB : MIMIC

CXA : Draining / dewatering system local control

CXB : Cooling water system local control

CXC : Raw water system local control

CXD : Drinking water system local control

CXE : Low pressure compressed air system local control

CXF : High pressure compressed air system local control

CXG : HVAC system local control

CXH: : Oil injection for thrust bearing

CXK : Chilled water control,

CXP : Pressure oil system, control

CXS : Oil treatment / Oil-water separation control

CXV : Inlet valve (Penstock) control system

CYA : Telephone EPAX/EPABX system

CYB : Telecommunication systems

CYE : Fire detection alarm system

CYF : Clock system (if separated from CKA)

CYG : Remote control system (only telecom eqpment)

CYH : Remote measuring and counting system (only telecom eqpment)

CYM : Access / security / surveillance control system

CYS : Radio / paging system

CYT : Closed circuit television system

CYU : Communication networks

G : Water supply and disposal

GAA : Raw water supply

GDA : Water treatment system

GDB : Water / Oil separation

GKA : Drinking water distribution system

GMA : Drainage system

GMB : Dewatering system

L : Steam-Water cycle

LN * : Water impounding works for hydraulic power plant

LNA : Headrace and tailrace system

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .9/A

LNB : Trash racks, Fish barrier

LNC : Dam, weir system (incl. hydraulic measurements)

LND : Spillway

LNE : Drainage system for the Dam

LNF : Pump system

LP*: Intake system, upper water system for hydraulic power plant

LPA : Trash racks

LPB : Isolating equipment

LPC : Piping and penstock system

LPE : Upstream surge tank

LQ* : Tailrace system, underwater system for hydraulic power plant

LQA : Tail-race system

LQB : Downstream surge tank

LQC : Isolating equipment

LQE : Trash racks for pumping

LRA : Lock

LRB : Lifting gear

LRC : Fish ladder

LS*: Common installations for hydraulic power plant

LSL : Drainage system (tunnel)

M : Main machine sets

The following list is not updated. For detailed information, please refer to KKS handbook.

MEA : Single Stage Pump Turbine Pump-Turbine

MEB : Double Stage Pump Turbine Pump-Turbine

MEC : Multi Stage Pump Turbine Pump-Turbine

MED : Deriaz Pump Turbine Pump-Turbine

MEF : Vertical Francis Turbine Turbine

MEG : Single Horizontal Francis Turbine Turbine

MEH : Double Horizontal Francis Turbine Turbine

MEI : Vertical Kaplan Turbine Turbine

MEJ : Propeller Turbine Turbine

MEK : SAXO Turbine Turbine

MEL : Bulb Turbine Turbine

MES : “S“ Amount Turbine – SAM Turbine

MEN : “S“ Aval Turbine – SAV Turbine

MEO : Pit Turbine Turbine

MEP : Vertical Pelton Turbine

MEQ : Horizontal Pelton Turbine

MS* : Spherical valve

MB* : Butterfly valve

MF* : Fixed cone valve

MG* : Gate Valve

Where is “*” is replaced by a letter below according to the location of the equipment:

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .10/A

I : Water intake

P : Head of Penstock (surge chamber)

Q : Spiral case inlet

A : Turbine Draft Tube

B : Bottom outlet

T : Tailrace R Residual Flow

MKA : Synchronous Motor/Generator Vertical Generator (Motor/Pump)

MKB : Synchronous Generator Vertical Generator (M&L)

MKD : Synchronous Bulb Generator Generator (M&L)

MKE : Asynchronous Generator (Variable speed) Generator (M&L)

MKF : Synchronous Generator Horizontal Generator (M&L)

MKG : Ring Motor Generator

MKH : Synchronous Condenser Generator

MKI : Small Synchronous Bulb generator Generator (Small)

MKJ : Asynchronous generator (Variable speed) Generator (Small)

MKK : Diesel Generator Generator

MEE : Thrust bearing if sold alone (not in generator neither in turbine scope)

MEU : Governor system MEM Start-up / SFC

MKC : Excitation (other than rotating parts) MTC Tisec

MRS : Speed increaser

P : Cooling water systems

PAC : Main cooling water system

PCC : Secondary cooling water system

Q : Auxiliary systems

QKA : Chilled water system

QSA : Mechanical oil treatment, storage and handling (generator, transformer and turbine)

QSB : Dielectric oil treatment, storage and handling

S : Ancillary systems

SAA : HVAC (Heating / Ventilation / Air conditioning)

SCA : Low pressure compressed air system

SCC : High pressure compressed air system

SGA : Fire water system,

SGC : Spray deluge / water / sprinkler system

SGF : Foam fire fighting system

SGJ : Fire fighting system (CO2)

SGK : Fire-fighting system (gas)

SGL : Fire fighting system (powder)

SGM : Fire barriers

SGP : Portable extinguisher

SGY : Fire detection system (local control equipment)

SLA : Lighting system

SMA : Cranes

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .11/A

SNA : Elevator

STA : Workshop equipment

STG : Laboratory workshop

U : Structures

UDA : General steel works (platforms…)

X : Heavy machinery (Auxiliaries)

