Professional Documents

Culture Documents

2.4 Research Paper - Machinery Mechanization - Water Pumping

Uploaded by

Arman RiveraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2.4 Research Paper - Machinery Mechanization - Water Pumping

Uploaded by

Arman RiveraCopyright:

Available Formats

ACTIVITY: ABP 32d – AB Machinery and Mechanization

Republic of the Philippines

Mindoro State University

Main Campus, Alcate, Victoria, Oriental Mindoro

INSTITUTE OF AGRICULTURAL AND BIOSYSTEMS ENGINEERING

Instruction:

Group yourself and select the group’s desired topic to discuss. All references must

be included following the APA format - Pictures, Tables and Formulas.

Arman M. Rivera

BSABE III

Water Pumping Machinery

Water pumps and dewatering

systems are water control

equipment that utilise pumping or

evaporation to remove or drain

various forms of water from

construction sites, riverbeds, mine

shafts, underground metro

networks, tunnels, caisson, and

even residential buildings. For

many sites, these systems are

critical during rainy season,

periods of heavy rain, or for site

in flood zones, as groundwater

and rain can flood an entire site

within just a few hours, causing

delays, surface erosion, structural damage, downtime and more.

There are a few sorts of water pumps, including positive displacement pumps, centrifugal

pumps, jet pumps, and submersible pumps. Some systems are installed to work continuously

as a long-term solution, where they are ready to kick into action on notice, while others are

utilised on and off or on a short-term basis (as equipment or service hire) typically after water

penetration or damage has occurred.

WHAT DO POWERPUMPS DO?

The main purpose of a water pumping system is to move water from one area to another.

They are often applied to construction sites as a form of water extraction, assisting in the

removal of water when excavating, at sewage plants, in flooded areas or when dealing with

water wells and oil wells. Water pumps are not limited however to just construction sites,

they can be utilised on residential sites, industrial sites or commercial sites assisting in

dewatering purposes. For hiring of water pumping systems a water pumper is required. A

water pumper operates the water pumping machine and ensures that it is running effectively.

MinSCAT-IABE-DABE: BSABE PROGRAM

1

ACTIVITY: ABP 32d – AB Machinery and Mechanization

With thousands of water pump suppliers listed on iSeekplant, you can find a qualified water

pumper near you with suppliers located in Brisbane, Sydney, Perth, Darwin and Australia

wide.

TYPES OF WATER PUMPS:

Manual Pumps

Suction/Piston/Plunger Pump

Rower Pump

Treadle Pump

Chain/Washer Pump

Direct action/Direct Drive/High Lift Pump

Rope (rotary) Pump

Deep-well Diaphragm Pump

Helical rotor/Progressive Cavity Pump

Deep-well Hand/Lift/Piston Pump

Mechanized Pumps

Automotive water pump

Agricultural water pump

Boiler Water circulating pump

Dewatering Pump

Groundwater remediation and Sampling Pump

Industrial Water Pump

Saltwater or sea water Pump

Storm Water Pump

Sump Pump

Wastewater Pump

Waterworks and water treatment Pumps

HAND PUMPS

Handpumps, which have been around for centuries,

can provide a cost-effective solution to allow the rural

poor to gain access to clean water for drinking and other

purposes. Handpumps are capable of lifting small

amounts of water from depths of up to 100 meters and

allow the water source to be sealed, reducing the risk for

potential source contamination during water collection

(Olley, 2008).

MinSCAT-IABE-DABE: BSABE PROGRAM

2

ACTIVITY: ABP 32d – AB Machinery and Mechanization

Operation Principle:

Handpumps operate on the principles of fluid

mechanics. Mechanical energy is used to lift the

water from some depth below ground to the

surface, and the water is moved by taking

advantage of pressure differences. The fluid moves

from an area of higher pressure to lower pressure

when the piston is moved up and down. When the

piston is moved upwards, there is a decrease in

pressure within the cylinder. This causes the water

to flow into the cylinder through the foot valve.

When the piston moves down, the water is forced

downwards, increasing the pressure. The foot valve

closes, the piston valve opens, and the high

pressure water exits through the outlet pipe.

Therefore, the pressure within the cylinder

automatically controls the operations of the foot

valve and piston valve.

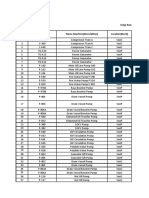

SPECIFICATIONS:

MinSCAT-IABE-DABE: BSABE PROGRAM

3

ACTIVITY: ABP 32d – AB Machinery and Mechanization

WATER PUMPING EQUIPMENT:

Suction/Piston/Plunger Pump

Piston pumps and plunger pumps are reciprocating positive displacement pumps that use

a plunger or piston to move media through a cylindrical chamber. They are also called well

service pumps, high pressure pumps, or high viscosity pumps because they can deliver high

pump pressures and are capable of handling both viscous and solids containing media.

