Professional Documents

Culture Documents

H-10207 00 0ea00-002f Fe-Cscs Control Level and Function Description - B

Uploaded by

nguyen rinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

H-10207 00 0ea00-002f Fe-Cscs Control Level and Function Description - B

Uploaded by

nguyen rinCopyright:

Available Formats

Dates : Name : Reference :

Approval Return Status

Comments

SigN Date

SigN.

SigN.

SigN.

SigN.

SigN.

B SigN. 2016/08/25 UPDATED ACCORDING TO 2nd DLM COMMENTS GFE

HXN LPH LPH

A SigN. 2016/05/14 First Issue GFA

HXN LPH LPH

REV ESTABLISHED CHECKED APPROVED DATE MODIFICATIONS STAT.

VIETNAM ELECTRICITY

TRI AN HYDROPOWER COMPANY

LOT NO.5:“DESIGN,MATERIAL,EQUIPMENT SUPPLY AND

TECHNICAL SERVICES”

CONTRANT NO:99/HD-TDTA/ALSTOM

PURCHASER: SUPPLIER:

ALSTOM-HYDRO

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION

SCALE SIZE

SUBSUPPLIER:

A4

REV. SH/SH END N of S

H-10207 00 0EA 00-002F FE 29

B 1/29

MODIFICATIONS TABLE

REV ESTABLISHED CHECKED APPROVED DATE MODIFICATIONS Status.

A HXN LPH LPH 2016/05/14 FIRST ISSUE GFA

B HXN LPH LPH 2016/08/25 UPDATED ACCORDING TO 2nd DLM COMMENTS GFE

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 2/B

CONTENTS

1 INTRODUCTION ....................................................................................................................................................... 5

1.1 DEFINITION OF THE CONTROL LEVELS ..................................................................................................... 6

1.2 LEVEL 5:MANUAL CONTROL ................................................................................................................................. 7

1.3 LEVEL 4:LOCAL PLC CONTROL ........................................................................................................................... 7

1.4 LEVEL 3 --- LCU CONTROL ................................................................................................................................... 7

1.5 LEVEL 2 --- CONTROLOG CONTROL ( PLANT )................................................................................................... 8

1.6 LEVEL 1 --- DISPATCHING CONTROL (A0/A2) ...................................................................................................... 8

2 CSCS MAIN FUNCTIONS AND STRUCTURE .................................................................................................... 8

2.1 CONTROL LEVEL .............................................................................................................................................. 8

2.1.1 CONTROL LEVEL SELECTION ................................................................................................................ 9

2.2 LCU FUNCTION AND STRUCTURE ............................................................................................................... 9

2.3 CONTROLOG: MAIN FUNCTION AND STRUCTURE ............................................................................... 10

2.3.1 GENERAL FUNCTION ............................................................................................................................. 10

2.3.2 COMPUTER SYSTEM EQUIPMENT ...................................................................................................... 11

2.3.2.1 ONE REDUNDANT CIS CONTROLOG INTERFACE STATION .................................................................. 11

2.3.2.2 TWO OPERATOR STATIONS (DOUBLE SCREENS) ..................................................................................... 11

2.3.2.3 TWO GATEWAY STATIONS ............................................................................................................................. 12

2.3.2.4 ONE REPORT STATION ..................................................................................................................................... 12

2.3.2.5 ONE ENGINEER DESIGN SERVER (CCAD SERVER) .................................................................................. 12

2.3.2.6 TWO PLANT ENGINEER STATIONS AND ONE TRAINING STATION ..................................................... 12

2.3.2.8 FOURE PRINTERS............................................................................................................................................... 12

3 UNIT LCU SYSTEMS : 0*CJA .............................................................................................................................. 13

3.1 GENERAL FUNCTION .................................................................................................................................... 13

3.2 LCU EQUIPMENTS (0*CJA) ........................................................................................................................... 14

3.3 UNIT CONTROL AND MONITOR (0*CJA) ................................................................................................... 15

3.3.1 UNIT OPERATION MODE ...................................................................................................................... 15

3.3.2 UNIT CONTROL SEQUENCE ................................................................................................................. 15

3.3.3 CONTROL AND MONITOR AT LEVEL 5 : LOCAL – LOCAL............................................................... 17

3.3.4 CONTROL AND MONITOR AT LEVEL 4 : LOCAL PLC CONTROL ................................................... 17

3.3.5 CONTROL AND MONITOR AT LEVEL 3 : LCU CONTROL ................................................................ 17

3.3.5.1 AUTO OR STEP BY STEP SEQUENCE ............................................................................................................ 17

3.3.5.2 STEP BY STEP SEQUENCE IN G DIRECTION ............................................................................................... 18

3.3.5.3 SYNCHRONIZATION MODE ............................................................................................................................ 19

3.3.5.4 REACTIVE POWER CONTROL......................................................................................................................... 20

3.3.5.5 AUTO LOAD REGULATION ............................................................................................................................. 20

3.3.5.6 EMERGENCY SHUTDOWN............................................................................................................................... 21

3.3.6 CONTROL AND MONITOR AT LEVEL 2 : MAIN ( CONTROLOG) CONTROL SYSTEM .................. 21

3.3.7 CONTROL AND MONITOR LEVEL 1 : DISPATCHING CENTRE (NATION/LOCAL) ...................... 21

3.3.8 REFERENCE DOCUMENTS ................................................................................................................... 22

4 220KV SWITCHYARD LCU SYSTEM CONTROL AND MONITOR (81CBC) ........................................... 22

4.1 GENERAL FUNCTION .................................................................................................................................... 22

4.2 LCU EQUIPMENTS (81CBC)......................................................................................................................... 23

4.3 CONTROL AND MONITOR (81CBC) ............................................................................................................ 23

4.3.1 CONTROL AND MONITOR AT LEVEL 5 : LOCAL - LOCAL ............................................................... 23

4.3.2 CONTROL AND MONITOR AT LEVEL 4 : LOCAL PLC CONTROL ................................................... 24

4.3.3 CONTROL AND MONITOR AT LEVEL 3 : LCU CONTROL .............................................................. 24

4.3.3.1 CONTROL AND MEASUREMENT ................................................................................................................... 24

4.3.3.2 OPERATION ......................................................................................................................................................... 24

4.3.4 CONTROL AND MONITOR AT LEVEL 2 :CONTROLOG CONTROL ................................................. 24

4.3.5 CONTROL AND MONITOR AT LEVEL 1 : DISPATCHING CONTROL .............................................. 25

4.4 REFERENCE DOCUMENTS ........................................................................................................................... 25

5 110KV SWITCHYARD LCU SYSTEM CONTROL AND MONITOR (82CBC) ........................................... 25

6 AUXILARY LCU SYSTEM (20CBA) ................................................................................................................... 25

6.1 GENERAL FUNCTION .................................................................................................................................... 25

6.2 LCU EQUIPMENTS(20CBA) .......................................................................................................................... 26

6.3 CONTROL AND MONITOR (20CBA) ............................................................................................................ 26

6.3.1 CONTROL AND MONITOR AT LEVEL 5 : LOCAL - LOCAL ............................................................... 26

6.3.2 CONTROL AND MONITOR AT LEVEL 4 : LOCAL PLC CONTROL .................................................. 26

6.3.3 CONTROL AND MONITOR AT LEVEL 3 : LCU CONTROL ................................................................. 27

6.3.4 CONTROL AND MONITOR AT LEVEL 2 : CONTROLOG CONTROL ............................................... 27

6.3.5 CONTROL AND MONITOR AT LEVEL 1 : DISPATCHING CONTROL ............................................. 27

6.4 REFERENCE DOCUMENTS ........................................................................................................................... 27

