Professional Documents

Culture Documents

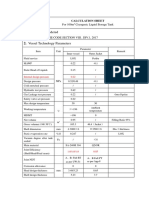

Main Head Calculation (Left Head & Right Head)

Uploaded by

vietsds0 ratings0% found this document useful (0 votes)

12 views1 pageThis document summarizes the calculations for determining the required thickness of a semi-ellipsoidal head on a pressure vessel. It provides the design parameters such as an internal pressure of 5.2 MPa and external pressure of 0.1 MPa. It then shows the calculations for minimum required thickness according to different code requirements, finding a minimum of 46 mm which satisfies the maximum allowable working pressure of 5.471 MPa internally and 3.28 MPa externally.

Original Description:

PPTX10

Original Title

X10

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes the calculations for determining the required thickness of a semi-ellipsoidal head on a pressure vessel. It provides the design parameters such as an internal pressure of 5.2 MPa and external pressure of 0.1 MPa. It then shows the calculations for minimum required thickness according to different code requirements, finding a minimum of 46 mm which satisfies the maximum allowable working pressure of 5.471 MPa internally and 3.28 MPa externally.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views1 pageMain Head Calculation (Left Head & Right Head)

Uploaded by

vietsdsThis document summarizes the calculations for determining the required thickness of a semi-ellipsoidal head on a pressure vessel. It provides the design parameters such as an internal pressure of 5.2 MPa and external pressure of 0.1 MPa. It then shows the calculations for minimum required thickness according to different code requirements, finding a minimum of 46 mm which satisfies the maximum allowable working pressure of 5.471 MPa internally and 3.28 MPa externally.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

6.

Main Head Calculation (Left Head & Right Head)

Type Semi-Ellipsoidal Head 2:1

Design Pressure Internal Pi 5.20 MPa 52.00 barg

Design Pressure External Pe 0.1034 MPa 1.0342 barg

o

Design Temperature (Max.) 270.00 C

o

Design Temperature (Min.) 10.00 C 78 barg

Fluid content Steam & Water

Fluid Content Density 789.00 kg/m3

Corrosion Allowance C 3.00 mm

Gravity of Earth g 9.8067 m/s2

Fluid Hight Hs 1500 mm

Outside Diameter Do 2200 mm

Inside Diameter Di 2108 mm

Material SA-516M Gr.485N

Max. Allowable Stress S 137.00 MPa

Calculations thickness under internal pressure (PG-29)

Static Liquid height

(top of nozzle to bottom of head) Ps=D*g*Hs 0.01 MPa

Pressure internal included static head P=Pi+Ps 5.21 MPa

As PG-29.7 Head required thickness

shall be made at least as thick as

required thickness of a seamless shell

of the same diameter as PG-27 treq. (Head) = treq. (Shell) 43.9 mm

As PG-33.3 Head required thickness is

the thickness required for a seamless

hemispherical head of radius equal to

90% of the inside diameter of the shell treq. (Head) = P*0.9*Di/ (2 S*w-

0.2*P)+C 39.2 mm

Weld joint strength reduction factor per

PG-26 w 1

Head minimum thickness (after forming) tmin. 46 mm Satisfy

Max. Allow. Working Pressure (internal) 5.471 MPa 54.708 barg

Check thickness with external pressure per PG-29.9

Unstayed dished heads with the pressure on the convex side shall have a maximum allowable working pressure

equal to 60% of that for heads of the same dimensions with the pressure on the concave side

Max. Allow. Working Pressure (external

pressure) MAEWP=60%*MAWP 3.28 MPa Satisfy

You might also like

- Design of Storage Tanks For Internal PressureDocument7 pagesDesign of Storage Tanks For Internal Pressuremanish318No ratings yet

- EA-105 After CoolerDocument26 pagesEA-105 After CoolerAKSHAY BHATKARNo ratings yet

- External Pressure-Dish Head and Shell-Taiwan TankDocument1 pageExternal Pressure-Dish Head and Shell-Taiwan TanknaimNo ratings yet