Operation:

Piston pumps and plunger pumps use a mechanism (typically rotational) to create a

reciprocating motion along an axis, which then builds pressure in a cylinder or working barrel

to force gas or fluid through the pump. The pressure in the chamber actuates the valves at

both the suction and discharge points.

Specification:

The primary specifications to consider when selecting pumps are flowrate, stroke

volume, pump head, pressure, horsepower, power rating, outlet diameter, and operating

temperature.

Discharge Size Size of the pump discharge or outlet connection.

Media Temperature Temperature of the media being pumped.

Maximum The maximum flow the pump is designed to generate.

Discharge Flow This value is dependent on the system or pressure head

the pump must enter.

Maximum Discharge The maximum pressure the pump is designed to

MinSCAT-IABE-DABE: BSABE PROGRAM

4

ACTIVITY: ABP 32d – AB Machinery and Mechanization

Pressure generate.

Rower Pump

The rower pump is an inclined version of the suction pump which is operated by pulling

directly on a ‘T’ bar connected to the piston rod. It is called the Rower pump because of the

rowing action used by the operator. The pump has the advantages of easy action to the

suction and piston valves and the relatively cheap cost of manufacture.

Treadle Pump

A treadle pump treadle pump treadle pump is another type of suction pump designed to

lift water from a depth of 7 metres or less. The treadle pump

has a lever pushed by the foot to drive the pump. Because leg

muscles are stronger than arm muscles, this design is less

tiring to use than other human powered water lifters. Most of

MinSCAT-IABE-DABE: BSABE PROGRAM

5

ACTIVITY: ABP 32d – AB Machinery and Mechanization

the parts can be manufactured locally hence the treadle pump is relatively simple and

inexpensive to build.

Parts of Treadle Pump

Chain Washer Pump

A chain pump consists of two large wheels, connected by an endless chain. The bottom

wheel is half immersed in the water source. The chain then carries the empty buckets back

down to be refilled and the process continues. Moat or pulley-system: It is a manual irrigation

method.

Direct action/Direct Drive/High Lift Pump

These pumps have a piston designed to operate

within water and have an internal pipe that acts

both as a piston and as a pump rod. As this is raised

the piston valve closes so that the water inside it is

raised and it also draws further water into the pump

body. When the pump handle is pushed down, the

MinSCAT-IABE-DABE: BSABE PROGRAM

6

ACTIVITY: ABP 32d – AB Machinery and Mechanization

internal pipe displaces the water that is in the pump body so that it flows into the pump ‘rod’

and in so doing water is also discharged from the pump.

Parts of Direct Action Hand Pump

Test Procedure:

The basic principle of a pumping test is that if we pump water from a well and measure

the pumping rate and the drawdown in the well, then substitute these measurements into an

appropriate formula and calculate the hydraulic characteristics of the aquifer.

MinSCAT-IABE-DABE: BSABE PROGRAM

7

ACTIVITY: ABP 32d – AB Machinery and Mechanization

Rope Pump

A rope pump is a kind of pump where a loose hanging rope is lowered into a well and

drawn up through a long pipe with the bottom immersed in water. On the rope, round disks or

knots matching the diameter of the pipe are attached which pull the water to the surface.

Various Rope Pump Models

The AB Model is designed for boreholes (tube-wells).

The AH Model is designed for hand dug wells and preferably includes a concrete well

cover.

The Pi Model is sometimes used on hand dug wells on household level.

Main Components of Rope Pump

MinSCAT-IABE-DABE: BSABE PROGRAM

8

ACTIVITY: ABP 32d – AB Machinery and Mechanization

Deep-well Diaphragm Pump

This type of pump working principle is as simple as two

valves opening and closing using air pressure to force a

piston back and forth. The flexible diaphragm shrinks and

expands like a balloon, it takes water in the inlet valve and

takes it out in the outlet valve which is connected to a hose

which leads the water to the surface.

Progressive Cavity Pump

A progressive cavity pump is a

positive displacement pump employing a

rotor and stator assembly to create a

temporary chambers to draw fluid into,

which ‘progress’ through the pump

resulting in the fluid being expelled

through the discharge port. They are

commonly found in waste water

applications for moving viscous slurry and

sludge containing softer-type solids.