7 INTAKE AND SPILLWAY CONTROL AND MONITOR (50CBD) ................................................................ 27

7.1 GENERAL FUNCTION .................................................................................................................................... 27

7.2 CSCS LCU EQUIPMENT...................................................................................................................................... 28

7.3 CONTROL AND MONITOR( 50CBD) ............................................................................................................ 28

7.3.1 CONTROL AND MONITOR AT LEVEL 5 : LOCAL - LOCAL ............................................................... 28

7.3.2 CONTROL AND MONITOR AT LEVEL 4 : LOCAL PLC CONTROL ................................................... 28

7.3.3 CONTROL AND MONITOR AT LEVEL 3 : LCU CONTROL .............................................................. 28

7.3.4 CONTROL AND MONITOR AT LEVEL 2 : CONTROLOG CONTROL ............................................... 29

7.3.5 CONTROL AND MONITOR LEVEL 1 : DISPATCHING CONTROL ................................................... 29

7.4 REFERENCE DOCUMENTS ........................................................................................................................... 29

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 4/B

1 INTRODUCTION

The aim of the present document is to define the basic operating conditions of TRI

AN Hydro Power Plant and the functions performed by its Computer Supervisory

Control System.

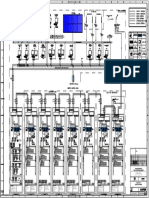

The Control & Monitoring System implemented is a distributed system made of:

- Local control Units including redundant MFC3000 controller, Programmable

Controllers (PLC), screens for Man Machine Interface (MMI) and various

conventional equipment such as relays, measure acquisition devices …

- Operator stations for control and monitoring of the whole power plant in each

powerhouse.

- Operator stations for control and monitoring of the whole power plant from the

Central Control Room.

- Interface with the Load Dispatching Centre through gateway stations.

In the present document, each local control station is described in the following way:

1- Function description: elementary systems covered and rough description

of the functions performed.

2- Main equipment of the local control station

3- Control level 5 – Equipment bay control

4- Control level 4 – Local control panel

5- Control level 3 – Local control unit (LCU)

6- Control level 2 – Central Control Room control (Plant)

7- Control level 1 – Load Dispatching control (A0/A2)

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 5/B

1.1 DEFINITION OF THE CONTROL LEVELS

The Supervisory Control System Tri An Hydro power plant may be controlled from

one or several of the following levels :

LEVEL 1 LOAD DISPATCH CENTRE

Gateway

/

CONTROL ROOM /

DEBUGGING ROOM

DISPATCH

CLOG

LEVEL 2

Operator Station

Remote auto Auto

Computer

*

Operator

Workstations Manu

Local Remote

LEVEL 3

LCU (MMI) Cell Controller * Auto

Local MMI

Local auto control

Manu

Local Remote

LEVEL 4

Local control * Auto

Control

cubicle Cubicle

Manu

EQUIPMENT OF THE SYSTEM

Remote

Local

Hardware

LEVEL 5 Switch (if exist)

Process * : depending on

the system

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 6/B

Following this drawing, the level 5 has the highest priority over all the others. Level

1 has the lowest priority.

1.2 Level 5:Manual control

This level is the lowest level. It is mainly used for initial testing and commissioning as

well as for maintenance.

The selection of the level makes itself on every equipment via a LOCAL – REMOTE

switch. For control the switch must be in “LOCAL” position.

In this level, the individual device will be controlled by the operator directly from the

local panels of the various process equipment via Push Buttons or Handles.

The operator should take all safety measures (verification that all devices associated

equipment is in an adequate position)

1.3 Level 4:Local PLC control

In this level, each auxiliary unit such as Dewatering system, Drainage pumps,

Ventilation, Fire fighting pumps, Air compressor system etc. can be control

and monitor automatically or manually by Local PLC panel nearby the

controlled equipments.

The selection is made by the switch on the panel, such as “Local-Manu/Local-

Auto/remote” selector.

For Automatic control, the selection must be as following:

¾ The individual device control level must be in “Remote”.

¾ The local PLC control level must be in “Local-auto” or “Remote”

¾ Selection the priority of device (pumps, compressors and etc.)

For Manual control, the selection must be as following:

¾ The individual device control level must be in “Remote”.

¾ The local PLC control level must be in “Local-manu”.

The control can be executed manually by operator via pushbuttons.

1.4 Level 3 --- LCU control

In this level, each auxiliary unit can be monitoring automatically.

The LCU just send general order “system starting/stopping” to local PLC, if

the auxiliary unit is involved in unit auto control sequence.

There also have level selection switch: “Local/Remote/Locked” in LCU panel

If LCU send general order to local PLC, the selection must be as following:

¾ The individual device control level must be in “Remote”.

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 7/B

¾ The local PLC control level must be in “Remote”.

¾ LCU control level must be in “ Local ”

The general control order (starting, stopping) will be send from Control

sequence.

1.5 Level 2 --- Controlog control ( PLANT )

In this level, for auxiliary units, the function is the same as 1.2,

There are some buttons in the mimic view to select plant control level:

“CLG/Dispatching”

If LCU send general order to local PLC, the selection must be as following:

¾ The individual device control level must be in “Remote”.

¾ The local PLC control level must be in “Remote”.

¾ LCU control level must be in “Remote “

¾ Plant system control “CLG”(Controlog)

The general control order (starting, stopping) will be send from Control

sequence.

1.6 Level 1 --- Dispatching control (A0/A2)

In this level, For auxiliary units, the function is the same as 1.2, If LCU send

general order to local PLC, the selection must be as following:

¾ The individual device control level must be in “Remote”.

¾ The local PLC control level must be in “Remote”.

¾ LCU control level must be in “Remote “

¾ Plant system control “Dispatching”

The general control order (starting, stopping) will be send from Control sequence.

2 CSCS MAIN FUNCTIONS AND STRUCTURE

2.1 CONTROL LEVEL

5 Levels of control are possible for auxiliary units such as pumps, air

compressors etc.:

- Level 5 --- MCC board

"Local-Local" from MCC board

- Level 4 --- Individual Control Boards(ICB) :

- " Local-PLC" from local PLC panel near the controlled

equipment Supplied by supplier

- Level 3 --- Group Control Center(GCC) :

"Local" from LCU cubicle Supplied by ALSTOM

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 8/B

- Level 2 --- Station Control Center(SCC):

"Remote" from Controlog operator station (CVS) Supplied by

ALSTOM

- Level1 --- Load Dispatch Center (LDC):

"Remote" from dispatching center

Note: Not all levels apply to all equipments.

2.1.1 CONTROL LEVEL SELECTION

In Each LCU GH001 cubicle, there is a “LOCAL/REMOTE /LOCKED” Control level selection

switch.

In Controlog operator station MIMIC view, there are pushbuttons to select “Controlog /A0

dispatch/A1 dispatch” control level when control level switch in “remote” position.

¾ “Local” selected : The control command is from LCU;

¾ “ Remote” selected :

z The control command is from Controlog when selected the “Controlog” In

MIMIC view

z The control command is from NATION Dispatching A0 when selected the “A0

Dispatching” In MIMIC view

z The control command is from LOCAL dispatching A2 when selected the “A2

Dispatching” In MIMIC view

¾ “Locked“ selected : locked the whole LCU control system, any operation is not

authorized, LCU keep the previous status.