- New PA Column - THK CalcDocument8 pagesNew PA Column - THK CalcSabariMechyNo ratings yet

- Tank Shell & SE HeadDocument1 pageTank Shell & SE Headmassive85No ratings yet

- Calculation Sheet: III. Calculation of Nozzle Neck Thickness Per UG-45Document3 pagesCalculation Sheet: III. Calculation of Nozzle Neck Thickness Per UG-45Fazri CME100% (1)

- Int PressDocument8 pagesInt Pressmanish318No ratings yet

- 100 KL Old CalDocument8 pages100 KL Old CalpavanNo ratings yet

- Blind Flange Design Calculation As Per Asme Section Vii Division - 1Document4 pagesBlind Flange Design Calculation As Per Asme Section Vii Division - 1mukesh100% (2)

- Upper Limit of Hydrotesst-R2Document26 pagesUpper Limit of Hydrotesst-R2vpjagannaathNo ratings yet

- Nozzle Check 211039CDocument3 pagesNozzle Check 211039CGaurav BedseNo ratings yet

- Nyco 22 Roo 390 Rev 0 Sids H 1ss v2 Monitor 2 Calc SHTDocument7 pagesNyco 22 Roo 390 Rev 0 Sids H 1ss v2 Monitor 2 Calc SHTghaithjasimNo ratings yet

- Nyco 22 Roo 390 Rev 0 Sids H 1ss v2 Monitor 2 Calc SHTDocument7 pagesNyco 22 Roo 390 Rev 0 Sids H 1ss v2 Monitor 2 Calc SHTghaithjasimNo ratings yet

- Clean Water Tank - Id - 7200x10900 HDocument208 pagesClean Water Tank - Id - 7200x10900 HWilly SastraleksanaNo ratings yet

- Bolt Torque Appendix-ODocument1 pageBolt Torque Appendix-OSachin5586100% (1)

- Design of Pressure Vessel by Using ASME Sec-VIII Div-1Document6 pagesDesign of Pressure Vessel by Using ASME Sec-VIII Div-1jhaamit4No ratings yet

- VSL CalDocument50 pagesVSL CalEmrahCayboyluNo ratings yet

- Calculation - Horizontal Pressure VesselDocument30 pagesCalculation - Horizontal Pressure VesselVlanic StudioNo ratings yet

- Sample Vessel Design (Sec - VIII Div.1)Document34 pagesSample Vessel Design (Sec - VIII Div.1)Chano Hanok100% (1)

- Narrow Face Flange - Slip On Hub TypeDocument17 pagesNarrow Face Flange - Slip On Hub TypeEng-CalculationsNo ratings yet

- Calc' Diesel Fuel (Rev)Document10 pagesCalc' Diesel Fuel (Rev)joko_tm02No ratings yet

- ASME 31 - 4 CalcDocument1 pageASME 31 - 4 CalcMarcoAlbaNo ratings yet

- IBR Calualations (28.12.22)Document10 pagesIBR Calualations (28.12.22)Sumit MishraNo ratings yet

- R1 - Calculation Report of Waste Water Storage Tank - Bangchack BiofuelDocument12 pagesR1 - Calculation Report of Waste Water Storage Tank - Bangchack BiofuelPete Rueangchim100% (3)

- Design Calculations For Pressure VesselsDocument43 pagesDesign Calculations For Pressure VesselsMoises Alvarez LeandroNo ratings yet

- NASA Vacuum Vessel Weight and Volume CalculationsDocument11 pagesNASA Vacuum Vessel Weight and Volume CalculationsVarun MalhotraNo ratings yet

- KimVic Rectangular-Tank-SizingDocument20 pagesKimVic Rectangular-Tank-SizingAdekimi EmmanuelNo ratings yet

- Bolt Up CalculationDocument12 pagesBolt Up CalculationAniket GaikwadNo ratings yet