XEA : Auxiliary water turbine

XKA : Auxiliary generator

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .12/A

6 LEVEL2 EQUIPMENT CODE

It is composed with 2 letters(A1,A2) and 4 (1 is optional)numerical digits(AN, AN ,AN, A3)

Breakdown level 0 1 2 3

Title Block Function Equipment key Component key

Designation of

G F0 F1 F2 F3 FN FN A1 A2 AN AN AN A3 B1 B2 BN BN (BN)

data character

Type of data

(N) (N) A A A N N A A N N N (A) A A N N N

character

Equipment unit

Apparatus,

Total

Signal code Part of plant C&I range Signal

Plant

Manufacturing

Installation

Table6.1 Identification of signals in breakdown level2

6.1 CODE--- A1 A2

A : Mechnical equipment

AA: valve,dampers,etc., include actuators, also manual; rupture disk equipment

AB: Isolating elements, air lock

AC: Heat exchangers, heat transfer surface

AE: Turning, driving, lifting and slewing gear (also manipulators)

AF: continuous conveyors, feeders (escalators)

AG: Generator units

AH: heating, cooling and air conditioning units

AJ: Size reduction equipment, only as part of process

AK: Compacting and packaging equipment, only as parts of process

AM: Mixers, agitators

AN: Compressor units, fans

AP: pump units

AS: Adjusting and tensioning equipment for non-electrical variables

AT: Cleaning, drying, filtering and separating equipment, excl. *BT*

AU: Braking, gearbox, coupling equipment, non-electrical converters

AV: Combustion equipment

AX: Test and monitoring equipment for plant maintenance

B: Mechnical equipment

BB: Storage equipment (tanks)

BE: Shaft ( for erection and maintenance only)

BF: Foundations

BN: Jet pumps, ejectors, injectors,hydrant

BP: flow restrictors, limiters,orifices(not metering orifices)

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .13/A

BQ: Hangers, supports, racks, piping penetrations

BR: Piping, ductwork, chutes

BS: Silencers

BT: Flue gas catalytic converter modules

BU: Insulation, sheathing

C: direct measuring circuit

CE: electrical variables(e.g. Current,voltage, power, electr. Frequency)

CF: Flow, rate

CG: distance, length, position, direction of rotation

CH: manual input as manually operated sensor(e.g. fire detector)

CK: Time

CL: Level(also for dividing line)

CM: Moisture, humidity\

CP: pressure

CQ: Quality variables ( analysis, material properties)

CR: Radiation variables

CS: Velocity, speed, frequency (mechanical), acceleration

CT: temperature

CU: Combined and other variables

CV: Viscosity

CW: Weight, mass

CX: Neutron Flux

CY: Vibration,expansion

D: Closed loop control circuit

DD: Density

DE: Electrical varibles (e.g. current, voltage, power, electr. frequency)

DF: Flow, rate

DG:distance, length, position, direction of rotation

DK:Time

DL:level(also for dividing line)

DM:Moisture, humidity

DP: pressure

DQ:Quality variables ( analysis, material properties)

DR:Radiation variables

DS:Velocity, speed, frequency (mechanical), acceleration

DT:temperature

DU:Combined and other variables

DV:Viscosity

DW:Weight, mass

DX:Neutron Flux

DY:Vibration,expansion

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .14/A

E:analog and binary signal conditioning

EA:open loop control( free for use)

EG:Alarm, annunciation (free for use)

EM:process computer

ER:Reactor protection

EU:Combined analog and binary signal conditioning

EW:Protection ( free for use)

F:indirect measuring circuits

FD:Density

FE:Electrical varibles (e.g. current, voltage, power, electr. frequency)

FF:Flow, rate

FG:distance, length, position, direction of rotation

FK:Time

FL:level(also for dividing line)

FM:Moisture, humidity

FP:pressure

FQ:Quality variables ( analysis, material properties)

FR:Radiation variables

FS:Velocity, speed, frequency (mechanical), acceleration

FT:temperature

FU:Combined and other variables

FV:Viscosity

FW:Weight, mass

FX:Neutron Flux

FY:Vibration,expansion

G:electrical equipment

GA~GG:Junction boxes and cable/bus penetrations( free for use)

GH:Electrical and instrumentation and control installation units identified as per process system

(e.g. cubicles, box)

GK:Information display and operator control equipment for process computers and automation

system

GM:Junction boxes for light-current system of national telecommunication services

GP:Subdistribution / junction box for lighting

GQ:Subdistribution / junction box for power sockets

GR:DC generating equipment, batteries

GS:switchgear equipment if not identified under process equipment

GT:transformer equipment

GU:Convertor equipment

GV:Structure-ralated earthing and lighting protection equipment, surge arrestors

GW:cabinet power supply equipment

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .15/A

GX:Actuating equipment for electrical variables

GY:Junction boxes for light-current system

GZ:Hangers, supports and racks for electrical and instrumentation and control equipment

H:Subassemblies of main and heavy machinery

HA:Machine stationary assembly

HB:Machine rotating assembly

HD:Bearing assembly

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .16/A

7 LEVEL3 COMPONENT CODE FOR VARIABLES

It is composed with 2 letters(B1,B2) and 3 numerical digits(BN, BN ,BN), the third number is optional