2.2 LCU FUNCTION AND STRUCTURE

The CONTROPLANT automation cell provides all the automation functions required

by the user who combines then according to the application:

- Sequential and combination control,

- Digital processing and loop control,

- Centralized or decentralized data acquisition and process actuation with source

dating,

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 9/B

- Inter-controller communications,

- Supervisory system communications.

The automation cell is broken down into three main parts:

- MFC3000 controller (redundant processing unit),

- X20 I/O controller

- Exchange units for the main network and sub network.

X20 I/O controllers are connected to the MFC3000 by a communication bus (E8000

network).

The MFC3000 controller is connected via exchange unit modules to :

S8000-E (100M ETHERNET) is for communication with other controllers and with the

CONTROLOG supervision and control system.

MODBUS network for communication with other external controller or with other

external equipment which one microprocessor based digital control system such as

unit temperature recorder, power transducer, online monitor, Etc.

For their detail information, Please refer to

“H-10207 00 0EA00-001F FA-CSCS SYSTEM CONFIGURATION DIAGRAM “

And their I/O Signal list of each LCU

2.3 CONTROLOG: MAIN FUNCTION AND STRUCTURE

2.3.1 GENERAL FUNCTION

The general purpose of the plant computer system is to provide a high automatized

control level for the control and supervision of the power plant.

The basic functions of the system are mainly built around the Human-Machine

Interface (HMI), printer outputs and computation functions.

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 10/B

The HMI allows the operators to get information from the whole of the process and

give orders as required.

The printer outputs enable the operator to obtain a full set of documents providing

a written record of changes in the process and of operational parameters.

The computation functions allow the development of calculations of operational

parameters to be recorded and printed, as well as algorithms for automatic

management of active power.

2.3.2 COMPUTER SYSTEM EQUIPMENT

The plant computer system is based on the Controlplant system, developed by

ALSTOM for the control and supervision of power plants. The following items are

provided as example (the actual equipments depend on the project):

2.3.2.1 ONE REDUNDANT CIS CONTROLOG INTERFACE STATION

The Controlog Interface Station (CIS) ensures the interface with the MFC3000 by

means of a S8000-E 100M fast optical ring Ethernet network, updates the system's

real time database and manages the printer outputs and computation function.

2.3.2.2 TWO OPERATOR STATIONS (DOUBLE SCREENS)

The operator stations - ensure the functions of man-machine interface:

- Alarms concerning events which are representative of functional anomalies in the

process. The alarms are displayed with several urgency levels and acknowledgement

request,

- Mimic views which enable the state of the various process parameters and actuators

to be displayed (views of units main transformers, switchyard, etc). The commands

for the process are produced by designation on the mimic view, for the operations

such as load setting, units start-up and shutdown orders,

- The main other ways to visualize the evolution of data are curves, bar graphs and

trend.

Two Operator stations will be installed in the control room, 1 Operator stations will

be installed in the machine house, and another one will be installed in the switchyard

room.

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 11/B

2.3.2.3 TWO GATEWAY STATIONS

There are two gateways A and B, gateway A is used for the communication with

dispatching centre NATION A0 by IEC101 and IEC104 protocol;

Gateway B is used for the communication with dispatching LOCAL A2 by IEC101 and

IEC104 protocol;

2.3.2.4 ONE REPORT STATION

The Controlog Reporter and Writer station provides all the functions necessary for

the all print out table producing and office work of the power plant.

The following functions are available:

Get information from CONTROLOG,

Create printout table in EXCEL.

2.3.2.5 ONE ENGINEER DESIGN SERVER (CCAD SERVER)

This station is used for the design and commissioning engineer to development,

design and test the control system.

2.3.2.6 TWO PLANT ENGINEER STATIONS AND ONE TRAINING STATION

It provides all the functions necessary for the supervision of the power plant.

Its supervisory functions are the same as CVS.

All the power plant operation can be simulated in the training station;

2.3.2.7 LARGE SCREEN VDUs

A large Screen VDU composed from 4x2x50 inch screens will be installed at control

room of powerhouse to display real time status of plant and switchyard.

2.3.2.8 FOURE PRINTERS

The printers provide all the functions necessary for all print out of the power plant.

The following functions are available:

- View hardcopy,

- Reports printing,

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 12/B

- Sequence of events printing,

- Daily, weekly, monthly and yearly logs printing,

- Program printing, etc.

Four printers will be installed in the control room, and another one will be installed in

the machine house.

3 UNIT LCU SYSTEMS : 0*CJA

3.1 GENERAL FUNCTION

Unit LCU is used to:

¾ Collect the data of the unit from the site and send all of the unit information to

the Controlog stations in central control room.

¾ Control and monitor :

Turbine and its auxiliaries,

Generator and its auxiliaries,

Main transformer,

GCB Switchboard,

Electrical Protection

Excitation system

Governor system,

Tailrace gate

Condenser mode

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 13/B

Cooling water system and other relative system

¾ All of the control function can be realized in “LOCAL” control level.

3.2 LCU EQUIPMENTS (0*CJA)

The Unit Local Control Unit is made of 3 cubicles (0*CJA00GH001 to 0*CJA00GH003)

including:

- Two MFC3000 controllers (with hot standby redundancy),

- 3 field controllers (PLC) including 3 CE1000 controllers

- I / O modules racks with B&R X20 modules

- EPL(Ethernet Power Link) network and switches;

- S8000 ring network and switches;

- One unit electrical measurement meter communicating with the MFC3000

through a local network,

- MFC3000 MODBUS TCP/IP or RS485 communication with temperature

measurement, Unit online monitoring, Excitation AVR and Governor TSLG;

- automatic synchroniser and synchro-check for manual synchronization,

- one colour MMI (touch screen) for local control and supervision,

- one control level selector switch,

- one control mode selector switch for synchronizer,

- one emergency stop pushbutton,

- various relays,

- power supplies

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 14/B

3.3 UNIT CONTROL AND MONITOR (0*CJA)

3.3.1 UNIT OPERATION MODE

Seven unit operation modes are provided ;

The designation of the operation modes is as follows :

1. Standstill (SS)

2. Standby (SB)

3. Rotating without excitation(SR)

4. Rotating with excitation(SE)

5. Generating (GE)

6. Generator condenser (GC)

7. Line Charge (CH)

3.3.2 UNIT CONTROL SEQUENCE

Start up sequence

The units can be started from the local HMI by auto and step by step mode.

It is can be also started from Controlog in control room by auto mode only.

Operation as following;

- Select the associated control mode(local or remote),

- Select the synchronization mode(auto, manu, test),

- Select the sequence mode(automatic, step by step) if control level in local,

- Select the operation mode to send the start order.

Normal shutdown sequence

The units can be stopped from the local HMI by auto and step by step mode

or Controlog Mimic view in automatic as follows:

- Select the stop to active stop sequence.

Quick shutdown or mechanical shutdown

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 15/B

The quick shutdown sequence is executed when a mechanical fault appears.

The closing of Wicket Gate are immediate but the opening of the unit

Circuit Breaker will be made after the lowering of the power.

The electrical braking is used during a quick shutdown sequence.

Emergency shutdown or electrical shutdown

The emergency shutdown sequence is executed when an electrical fault

appears.

The closing of intake gate with special condition, the opening of the GCB,

FCB and the closing of Wicket Gate are immediate.

The electrical braking is not allowed.

Priority levels of shutdown sequences

The normal shutdown sequence has the priority over the start up sequence.

The quick shutdown sequence has the priority over the normal shutdown.

