Professional Documents

Culture Documents

Incidents (Anode Rodding-Bake Oven)

Uploaded by

pabitra panda0 ratings0% found this document useful (0 votes)

12 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views1 pageIncidents (Anode Rodding-Bake Oven)

Uploaded by

pabitra pandaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

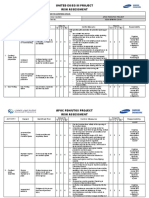

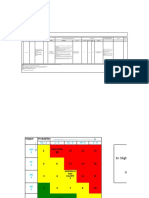

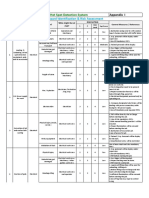

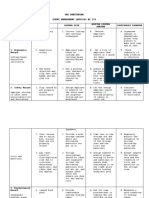

# Incident type Date Time Location BP Description Cause Findings Recommendation IP Unique ID

1. Incident root cause and its learning points to be

1. Work was carried out under in adequate

shared in TBT in all area.

supervision from B&R.

2. Area housekeeping to be done before starting of

2. Inadequate illumination found at workplace.

each activity.And this to be followed till the

3. Wrong position or posture of the workman was not

completion of the activity.

good.

3. All the activities to be done in presence of job

Person gt hurt on his left leg due to strike bystructural steel 4. Inadequate access to the workplace.

1 First Aid 04-01-2022 15:03 Anode Rodding Shop B&R supervisor at site for adequate supervision. Pradeep K Panika 1577023

as fell down on same level because of poor housekeeping. 5. Failing to keep constant attention to the site.

4. Area lighting will be ensured and enough lighting

Unsafe act done by Pradip Kumar Panika.

arrangements to be made before commencing the

6. Poor housekeeping observed at workplace as there

activity.

was no safe access provided.

5. Pre-job discussion to be done by the job supervisor

7. Non-availability of safety head from B&R to check

before starting of each separate activity.

and coordinate all the safety compliances.

1. Work was started with due excavation clearance

along with PTW and other formalities. 1. Utility drawing to be updated incorporating above

line. All plantwide pipeline drawings need to be cross

2. Utility and Fire team has approved based on their checked for its correctness.

experience & drawings available with them. 2. Electrical cable routing layout across the plant to be

During excavation with excavator underground pipe got 1. Wrong ground clearance was given by the 3. Effected pipe line details were not available in the cross checked and updated to avoid similar incidents.

2 Near Miss 02-07-2022 Anode ware house B&R

damaged concerned authority. drawing. This portion of the line might have been laid 3. Area assessment to be done with the help of Metal

later i.e. As-built drawing was not prepared after Detector prior to any excavation.

4. Communication of the incident to be done across all

installation of new line.

project areas to sensitize the people working on the

4. Following the above drawing is the root cause of safety precautions to be taken during excavations.

line puncture.

1. Adequate illumination must be provided before

starting of any activity.

2. Adequate supervision must be ensured in the

1. Poor Illumination

working area.

2. Poor supervision

While concrete dismantling with hydraulic breaker 02 inch 3. Any rocess line near to the working area must be

6 Near Miss 29-04-2022 16:00 Anode ware house B&R 3. Compressed air line was not barricaded

compressed line got damaged due to poor illumination barricaded in advance previous to the start of the

4. Excavator operator was unware the presence of

work and communication should be made to the

compressor line near to the dismantling area

operator well in advance.

4. Observation should be shared with the working

crew in general tbt in all area.

1. Hydra's boom got stuck wire rope sling attached to 1. Immediately infrom to Engg/Supervisor.

the top of the structure. 2.The supervisor and the engineer told both the

on date. 07.06.2022 @05:20 pm During material shifting.

2. The flag man that was engaged in that hydra was people that tomorrow its incident regard should be

7 Near Miss 07-06-2022 17:20 Anode Rodding Shop B&R Hydra boom gets stuck in a sling attached to the top

not properly skilled. So the flag man could not give discussed at a TBT.

structure.

the right signal, hydra's boom got stuck in the sling of 3. Flagman is must in hydra while material shifting

the above structure. and lifting.