Breakdown level 0 1 2 3

Total

Title System key Equipment key Component key

Plant

Designation of

G F0 F1 F2 F3 FN FN A1 A2 AN AN AN A3 B1 B2 BN BN (BN)

data character

Type of data

(N) (N) A A A N N A A N N N (A) A A N N N

character

Equipment unit

Apparatus,

Total

Signal code Part of plant C&I range Signal

Plant

Manufacturing

Installation

Prefix X, Y, Z

Signal type

Signal-number

Table7.1 Identification of signals in breakdown level 3

Component code main split (B1)

“B1” Designation

- Electro-technical Components

K Mechanical Components

M Mechanical Components (apparatus)

Q Instrumentation and Control Components

X Input signals for CSCS system

Y Output signals for CSCS system

Z Calculated signals for CSCS system

Table 7.2 Function key B1

The signal ranges and applications are designated in the 2nd alphabetical data character. The

individual signal types and applications are designated in the following 2 numerical data characters.

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .17/A

7.1 “B1B2”

7.1.1 Input signals (from field to C&M system)

Signal Definition Binary /

B1+B2 Analogue

XA Binary signals from Black-Box via communication link Binary

(e.g. AVR status)

XG Binary signals from contact (e.g. limit switch contact) Binary

XH Binary limit signals derived from analogue process Binary

signals (e.g. oil/water tank level limits)

XJ Analogue signals from Black-Box via communication Analogue

link (e.g. electrical measures from energy meter)

XL Binary signals from operator control panel/desk (e.g. Binary

push-button contact)

XM Alarm binary signals from contact (e.g. pump driver Binary

fault)

XN Alarm binary signals from Black-Box via

communication link (e.g. electrical protection trip)

XQ Analogue signals (4-20 mA, 0-10 V, RTD…) Analogue

XZ Free for use Binary/

Analogue

Table 7.3 Key B1=X – Input signal types

7.1.2 Output signals (from C&M system to field)

Signal Definition Binary /

B1+B2 Analogue

YA Binary output command towards Black-Box via Binary

communication link

YL Binary output command from contact (e.g. circuit breaker Binary

closing order)

YG Binary output for status indication (e.g. lamp for ON/OFF Binary

indication)

YJ Analogue command (set-point) towards Black-Box via Analogue

communication link

YM Binary output for alarm indication (e.g. fault lamp) Binary

YQ Analogue output (4-20 mA, 0-10 V, …) Analogue

YZ Free for use Binary /

Analogue

Table 7-4 Key B1=Y – Output signal types

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .18/A

7.1.3 Calculated (output) signals (from C&M system to field)

Signal Definition Binary /

B1+B2 Analogue

ZA Calculated binary AUTO command Binary

ZB

ZC Binary condition result for AUTO CMD Binary

ZD Binary parameter Binary

ZE Calculated binary AUTO emerge command Binary

ZG Calculated feedback binary signals Binary

ZH Calculated binary limit signals derived from analogue Binary

process signals

ZI

ZJ Binary condition result for HMI CMD

ZK Calculated binary signals By HMI

ZL Binary command from system computer (HMI, Gateway,…) Binary

ZM Calculated alarm binary signals Binary

ZN

ZO Auto setpoint Analogue

ZP setpoint feedback Analogue

ZQ Calculated analogue signals Analogue

ZR Analogue command (set-point) from system computer Analogue

(HMI, Gateway,…)

ZS Sequence steps

ZT Time parameter Analogue

ZU Calculated multi-variables (e.g. for HMI object animation) Analogue

ZV Calculated analogue signals By HMI Analogue

ZW Analog parameter Analogue

ZX

ZY

Free for use Binary /

ZZ Analogue

Table 7-5 Key B1=Z – Calculated (output) signal types

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .19/A

7.1.4 Controller Automatically generating Internal Variables

Signal Definition Binary /

B1+B2 Analogue

BI Controller boolean Binary

II Controller integer Analogue

WI Controller word Analogue

RI Controller real Analogue

DI Controller double integer Analogue

LI Controller long word Analogue

Table 7-6 Key B2=I – Automatically generating internal variables types

Please note that those variable types are not following KKS identification rules. Because they are

internally used in the software and are not necessary for external use ( Centralog HMI,…).

7.2 “BN”

The signal numbering rule (numerical characters BNN) is to be defined as following.

7.2.1 Analogue signals

For analogue signals, BNN represents the serial number of signals.

Input analogue: XQ01, XQ02 ……

Output analogue: YQ01, YQ02 ......

Calculated result analogue: ZQ01, ZQ02 …….