The emergency shutdown sequence has the priority over the quick

shutdown sequence.

Normal shutdown sequence and quick shutdown sequence are only made

by the controller.

Emergency shutdown sequence is made by the controller and by hardwire

relayed sequence (emergency stop relay).

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 16/B

3.3.3 CONTROL AND MONITOR AT LEVEL 5 : LOCAL – LOCAL

This level will be used for commissioning or maintenance (routine or repair) or

training operation or when the programmable logic controller of the local control

panel is locked, it is possible to individually start or stop the equipment/device from

their local control board when their LOCAL/REMOTE switches (sometimes also called

AUTO/MANU), located on the equipment local control board are on the "LOCAL"

position.

In this level only the basic safety functions are ensured. Any operations on the

related equipment are under the full responsibility of the operator.

3.3.4 CONTROL AND MONITOR AT LEVEL 4 : LOCAL PLC CONTROL

In this level which will be used mainly during commissioning and maintenance, it is

possible to individually start or stop the equipment/device from their local control

panel when:

- their “LOCAL/REMOTE/LOCKED” switches, located on the unit local control panel are

on the "LOCAL" position

Some systems’ equipment can then be controlled manually or automatically,

depending on the position of the “MANU/AUTO” switches located on the local control

panel.

3.3.5 CONTROL AND MONITOR AT LEVEL 3 : LCU CONTROL

Unit control by unit LCU HMI Views. Control level in “Local”.

3.3.5.1 AUTO OR STEP BY STEP SEQUENCE

“Automatic or step by step” selector for the unit start up or shutdown sequence is

made through the views displayed on the local HMI.

In all case, the required sequence is displayed on a view of local HMI.

In case of “step by step”, a validation of each step is required from the operator.

In case of “Automatic “, after a start/stop order given; the required sequence of

controller is automatically lunched.

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 17/B

3.3.5.2 STEP BY STEP SEQUENCE IN G DIRECTION

- Select “step by step” mode,

- Select operation mode “G” or “GC” (final target status),

- Press “start up” or “shutdown” push-button to start or stop the unit.

The Step by step sequence view in G direction will appear;

In start up sequence, it shall include some intermediate steps in start up as

following:

Step1: preparation

Step2: speed up (rotating)

Step3: excitation

Step4: synchronization

Step5: GE-Generating

Step6: GC if GC operation mode selected

Step7: GC to GE if GE operation mode from GC.

Any action will be stopped on each intermediate step, waiting for validation from

operator , if all the conditions are OK for the next intermediate step to that step after

validation, waiting for validation again, till to final target status.

Description of the automatic sequence in G direction

- Select “automatic” mode,

- Select operation mode “G” or “GC” (final target status);

The automatic sequence view in G direction will appear:

All the intermediate steps in step by step mode will be ignored.

- Press “start up” or “shutdown” push-button to start or stop the unit.

The sequence will be activated automatically till to the final target status.

For the main action in each sequence; Please refer to the documents

“H-10207 00 CJA 00-001F FF-UNIT SEQUENCE FLOW CHART”;

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 18/B

And “H-10207 00 CJA 00-001F DC- UNIT LCU O&M MANUAL”

3.3.5.3 SYNCHRONIZATION MODE

A synchronization mode selector is on the 0*CJA00GH003 cubicles to select the

automatic or the manual synchronization.

The selection are as follows:

- Test,

- Manu,

- Auto.

Manu:

The manual synchronization is performed with the following devices :

- Synchronism check relay to permit closure of the unit Circuit Breaker,

- Synchroscope column with double frequency meter, differential voltmeter

and synchronoscope,

- Two push-buttons to adjust the voltage (+, -),

- Two push-buttons to adjust the speed (+, -).

Auto:

The sequence is performed by an automatic synchronizer.

The closing order of the unit Circuit Breaker and the different adjustments (+/-

V and +/- U) are made directly from the automatic synchronizer.

Test:

The closing order is locked in test selection.

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 19/B

The automatic synchronizing mode is the normal used. When the remote

control mode is selected, the automatic synchronizing mode is automatically

selected independently of the synchronization mode selected by local HMI.

3.3.5.4 REACTIVE POWER CONTROL

Two modes of reactive regulation are allowed:

- AQR: it can be selected from remote and local control mode (it is available for G, GC

mode).

- AVR: it can be selected from remote only (it is available for G, GC mode).

a) In Generating mode

Three modes of regulation are allowed :

- Automatic regulations (AQR ,AVR ),

AQR and AVR regulation is performed by the unit controller.

The reactive power, voltage set points are set from view located on local HMI and

Controlog mimic views

b) In GC operation mode

Identical to G mode

3.3.5.5 AUTO LOAD REGULATION

Two modes of auto load regulation are allowed:

- Active power control: it can be selected from remote or local control mode.

- Gate opening control: it can be selected from remote or local control mode.

Active power and Gate opening control are only available in G mode and is

performed by the speed regulator through active power or opening set point sent

from the unit controller.

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 20/B

3.3.5.6 EMERGENCY SHUTDOWN

One emergency push-buttons are provided on the 0*CJA00GH001 cubicle.

It is for unit emergency shutdown,

3.3.6 CONTROL AND MONITOR AT LEVEL 2 : MAIN ( CONTROLOG) CONTROL

SYSTEM

The 220 units can be controlled from the Controlog station when the control level

selector “ CONTROLOG / NATION DISPATCHING /LOCAL DISPATCHING”, on the

MIMIC view, is in "CONTROLOG" position.

The main functions of Controlog are as follows:

- Indication of individual faults,

- Indication of operation mode,

- Selection of individual or joint power control,

- Unit start up or shutdown for all unit operation modes,

- Set point adjustment of voltage ,reactive power, gate opening,

- Indication of equipment status,

Indication of main measurements: such as voltage, current, power, frequency etc.

The unit sequence start and stop operation is the same as it in LCU level and only

have the automatic sequence execution.

3.3.7 CONTROL AND MONITOR LEVEL 1 : DISPATCHING CENTRE (NATION/LOCAL)

To allow the unit control from the dispatching center, the control level selector

“ CONTROLOG / A0 DISPATCHING /A2 DISPATCHING", on the CONTROLOG

MIMIC VIew will be in "A0 DISPATCHING” or “A2 DISPATCHING " control level.

The main functions are as follows:

- Start up and shut down the units,

- Active power for each unit adjustment by means of a set point or plant power for

all plant.

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 21/B

- The major states and measurement are sent to the dispatching.

Refer to the documents to find the detail information :

H-10207 99CKA 00-002F FE-CSCS HYDROPROCESS APPLICATION DESCRIPTION

H-10207 99CKA 00-001F FP- IEC101 COMM. LIST BETWEEN HQ HPP AND DISPATCHING

CENTER

3.3.8 REFERENCE DOCUMENTS

The detail information can refer to the documents :

H-10207 00 CJA 00-001F DC- UNIT LCU O&M MANUAL

4 220KV SWITCHYARD LCU SYSTEM CONTROL AND MONITOR (81CBC)

4.1 GENERAL FUNCTION

220kV switchyard LCU is used to:

Collect the data from the site of the 220kV switchyard system and send all of the

220kV switchyard information to the Controlog stations in central control room and

ensures the control and supervision of the 220kV switchyard.

¾ Control and monitor : as following example (the actual equipments depend on

the project)

220kV Circuit breakers

220kV disconnect switches

220kV earthing switches

220kV busbars

220kV lines

All of the control will be realized in CSCS “LOCAL” or “REMOTE” control level.

