Professional Documents

Culture Documents

Teknicast Sdn. BHD.: Leader in Precision, Partner in Solutions'

Uploaded by

NOR ASYIKINOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Teknicast Sdn. BHD.: Leader in Precision, Partner in Solutions'

Uploaded by

NOR ASYIKINCopyright:

Available Formats

Teknicast Sdn. Bhd.

Doc: Title: Caliper Calibration Issue/Rev:

WI-CAL-001 01/00

TEKNICAST SDN. BHD.

‘LEADER IN PRECISION, PARTNER IN SOLUTIONS’

STANDARD CALIBRATION PROCEDURE

FOR

CALIPER

DOCUMENT NO.: WI-CAL-001

Name Signature Effective Date

Prepared by: Mohd Azrin Kamarudin 20th Dec 2013

Mohd Helmie b Mohd

Reviewed by: 20th Dec 2013

Kalimi

Approved by: Rajeshwaran Chinniah 20th Dec 2013

Effective Date: 20th Dec 2013 Page 1 of 11

Teknicast Sdn. Bhd.

Doc: Title: Caliper Calibration Issue/Rev:

WI-CAL-001 01/00

Issue and Revision History

Issue / Rev No. Description Reviewed By Approved By Effective Date

Rajeshwaran

01/00 Initial Release Norhaslinda 20th Dec 2013

Chinniah

Include Caliper 300

Rajeshwaran

mm into Calibration Helmie

Chinniah

scope

1.0 Scope

Effective Date: 20th Dec 2013 Page 2 of 11

Teknicast Sdn. Bhd.

Doc: Title: Caliper Calibration Issue/Rev:

WI-CAL-001 01/00

This instruction specifies calibration of caliper with range of 0 to 150 mm, 0 to 200 mm and 0 to

300mm.

2.0 Basis of Calibration

2.1 The basis of calibration is based on JIS B7507:1993

2.2 ISO Guide to the Expression of Uncertainty, 1st Edition, 1995

3.0 Equipment Use

3.1 Gauge Block

3.2 Caliper Checker

4.0 Environmental Condition

4.1 Temperature 20 ± 2°C

4.2 Relative humidity 55 ± 5 %

5.0 Pre Calibration Inspection

5.1 Clean test instrument so that dirt would not get in the way of proper measurement

5.2 Inspect measuring surface for dent or nick that might affect the straightness. Clean of

any nick found using high grade sand paper or using precision file to rub off any

protrusion or sharp edges.

5.3 Ensure all moveable parts operate smoothly and correctly.

5.4 Ensure the repeatability is achieved by moving the caliper forth and back few times

and then go to zero back. See if it able to read zero again.

5.5 Leave the test instrument in the calibration area for a period of not less four hours

before proceed with the calibration.

6.0 Preparation

6.1 Clean block gauges and caliper checker required and place them together with the

test instrument to stabilize.

7.0 Calibration Instruction

Effective Date: 20th Dec 2013 Page 3 of 11

Teknicast Sdn. Bhd.

Doc: Title: Caliper Calibration Issue/Rev:

WI-CAL-001 01/00

7.1 External Measurement

7.1.1 Lay Caliper Checker horizontally on Granite Table.

7.1.2 Set test instrument to zero. External jaw should close together. Depress

pointer release button to ensure zero repeats.

7.1.3 Set the test instrument to measure size available in Caliper Checker which are:

10.00, 20.00, 49.88, 99.76, 149.64, 199.52 (199.52 mm is extra measurement

for test instrument with range of 0 to 200mm), 249.40 and 299.28 mm ( 249.40

and 299.28 mm is extra measurement for test instrument with range of 0 to

300mm).

7.1.4 Read off the value indicated by the digital indicator and record the data.

7.1.5 Repeat step 7.1.2 until 7.1.4 for 2 times more.

7.2 Internal Measurement

7.2.1 Lay Caliper Checker horizontally on Granite Table.

7.2.2 Set test instrument to zero. Internal jaw should close together. Depress pointer

release button to ensure zero repeats.