Double Diaphragm Pump

A double diaphragm pump is a positive displacement pump which utilises two flexible

diaphragms that reciprocate back and forth, creating a temporary chamber, which both draws

in and expels fluid through the pump. The diaphragms work as a separation wall between the

air and the liquid.

MinSCAT-IABE-DABE: BSABE PROGRAM

9

ACTIVITY: ABP 32d – AB Machinery and Mechanization

How it Works?

When you connect compressed air to an AODD pump, it goes into an air motor which

directs the air to push a diaphragm, ‘pushing the liquid out’. The diaphragm which gets

pushed is connected to a shaft which will pull the opposite diaphragm creating a cavity on the

other side, ‘drawing in the liquid’. At the bottom and top of the two cavities, there are one

way valves, often a ball valve or a flap valve. So when a cavity is closed it pushes the liquid

up and out while on the other side, it opens a cavity sucking in the liquid. This will then

alternate back closing the cavity on the other side and opening the other.

MECHANIZED PUMPS

Automotive Water Pump

Automotive water pump also known as the

coolant pump must drive the coolant and safeguard

the circulation required for heat exchange. As such,

within the heating and cooling system, it helps the

engine to reach optimum operating temperature

quickly, to stay at this temperature and to avoid

overheating. The cooling system runs from the

radiator to the engine and back to the radiator.

How it Works?

The fan belt only turns hen the engine is running. At this point the central spindle of the

pump also turns. When the central spindle turns, the paddle-like protrusions also turn and

utilize the centrifugal force, it creates suction. This allows the pump to get water from the

radiator and then sends it to the engine by the hoses. The water then absorbs the heat being

generated by the engine and goes back to the radiator where it is cooled.

AGRICULTURAL WATER PUMP

The agriculture water pump is the

most effective machine for irrigation

purposes. They play a fundamental part

in agriculture as they pump water from

the source to the agricultural field.

Pumps can be used for many types of

irrigation, such as drip, sprinkler, and

using a hosepipe.

Various types of fuel operated

water pump machines are available in

the market. Some of the types include

diesel, petrol, kerosene, and electrically operated water pump machines. They are chosen

based on the budget, land size, water source, power sources required.

Applications of water pump are Domestic use, Irrigation of farms, Agriculture use,

Submerged pump in Fountains, Wells, Sumps, and Water tanks.

MinSCAT-IABE-DABE: BSABE PROGRAM

10

ACTIVITY: ABP 32d – AB Machinery and Mechanization

TYPE OF FUEL OPERATED WATER PUMP

1. Petrol Engine Water Pump

2. Diesel Engine Water Pump

3. Kerosine Engine Water Pump

4. Electric Water Pump

PETROL ENGINE WATER PUMP

As the name shows these pumps are operated

by using a 4-stroke petrol engine, able to pump

water from source to the field effectively.

DIESEL ENGINE WATER PUMP

These water pumps operated by 4-stroke diesel

fuel operated engine have a single cylinder

KEROSENE/GASOLINE WATER PUMP

Kerosene engine water pumps use petrol fuel to start but run with kerosene fuel. It is a

cost-effective engine.

MinSCAT-IABE-DABE: BSABE PROGRAM

11

ACTIVITY: ABP 32d – AB Machinery and Mechanization

ELECTRIC WATER PUMP

In this section we have an open well submersible water pump, self-priming electric water

pump and electric operated water pump machines.

Open well submersible: KK-WPE-37SB, KK-

WPE-400SB, KK-WPE-750SB, and KK-WPE-

75SB.

Self-priming electric water pump: KK-WPE-

10010SP, KK-WPE-5010SP, and KK-WPE-

7510SP.

Water pump machines: KK-WPE-2510, KK-

WPE-4015 and KK-WPE-5020.

PARTS OF ELECTRIC WATER PUMP

BOILER CIRCULATING WATER PUMP

The Boiler circulating pump motor (wet winding

motor) is manufactured by HPC in the early 1980s with

transferring KSB technology from Germany. The motor

was specially designed and manufactured with three-

phase squirrel cage asynchronous motor, mainly applied

to 300MW and 600MW subcritical boiler as circulating

water pumps or circulation system of primary coolant

loop in small nuclear power plant. A special pump test

bench has been constructed In order to meet the needs of

MinSCAT-IABE-DABE: BSABE PROGRAM

12

ACTIVITY: ABP 32d – AB Machinery and Mechanization

the market to develop a new product for the 1000MW supercritical circulating boiler water

pump and motor.