7.2.2 Binary signals

For binary signals, BNN represents the meaning of signals. We assort the message meaning of

binary signals by 4 classes:

Class 1: Control signals

- ON/OFF OPEN/CLOSE operation control signals

We call this kind of HMI operation control as “0” type control, the HMI control block name

will be “Equipment code” + “0”

- Other control signals

We call this kind of HMI operation control as “1” type control block, the HMI control block

name will be “Equipment code” + “1”

Control signals

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .20/A

On/Off Open/Close Control signals Other Control signals

message

Bn XG/XL/YL/ZL/ZA Bn XG/XL/YL/ZL/ZA message as

as

01 On/Close(GS)/Open(AA) 11 cmd1/fb1 set/lock/inhab

02 Off/Open(GS)/Close(AA) 12 cmd2/fb2 reset/un-lock/releas

03 Block/Middel 13 cmd3/fb3

04 14 cmd4/fb4

Table 4-7

Example: Cooling water circulation pump: 01PAC10_AP001

HMI Control block name: 01PAC10_AP001_0

ZL01: On HMI command

ZJ01: On HMI command criteria synthetic

ZA01: On Auto command

XG01: On position feedback

YL01: On order output

ZL02: Off HMI command

ZJ02: Off HMI command criteria synthetic

ZA02: Off Auto command

XG02: Off position feedback

YL02: Off order output

If there is a “reset” operation for this pump

HMI Control block name: 01PAC10_AP001_1

ZL12: Reset HMI command

ZJ12: Reset HMI command criteria synthetic

YL12: Reset order output

Class 2: Selection signals

- Auto/Hand control mode selection signals

We call this kind of HMI operation control as “2” type control, the HMI control block name

will be “Equipment code” + “2”

- Local/Remote control level selection signals

We call this kind of HMI operation control as “3” type control, the HMI control block name

will be “Equipment code” + “3”

- Other selection(Control object) signals

We call this kind of HMI operation control as “4” type control, the HMI control block name

will be “Equipment code” + “4”

Selection signals

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .21/A

Control mode signals Control level signals

Bn XG/XL/YL/ZL/ZA message as Bn XL/YL/ZL/ZA message as

20 General Auto selected 30 General Remote selected

21 Auto Joint/individual 31 Remote analog/pulse

22 Hand 32 Local

23 33 Test

24 34

Control object selector signals

Bn XL/YL/ZL/ZA message as

40 General selection selected

41 Select 1 main/standby

pump1/2/3/4

42 Select 2

power/opening

43 Select 3 AVR/AQR/AFR

44 Select 4

45

Table 4-8

Example: Auto/Hand control mode for 01PAC10_AP001

HMI Control block name: 01PAC10_AP001_2

ZL21: Auto mode HMI command

ZJ21: Auto mode HMI command criteria synthetic

ZG21: Auto mode feedback

ZL22: Hand mode HMI command

ZJ22: Hand mode HMI command criteria synthetic

ZG22: Hand mode feedback

Example: Main pump selector for pump group 01PAC10_EA001

HMI Control block name: 01PAC10_EA001_4

01PAC10_EA001 ZL41: Pump 1 select HMI command

01PAC10_EA001 ZJ41: Pump 1 select HMI command criteria synthetic

01PAC10_EA001 ZL42: Pump 2 select HMI command

01PAC10_EA001 ZJ42: Pump 2 select HMI command criteria synthetic

01PAC10_AP001_ZG40: Pump 1 main pump Selected

0PAC10_AP002_ZG40: Pump 2 main pump Selected

Class 3: Status signals

- Available status signals

- Fault status signals

Fault/Available Status signals

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .22/A

Alarm/Fault signals Available signals

message

Bn XM/ZM Bn XM/ZM message as

as

00 General Fault Abnormal 50 General available normal

Fault ok

01 Fault 1 alarm 51 Available 1 ready

02 Fault 2 unavailable 52 Available 2 available

n-energiz energized

03 Fault 3 Extract 53 Available 3 plug-in

04 Fault 4 54 Available 4

05 Fault 5 55 Available 5

06 Fault 6 56 Available 6

07 Fault 7 57 Available 7

08 Fault 8 58 Available 8

09 Fault 9 59 Available 9

Table 4-9

Example: Cooling water circulation pump: 01PAC10_AP001

XM01: Motor fault

XM02: AC Power supply fault

ZM00: Pump General Fault result

ZM01: Pump ON overtime alarm

ZM02: Pump OFF overtime alarm

XM51: Switchboard available

XM52: Control Power supply ok

ZM50: Pump General available result

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .23/A

Class 4: Thresholds signals

Threshold Signals Threshold Signals (Negtive)

Bn XH/ZH message as Bn XH/ZH message as

01 min no-volt 51 Not-min

02 very low 52 Not-very low

03 low low 53 Not-low low

04 low 54 Not-low

05 normal flow normal 55 Not-normal flow abnormal

06 high 56 Not-high

07 high high 57 Not-high high

08 very high 58 Not-very high

09 max overload 59 Not-max

Table 7-10

Sequence step signals

For Sequence step signals, the first 2 digitals of BNN (3 digitals) represent the step order number,

the last digital represents the meaning of the signal.