- API 650 Design TanksDocument34 pagesAPI 650 Design Tankssash100% (1)

- Flat Head Calculation: According To ASME VIII Div.1Document4 pagesFlat Head Calculation: According To ASME VIII Div.1AlliaNo ratings yet

- API - 650 Design Calculation Strength Calcn 3-T-333 (Rev-C)Document17 pagesAPI - 650 Design Calculation Strength Calcn 3-T-333 (Rev-C)SUNNY GUPTANo ratings yet

- Weir Plate or Baffle Plate CalculationDocument2 pagesWeir Plate or Baffle Plate CalculationamaNo ratings yet

- Design Calculation TankDocument28 pagesDesign Calculation TankAsongwe HansNo ratings yet

- 50 Inch Manhole Neck CalculationDocument2 pages50 Inch Manhole Neck CalculationLawrence LawrenceNo ratings yet

- Rectangular Tank Satu LagiDocument1 pageRectangular Tank Satu LagiSteve MoonNo ratings yet

- Blind Flange Calculation11Document3 pagesBlind Flange Calculation11jaymuscatNo ratings yet

- PTB E4.4.2 Conical Shell (2017)Document3 pagesPTB E4.4.2 Conical Shell (2017)NicolaSaviliNo ratings yet

- Flat Head Calculation (Based On Ug 34)Document2 pagesFlat Head Calculation (Based On Ug 34)rustamriyadiNo ratings yet

- FRP Vessel Calc Asme RTP 1Document7 pagesFRP Vessel Calc Asme RTP 1GautamNo ratings yet

- F-0201 Special Blind Calculation (N9)Document2 pagesF-0201 Special Blind Calculation (N9)rustamriyadiNo ratings yet

- Mathcad - 01 - Sump TankDocument10 pagesMathcad - 01 - Sump Tankisrar khan0% (1)

- Narrow Face Flange - Slip On Hub Type For External PressureDocument23 pagesNarrow Face Flange - Slip On Hub Type For External PressureEng-CalculationsNo ratings yet

- SHELL THICKNESS CHECK-ASME Section VIIIDocument2 pagesSHELL THICKNESS CHECK-ASME Section VIIIskocogluNo ratings yet

- Calculation Sheet: Act IDocument2 pagesCalculation Sheet: Act IFazri CMENo ratings yet

- Narrow Face Flange - Smooth BoreDocument17 pagesNarrow Face Flange - Smooth BoreEng-CalculationsNo ratings yet

- Narrow Face Flange - Smooth Bore For External PressureDocument17 pagesNarrow Face Flange - Smooth Bore For External PressureEng-CalculationsNo ratings yet

- Vdocument - in API 650 TankDocument35 pagesVdocument - in API 650 TanklasssyNo ratings yet

- Torispherical HeadDocument5 pagesTorispherical HeadLiaquat AliNo ratings yet

- Bolt Stress RevBDocument50 pagesBolt Stress RevBMichael Walters100% (1)

- Pipe ThicknessDocument1 pagePipe ThicknessalvinchuanNo ratings yet

- Code Calcs Rev1Document11 pagesCode Calcs Rev1Tauqeer AhmedNo ratings yet

- Piping DesignDocument1 pagePiping DesignRAJASEKAR KingNo ratings yet

- Storage Tank Design Calculation - Api 650Document92 pagesStorage Tank Design Calculation - Api 650Abelardo ContrerasNo ratings yet

- ENG K22014 H-072 DR A 05 Rev A - Torque TighteningDocument10 pagesENG K22014 H-072 DR A 05 Rev A - Torque TighteningQuraisy AmriNo ratings yet

- Nozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim GalalaDocument5 pagesNozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim Galalapaary100% (2)

- Mechanical Calculation Tanky 53 KLDocument4 pagesMechanical Calculation Tanky 53 KLm khaeronNo ratings yet