INDUSTRIAL WATER PUMP

Industrial water pumps have many different functions, which allows them to be highly

versatile in industrial settings. These pumps are able to:

Remove excess water from construction sites

Pump water away in areas that are usually flooded from heavy rains

Get rid of water in areas where stagnant water causes costly disruptions of work

Pump water to many different manufacturing processes, which extend from cooling and

thermal processes to mining and power processes

Help with the treatment of effluent and wastewater

The exact functions of your industrial water pump depend on the type of pump that you

choose. If you are looking to send water to numerous manufacturing process throughout the

facility, you will likely need to obtain a large water pump with enough space to send water to

the entire facility.

2 COMMON TYPES OF INDUSTRIAL WATER PUMPS

While there are many different types of industrial water pumps that you can obtain for

your facility, these types can be further divided into two separate categories, which include

centrifugal pumps and positive displacement pumps. Understanding the difference between

these two pump types should make it easy for you to identify which one is right for your

industrial facility. Centrifugal pumps are much more common than positive displacement

pumps and are used solely for moving water. On the other hand, positive displacement pumps

are able to move water and build pressure when necessary.

CENTRIFUGAL PUMPS

Centrifugal pumps have the potential to be very large to account for the needs of an

industrial facility, these pumps are also very simplistic and contain only a few moving parts.

The flow of water through a centrifugal pump is steady and consistent, which is why these

pumps are used solely for moving water. If you work in an industrial setting that needs to

send water to various manufacturing processes, a centrifugal pump may be enough to provide

for all of your needs.

Before a centrifugal pump can be used, it must be primed, which is why these particular

pumps work well when placed below the input source or fully submersed.The many different

kinds of centrifugal pumps available to you include:

Booster pumps

Fire pumps

Submersible pumps

Self-priming pumps• Well pumps

Trash pumps

Vertical turbine pumps

Grinder pumps

Axial flow pumps

MinSCAT-IABE-DABE: BSABE PROGRAM

13

ACTIVITY: ABP 32d – AB Machinery and Mechanization

PERFORMANCE SPECIFICATIONS

Centrifugal pump selection is defined by a few key specifications, including flow rate,

head, power, and efficiency.

• Flow rate describes the rate at which the pump can move fluid through the system,

typically expressed in gallons per minute (gpm). The rated capacity of a pump must be

matched to the flow rate required by the application or system.

• Pressure is a measure of the force per unit area of resistance the pump can handle or

overcome, expressed in bar or psi (pounds per square inch). As in all centrifugal pumps, the

pressure in axial flow pumps varies based on the pumped fluid's specific gravity. For this

reason, head is more commonly used to define pump energy in this way.

• Head is the height above the suction inlet that a pump can lift a fluid. It is a shortcut

measurement of system resistance (pressure) which is independent of the fluid's specific

gravity, expressed as a column height of water given in feet (ft) or meters (m).

• Net positive suction head (NPSH) is the difference between the pump's inlet stagnation

pressure head and the vapor pressure head. The required NPSH is an important parameter in

preventing pump cavitation.

• Output power, also called water horsepower, is the power actually delivered to the fluid by

the pump, measured in horsepower (hp).

• Input power, also called brake horsepower, is the power that must be supplied to the pump,

measured in horsepower (hp).

MinSCAT-IABE-DABE: BSABE PROGRAM

14

ACTIVITY: ABP 32d – AB Machinery and Mechanization

• Efficiency is the ratio between the input power and output power. It accounts for energy

losses in the pump (friction and slip) to describes how much of the input power does useful

work.

POSITIVE DISPLACEMENT PUMPS

Positive displacement pumps are unique in that they don’t come with an impeller,

which is a rotating component that’s found in centrifugal water pumps. Instead of using

impellers, positive displacement pumps are outfitted with reciprocating or rotating parts that

are designed to move water while also increasing pressure around the discharge side of

the water pump. There are a variety of different positive displacement pumps that your

industrial facility can use, which extend to:

• Peristaltic pumps

• Plunger pumps

• Piston pumps

• Diaphragm pumps

• Metering pumps

• Flexible impeller pumps

GROUNDWATER REMEDIATION AND SAMPLING PUMP

MinSCAT-IABE-DABE: BSABE PROGRAM

15

ACTIVITY: ABP 32d – AB Machinery and Mechanization

Grundfos Redi-Flo2 Submersible Pump

The Redi-Flo2 electrical submersible pump provides smooth, uninterrupted water flow to

depths of 280 feet.