1. Hazards in the working area should be identified

1. Pressure line was not isolated before dismantle and killed before to work.

activity. 2. Any pressure line in the working area shall be

A pressure pipe (1" Dia) is damaged and air is released

10 Near Miss 08-08-2022 16:54 Anode Rodding Shop B&R 2. Negligence of site engineer isolated before statr of the work.

during dismantling of concrete building

3. Poor supevision. 3. Incident should be discussed in the daily TBT to

4. Poor area lighting avoid further reccurrence.

4. Area lighting to be improved as per indian standard.

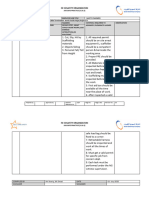

1. Nozzle of the gas cutting set was blocked as the

1. Intimated all contractors to use only ISI marked

gas cutter doing gas cutting activity very close to the

equipments in gas cutting set.

During gas cutting activity blow pipe of the torch was got metal. Metal went insid of the nozzle hole and

19 Near Miss 26.12.2022 12:00 Bake Oven B&R 2. Standard pin should be used for gas cutting set

Burst out, no injury or no any other damaged occurred. blocked.

nozzle cleaning.

2. Gas cutting torch was of non-standard material.

3. Oxygen flow must be greater in respect of DA flow.

You might also like

- Apoc Risk Assessment Format - Sesa-Bfim-Ra-Cs-001Document11 pagesApoc Risk Assessment Format - Sesa-Bfim-Ra-Cs-001Abdul WasayNo ratings yet

- 5.19-FO-33-JOB SAFE PRACTICE Hajer-Nujha SS - T-6Document2 pages5.19-FO-33-JOB SAFE PRACTICE Hajer-Nujha SS - T-6Shariq AhmedNo ratings yet

- OCP 09 F03 JSA FormatDocument5 pagesOCP 09 F03 JSA FormatBibin JacobNo ratings yet

- JSA For Floor & Wall TilingDocument2 pagesJSA For Floor & Wall TilingSatya Naidu91% (11)

- FOB Superstructure South FOBDocument19 pagesFOB Superstructure South FOBPinaki BhattacharjeeNo ratings yet

- ExcavationDocument3 pagesExcavationKoneti JanardhanaraoNo ratings yet

- Maintenance ScheduleDocument4 pagesMaintenance Schedulerobelyn veranoNo ratings yet

- Loacation Recce - ItalyDocument2 pagesLoacation Recce - Italyamy_mcdermottNo ratings yet

- Job Safety & Environment Analysis: Revision NoDocument3 pagesJob Safety & Environment Analysis: Revision NonishanthNo ratings yet

- RCC Safety Supervisor: CivilDocument7 pagesRCC Safety Supervisor: CivilDwitikrushna RoutNo ratings yet

- S.No Location Issues Photos Root Cause Immediate Action Corrective Action Preventive Action Proposed Support RequiredDocument3 pagesS.No Location Issues Photos Root Cause Immediate Action Corrective Action Preventive Action Proposed Support RequiredSiva SankarNo ratings yet

- Cable Pulling / Laying, Glanding and Termination SopDocument12 pagesCable Pulling / Laying, Glanding and Termination SopStansilous Tatenda Nyagomo0% (1)

- Abdul Jabbar 00656815 IG2 AssignmentDocument18 pagesAbdul Jabbar 00656815 IG2 AssignmentrubentemmuaNo ratings yet

- Group CDocument389 pagesGroup CthinkbxyzNo ratings yet

- 1 Training Activity MAtrixDocument7 pages1 Training Activity MAtrixvergel itimNo ratings yet

- ObservasiDocument11 pagesObservasiMiftahul ArifinNo ratings yet

- Method Statement For Scaffolding WorkDocument4 pagesMethod Statement For Scaffolding WorkChayank TiwariNo ratings yet