- Nozzle SummaryDocument1 pageNozzle SummaryvietsdsNo ratings yet

- PT 3Document1 pagePT 3vietsdsNo ratings yet

- Purpose: Autopipe - Installation Test SetDocument1 pagePurpose: Autopipe - Installation Test SetvietsdsNo ratings yet

- PP 7Document1 pagePP 7vietsdsNo ratings yet

- PT 9Document1 pagePT 9vietsdsNo ratings yet

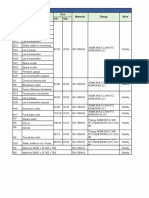

- Bill of Materials: Heads / CoversDocument1 pageBill of Materials: Heads / CoversvietsdsNo ratings yet

- TT 3Document1 pageTT 3vietsdsNo ratings yet

- 10-YEAR Warranty: Now Carbon NeutralDocument2 pages10-YEAR Warranty: Now Carbon NeutralvietsdsNo ratings yet

- Deficiencies Summary: Hand Hole (N8)Document1 pageDeficiencies Summary: Hand Hole (N8)vietsdsNo ratings yet

- Slip StreamDocument1 pageSlip StreamvietsdsNo ratings yet

- ZhongtaiDocument4 pagesZhongtaivietsdsNo ratings yet

- Detail C2 Plan View: Freeport LNG Liquefaction ProjectDocument1 pageDetail C2 Plan View: Freeport LNG Liquefaction ProjectvietsdsNo ratings yet

- Petty Cash Receipt: AmountDocument1 pagePetty Cash Receipt: AmountvietsdsNo ratings yet

- Introduction To Irrigation DesignDocument40 pagesIntroduction To Irrigation DesignEifa Mat LazimNo ratings yet

- Complete Guide On Plans & CalculationsDocument92 pagesComplete Guide On Plans & CalculationsDIEGOZaf100% (2)

- Adobe Scan 12-Apr-2024Document3 pagesAdobe Scan 12-Apr-2024amitk397115No ratings yet

- Master of Science (MSC) in Water Resources EngineeringDocument8 pagesMaster of Science (MSC) in Water Resources EngineeringAthiyo MartinNo ratings yet

- Gold Line ManualDocument10 pagesGold Line ManualAnonymous OvwqAMyrWxNo ratings yet

- Differential VaporisationDocument8 pagesDifferential VaporisationMohd RafiqNo ratings yet

- Comparison Between Nano & Conventional LubesDocument1 pageComparison Between Nano & Conventional LubesSamir Chandrakant BhagwatNo ratings yet

- Regulator Seat Leakage: American National StandardDocument7 pagesRegulator Seat Leakage: American National StandardThiago Ribeiro da SilvaNo ratings yet

- The Effects of Wake Splitter Plates On The Flow Past A Circular Cylinder in The Range 10R5101973Journal of Fluid MechanicsDocument12 pagesThe Effects of Wake Splitter Plates On The Flow Past A Circular Cylinder in The Range 10R5101973Journal of Fluid MechanicsDeepak RajpurohitNo ratings yet

- Section 4Document3 pagesSection 4Aduchelab AdamsonuniversityNo ratings yet

- Sea Water Systems For HM Surface ShipDocument211 pagesSea Water Systems For HM Surface Shiplaminars75% (4)

- Eneos Sustina AllDocument2 pagesEneos Sustina Alldan0410No ratings yet

- Agar Mpfm300 SpecDocument4 pagesAgar Mpfm300 SpecCristhian Torres0% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document9 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Lhsan Rajawi100% (1)

- BSLTPCH 3 P 3 B2Document17 pagesBSLTPCH 3 P 3 B2Eni SumarsihNo ratings yet

- 206L3MM206L3MMCH29Document34 pages206L3MM206L3MMCH29camiloguayazanNo ratings yet

- Design of DesandersDocument5 pagesDesign of Desandersguildkey0% (1)

- Gardner Denver Electra Saver II Parts ManualDocument52 pagesGardner Denver Electra Saver II Parts ManualAndres Jimenez67% (6)