Features:

• Ideal for both high flow rates needed for purging and low flow rates for sampling

• 1.8" diameter allows for easy access into 2" wells

• Made from chemically inert materials for maximum sample integrity and easy

decontamination

PROACTIVE PUMPS

Proactive Monsoon Engineered Plastic Pump

The Engineered Plastic Monsoon pump is capable of pumping up to 120 feet from

ground level by simply connecting it to a Power Booster 2 Controller & 12V battery.

Features:

• Sleek outside design minimizes well hang-ups

• Pump can run continuously in water without the need for a cool down

• 400 hour motor life provides a very economical sampling and purging solution

ATHENA PUMP

Pegasus Athena Peristaltic Pump

Athena peristaltic pump, mounted in Pelican 1300 case. Includes pump, DC power cord

& Easy-Load II pump head

SALTWATER OR SEA WATER PUMP

MinSCAT-IABE-DABE: BSABE PROGRAM

16

ACTIVITY: ABP 32d – AB Machinery and Mechanization

Salt water pumps are mainly used in coastal areas. They are used in the same way a

standard submersible pump can be used, the main difference is the high amounts of corrosive

salt in the water so a salt water pump is needed instead. Submersible salt water pumps are

often highly recommended for coastal flood defence projects as they are small and easily

stored, quick to use and extremelyeffective at pumping water.

The submersible salt water pumps are easily transported and can be powered by a 230v

mains supply, or alternatively we also offer a 400v 3 -phase pump. These are very popular

within the marine industry

References:

• PHILIPPINE NATIONAL STANDARD (2010). AMTEC-UPLB – PCARRD Project:

“Development of Standards for Agricultural Production and Postharvest Machinery” ICS

65.060.01

• Jenna Martin (2010). Handpumps for Rural Water Supply. University of South Florida

(Tampa)

• Jane Olley (2008). Human-Powered Handpumps for Water Lifting. Practical Action The

Schumacher Centre for Technology and Development Bourton-onDunsmore Rugby,

Warwickshire, CV23 9QZ United Kingdom

• WEDC: Developing Knowledge and Capacity in Water and Sanition. The Rower pump:

technical details . Poster 44

• Simon Watt, Water Consultant. The Chain and Washer Pump Intermediate Technology

Publications, 9 King Street, London WC2E 8HN.

• International Development Enterprises (iDE) (2021). Engineering for Change

• Erpf, K. (2005). The Rope Pump Concept. Practica Foundation

MinSCAT-IABE-DABE: BSABE PROGRAM

17

You might also like

- Water PumpingDocument39 pagesWater PumpingArman RiveraNo ratings yet

- PUMPSDocument4 pagesPUMPSJireh LoquinarioNo ratings yet

- Development of Test Facility and Experimental Analysis Submersible PumpDocument4 pagesDevelopment of Test Facility and Experimental Analysis Submersible PumpShridhar ZambareNo ratings yet

- Pump Basic SizingDocument15 pagesPump Basic Sizingmrf_neoNo ratings yet

- Chapter 6 PDFDocument7 pagesChapter 6 PDFCalvin KewNo ratings yet

- Perret 1994Document32 pagesPerret 1994julio juarezNo ratings yet

- Treadle NoteDocument8 pagesTreadle NoteredaeNo ratings yet

- Cycle Operated PumpDocument44 pagesCycle Operated PumpTushar KhorateNo ratings yet

- Ham Ro Midterm Report Part 2Document12 pagesHam Ro Midterm Report Part 2Shailesh AcharyaNo ratings yet

- Hand Pump - WikipediaDocument13 pagesHand Pump - WikipediaSrinivas DsNo ratings yet

- Submersible PumpDocument32 pagesSubmersible PumpRabbuni GangavarapuNo ratings yet

- College of Engineering and ArchitectureDocument16 pagesCollege of Engineering and Architecturemalyn gorospeNo ratings yet

- Design of 15 Meter Head Hydraulic Ram Pump: Y Y M, Z M HDocument5 pagesDesign of 15 Meter Head Hydraulic Ram Pump: Y Y M, Z M HAshutosh DongarwarNo ratings yet

- Chapter - 1: Cycle Operated Centrifugal Water PumpDocument44 pagesChapter - 1: Cycle Operated Centrifugal Water PumpTushar KhorateNo ratings yet

- Pumps N MechDocument17 pagesPumps N MechmeerhatNo ratings yet

- Chapter - 1: Name - 409 Marine EngineeringDocument42 pagesChapter - 1: Name - 409 Marine Engineeringisrat jahanNo ratings yet

- Module 8 Pumps For Water Supply 1 RevisedDocument29 pagesModule 8 Pumps For Water Supply 1 Revisedادزسر بانديكو هادوله33% (3)