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 22/B

And the operation is manually with interlocking made in controller and 220kV

SWITCHYARD supplier hardware.

4.2 LCU EQUIPMENTS (81CBC)

The switchyard Local Control Unit is made of 4 cubicles (80CBC00GH001 to

80CBC00GH004) including:

- Two MFC3000 controllers (with hot standby redundancy),

- 2 field controllers (PLC) including 2 CE1000 controllers

- I / O modules racks with B&R X20 modules

- EPL(Ethernet Power Link) network and switches;

- S8000 ring network and switches;

- MFC3000 MODBUS TCP/IP or RS485 communication with related devices,

- automatic synchroniser and synchro-check for manual synchronization,

- one colour MMI (touch screen) for local control and supervision,

- one control level selector switch,

- one control mode selector switch for synchronizer,

- various relays,

- power supplies

4.3 CONTROL AND MONITOR (81CBC)

4.3.1 CONTROL AND MONITOR AT LEVEL 5 : LOCAL - LOCAL

At this level, the operator can control locally the switchyard equipment:

- Circuit Breaker,

- Disconnecting switches,

- Earthing switches.

The interlocking, the local control and safety operation of the switchyard

equipments in this level is out of Alstom scope

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 23/B

4.3.2 CONTROL AND MONITOR AT LEVEL 4 : LOCAL PLC CONTROL

At this level, the control and monitor is out of Alstom scope.

4.3.3 CONTROL AND MONITOR AT LEVEL 3 : LCU CONTROL

220kV switchyard control by LCU HMI Views. Control level in “Local”.

4.3.3.1 CONTROL AND MEASUREMENT

- Indications of the 220kV switchyard equipment status,

- Fault indication of the switchyard,

- The equipment level in “remote “ and the CSCS control level in “local’.

220kV CB and DS and ES control opening/closing are send from LCU local HMI

MIMIC view manually.

- All of the CB in 220kV switchyard, will be control in CSCS LCU local HMI views

manually

with the synchronization device.

- Electrical parameter measuring and electrical energy metering

4.3.3.2 OPERATION

The synchronization mode selection switch is in 80CBC00GH003 cubicle .

The mode selection is the same as unit.

Select the control mode in “Local “

For CB control:

¾ Select the CB first

¾ Select the synchronization mode if it need to closing

¾ Send the closing and opening order from the MIMIC view Buttons

All DS and ES also can be controlled in manually with interlock in controller.

4.3.4 CONTROL AND MONITOR AT LEVEL 2 :CONTROLOG CONTROL

Select the control mode in “Remote “ and “Controlog”;

The other is the same as 4.3.1.

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 24/B

4.3.5 CONTROL AND MONITOR AT LEVEL 1 : DISPATCHING CONTROL

Select the control mode in “Remote” and “NATION dispatching“ or “LOCAL

dispatching“

The other is the same as 4.3.1

4.4 REFERENCE DOCUMENTS

The detail information can refer to the documents :

H-10207 80 CBC 00-001F DC-SWITCHYARD LCU O&M MANUAL

5 110kV SWITCHYARD LCU SYSTEM control and monitor (82CBC)

110kV switchyard LCU is almost the same as 220kV switchyard LCU, only the Control

and monitor objects are 110kV equipments;

6 AUXILARY LCU SYSTEM (20CBA)

6.1 GENERAL FUNCTION

Power plant common auxiliary equipments LCU is used to:

- Collect the data from the site and send all of the information to the Controlog

stations in central control room.

- Control and monitor the plant auxiliary equipment, as following:

- Drainage pump Station,

- Dewatering pump Station,

- Sewage water pump station,

- Air & Compensation compressor,

- 0.4kV distribution,

- 6.3KV KPY1 distribution,

- 220VDC System and UPS

- Common cooling water system, etc.

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 25/B

6.2 LCU EQUIPMENTS(20CBA)

The Main Auxiliaries Local Control Station is made of 2 cubicles (20CBA00GH001 to

20CBA00GH002) including:

- Two MFC3000 controllers (with hot standby redundancy),

- 2 field controllers (PLC) 2 CE1000 controllers

- I / O modules racks with B&R X20 modules

- EPL(Ethernet Power Link) network and switches;

- S8000 ring network and switches;

- 1 colour MMI (touch screen) for local control and supervision,

- various relays,

- power supplies …

6.3 CONTROL AND MONITOR (20CBA)

6.3.1 CONTROL AND MONITOR AT LEVEL 5 : LOCAL - LOCAL

At this level, the operator can control locally by the local cubicle, as following:

- Pumps stations

- MV or LV Circuit Breakers

- Air compressors

- 0.4kV distribution

Etc.

The control and monitor in this level is out of CSCS scope

6.3.2 CONTROL AND MONITOR AT LEVEL 4 : LOCAL PLC CONTROL

The control and monitor in this level is out of CSCS scope

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 26/B

6.3.3 CONTROL AND MONITOR AT LEVEL 3 : LCU CONTROL

The status, main faults and measurements of the station service can be displayed on

the MMI through mimic views or alarm screens regardless of the control level

selected.

The control of the circuit breakers is possible from this level when:

- the LOCAL/REMOTE switch on local control panels is on the “REMOTE” position

when the LOCAL/REMOTE switches of all its circuit breakers are on the “ REMOTE”

position.

6.3.4 CONTROL AND MONITOR AT LEVEL 2 : CONTROLOG CONTROL

The control of the different equipment is possible from this level when the

LOCAL/REMOTE switch on the LCU cubicle is on the “REMOTE” position.

6.3.5 CONTROL AND MONITOR AT LEVEL 1 : DISPATCHING CONTROL

The control of the different equipment is possible from this level when the

LOCAL/REMOTE switch on the LCU cubicle is on the “REMOTE” position.

6.4 REFERENCE DOCUMENTS

H-10207 20 CBA 00-001F DC - COMMON AUXILIARY LCU O&M MANUAL

7 INTAKE AND SPILLWAY CONTROL AND MONITOR (50CBD)

7.1 GENERAL FUNCTION

This system ensures the control and supervision of Intake gates and the other

auxilaries.

It is used to:

- Collect the data from the site send all of the information to the Controlog stations

in central control room.

- Control and monitor 4 of intakes (4 gates);

- Measurement of water level of reservoir

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 27/B

7.2 CSCS LCU Equipment

The intake gate and spillway Local Control Station is made of 1 cubicle

(50CBD00GH001) including:

- Two MFC3000 controllers (with hot standby redundancy),

- 1 field controllers (PLC) including 1 CE1000 controllers

- I / O modules racks with B&R X20 modules

- EPL(Ethernet Power Link) network and switches;

- S8000 ring network and switches;

- one colour MMI (touch screen) for local control and supervision,

- various relays,

- power supplies …

7.3 CONTROL AND MONITOR( 50CBD)

7.3.1 CONTROL AND MONITOR AT LEVEL 5 : LOCAL - LOCAL

At this level, the operator can control locally by the local cubicle

- Intake gates : total 4

- Measurement of water level of reservoir

It is out of CSCS scope

7.3.2 CONTROL AND MONITOR AT LEVEL 4 : LOCAL PLC CONTROL

At this level, the control can be done by local PLC controller.

It is out of scope of CSCS

7.3.3 CONTROL AND MONITOR AT LEVEL 3 : LCU CONTROL

All of the intake and spillway gates can be monitored and controlled manually by

LCU HMI views when the equipment control level in “remote “mode and the CSCS

control level in “local”.