Sequence step Signals

xx: Step number (01 – 99)

B1B2Bn ZS Type

ZSxx0 The step criteria synthetic Binary

ZSxx1 The step status: “1” means current step Binary

ZSxx5 The step condition: “1” means satisfied Binary

ZSxx7 The step timer count Word

ZSxx8 The step overtime parameter Word

ZSxx9 The step overtime alarm Binary

Table 7-11

Example: A sequence: 01CJA10 _EA001

Sequence On/Off Control block name: 01CJA10_EA001_0

Relactive Variable name:

ZL01: Sequence On HMI command

ZJ01: Sequence On HMI command criteria synthetic

ZG01: Sequence In-progress feedback

ZQ01: Sequence time counting

ZT01: Sequence time parameter

ZM01: Sequence Overtime

Example: A sequence step 01: EA001 ZS01

ZS010: Step criteria synthetic

ZS011: Current step

ZS015: Step condition

CSCS KKS IDENTIFICATION RULE FOR VARIABLES .24/A

You might also like

- Approval Return Status Document FAT ProcedureDocument18 pagesApproval Return Status Document FAT Procedurenguyen rinNo ratings yet

- H-10207 00 0ea00-001f Ec-Cscs Cubicles Equipment Technical Specification - BDocument16 pagesH-10207 00 0ea00-001f Ec-Cscs Cubicles Equipment Technical Specification - Bnguyen rinNo ratings yet

- H-10207 00 0ea00-001f Da-Cscs Main Equipment Datasheets - CDocument124 pagesH-10207 00 0ea00-001f Da-Cscs Main Equipment Datasheets - Cnguyen rinNo ratings yet

- CB MX71ZZ El Rep 0001 000Document56 pagesCB MX71ZZ El Rep 0001 000alemdar.muhendislik25No ratings yet

- H-10207 00 Cja 00-001F Dc-Unit Lcu O&m Manual - ADocument35 pagesH-10207 00 Cja 00-001F Dc-Unit Lcu O&m Manual - Anguyen rinNo ratings yet

- 1HC210629518Document27 pages1HC210629518MayurNo ratings yet

- Control Level and Function DescriptionDocument29 pagesControl Level and Function Descriptionnguyen rinNo ratings yet

- H-10207 99cka 00-003f Dc-Cscs System Software Installation Manuals - ADocument30 pagesH-10207 99cka 00-003f Dc-Cscs System Software Installation Manuals - Anguyen rinNo ratings yet

- project specification for fire and gas systemDocument16 pagesproject specification for fire and gas systemOmar TocmoNo ratings yet

- BZOF-MT-PRO-00035 - 0 DATA Logger Recording ProcedureDocument25 pagesBZOF-MT-PRO-00035 - 0 DATA Logger Recording ProcedureManik KNo ratings yet

- 12 Fire Protection SystemDocument8 pages12 Fire Protection SystemunnicyriacNo ratings yet

- Preventive Maintenance Report For BNG (Supplied by Utstarcom)Document3 pagesPreventive Maintenance Report For BNG (Supplied by Utstarcom)pavanNo ratings yet

- User Manual For 5123 Terminals VEDocument22 pagesUser Manual For 5123 Terminals VEOdd Egil Holta100% (2)

- Royal Commission For Jubail and Yanbu 021-C19: Document No: Rev. I C - 0 3 3 0 - F - 1 0 2Document12 pagesRoyal Commission For Jubail and Yanbu 021-C19: Document No: Rev. I C - 0 3 3 0 - F - 1 0 2arshad iqbalNo ratings yet

- Jack Hydraulic, Aircraft, 5-Ton Type A-5 PART NO. 53D22020 NSN 1730-00-540-2343 (EIC: N/A)Document35 pagesJack Hydraulic, Aircraft, 5-Ton Type A-5 PART NO. 53D22020 NSN 1730-00-540-2343 (EIC: N/A)mecambNo ratings yet

- NDB Manuals (06 NDB) PDFDocument121 pagesNDB Manuals (06 NDB) PDFLe HienNo ratings yet

- Specification For High Voltage Switchgear: Owner Kandhkot Field Gas Compression Station (KFGCS) Project ContractorDocument19 pagesSpecification For High Voltage Switchgear: Owner Kandhkot Field Gas Compression Station (KFGCS) Project ContractorHassen LazharNo ratings yet

- C - SRT1F - e - Ed7 (Commissioning Report) PDFDocument29 pagesC - SRT1F - e - Ed7 (Commissioning Report) PDFJoseMiguelBlancoAlvarezNo ratings yet

- NY8B062D_v1.8Document115 pagesNY8B062D_v1.8webebe9888No ratings yet

- 690C.D WD PDFDocument134 pages690C.D WD PDFYosmeli Zapata100% (1)

- 3670-BQ-DOCS-164 - 01 PA System TPDocument20 pages3670-BQ-DOCS-164 - 01 PA System TPBookmarks On ChromeNo ratings yet

- 60601-1 Report SW 2.5 Ceiling OPMI Lumera 700Document6 pages60601-1 Report SW 2.5 Ceiling OPMI Lumera 700Miguel BascunanNo ratings yet

- Commissioning Report SummaryDocument29 pagesCommissioning Report SummaryEze Alexander IkNo ratings yet

- Surface Flowrates Calculation For Well Testing V1 - 2 - 3905201 - 01 PDFDocument48 pagesSurface Flowrates Calculation For Well Testing V1 - 2 - 3905201 - 01 PDFSaïd Ben Abdallah100% (1)

