Professional Documents

Culture Documents

Flexural Design Example - (B)

Uploaded by

Zohaib AhmadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flexural Design Example - (B)

Uploaded by

Zohaib AhmadCopyright:

Available Formats

1

FLEXURAL DESIGN OF PRERSTRESS MEMBERS

(EXAMPLES)

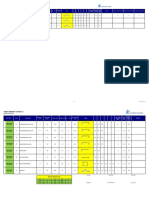

CASE C: LIMIT ZONE FOR TENDON CENTROID

PROBLEM STATEMENT

Determine the limiting tendon zone for the 40-ft span post-tensioned beam of 28-in. depth designed in

case A.

SOLUTION

Results of that design are summarized as follows:

fci = - 2,520 psi Mo = 50 ft-kips S1 = 1,422 in3.

fti = + 195 psi Mt = 350 ft-kips S2 = 1,422 in3.

fcs = -2,700 psi Pi = 279 kips Ac = 240 in2.

fts = + 465 psi Pe = 237 kips r2 = - 82.9 kips

Moment Distribution

Since the member self-weight and all superimposed loads are uniformly distributed, the variation of all

moments is parabolic in nature, from maximum at midspan to zero at supports. Accordingly, the

moment ordinates will be established:

Mid span Quarter span Support

Mo 50 ft-kips 37.5 ft-kips 0

Mt 350 ft-kips 262.5 ft-kips 0

Lower Limit of Steel Centroid from Eq. 4.10

e (x) < fti S1 / Pi + S1 / Ac + Mo (x) / Pi

At Support:

e (x) = 195 x 1422/279,000 + 1422/240 + 0 = 6.92 in.

2

At Quarter Span

e (x) = 6.92 + 37.5 x 12, 000/279,000 = 8.53 in.

At Mid span

e (x) = 6.92 + 50 x 12, 000/279,000 = 9.07 in.

Lower Limit of Steel Centroid from Eq. 4.11

e (x) < - fci S2 / Pi - S2 / Ac + Mo (x) / Pi

At Support:

e (x) = 2520 x 1422/279,000 - 1422/240 + 0 = 6.92 in.

At Quarter Span

e (x) = 6.92 + 37.5 x 12, 000/279,000 = 8.53 in.

At Mid span

e (x) = 6.92 + 50 x 12, 000/279,000 = 9.07 in.

Identical results from 2 equations simply confirm that the prestress force has been choosen to exactly

satisfy the stress limits fti and fci.

Upper Limit of Steel Centroid from Eq. 4.12

e (x) > fcs S1 / Pe + S1 / Ac + Mo (x) / Pe

At Support:

e (x) = - 2700 x 1422/237,000 + 1422/240 + 0 = - 10.28 in.

At Quarter Span

e (x) = - 10.28 + 263 x 12, 000/237,000 = 3.04 in.

At Mid span

e (x) = - 10.28 + 350 x 12, 000/237,000 = 7.44 in.

Upper Limit of Steel Centroid from Eq. 4.13

3

e (x) > fts S2 / Pe - S2 / Ac + Mt (x) / Pe

At Support:

e (x) = - 465 x 1422/237,000 + 1422/240 + 0 = - 8.72 in.

At Quarter Span

e (x) = - 8.72 + 263 x 12, 000/237,000 = 4.60 in.

At Mid span

e (x) = - 8.72 + 350 x 12, 000/237,000 = 9.00 in.

The second equation based on limiting tension, will control in the loaded stage.

Eq. 4.10 or 4.11

4

5

You might also like

- Flexural Design of Prerstress Members (Examples) : Case C: Limit Zone For Tendon CentroidDocument6 pagesFlexural Design of Prerstress Members (Examples) : Case C: Limit Zone For Tendon CentroidRaja AliNo ratings yet

- Flexural Design Examples - (C)Document7 pagesFlexural Design Examples - (C)Zohaib AhmadNo ratings yet

- Flexural Design Examples - (A) - 1Document11 pagesFlexural Design Examples - (A) - 1Zohaib AhmadNo ratings yet

- Chapter 9Document12 pagesChapter 9Jelianne Kyla Tanpian0% (1)

- Prestressed Girder DesignDocument6 pagesPrestressed Girder DesignAhsan Khan100% (1)