- Bar Bending & Cutting JSADocument2 pagesBar Bending & Cutting JSACharantej TejaNo ratings yet

- Job Safety Analysis WorksheetDocument3 pagesJob Safety Analysis Worksheetmohammed a hseNo ratings yet

- F 08 Weekly Observation ReportDocument38 pagesF 08 Weekly Observation ReportVara PrasadNo ratings yet

- Risk Assessment For K.B. Come Clean Ltd. 2023-2024Document22 pagesRisk Assessment For K.B. Come Clean Ltd. 2023-2024kasiaNo ratings yet

- Jsa ExcavationDocument3 pagesJsa ExcavationCherrycherry BetonioNo ratings yet

- Risk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control BuildingDocument14 pagesRisk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control Buildingnsadnan91% (82)

- Brick Work BSM Jha - 1Document3 pagesBrick Work BSM Jha - 1Dwitikrushna RoutNo ratings yet

- JSA - Hot WorkDocument3 pagesJSA - Hot WorkNisith SahooNo ratings yet

- Risk Assessment For Hot Spot Detection SystemDocument2 pagesRisk Assessment For Hot Spot Detection SystemprabhumanocNo ratings yet

- 3 RN Sop PDFDocument4 pages3 RN Sop PDFDwitikrushna RoutNo ratings yet

- TilingDocument6 pagesTilingrenovobuilders1820No ratings yet

- JSA Fitting and Welding Work For Pipe Trench InstalationDocument6 pagesJSA Fitting and Welding Work For Pipe Trench InstalationVishnu VijayanNo ratings yet

- R.K Construction: Job Hazard AnalysisDocument3 pagesR.K Construction: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- Standard Operating Procedure SOP - NO.-01 Joda Date:-19.09.2020Document6 pagesStandard Operating Procedure SOP - NO.-01 Joda Date:-19.09.2020Dwitikrushna Rout50% (2)

- JSA GI Earthstrip at PTAO&M Building 05Document5 pagesJSA GI Earthstrip at PTAO&M Building 05Saiyad RiyazaliNo ratings yet

- SectionDocument1 pageSectionYOng ChoonNo ratings yet

- Ohs Monitoring Event Management Services NC IiiDocument5 pagesOhs Monitoring Event Management Services NC IiiIrishNo ratings yet

- Hira Plastering Finishing WorkDocument2 pagesHira Plastering Finishing WorkDwitikrushna Rout0% (1)

- JSA For Foundation Concrete RepairDocument6 pagesJSA For Foundation Concrete RepairOvais FarooqNo ratings yet

- JSA ChainlinkfanceDocument7 pagesJSA ChainlinkfanceAnees TNo ratings yet

- 05 - PC GraDocument1 page05 - PC GraDwitikrushna RoutNo ratings yet

- Job Safety Analysis For Pipeline WeldingDocument4 pagesJob Safety Analysis For Pipeline WeldingImranuddin Syed83% (6)

- 5.19-FO-33-JOB SAFE PRACTICE Hajer-Nujha SS - T-10Document1 page5.19-FO-33-JOB SAFE PRACTICE Hajer-Nujha SS - T-10Shariq AhmedNo ratings yet

- Job Safety & Environment Analysis: Revision NoDocument3 pagesJob Safety & Environment Analysis: Revision NonishanthNo ratings yet

- Stop Card Kelompok 3 FS BDocument2 pagesStop Card Kelompok 3 FS BReza IsnawanNo ratings yet

- Risk Assessment For Trial Pit Excavation-RevDocument15 pagesRisk Assessment For Trial Pit Excavation-RevRawoofuddin ChandNo ratings yet

- TRA of Manual Chipping NightDocument2 pagesTRA of Manual Chipping NightmarvinNo ratings yet

- AST JSA Excavations.Document3 pagesAST JSA Excavations.md_rehan_2No ratings yet

- PCC Safety Supervisor: CivilDocument4 pagesPCC Safety Supervisor: CivilDwitikrushna RoutNo ratings yet