- MNP DS 4035Document6 pagesMNP DS 4035Dinesh RajNo ratings yet

- Tinrhert Field Development Project - Epc 1 Inlet Separation and Boosting Facility in OhanetDocument19 pagesTinrhert Field Development Project - Epc 1 Inlet Separation and Boosting Facility in OhanetbelhaskaNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument17 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- 22BMJ 045 FEA 03 - Rev 0 - 23.07.05Document14 pages22BMJ 045 FEA 03 - Rev 0 - 23.07.05TEP DesignNo ratings yet

- 200 20 Pi DTS 00003Document111 pages200 20 Pi DTS 00003ritesh142No ratings yet

- H-10207 99cka 00-002F FC-CSCS Mimic Views Basic Principle - ADocument54 pagesH-10207 99cka 00-002F FC-CSCS Mimic Views Basic Principle - Anguyen rinNo ratings yet

- RET670 RELAY ACCEPTANCE TESTDocument17 pagesRET670 RELAY ACCEPTANCE TESTSARAVANAN ANo ratings yet

- MY-SK410B-GIP-EL-DTS-0001-00 Rev.F0Document20 pagesMY-SK410B-GIP-EL-DTS-0001-00 Rev.F0AshNo ratings yet

- YCASDocument88 pagesYCASGabriel Orellan100% (1)

- Indian Oil Corporation LTD,: Petreco International (Me) LTDDocument11 pagesIndian Oil Corporation LTD,: Petreco International (Me) LTDDark KnightNo ratings yet

- OTIS Error-Ref-LCB2-CAC PDFDocument21 pagesOTIS Error-Ref-LCB2-CAC PDFhabibulla100% (5)

- Murata Lbca2hnzyz 711Document23 pagesMurata Lbca2hnzyz 711dejan_blazekaNo ratings yet

- Testing and Balancing AcsDocument10 pagesTesting and Balancing Acsroshan jaiswalNo ratings yet

- Commissioning Procedure EngrDocument11 pagesCommissioning Procedure EngrkumarNo ratings yet

- Product Specification: Boe Hydis Technology Co., LTDDocument25 pagesProduct Specification: Boe Hydis Technology Co., LTDSergey DNo ratings yet

- 200 20 Pi DTS 00008Document72 pages200 20 Pi DTS 00008ritesh142No ratings yet

- S. & A. S. LTD Cabin Control Board User's ManualDocument19 pagesS. & A. S. LTD Cabin Control Board User's ManualKhaled ZakariaNo ratings yet

- Open Edge Chassis OCP Contribution v1.4 PDFDocument37 pagesOpen Edge Chassis OCP Contribution v1.4 PDFVasanth SNo ratings yet

- W83627DHGDocument268 pagesW83627DHGHelio SouzaNo ratings yet

- Eaton Guidespec Substation Tranformer Dry Type 26 12 16Document9 pagesEaton Guidespec Substation Tranformer Dry Type 26 12 16Homero BasalduaNo ratings yet

- RAF-917-10-36-P220 RET670 F67 Comp SATDocument8 pagesRAF-917-10-36-P220 RET670 F67 Comp SATSARAVANAN ANo ratings yet

- Product Guid Ret 670Document176 pagesProduct Guid Ret 670IvoNo ratings yet

- Red 670 2.2Document184 pagesRed 670 2.2Joao MartinsNo ratings yet

- Scaaa 9 R 2Document35 pagesScaaa 9 R 2Tarig Mohamed KhearNo ratings yet

- Eil Cable EntryDocument85 pagesEil Cable EntryHarshkumar PatelNo ratings yet

- 0454 Icpl Ds 009 Tfms EquipmentDocument196 pages0454 Icpl Ds 009 Tfms Equipmentvikaspandey0702No ratings yet

- DCS Upgrade TitleDocument37 pagesDCS Upgrade Titles07081991100% (1)

- Online Continuous Emission Monitoring ProtocolsDocument33 pagesOnline Continuous Emission Monitoring Protocolsnaina ka madhavNo ratings yet

- PCS-9705S - X - Technical Manual Supplement - EN - UK General - X - R1.00Document15 pagesPCS-9705S - X - Technical Manual Supplement - EN - UK General - X - R1.00Thong Dang SyNo ratings yet

- Indra: Atlas Copco K.KDocument32 pagesIndra: Atlas Copco K.KhichamNo ratings yet

- R110J Instrument Symbols PDFDocument47 pagesR110J Instrument Symbols PDFruben'sNo ratings yet

- Central Electricity Board: Ceb 2015 SSDG Net-Metering Scheme Application FormDocument4 pagesCentral Electricity Board: Ceb 2015 SSDG Net-Metering Scheme Application Formgraceenggint8799No ratings yet

- DRV5013-Q1 Automotive Digital-Latch Hall Effect SensorDocument35 pagesDRV5013-Q1 Automotive Digital-Latch Hall Effect SensorEcus ElectronicsNo ratings yet

- Driller's Console Chapter 4 PDFDocument41 pagesDriller's Console Chapter 4 PDFpabloNo ratings yet

- Alstom 110kV switchyard equipment documentsDocument72 pagesAlstom 110kV switchyard equipment documentsnguyen rinNo ratings yet