- م-9 كولومDocument9 pagesم-9 كولومنور عليNo ratings yet

- ACI318 MNDocument5 pagesACI318 MNhaixdproNo ratings yet

- Example of Design of A Deep Beam Using Strut Tie ModelDocument34 pagesExample of Design of A Deep Beam Using Strut Tie Modeldaniel workuNo ratings yet

- Mathcad - Beam RB-1Document7 pagesMathcad - Beam RB-1lnt4No ratings yet

- Ultimate Moment Capacity of Reinforced Concrete Section To EN 1992-2 - Clause 6.1Document5 pagesUltimate Moment Capacity of Reinforced Concrete Section To EN 1992-2 - Clause 6.1Randhir BharatNo ratings yet

- CES522 RC BEAM - DESIGN - Topic 2b - CB Example (Lecturer Vers)Document11 pagesCES522 RC BEAM - DESIGN - Topic 2b - CB Example (Lecturer Vers)muizzey aufaNo ratings yet

- Lecture 4 - Losses in PSDocument12 pagesLecture 4 - Losses in PSLexi BarcelonNo ratings yet

- Structure - IV CE 3251Document63 pagesStructure - IV CE 3251Abbdullah RayhanNo ratings yet

- Short Columns Subject To Axial Load and BendingDocument13 pagesShort Columns Subject To Axial Load and BendingHerbert PalacioNo ratings yet

- Flexural Analysis and Design of Beams: Lecture # 8Document15 pagesFlexural Analysis and Design of Beams: Lecture # 8Fuaad Abdirizak ElmiNo ratings yet

- Diseño de PlacasDocument11 pagesDiseño de PlacasSovich82No ratings yet

- Para Kay UnadDocument9 pagesPara Kay Unadjomar mendozaNo ratings yet

- Design of Slab - One Way Slab Design Learn Everything - CivilDocument14 pagesDesign of Slab - One Way Slab Design Learn Everything - Civilutsavthaker2541No ratings yet

- LBYCVD2 Compex 2Document7 pagesLBYCVD2 Compex 2sg.comNo ratings yet

- Flexural Design of Singly Reinforced Beam Sections by LSMDocument12 pagesFlexural Design of Singly Reinforced Beam Sections by LSMKallem KiranmayiNo ratings yet

- BS8110 97Document50 pagesBS8110 97mgdarioNo ratings yet

- BS8110 97 PDFDocument50 pagesBS8110 97 PDFimranmehfoozNo ratings yet

- Design of Slabs1Document8 pagesDesign of Slabs1Tonette AmorNo ratings yet

- Selection of Concrete-FilledDocument2 pagesSelection of Concrete-Filledivan bolañosNo ratings yet

- Examples On ColumnsDocument31 pagesExamples On ColumnsZekariyas AbushaNo ratings yet

- Column LRFDshear (SI)Document12 pagesColumn LRFDshear (SI)donnybtampubolonNo ratings yet

- 2-Spiral Short ColumnsDocument14 pages2-Spiral Short ColumnsmagedNo ratings yet

- Example #2 - Flexural Strength With Unbonded Tendons: 86 Post-Tensioned Concrete - Principles and PracticeDocument23 pagesExample #2 - Flexural Strength With Unbonded Tendons: 86 Post-Tensioned Concrete - Principles and PracticeMinh TríNo ratings yet

- Assignment 4: Question 1 REF Output Calculations: MSC - Str/Ecs 762/seismic DesignDocument11 pagesAssignment 4: Question 1 REF Output Calculations: MSC - Str/Ecs 762/seismic DesignMai OthmanNo ratings yet

- RC04 Bending2Document40 pagesRC04 Bending2Cristhianares Lonjawon OboLightNo ratings yet

- Column Design Detail Report:: (Design by Limit State Method As Per IS 456: 2000)Document3 pagesColumn Design Detail Report:: (Design by Limit State Method As Per IS 456: 2000)ParamesWaranNo ratings yet

- Structu4l ST33L De3sign ProblemDocument6 pagesStructu4l ST33L De3sign ProblemLimuel Milo Lebios0% (1)

- Section 2 - Bidding DataDocument5 pagesSection 2 - Bidding DataRASIKA NATHNo ratings yet