- HIRA - Height WorkDocument3 pagesHIRA - Height WorkHiralal Pattanayak100% (2)

- LAB EXER 1 (Crop Scie Lab)Document7 pagesLAB EXER 1 (Crop Scie Lab)Zyra Macasling100% (3)

- JSA-002 JSA For TCFDocument4 pagesJSA-002 JSA For TCFRafeeq Ur RahmanNo ratings yet

- Hadeed JSA Shearing Machine InstallationDocument11 pagesHadeed JSA Shearing Machine InstallationDhanu NikkuNo ratings yet

- HSE Risk Assessment - Stone Vanity TopDocument3 pagesHSE Risk Assessment - Stone Vanity TopAbrar AhmedNo ratings yet

- PTO Project - Fire Line Pipe Fabrication at Magazine 10Document3 pagesPTO Project - Fire Line Pipe Fabrication at Magazine 10John NainggolanNo ratings yet

- 62 - 16mm Rod Welding in PTCDocument2 pages62 - 16mm Rod Welding in PTCAbdan Fahwal RahmanNo ratings yet

- JSA-02 Manual ExcavationDocument2 pagesJSA-02 Manual ExcavationSujith KSNo ratings yet

- Risk Assesment Project VimalDocument7 pagesRisk Assesment Project VimalHASHIM TKNo ratings yet

- Jsa Ground Grid MocksvilleDocument2 pagesJsa Ground Grid MocksvilleChristopher NewbyNo ratings yet

- Scrap Material Handling & Loading Jha - 1Document2 pagesScrap Material Handling & Loading Jha - 1Dwitikrushna Rout100% (1)

- JSA of Glass FixingDocument5 pagesJSA of Glass FixingPAVANKUMAR50% (2)

- 18 SOP For Heavy VehiclesDocument1 page18 SOP For Heavy Vehiclespabitra pandaNo ratings yet

- Quick Life Academy, Bhubaneswar, ODISHA: Pabitra Panda Simanchala PandaDocument2 pagesQuick Life Academy, Bhubaneswar, ODISHA: Pabitra Panda Simanchala Pandapabitra pandaNo ratings yet

- Safety Violation LogDocument2 pagesSafety Violation Logpabitra pandaNo ratings yet

- Contractor Worker TransactionDocument138 pagesContractor Worker Transactionpabitra pandaNo ratings yet

- December-22 (Week-1)Document11 pagesDecember-22 (Week-1)pabitra pandaNo ratings yet

- TUV SUD Correct Use of Certification MarksDocument9 pagesTUV SUD Correct Use of Certification Markspabitra pandaNo ratings yet

- UntitledDocument6 pagesUntitledpabitra pandaNo ratings yet

- 17016/VISAKHA EXP Sleeper Class (SL)Document2 pages17016/VISAKHA EXP Sleeper Class (SL)pabitra pandaNo ratings yet

- To Whom So Ever It May Concern: Ref. No: ACIL-IBCL/128/082015Document1 pageTo Whom So Ever It May Concern: Ref. No: ACIL-IBCL/128/082015pabitra pandaNo ratings yet

- EOI For Online CTS ExamDocument20 pagesEOI For Online CTS Exampabitra pandaNo ratings yet

- Emergency Response PlanDocument14 pagesEmergency Response Planpabitra panda100% (1)

- Incident Investigation & ReportingDocument54 pagesIncident Investigation & Reportingpabitra pandaNo ratings yet

- HSE Observation Status Up To 12.04.2022Document26 pagesHSE Observation Status Up To 12.04.2022pabitra pandaNo ratings yet

- Date Contractor Name Balco Id Contractor Workers Name Po NoDocument6 pagesDate Contractor Name Balco Id Contractor Workers Name Po Nopabitra pandaNo ratings yet

- SL No Observation Compliance Status: Bridge and Roof Co. (India) LTDDocument3 pagesSL No Observation Compliance Status: Bridge and Roof Co. (India) LTDpabitra pandaNo ratings yet