- Fabrication of Dual Side Water Pumping SystemDocument5 pagesFabrication of Dual Side Water Pumping SystemGuru Vignesh SelvarajanNo ratings yet

- Pumping Stations: Compiled By: Beat Stauffer (Seecon International GMBH), Dorothee Spuhler (Seecon International GMBH)Document4 pagesPumping Stations: Compiled By: Beat Stauffer (Seecon International GMBH), Dorothee Spuhler (Seecon International GMBH)Kaniz PriyangkaNo ratings yet

- Hydraulics MicroprojectDocument11 pagesHydraulics MicroprojectsoumyasonawaneNo ratings yet

- Pumps Notes Level 1 REV 3Document10 pagesPumps Notes Level 1 REV 3Collins Obari AdiyeNo ratings yet

- Jet Pump Vs Submercible PumpDocument14 pagesJet Pump Vs Submercible PumpxiaoyaojacNo ratings yet

- BAHIR DAR UNIVERSITY - Design of Centrifugal Pump AbDocument30 pagesBAHIR DAR UNIVERSITY - Design of Centrifugal Pump AbADEFRIS BELACHEWNo ratings yet

- Sanitation, Plumbing Design & Installation: H. Water Pump, Tank Cistern, Sewage and Scum PitDocument8 pagesSanitation, Plumbing Design & Installation: H. Water Pump, Tank Cistern, Sewage and Scum Pithermano balbonNo ratings yet

- Performance Analysis of Reciprocating PumpDocument8 pagesPerformance Analysis of Reciprocating PumpMohamed HassanNo ratings yet

- Submitted To:-Submitted By: - Mrs. Monika Sharma Roll No. 19 To 25 Hod, Civil Engineering DepartmentDocument30 pagesSubmitted To:-Submitted By: - Mrs. Monika Sharma Roll No. 19 To 25 Hod, Civil Engineering DepartmentDeepak AgrawalNo ratings yet

- Des Mi Modula Seng LDocument46 pagesDes Mi Modula Seng Ljohndmariner123No ratings yet

- Positive Displacement Pump Pressure or Head: Activity No. 3 Physical Study of Pump UnitDocument9 pagesPositive Displacement Pump Pressure or Head: Activity No. 3 Physical Study of Pump UnitMerie Ann Aumentado CallejaNo ratings yet

- AE 152 M7 - Pumps and PumpingDocument50 pagesAE 152 M7 - Pumps and Pumpinggregorio roaNo ratings yet

- Emergency Steering in ShipDocument34 pagesEmergency Steering in ShipMayilai AshokNo ratings yet

- Pumps - How It WorksDocument4 pagesPumps - How It Workssher123No ratings yet

- Water PumpsDocument6 pagesWater PumpsVanasti SinghalNo ratings yet

- Submersible PumpDocument7 pagesSubmersible PumpabhibawaNo ratings yet

- C3 - PumpsDocument18 pagesC3 - Pumpsdtdjpn2ksbNo ratings yet

- Pump Cuplings:: Centrifugal PumpsDocument5 pagesPump Cuplings:: Centrifugal PumpsSaswata PradhanNo ratings yet

- Ce 016 Laboratory Exercise No 6 Group 3Document32 pagesCe 016 Laboratory Exercise No 6 Group 3Raymond Delos SantosNo ratings yet

- PumpsDocument6 pagesPumpsSalehAfadlehNo ratings yet

- Pumps TypesDocument14 pagesPumps TypesAbdallah Mansour100% (1)

- Centrifugal Pump: Notes, Application, Methods, Principle and DiagramDocument15 pagesCentrifugal Pump: Notes, Application, Methods, Principle and DiagramRenNo ratings yet

- Fluid Machinery LabDocument12 pagesFluid Machinery LabTimotheus HauwangaNo ratings yet

- Litreature Review 1. History of Water Pumping Technolgy: Water Pumps How Potable Water Is To The Top of The BuildingDocument6 pagesLitreature Review 1. History of Water Pumping Technolgy: Water Pumps How Potable Water Is To The Top of The BuildingAwanyo thomasNo ratings yet

- API Pump Selection GuideDocument14 pagesAPI Pump Selection Guideveron_xiiiNo ratings yet

- Intakes - Pumps - and - Pipes U-3Document15 pagesIntakes - Pumps - and - Pipes U-3Dheeraj RanganathNo ratings yet

- Pendulam Based Water PumpDocument12 pagesPendulam Based Water PumpGopuNo ratings yet