The interlock is inside the controller program and intake and spillway gates supplier.

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 28/B

7.3.4 CONTROL AND MONITOR AT LEVEL 2 : CONTROLOG CONTROL

All of the intake and spillway gates can be monitored and controlled manually by

Controlog MIMIC views when the gates control level in “remote “mode and the

CSCS control level in “local”.

The interlock is inside the controller program and intake and spillway gates supplier.

7.3.5 CONTROL AND MONITOR LEVEL 1 : DISPATCHING CONTROL

- Monitor intake gates position

- Monitor upstream water level

- No control

7.4 REFERENCE DOCUMENTS

The detail information can refer to the documents:

H-10207 50 CBD 00-001F DC - INTAKE GATE LCU O&M MANUAL

CSCS CONTROL LEVEL AND FUNCTION DESCRIPTION 29/B

You might also like

- Variable Speed Pumping: A Guide to Successful ApplicationsFrom EverandVariable Speed Pumping: A Guide to Successful ApplicationsRating: 3 out of 5 stars3/5 (2)

- Nonlinear Traction Control Design for Parallel Hybrid VehiclesFrom EverandNonlinear Traction Control Design for Parallel Hybrid VehiclesNo ratings yet

- H-10207 99cka 00-002f Fe-Cscs Hydroprocess Application Description - BDocument43 pagesH-10207 99cka 00-002f Fe-Cscs Hydroprocess Application Description - Bnguyen rinNo ratings yet

- H-10207 00 0ea00-001f Ec-Cscs Cubicles Equipment Technical Specification - BDocument16 pagesH-10207 00 0ea00-001f Ec-Cscs Cubicles Equipment Technical Specification - Bnguyen rinNo ratings yet

- H-10207 00 Cja 00-001F Dc-Unit Lcu O&m Manual - ADocument35 pagesH-10207 00 Cja 00-001F Dc-Unit Lcu O&m Manual - Anguyen rinNo ratings yet

- H-10207 00 Cja 00-001F Ft-Unit Lcu 1 Application Program - ADocument240 pagesH-10207 00 Cja 00-001F Ft-Unit Lcu 1 Application Program - Anguyen rinNo ratings yet

- H-10207 99cka 00-002F FC-CSCS Mimic Views Basic Principle - ADocument54 pagesH-10207 99cka 00-002F FC-CSCS Mimic Views Basic Principle - Anguyen rinNo ratings yet

- H-10207 99cka 00-003f Dc-Cscs System Software Installation Manuals - ADocument30 pagesH-10207 99cka 00-003f Dc-Cscs System Software Installation Manuals - Anguyen rinNo ratings yet

- H-10207 99cka 00-003F FC-CSCS Mimic Views List - ADocument43 pagesH-10207 99cka 00-003F FC-CSCS Mimic Views List - Anguyen rinNo ratings yet

- H-10207 99cka 00-102f Dc-Cscs Controlog Function Test Procedule - ADocument31 pagesH-10207 99cka 00-102f Dc-Cscs Controlog Function Test Procedule - Anguyen rinNo ratings yet

- H-10207 99cka 00-101f Dc-Cscs Hydroprocess Fat Procedure - ADocument37 pagesH-10207 99cka 00-101f Dc-Cscs Hydroprocess Fat Procedure - Anguyen rinNo ratings yet

- Saline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentDocument23 pagesSaline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentBhavanishankar ShettyNo ratings yet

- H-10207 00 0ea00-001f DB-CSCS KKS Identification Rule For Variables - ADocument24 pagesH-10207 00 0ea00-001f DB-CSCS KKS Identification Rule For Variables - Anguyen rinNo ratings yet

- SDDto) - Ok3Document78 pagesSDDto) - Ok3zainudin simonNo ratings yet

- ServiceDocument87 pagesServicerudimalakutNo ratings yet

- 0069 - DTCB - O&M ManualDocument115 pages0069 - DTCB - O&M ManualkwakerNo ratings yet

- MRF 03Document411 pagesMRF 03engrshoaib2308No ratings yet

- 01 Exhibit I - Scope of Work - Schedule 2 - Engineering Design - Load Out - Transportation. Installation Commissioning - 25.11.2022Document59 pages01 Exhibit I - Scope of Work - Schedule 2 - Engineering Design - Load Out - Transportation. Installation Commissioning - 25.11.2022Karikalan JayNo ratings yet

- 090.040-M - QHD Compressor Control 2016-11 PDFDocument116 pages090.040-M - QHD Compressor Control 2016-11 PDFEdgar Joel Torres OlórteguiNo ratings yet

- Process Control and Shutdown Philosophy PDFDocument12 pagesProcess Control and Shutdown Philosophy PDFIdil FitriNo ratings yet

- Specification For High Voltage Switchgear: Owner Kandhkot Field Gas Compression Station (KFGCS) Project ContractorDocument19 pagesSpecification For High Voltage Switchgear: Owner Kandhkot Field Gas Compression Station (KFGCS) Project ContractorHassen LazharNo ratings yet

- H-10207 00 Cja 00-101F Dc-Unit Lcu Cubicle Fat Procedure - ADocument18 pagesH-10207 00 Cja 00-101F Dc-Unit Lcu Cubicle Fat Procedure - Anguyen rinNo ratings yet

- 2.5.33 GD357927R1 3.xMW WTG CAPABILITIES FOR GRID CONNDocument56 pages2.5.33 GD357927R1 3.xMW WTG CAPABILITIES FOR GRID CONNWeldayNo ratings yet

- AP1000 Design Control Document: Tier 2 Master Table of Contents Section TitleDocument32 pagesAP1000 Design Control Document: Tier 2 Master Table of Contents Section TitleBob HavrNo ratings yet

- PP Aaa PP1 123Document20 pagesPP Aaa PP1 123Rabah AmidiNo ratings yet

- Design Guidelines Wastewater Networks - Pumping SystemsDocument17 pagesDesign Guidelines Wastewater Networks - Pumping SystemshajerNo ratings yet

- H-6745 00 Gma 00 101 Ec ADocument26 pagesH-6745 00 Gma 00 101 Ec Afuad aliNo ratings yet

- L1-CHE-SPE-130 Vertical Transport LiftsDocument42 pagesL1-CHE-SPE-130 Vertical Transport Lifts4493464No ratings yet

- Specification - Automatic Wet Sprinkler SystemsDocument22 pagesSpecification - Automatic Wet Sprinkler SystemsJaseelKanhirathinkalNo ratings yet

- Chapter 1 HCX3 User ManualDocument111 pagesChapter 1 HCX3 User ManualSergei Kurpish100% (1)

- VH 2600Document29 pagesVH 2600liaNo ratings yet

- D4035 - W69 - Ener Mon and MGMT Sys - Rev 0Document14 pagesD4035 - W69 - Ener Mon and MGMT Sys - Rev 0thamer al-salekNo ratings yet

- Mumbai Metro Line 3Document34 pagesMumbai Metro Line 3sanjaig100% (1)

- Reference Manual: Power Factor Regulator BLR-CX-R / BLR-CX-TDocument40 pagesReference Manual: Power Factor Regulator BLR-CX-R / BLR-CX-Tbaharuddin amnurNo ratings yet

- FLS Airtech ESP Controller - PIACS User ManualDocument39 pagesFLS Airtech ESP Controller - PIACS User Manualtvrao161100% (9)