- Lecture (2) - Design of Axially Loaded Short Tied and Spiral ColumnsDocument40 pagesLecture (2) - Design of Axially Loaded Short Tied and Spiral ColumnsSayed Ahmed EL-SayedNo ratings yet

- Pc-1 (Single Pile) : Therefore: VC 5mpa Vu VC, OkDocument3 pagesPc-1 (Single Pile) : Therefore: VC 5mpa Vu VC, OkNeil SonNo ratings yet

- Doubly Reinforced BeamDocument19 pagesDoubly Reinforced BeamLavender HoneyNo ratings yet

- 1) Strength of Materials 1.1 ConcreteDocument4 pages1) Strength of Materials 1.1 ConcretejaffnaNo ratings yet

- Design of Hyd. CylindersDocument10 pagesDesign of Hyd. CylindersVinod YbNo ratings yet

- ColumnDocument20 pagesColumnAhmed EwisNo ratings yet

- Answer Sceme For Mid Term BAA2213 Sem 1 201314Document5 pagesAnswer Sceme For Mid Term BAA2213 Sem 1 201314Muhammad DulabunNo ratings yet

- Steel Page 60Document108 pagesSteel Page 60Rawaz KanabieNo ratings yet

- Strength of MaterialsDocument29 pagesStrength of MaterialsMeennnNo ratings yet

- Design of ConcreteDocument36 pagesDesign of ConcreteDenden Dermawan100% (3)

- TPCC 7 Singly RC BeamDocument22 pagesTPCC 7 Singly RC BeamMichael Joshua MacasarteNo ratings yet

- Strut and Tie ModelDocument30 pagesStrut and Tie ModelRoya Abn100% (2)

- Example Flange Beam PDFDocument17 pagesExample Flange Beam PDFFarhana HussinNo ratings yet

- Design of Doubly Reinforced RC Beam (ACI 318-14) : Particulars Remarks 1 Material Properties Codes and SectionsDocument71 pagesDesign of Doubly Reinforced RC Beam (ACI 318-14) : Particulars Remarks 1 Material Properties Codes and SectionsLavender HoneyNo ratings yet

- Walk Way CalculationsDocument71 pagesWalk Way CalculationszakariaalbashiriNo ratings yet

- Axial Load Capacity of Columns: (Short) : N ST G ST G ST STDocument9 pagesAxial Load Capacity of Columns: (Short) : N ST G ST G ST STAurora VillalunaNo ratings yet

- Column DesignDocument56 pagesColumn DesignSakar ShresthaNo ratings yet

- Design Calculation & AnalysisDocument13 pagesDesign Calculation & AnalysisAbel Meketa100% (1)

- ADAPT TN178 Strain CompatibilityDocument6 pagesADAPT TN178 Strain CompatibilitytrabajosicNo ratings yet

- RC BeamDocument77 pagesRC BeamJvv GudboyNo ratings yet

- Ub356 Bolted SpliceDocument4 pagesUb356 Bolted SpliceihpeterNo ratings yet

- Design of Deep Beam by Strut and Tie Method and Fluxural Theory - Civil Engineering Ryerson Assignment 3-bDocument14 pagesDesign of Deep Beam by Strut and Tie Method and Fluxural Theory - Civil Engineering Ryerson Assignment 3-bAfzal Waseem100% (1)

- Design Calculation Hydraulic JackDocument13 pagesDesign Calculation Hydraulic Jackalam100% (1)

- 1.0 Design Check of RC Beam at R/F 1.1) Design ParametersDocument2 pages1.0 Design Check of RC Beam at R/F 1.1) Design ParametersMr LamNo ratings yet

- DesignDocument34 pagesDesignAbhay SuwalNo ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Original Material "S" Green: Technical InformationDocument1 pageOriginal Material "S" Green: Technical InformationPedro Henriques RamosNo ratings yet

- Eutectic Cell and Nodule Count in Cast Irons: International Journal of Cast Metals ResearchDocument8 pagesEutectic Cell and Nodule Count in Cast Irons: International Journal of Cast Metals ResearchKhairul MuzafarNo ratings yet