- H-10207 20 Cba 00-001F Tl-Auxilary Aux Lcu5 Equipment Drawing - DDocument97 pagesH-10207 20 Cba 00-001F Tl-Auxilary Aux Lcu5 Equipment Drawing - Dnguyen rinNo ratings yet

- H-10207 82 CBC 00-001F FS-110KV SWITCHYARD LCU7 ELECTRICAL DRAWING - D Part1Document112 pagesH-10207 82 CBC 00-001F FS-110KV SWITCHYARD LCU7 ELECTRICAL DRAWING - D Part1nguyen rinNo ratings yet

- H-10207 81 CBC 00-001F TL-220kV SWITCHYARD LCU6 EQUIPMENT DRAWING - DDocument32 pagesH-10207 81 CBC 00-001F TL-220kV SWITCHYARD LCU6 EQUIPMENT DRAWING - Dnguyen rinNo ratings yet

- Cataloge Schneider-Catalogue SchneiderDocument76 pagesCataloge Schneider-Catalogue Schneidernguyen rinNo ratings yet

- LCU8 controllers configuration documentDocument22 pagesLCU8 controllers configuration documentnguyen rinNo ratings yet

- H-10207 99cka 00-003F FC-CSCS Mimic Views List - ADocument43 pagesH-10207 99cka 00-003F FC-CSCS Mimic Views List - Anguyen rinNo ratings yet

- Control Contactors RemotelyDocument11 pagesControl Contactors Remotelynguyen rinNo ratings yet

- H-10207 50 CBD 00-001F FS - Intake Lcu8 Electrical Drawing - DDocument43 pagesH-10207 50 CBD 00-001F FS - Intake Lcu8 Electrical Drawing - Dnguyen rinNo ratings yet

- CSCS ALSPA S6 Controplant DCS Product DescriptionDocument14 pagesCSCS ALSPA S6 Controplant DCS Product Descriptionnguyen rinNo ratings yet

- H-10207 99cka 00-003f Dc-Cscs System Software Installation Manuals - ADocument30 pagesH-10207 99cka 00-003f Dc-Cscs System Software Installation Manuals - Anguyen rinNo ratings yet

- H-10207 99cka 00-002F TL-CCR Cubicle Equipment Drawing - DDocument16 pagesH-10207 99cka 00-002F TL-CCR Cubicle Equipment Drawing - Dnguyen rinNo ratings yet

- H-10207 00 Cja 00-001F Tl-Unit Lcu Equipment Drawing - DDocument42 pagesH-10207 00 Cja 00-001F Tl-Unit Lcu Equipment Drawing - Dnguyen rinNo ratings yet

- H-10207 81 CBC 00-001F FT-220KV Switchyard Lcu6 Application ProgramDocument241 pagesH-10207 81 CBC 00-001F FT-220KV Switchyard Lcu6 Application Programnguyen rinNo ratings yet

- H-10207 00 Cja 00-001F Ft-Unit Lcu 1 Application Program - ADocument240 pagesH-10207 00 Cja 00-001F Ft-Unit Lcu 1 Application Program - Anguyen rinNo ratings yet

- H-10207 82 CBC 00-001F FT-110KV Switchyard Lcu7 Application Program - ADocument263 pagesH-10207 82 CBC 00-001F FT-110KV Switchyard Lcu7 Application Program - Anguyen rinNo ratings yet

- H-10207 99cka 00-102f Dc-Cscs Controlog Function Test Procedule - ADocument31 pagesH-10207 99cka 00-102f Dc-Cscs Controlog Function Test Procedule - Anguyen rinNo ratings yet

- H-10207 00 0ea00-001f FS-CSCS Network Connetion Drawing - CDocument1 pageH-10207 00 0ea00-001f FS-CSCS Network Connetion Drawing - Cnguyen rinNo ratings yet

- Control Level and Function DescriptionDocument29 pagesControl Level and Function Descriptionnguyen rinNo ratings yet

- CSCS Hydroprocess FAT Procedure Initialization and Control ModesDocument37 pagesCSCS Hydroprocess FAT Procedure Initialization and Control Modesnguyen rinNo ratings yet

- EVNHPC TRI AN Unit Cooling System ApprovalDocument1 pageEVNHPC TRI AN Unit Cooling System Approvalnguyen rinNo ratings yet

- H-10207 00 Cja 00-001F Ff-Unit Sequence Flow Chart - BDocument29 pagesH-10207 00 Cja 00-001F Ff-Unit Sequence Flow Chart - Bnguyen rinNo ratings yet

- H-10207 99cka 00-002f Fe-Cscs Hydroprocess Application Description - BDocument43 pagesH-10207 99cka 00-002f Fe-Cscs Hydroprocess Application Description - Bnguyen rinNo ratings yet

- H-10207 00 0ea00-002f DB-CSCS Abbreviation List - ADocument33 pagesH-10207 00 0ea00-002f DB-CSCS Abbreviation List - Anguyen rinNo ratings yet

- H-10207 00 Cja 00-001F Fp-Unit Lcu Io Signal List - DDocument31 pagesH-10207 00 Cja 00-001F Fp-Unit Lcu Io Signal List - Dnguyen rinNo ratings yet