- Operation and Maintenance Manual FOR Switchover Models: Rsu-S-Tr Rsu-S/S-TrDocument52 pagesOperation and Maintenance Manual FOR Switchover Models: Rsu-S-Tr Rsu-S/S-TrMartinien N'tamonNo ratings yet

- Roads and Maritime Services (RMS) Rms Specification D&C R164 Tunnel Jet FansDocument32 pagesRoads and Maritime Services (RMS) Rms Specification D&C R164 Tunnel Jet FansArmin IranfarNo ratings yet

- CLX-Ex Online Residual Chlorine Monitor: Owner'S ManualDocument45 pagesCLX-Ex Online Residual Chlorine Monitor: Owner'S ManualIgor DoroshchukNo ratings yet

- GRDU-EG-PRC-04-001-A1 CommentsDocument14 pagesGRDU-EG-PRC-04-001-A1 CommentsHermenegildo ZolaNo ratings yet

- PP Aaa PP1 136Document37 pagesPP Aaa PP1 136Rabah AmidiNo ratings yet

- Circulation Water Pump 14-PC 1240 A/BDocument86 pagesCirculation Water Pump 14-PC 1240 A/Bmechmohan26No ratings yet

- FAT Procedure CT-contohDocument13 pagesFAT Procedure CT-contohAbid SukantoNo ratings yet

- CRRC-GSEZ-2019015-1Escort Air Brake Equipment Munual PDFDocument131 pagesCRRC-GSEZ-2019015-1Escort Air Brake Equipment Munual PDFChristopher Ulrich Moussavou MbinaNo ratings yet

- QA10-G-003 - Vol II Sec 3 - Special Conditions of Contract - English - With Track ChangesDocument31 pagesQA10-G-003 - Vol II Sec 3 - Special Conditions of Contract - English - With Track ChangesLouis ClarkNo ratings yet

- Line Sizing GuidelinesDocument32 pagesLine Sizing Guidelinesyunjun12100% (2)

- Line Sizing GuidelinesDocument33 pagesLine Sizing GuidelinesDavid Gustavo Duran TangoNo ratings yet

- MCS-8 Chiller Manual 4.10Document81 pagesMCS-8 Chiller Manual 4.10Bruze AntoNo ratings yet

- SSP-CRCO-SS05-SYSW-PRO-00119 - 04 - PAT Procedure For 750V DC Earth SwitchDocument31 pagesSSP-CRCO-SS05-SYSW-PRO-00119 - 04 - PAT Procedure For 750V DC Earth Switchabu bakarNo ratings yet

- CB MX71ZZ El Rep 0001 000Document56 pagesCB MX71ZZ El Rep 0001 000alemdar.muhendislik25No ratings yet

- SULBAGUT-1 Document Comment Response Sheet (CRS) : SBG1-00-0H-3-MST-0029Document31 pagesSULBAGUT-1 Document Comment Response Sheet (CRS) : SBG1-00-0H-3-MST-0029zainudin simonNo ratings yet

- Gcm02-Mt-Ing4 New1 PDFDocument57 pagesGcm02-Mt-Ing4 New1 PDFabdel jabbar67% (3)

- Fire PreventionDocument26 pagesFire PreventionABHISHEKNo ratings yet

- Functional Design Spec Cameron Scanner 2000 MVT - Rev 1Document28 pagesFunctional Design Spec Cameron Scanner 2000 MVT - Rev 1Ysidro MundarainNo ratings yet

- J.21039 - UNIOLEO - CCS SCTU+C+TPCP For CustomerDocument129 pagesJ.21039 - UNIOLEO - CCS SCTU+C+TPCP For CustomerHarris Fikren TNo ratings yet

- Specification 13320 Revision7Document40 pagesSpecification 13320 Revision7bilgipaylasimNo ratings yet

- WP 04-Ed1301Document36 pagesWP 04-Ed1301Maintenance DepartmentNo ratings yet

- Next Generation SDH/SONET: Evolution or Revolution?From EverandNext Generation SDH/SONET: Evolution or Revolution?Rating: 2.5 out of 5 stars2.5/5 (2)

- H-10207 20 Cba 00-001F Tl-Auxilary Aux Lcu5 Equipment Drawing - DDocument97 pagesH-10207 20 Cba 00-001F Tl-Auxilary Aux Lcu5 Equipment Drawing - Dnguyen rinNo ratings yet

- H-10207 81 CBC 00-001F TL-220kV SWITCHYARD LCU6 EQUIPMENT DRAWING - DDocument32 pagesH-10207 81 CBC 00-001F TL-220kV SWITCHYARD LCU6 EQUIPMENT DRAWING - Dnguyen rinNo ratings yet

- H-10207 82 CBC 00-001F FS-110KV SWITCHYARD LCU7 ELECTRICAL DRAWING - D Part2Document72 pagesH-10207 82 CBC 00-001F FS-110KV SWITCHYARD LCU7 ELECTRICAL DRAWING - D Part2nguyen rinNo ratings yet

- Cataloge Schneider-Contactor CTDocument11 pagesCataloge Schneider-Contactor CTnguyen rinNo ratings yet

- H-10207 82 CBC 00-001F FS-110KV SWITCHYARD LCU7 ELECTRICAL DRAWING - D Part1Document112 pagesH-10207 82 CBC 00-001F FS-110KV SWITCHYARD LCU7 ELECTRICAL DRAWING - D Part1nguyen rinNo ratings yet

- H-10207 50 CBD 00-001F TL - Intake Lcu8 Equipment Drawing - DDocument22 pagesH-10207 50 CBD 00-001F TL - Intake Lcu8 Equipment Drawing - Dnguyen rinNo ratings yet

- H-10207 99cka 00-003F FC-CSCS Mimic Views List - ADocument43 pagesH-10207 99cka 00-003F FC-CSCS Mimic Views List - Anguyen rinNo ratings yet

- Cataloge Schneider-Catalogue SchneiderDocument76 pagesCataloge Schneider-Catalogue Schneidernguyen rinNo ratings yet

- H-10207 00 Cja 00-001F Tl-Unit Lcu Equipment Drawing - DDocument42 pagesH-10207 00 Cja 00-001F Tl-Unit Lcu Equipment Drawing - Dnguyen rinNo ratings yet

- H-10207 00 0ea00-001f Da-Cscs Main Equipment Datasheets - CDocument124 pagesH-10207 00 0ea00-001f Da-Cscs Main Equipment Datasheets - Cnguyen rinNo ratings yet

- H-10207 00 0ea00-001f Fa-Cscs System Configuration Diagram - DDocument1 pageH-10207 00 0ea00-001f Fa-Cscs System Configuration Diagram - Dnguyen rinNo ratings yet

- H-10207 00 Cja 00-001F Ff-Unit Sequence Flow Chart - BDocument29 pagesH-10207 00 Cja 00-001F Ff-Unit Sequence Flow Chart - Bnguyen rinNo ratings yet

- H-10207 00 0ea00-001f Fe-Cscs Alspa S6 Controplant DCS Product Description - ADocument14 pagesH-10207 00 0ea00-001f Fe-Cscs Alspa S6 Controplant DCS Product Description - Anguyen rinNo ratings yet

- H-10207 50 CBD 00-001F FS - Intake Lcu8 Electrical Drawing - DDocument43 pagesH-10207 50 CBD 00-001F FS - Intake Lcu8 Electrical Drawing - Dnguyen rinNo ratings yet

- H-10207 81 CBC 00-001F FT-220KV Switchyard Lcu6 Application ProgramDocument241 pagesH-10207 81 CBC 00-001F FT-220KV Switchyard Lcu6 Application Programnguyen rinNo ratings yet