- What Is A Pump?Document11 pagesWhat Is A Pump?John John MarfalNo ratings yet

- Assignment: Name Muhammad ArsalanDocument8 pagesAssignment: Name Muhammad ArsalanMuhammad Arsalan TariqNo ratings yet

- 2-Positive Displacement Pumps: Required, and They Will Maintain This Constant Rate Irrespective of Changes in TheDocument3 pages2-Positive Displacement Pumps: Required, and They Will Maintain This Constant Rate Irrespective of Changes in TheAramNawzadNo ratings yet

- Ipe Plate 2 Fluid MachineriesDocument93 pagesIpe Plate 2 Fluid Machineriesjanuel borelaNo ratings yet

- Peristaltic PumpDocument17 pagesPeristaltic PumpNikki PrakashNo ratings yet

- Pumps, Fans and Blowers and CompressorsDocument80 pagesPumps, Fans and Blowers and CompressorsRomart Barosa100% (2)

- Term Paper: Fluid MechanicsDocument13 pagesTerm Paper: Fluid Mechanicsdharmendrarj_3No ratings yet

- Midterm Final ReportDocument17 pagesMidterm Final ReportShailesh AcharyaNo ratings yet

- Optimising Hydram Performance by Using Variable Stroke Waste ValveDocument8 pagesOptimising Hydram Performance by Using Variable Stroke Waste ValveAgung FauziNo ratings yet

- Pumps Fan BlowerDocument20 pagesPumps Fan BlowerUma GoNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Groundwater Technology Handbook: A Field Guide to Extraction and Usage of GroundwaterFrom EverandGroundwater Technology Handbook: A Field Guide to Extraction and Usage of GroundwaterRating: 5 out of 5 stars5/5 (1)

- MeasurementDocument7 pagesMeasurementArman RiveraNo ratings yet

- Food Processing - Rivera, A. 1Document1 pageFood Processing - Rivera, A. 1Arman RiveraNo ratings yet

- 2.4 Research Paper - Machinery Mechanization - Water PumpingDocument17 pages2.4 Research Paper - Machinery Mechanization - Water PumpingArman RiveraNo ratings yet

- Vivas Basabeiii Abp32d Rice and Other Crop Processing MachineryDocument69 pagesVivas Basabeiii Abp32d Rice and Other Crop Processing MachineryArman RiveraNo ratings yet

- Food Processing - Rivera, A. 1Document1 pageFood Processing - Rivera, A. 1Arman RiveraNo ratings yet

- Objectives of Industry ImmersionDocument10 pagesObjectives of Industry ImmersionArman RiveraNo ratings yet

- 6a Rice and Other Crop Processing Machinery CompressDocument140 pages6a Rice and Other Crop Processing Machinery CompressArman RiveraNo ratings yet

- Machinery MechanizationDocument5 pagesMachinery MechanizationArman RiveraNo ratings yet

- Local Media5842916977740125332Document27 pagesLocal Media5842916977740125332Arman RiveraNo ratings yet

- Crop ProtectionDocument21 pagesCrop ProtectionArman RiveraNo ratings yet

- Crop Protection MachineryDocument50 pagesCrop Protection MachineryArman RiveraNo ratings yet

- 2.3 Research Paper - Machinery Mechanization - Crop ProtectionDocument14 pages2.3 Research Paper - Machinery Mechanization - Crop ProtectionArman RiveraNo ratings yet

- 2.5 Research Paper - Machinery Mechanization - Harvesting and Threshing MachineDocument29 pages2.5 Research Paper - Machinery Mechanization - Harvesting and Threshing MachineArman RiveraNo ratings yet

- 2.2 Research Paper - Machinery Mechanization - Crop Establishment MachineryDocument24 pages2.2 Research Paper - Machinery Mechanization - Crop Establishment MachineryArman RiveraNo ratings yet

- 2.1 Research Paper - Machinery Mechanization - Tillage MachineryDocument32 pages2.1 Research Paper - Machinery Mechanization - Tillage MachineryArman RiveraNo ratings yet

- Module 7 AB Power Water PowerDocument3 pagesModule 7 AB Power Water PowerArman RiveraNo ratings yet

- Module 4 AB Power TractorDocument3 pagesModule 4 AB Power TractorArman RiveraNo ratings yet

- HYDROMETEOROLOGY - Introduction To Meteorology - RiveraDocument5 pagesHYDROMETEOROLOGY - Introduction To Meteorology - RiveraArman RiveraNo ratings yet