- High Pressure Boiler Water TreatmentDocument90 pagesHigh Pressure Boiler Water Treatmentak_thimiri100% (1)

- Nycolube 127 TDSDocument1 pageNycolube 127 TDSpokleNo ratings yet

- Chapter 1Document13 pagesChapter 1Gie Andal0% (3)

- Computer Application in Hydraulic EngineeringDocument6 pagesComputer Application in Hydraulic Engineeringkawser zamanNo ratings yet

- RA9275Document49 pagesRA9275znarf_ryanNo ratings yet

- MEE 302 - Tutorial 1-1Document3 pagesMEE 302 - Tutorial 1-1acemumbiNo ratings yet

- White6ed P6.52 53Document2 pagesWhite6ed P6.52 53Prince John MedinaNo ratings yet

- Guidelines On Compressor Sizing and SelectionDocument35 pagesGuidelines On Compressor Sizing and SelectionIan LuyaoNo ratings yet

- Diagram Hydraulic Power PackDocument1 pageDiagram Hydraulic Power PackYuri SetiadiNo ratings yet

- Instruction Manual Uniwave ProjectileDocument9 pagesInstruction Manual Uniwave ProjectilesentyNo ratings yet

- Aerodynamics in CarsDocument20 pagesAerodynamics in CarsSagar KnNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document3 pagesGujarat Technological University: W.E.F. AY 2018-19suraj nakumNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Arduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!From EverandArduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!Rating: 3 out of 5 stars3/5 (1)

- DIY Drones for the Evil Genius: Design, Build, and Customize Your Own DronesFrom EverandDIY Drones for the Evil Genius: Design, Build, and Customize Your Own DronesRating: 3.5 out of 5 stars3.5/5 (3)

- Practical Robotics in C++: Build and Program Real Autonomous Robots Using Raspberry Pi (English Edition)From EverandPractical Robotics in C++: Build and Program Real Autonomous Robots Using Raspberry Pi (English Edition)No ratings yet

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.From EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Rating: 4 out of 5 stars4/5 (5)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)

- Medical and Healthcare Robotics: New Paradigms and Recent AdvancesFrom EverandMedical and Healthcare Robotics: New Paradigms and Recent AdvancesOlfa BoubakerNo ratings yet

- Digital Twin Development and Deployment on the Cloud: Developing Cloud-Friendly Dynamic Models Using Simulink®/SimscapeTM and Amazon AWSFrom EverandDigital Twin Development and Deployment on the Cloud: Developing Cloud-Friendly Dynamic Models Using Simulink®/SimscapeTM and Amazon AWSNo ratings yet

- SAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildFrom EverandSAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildRating: 5 out of 5 stars5/5 (5)

- The AI Generation: Shaping Our Global Future with Thinking MachinesFrom EverandThe AI Generation: Shaping Our Global Future with Thinking MachinesRating: 4 out of 5 stars4/5 (2)

- ChatGPT: The Future of Intelligent ConversationFrom EverandChatGPT: The Future of Intelligent ConversationRating: 3.5 out of 5 stars3.5/5 (8)

- Building with Virtual LEGO: Getting Started with LEGO Digital Designer, LDraw, and MecabricksFrom EverandBuilding with Virtual LEGO: Getting Started with LEGO Digital Designer, LDraw, and MecabricksNo ratings yet

- Evil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityFrom EverandEvil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityRating: 4.5 out of 5 stars4.5/5 (3)

- Artificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsFrom EverandArtificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsRating: 5 out of 5 stars5/5 (3)

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (4)

- A Welder’s Handbook to Robotic ProgrammingFrom EverandA Welder’s Handbook to Robotic ProgrammingRating: 5 out of 5 stars5/5 (3)

- Artificial Intelligence: Machine Learning, Deep Learning, and Automation ProcessesFrom EverandArtificial Intelligence: Machine Learning, Deep Learning, and Automation ProcessesRating: 5 out of 5 stars5/5 (2)