- H-10207 82 CBC 00-001F FT-110KV Switchyard Lcu7 Application Program - ADocument263 pagesH-10207 82 CBC 00-001F FT-110KV Switchyard Lcu7 Application Program - Anguyen rinNo ratings yet

- H-10207 99cka 00-002F TL-CCR Cubicle Equipment Drawing - DDocument16 pagesH-10207 99cka 00-002F TL-CCR Cubicle Equipment Drawing - Dnguyen rinNo ratings yet

- H-10207 99cka 00-102f Dc-Cscs Controlog Function Test Procedule - ADocument31 pagesH-10207 99cka 00-102f Dc-Cscs Controlog Function Test Procedule - Anguyen rinNo ratings yet

- H-10207 00 0ea00-001f FS-CSCS Network Connetion Drawing - CDocument1 pageH-10207 00 0ea00-001f FS-CSCS Network Connetion Drawing - Cnguyen rinNo ratings yet

- H-10207 99cka 00-003f Dc-Cscs System Software Installation Manuals - ADocument30 pagesH-10207 99cka 00-003f Dc-Cscs System Software Installation Manuals - Anguyen rinNo ratings yet

- H-10207 00 Cja 00-101F Dc-Unit Lcu Cubicle Fat Procedure - ADocument18 pagesH-10207 00 Cja 00-101F Dc-Unit Lcu Cubicle Fat Procedure - Anguyen rinNo ratings yet

- H-10207 00 0ea00-002f DB-CSCS Abbreviation List - ADocument33 pagesH-10207 00 0ea00-002f DB-CSCS Abbreviation List - Anguyen rinNo ratings yet

- H-10207 00 0ea00-001f Ed-Cscs Power Consumer List - ADocument9 pagesH-10207 00 0ea00-001f Ed-Cscs Power Consumer List - Anguyen rinNo ratings yet

- H-10207 99cka 00-101f Dc-Cscs Hydroprocess Fat Procedure - ADocument37 pagesH-10207 99cka 00-101f Dc-Cscs Hydroprocess Fat Procedure - Anguyen rinNo ratings yet

- H-10207 00 0ea00-001f PB-CSCS Spare Parts and Maintenance Tools List - CDocument4 pagesH-10207 00 0ea00-001f PB-CSCS Spare Parts and Maintenance Tools List - Cnguyen rinNo ratings yet

- H-10207 00 Cja 00-001F Fp-Unit Lcu Io Signal List - DDocument31 pagesH-10207 00 Cja 00-001F Fp-Unit Lcu Io Signal List - Dnguyen rinNo ratings yet

- Substation Ground Grid DesignDocument13 pagesSubstation Ground Grid DesignCoenie_Odendaa_8871No ratings yet

- Model Answer: Important Suggestions To ExaminersDocument33 pagesModel Answer: Important Suggestions To ExaminersVaishnvi MarbateNo ratings yet

- A Solution For Maintenance of Power Transformer Operating UnDocument13 pagesA Solution For Maintenance of Power Transformer Operating UnFerry OpilOpNo ratings yet

- CV of Md. Rafiqul Islam PDFDocument3 pagesCV of Md. Rafiqul Islam PDFRafiqul IslamNo ratings yet

- Separation of MV and LV Earthing Systems in Electrical Distribution Substations - 2 ColumnDocument3 pagesSeparation of MV and LV Earthing Systems in Electrical Distribution Substations - 2 ColumnsanibubaNo ratings yet

- 220kV and 33kV Circuit Breakers BHEL PDFDocument77 pages220kV and 33kV Circuit Breakers BHEL PDFSellappan Muthusamy75% (4)

- Per Bay Cost Model For Electrical SubstationsDocument23 pagesPer Bay Cost Model For Electrical Substationswilliamb285No ratings yet

- Advanced Distribution Management System: Implementation, Assessment, and ChallengesDocument5 pagesAdvanced Distribution Management System: Implementation, Assessment, and ChallengesANGEL ALFONSO NAVARRO LA ROSANo ratings yet

- Diversity Case PDFDocument14 pagesDiversity Case PDFALI AKHTARNo ratings yet

- RPT 0 Ou 0 Lhqoojffcciybvxiwk 45Document11 pagesRPT 0 Ou 0 Lhqoojffcciybvxiwk 45Tori SmallNo ratings yet

- Section 7 - Breaker Failure Protection: SEL-751A Feeder Protection Relay - APP 751ADocument12 pagesSection 7 - Breaker Failure Protection: SEL-751A Feeder Protection Relay - APP 751ABouazzaNo ratings yet

- Telecoms Engineer: BSC, Cemap, Mscte, CcentDocument6 pagesTelecoms Engineer: BSC, Cemap, Mscte, CcentChu Tiến ĐạtNo ratings yet

- PR1MA Guidelines & SpecificationDocument80 pagesPR1MA Guidelines & SpecificationIr Aizuddin100% (1)

- Substation LightingDocument13 pagesSubstation LightingHikmat AyerNo ratings yet

- ITER Electrical Design Handbook Earthing and Lightning ProtectionDocument64 pagesITER Electrical Design Handbook Earthing and Lightning ProtectionMuhammad Asif Iqbal100% (1)

- Volume I - 145KV Gas Insulated Switchgear and Cranes PDFDocument248 pagesVolume I - 145KV Gas Insulated Switchgear and Cranes PDFSunil G ParakkalNo ratings yet

- 16 Samss 508 PDFDocument19 pages16 Samss 508 PDFnadeemNo ratings yet

- GIS CB Time TestingDocument26 pagesGIS CB Time TestingVISHAL TELANGNo ratings yet

- Corporate Profile JaksonDocument88 pagesCorporate Profile JaksonRSNo ratings yet

- SVL Testing GuideDocument7 pagesSVL Testing GuideNagaraj RamNo ratings yet

- Index of Relay Papers 1946 (1949) - 2012Document51 pagesIndex of Relay Papers 1946 (1949) - 2012tandin tshewangNo ratings yet

- Horizontal Comm GooseDocument80 pagesHorizontal Comm Gooseranjith kumarNo ratings yet

- High Voltage Distribution System (HVDS) - An Alternate For Improvement of Voltage Drop ProfileDocument7 pagesHigh Voltage Distribution System (HVDS) - An Alternate For Improvement of Voltage Drop ProfileHarshita bajajNo ratings yet

- LA Condition MonitoringDocument20 pagesLA Condition MonitoringPET MADAKKATHARANo ratings yet

- Construction of 230 KV UNd CableDocument6 pagesConstruction of 230 KV UNd CableterimakabosraNo ratings yet

- Decommissioning Transmission Lines PDFDocument4 pagesDecommissioning Transmission Lines PDFHosam AlzubairyNo ratings yet

- TCN Journal 2021 April EditionDocument64 pagesTCN Journal 2021 April EditiontcnjournalonlineNo ratings yet

- Electrical SupervisorDocument13 pagesElectrical SupervisorMarilyn PantorillaNo ratings yet

- K02-S01 Rev 2 Mar 2019 (A) Plant Paging and PA System SpecificationDocument8 pagesK02-S01 Rev 2 Mar 2019 (A) Plant Paging and PA System SpecificationMohamed AdelNo ratings yet

- Earth Fault Distance Computation With Fundamental Frequency Signals Based On Measurements in Substation Supply BayDocument43 pagesEarth Fault Distance Computation With Fundamental Frequency Signals Based On Measurements in Substation Supply BayJagath PrasangaNo ratings yet