- ProductCatalogue en 2020 Web EmailDocument57 pagesProductCatalogue en 2020 Web EmailAlexandru NeatuNo ratings yet

- As 1720.1-1988 PDFDocument87 pagesAs 1720.1-1988 PDFIvan LiewNo ratings yet

- Bar Bending Batching PlantDocument3 pagesBar Bending Batching PlantAnonymous 5OUozYNo ratings yet

- Grape County Resort NasikDocument1 pageGrape County Resort Nasikaugupta2001No ratings yet

- HW - 05 2Document2 pagesHW - 05 2foufou2003No ratings yet

- Experiment On Flow Through PipesDocument2 pagesExperiment On Flow Through PipesAyon Sengupta100% (1)

- AGHO Catalogue Hydraulic Hose 18-06-2018 en Low-ResDocument31 pagesAGHO Catalogue Hydraulic Hose 18-06-2018 en Low-ResTuan buivietNo ratings yet

- Vetotop CS536: Premixed 30 To 100 MM Thick Cementitious ScreedDocument2 pagesVetotop CS536: Premixed 30 To 100 MM Thick Cementitious ScreedSHAIK ASIMUDDINNo ratings yet

- Astm 524-96Document8 pagesAstm 524-96JOSEPH REFUERZONo ratings yet

- Air Conditioner: Owner'S ManualDocument84 pagesAir Conditioner: Owner'S ManualPepe CarreraNo ratings yet

- N4000-6 FC N4000-6 FC LD: Fast-Cure, High-Tg Multifunctional EpoxyDocument2 pagesN4000-6 FC N4000-6 FC LD: Fast-Cure, High-Tg Multifunctional EpoxyRafael CastroNo ratings yet

- Material Science Cheatsheet For Midterm (NEWEST)Document1 pageMaterial Science Cheatsheet For Midterm (NEWEST)DillNo ratings yet

- Pilot Es Dina MicaDocument8 pagesPilot Es Dina MicaPedro GarciaNo ratings yet

- RFI 150 ResponseDocument3 pagesRFI 150 ResponseAmogh SwamyNo ratings yet

- Green Leaf Exotica Apartment Brochure PDFDocument12 pagesGreen Leaf Exotica Apartment Brochure PDFbhaskar_yogendraNo ratings yet

- Exceptionally Stable Floating Underlay For Vinyl, Linoleum & Other Resilient FloorsDocument2 pagesExceptionally Stable Floating Underlay For Vinyl, Linoleum & Other Resilient FloorsFloorkitNo ratings yet

- Marco Island Executive Airport Terminal Construction Change of Order #5 - 2021Document5 pagesMarco Island Executive Airport Terminal Construction Change of Order #5 - 2021Omar Rodriguez OrtizNo ratings yet

- CH 02 Load EstimationDocument19 pagesCH 02 Load EstimationMuhammed FekryNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofjitendraNo ratings yet

- Ursa Major Elementary School Collapse Prevention Findings ReportDocument33 pagesUrsa Major Elementary School Collapse Prevention Findings ReportAlaska's News SourceNo ratings yet

- MT BitsDocument12 pagesMT BitsKundan KumarNo ratings yet

- Causes and Prevention of Cracks in BuildingDocument34 pagesCauses and Prevention of Cracks in Buildingvatika100% (2)

- Versatility & Durability: Engineered Liquid Level SolutionsDocument12 pagesVersatility & Durability: Engineered Liquid Level SolutionsnovriNo ratings yet

- CX7P9 Calefaccion PDFDocument92 pagesCX7P9 Calefaccion PDFJuan IdrovoNo ratings yet

- ASTM D149-2009 (2013) - 2500 DIelectricDocument3 pagesASTM D149-2009 (2013) - 2500 DIelectricmateoNo ratings yet

- VENTURIMETERDocument4 pagesVENTURIMETERKailash RajuNo ratings yet

- Chapter b04 Stress Analysis of Piping System PDFDocument108 pagesChapter b04 Stress Analysis of Piping System PDFrogel_ganaNo ratings yet

- Solution of Shellside Pressure Drop and Heat Transfer by Stream Analysis MethodDocument6 pagesSolution of Shellside Pressure Drop and Heat Transfer by Stream Analysis MethodacckypenrynNo ratings yet