- Module 6 AB Power Wind GenerationDocument3 pagesModule 6 AB Power Wind GenerationArman RiveraNo ratings yet

- Module 5 AB Power Solar PowerDocument4 pagesModule 5 AB Power Solar PowerArman RiveraNo ratings yet

- The Centrifugal Pump Has The Following Main ComponentsDocument21 pagesThe Centrifugal Pump Has The Following Main Componentsrohan sharmaNo ratings yet

- Garcia, S.A. - 19-05502 - Assignment 2Document3 pagesGarcia, S.A. - 19-05502 - Assignment 2Samuel Garcia100% (1)

- ZAMA Kits Price ListDocument14 pagesZAMA Kits Price ListHugoNo ratings yet

- AE31008: Tutorial Problems On Ideal Cycle AnalysisDocument1 pageAE31008: Tutorial Problems On Ideal Cycle AnalysisDivyansh RathiNo ratings yet

- Pumps & TurbinesDocument67 pagesPumps & Turbinesapi-372110090% (10)

- Tipos de Bombas CentrifugasDocument34 pagesTipos de Bombas CentrifugasJorge Fernandez EdelmanNo ratings yet

- Computational Fluid Dynamics Analysis of A Turbocharger SystemDocument4 pagesComputational Fluid Dynamics Analysis of A Turbocharger Systemmuthu vNo ratings yet

- Doubt FullDocument14 pagesDoubt Fullr09033No ratings yet

- Pumps-Part 03-By Ramy GhorabaDocument23 pagesPumps-Part 03-By Ramy GhorabaPrashant ManoriNo ratings yet

- Centrifugal Pump Working Principle With DiagramDocument12 pagesCentrifugal Pump Working Principle With Diagramadeel ahmadNo ratings yet

- Check List IpalDocument1 pageCheck List IpalBambang Andy SuhartoNo ratings yet

- Grundfos Pumps CR18Document2 pagesGrundfos Pumps CR18Wil MolinaNo ratings yet

- Bomba A2fo Bosch RexrothDocument3 pagesBomba A2fo Bosch RexrothHIDRAFLUIDNo ratings yet

- Axial Piston Pump Series PV: Variable DisplacementDocument32 pagesAxial Piston Pump Series PV: Variable DisplacementGyanaranjan NayakNo ratings yet

- Numerical Flow Analysis of An Axial Flow PumpDocument6 pagesNumerical Flow Analysis of An Axial Flow Pumpbinho58No ratings yet

- Axial Flow Compressors: An Efficient Way To Ingest Life in Large Amount of Fluids !!!Document30 pagesAxial Flow Compressors: An Efficient Way To Ingest Life in Large Amount of Fluids !!!Keerthi MNo ratings yet

- Rotating Eqmnt Selection ReportDocument16 pagesRotating Eqmnt Selection ReportloqNo ratings yet

- Grafik Seri ParalelDocument10 pagesGrafik Seri ParalelIrul AldaniNo ratings yet

- What Is Pump Priming and Why It Is Required With PDFDocument9 pagesWhat Is Pump Priming and Why It Is Required With PDFAnas Al’BazzazNo ratings yet

- Hydraulic Machine PPT Updated 08-09-2023Document108 pagesHydraulic Machine PPT Updated 08-09-2023ghostsnimitzNo ratings yet

- Dke672 ch5Document49 pagesDke672 ch5Amit YadavNo ratings yet

- Equipment ListDocument71 pagesEquipment ListMuhammad Fahmmi Bin MahmudNo ratings yet

- Fma3602 Fi Concession Examination 2020Document3 pagesFma3602 Fi Concession Examination 2020Shadreck Ndlovu100% (1)

- ME & AE Running Hours S VDocument87 pagesME & AE Running Hours S VAdhitya satria prabowoNo ratings yet

- Nigam Organization Structure 24102016Document180 pagesNigam Organization Structure 24102016sunuprvunlNo ratings yet

- Lem Lel eDocument4 pagesLem Lel eHussenuNo ratings yet

- Turbine Manual Bhel4Document2 pagesTurbine Manual Bhel4parthibanemails5779No ratings yet

- Hs Hhs Ms Pump Performance SheetDocument1 pageHs Hhs Ms Pump Performance SheetsunbopumpNo ratings yet

- Section 4Document5 pagesSection 4Eslam HusseinNo ratings yet

- Important Gate Topics For Mechanical Engineering (Me) - Mechanical Gate Basic ConceptsDocument9 pagesImportant Gate Topics For Mechanical Engineering (Me) - Mechanical Gate Basic ConceptsSatheesh ChandranNo ratings yet