- Application of Lean in Caterpillar IncDocument6 pagesApplication of Lean in Caterpillar IncAyush GautamNo ratings yet

- Dr. Tadisina Kishen Kumar ReddyDocument2 pagesDr. Tadisina Kishen Kumar ReddyReeta DuttaNo ratings yet

- (检验室)计算机化系统验证核心文件(中英文对照)Document18 pages(检验室)计算机化系统验证核心文件(中英文对照)JasonNo ratings yet

- c1Document18 pagesc1samira1farooqiNo ratings yet

- World Audio Level Reference PDFDocument1 pageWorld Audio Level Reference PDFHector Herrera ChavezNo ratings yet

- Canam Purlins and Girts Catalogue CanadaDocument0 pagesCanam Purlins and Girts Catalogue CanadasaivanvalendezNo ratings yet

- ISO 9001 - ISO 14001 - ISO 27001 Online Training - AdviseraDocument18 pagesISO 9001 - ISO 14001 - ISO 27001 Online Training - AdviseramnamkyNo ratings yet

- Arcati Mainframe Yearbook 2012Document173 pagesArcati Mainframe Yearbook 2012Kavungal Abdul JaleelNo ratings yet

- Epoxy Resin 8111Document1 pageEpoxy Resin 8111jose gualavisiNo ratings yet

- SB 11-642Document18 pagesSB 11-642clipper996No ratings yet

- Excel IFERROR Function With Formula ExamplesDocument5 pagesExcel IFERROR Function With Formula ExamplesP Singh KarkiNo ratings yet

- Design Research Guide (Arch. Sampan)Document40 pagesDesign Research Guide (Arch. Sampan)crono66No ratings yet

- AP Textile, Apparel & Garments Policy 2018-2023 PDFDocument20 pagesAP Textile, Apparel & Garments Policy 2018-2023 PDFhymaNo ratings yet

- Simulation Using PromodelDocument711 pagesSimulation Using PromodelMulky TianovalNo ratings yet

- BS en 571-1Document16 pagesBS en 571-1Dang Thanh TuanNo ratings yet

- Building A Joint Venture in An Emerging Market: - A Burmah Castrol Case StudyDocument16 pagesBuilding A Joint Venture in An Emerging Market: - A Burmah Castrol Case StudyNikhil SachdevaNo ratings yet

- What Is Free/Open-Source Software (FOSS) ?Document24 pagesWhat Is Free/Open-Source Software (FOSS) ?Marko SchuetzNo ratings yet

- Internship Report: Superior University (Duniya Television)Document9 pagesInternship Report: Superior University (Duniya Television)Vic KeyNo ratings yet

- List SA1 99e Agreed ApproveddocxDocument3 pagesList SA1 99e Agreed ApproveddocxabhishekinfoNo ratings yet

- CMPMDocument3 pagesCMPMJaphet BumaatNo ratings yet

- Bs 5950 Part4 1994 Design of Composite SlabsDocument39 pagesBs 5950 Part4 1994 Design of Composite SlabsEng Venance MasanjaNo ratings yet

- Fmea GuideDocument11 pagesFmea GuideSASIKUMARNo ratings yet

- Ata 100 CodeDocument11 pagesAta 100 CodeEli Granados100% (2)

- TSB XK 2101505Document2 pagesTSB XK 2101505jdroalkvamNo ratings yet

- Glotut 01 AnsDocument2 pagesGlotut 01 AnsJean LawNo ratings yet

- Rman DocumentDocument11 pagesRman Documentsantababu100% (2)

- All SAP Transaction Codes With Report and Description For MDocument28 pagesAll SAP Transaction Codes With Report and Description For MsanbharasNo ratings yet

- BS AssignmentDocument6 pagesBS AssignmentCall DutyNo ratings yet

- J S Auto Cast Foundry India PVT LTD.,: Tool LayoutDocument24 pagesJ S Auto Cast Foundry India PVT LTD.,: Tool Layoutkishore RavindranNo ratings yet