- H-10207 99cka 00-002F FC-CSCS Mimic Views Basic Principle - ADocument54 pagesH-10207 99cka 00-002F FC-CSCS Mimic Views Basic Principle - Anguyen rinNo ratings yet

- TriAn DCS Spare Parts and Maintenance Tools ListsDocument4 pagesTriAn DCS Spare Parts and Maintenance Tools Listsnguyen rinNo ratings yet

- Official All Things Turmeric PPT GuidebookDocument14 pagesOfficial All Things Turmeric PPT Guidebookapi-507527047No ratings yet

- Development of Female Genital Tract and Its AnomaliesDocument44 pagesDevelopment of Female Genital Tract and Its AnomaliesSuresh KatakamNo ratings yet

- Mapsco Street GuidesDocument5 pagesMapsco Street Guidesapi-256961360No ratings yet

- Step-by-Step Planning for Escalators and Moving WalksDocument21 pagesStep-by-Step Planning for Escalators and Moving WalksYusup SNo ratings yet

- Treatment of Acid-Related Disorders - SeminarDocument40 pagesTreatment of Acid-Related Disorders - SeminarZana Mohammed0% (1)

- Asme Section II A Sa-435 Sa-435mDocument4 pagesAsme Section II A Sa-435 Sa-435mAnonymous GhPzn1xNo ratings yet

- Wood Turning NotesDocument36 pagesWood Turning Notestheodrosyo0% (1)

- 42183878Document264 pages42183878Sakthirama VadiveluNo ratings yet

- 1 PB PDFDocument11 pages1 PB PDFaldo surya pratamaNo ratings yet

- Just-in-Time and Lean Production Systems: Professor AhmadiDocument29 pagesJust-in-Time and Lean Production Systems: Professor AhmadiawaisjinnahNo ratings yet

- Chiller Maintenance Service 2015Document29 pagesChiller Maintenance Service 2015Huong Ban MaiNo ratings yet

- Company & Project Information for Electrical, Instrumentation ServicesDocument28 pagesCompany & Project Information for Electrical, Instrumentation ServicesMrudul PatilNo ratings yet

- SI 410 Weighing Indicator User ManualDocument64 pagesSI 410 Weighing Indicator User ManualShehab100% (2)

- NAS810 Protection of Fluid Lines & EquipDocument1 pageNAS810 Protection of Fluid Lines & EquipfdhgjklNo ratings yet

- Peppermint Bardon Dress Instructions 1Document17 pagesPeppermint Bardon Dress Instructions 1VINGANo ratings yet

- Proposal For Mining Skill TrainingDocument31 pagesProposal For Mining Skill Trainingdwarka prasad100% (1)

- Biosystems Engineering BS CurriculumDocument2 pagesBiosystems Engineering BS CurriculumAsiiimweNo ratings yet

- Microwave Path Profile Chart PreparationDocument40 pagesMicrowave Path Profile Chart PreparationJohn Dexter RealizoNo ratings yet

- Sample Weekly Home Learning PlansDocument2 pagesSample Weekly Home Learning PlansJINGKY HUMAMOYNo ratings yet

- Kumiko Jigs Japanese Woodworking PDFDocument9 pagesKumiko Jigs Japanese Woodworking PDFJaime Montiel100% (1)

- Guidelines For Dengue Surveillance Edition2.PDF WHODocument115 pagesGuidelines For Dengue Surveillance Edition2.PDF WHOFebyan Kuan Lu Hap100% (1)

- Paracetamol GuideDocument3 pagesParacetamol GuideJanine SantosNo ratings yet

- Oval Lake Hospital: Managing Your Data With Data ToolsDocument7 pagesOval Lake Hospital: Managing Your Data With Data ToolsJacob SheridanNo ratings yet

- Public List Programs by Specialty 460Document9 pagesPublic List Programs by Specialty 460Enta SyngNo ratings yet

- (MT 6322 - MYCO VIRO LAB) Unit 7 Laboratory Diagnosis For Negative-Sense (-) ssRNA VirusesDocument15 pages(MT 6322 - MYCO VIRO LAB) Unit 7 Laboratory Diagnosis For Negative-Sense (-) ssRNA VirusesAbbas MaghazehiNo ratings yet

- UTHM Construction Safety Group AssignmentDocument19 pagesUTHM Construction Safety Group AssignmentWan Muhammad Faiz Bin Mohd RoslanNo ratings yet

- Pneumatic System and Basic Valve UsedDocument401 pagesPneumatic System and Basic Valve Usedtarang srivasNo ratings yet

- Pages From 0625 - s16 - QP - 42 - 01Document2 pagesPages From 0625 - s16 - QP - 42 - 01lelon ongNo ratings yet

- Methyl methacrylate allergy case study in dentistry studentDocument3 pagesMethyl methacrylate allergy case study in dentistry studentDaniela CapitanuNo ratings yet

- Suvarnaprashan Sanskar EnglishDocument4 pagesSuvarnaprashan Sanskar EnglishLifecare Ayurveda Drnikul PatelNo ratings yet