7.2.3 Set the test instrument to measure size available in Caliper Checker which are:

20.00, 49.88, 99.76, 149.64, 199.52 (199.52 mm is extra measurement for test

instrument with range of 0 to 200 mm), 249.40 and 299.28 mm (249.40 and

299.28 mm is extra measurement for test instrument with range of 0 to

300mm).

7.2.4

7.2.5 Read off the value indicated by the digital indicator and record the data.

7.2.6 Repeat step 7.2.2 until 7.2.4 for 2 times more.

7.3 Depth Measurement

7.3.1 Lay Block Gauge vertically on Granite Table.

7.3.2 Set test instrument to zero. External jaw should close together. Depress

pointer release button to ensure zero repeats.

7.3.3 Set the test instrument to measure Block Gauge size of 3.10, 15.80, 25.00,

75.00 and 100.00 mm.

7.3.4 Read off the value indicated by the digital indicator and record the data.

7.3.5 Repeat step 7.3.2 until 7.3.4 for 2 times more.

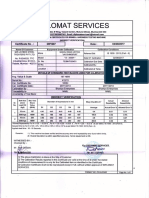

8.0 Calibration Data

Effective Date: 20th Dec 2013 Page 4 of 11

Teknicast Sdn. Bhd.

Doc: Title: Caliper Calibration Issue/Rev:

WI-CAL-001 01/00

Table 1 : External Measurement

Nominal Read 1 Read 2 Read 3 M

10.00 R1 R2 R3 M1

20.00 R1 R2 R3 M1

49.88 R1 R2 R3 M1

99.76 R1 R2 R3 M1

149.64 R1 R2 R3 M1

199.52* R1 R2 R3 M1

249.40** R1 R2 R3 M1

299.28** R1 R2 R3 M1

*Fill up if test instrument range from 0 to 200mm only.

**Fill up if test instrument range from 0 to 300mm only.

Table 2: Internal Measurement

Nominal Read 1 Read 2 Read 3 M

10.00 R1 R2 R3 M1

20.00 R1 R2 R3 M1

49.88 R1 R2 R3 M1

99.76 R1 R2 R3 M1

149.64 R1 R2 R3 M1

199.52* R1 R2 R3 M1

249.40*

* R1 R2 R3 M1

299.28*

* R1 R2 R3 M1

*Fill up if test instrument range from 0 to 200mm only.

**Fill up if test instrument range from 0 to 300mm only.

Table 3: Depth Measurement

Nominal Read 1 Read 2 Read 3 M

3.10 R1 R2 R3 M1

15.80 R1 R2 R3 M1

25.00 R1 R2 R3 M1

75.00 R1 R2 R3 M1

100.00 R1 R2 R3 M1

9.0 Calculation

Effective Date: 20th Dec 2013 Page 5 of 11

Teknicast Sdn. Bhd.

Doc: Title: Caliper Calibration Issue/Rev:

WI-CAL-001 01/00

9.1 Measured value

9.1.1 For each of the nominal range from 0 to 200 mm determine the mean, M value

as below:

(R1 + R2 + R3) ÷ 3 = M

9.1.2 With the use of a reference equipment correction, the measured value is:

Measured value = M + Correction

9.1.3 Report all measured value

10.0 Uncertainty

10.1 Sources that can contribute to the error are as below :-

10.1.1 ∆ Reference equipment (caliper checker) standard uncertainty U 1 and degree

of freedom v1

10.1.2 ∆ Reference equipment (gauge block) standard uncertainty U 2 and degree of

freedom v2

10.1.3 ∆ Scale readability standard uncertainty U3 and degree of freedom v3

10.1.4 ∆ Scale repeatability standard uncertainty U4 and degree of freedom v4

10.1.5 ∆ Variation of length due to change of temperature during measurement

(caliper checker) standard uncertainty U5 and degree of freedom v5

10.1.6 ∆ Variation of length due to change of temperature during measurement

(gauge block) standard uncertainty U6 and degree of freedom v6

10.2 Individual Component Calculation :

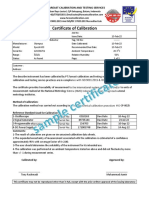

10.2.1 ∆ Caliper Checker

This is type B because it is obtained from calibration certificate of Caliper

Checker

S1

Standard uncertainty, U 1=

k

S1 value is obtained from manufacturer tolerance

k value is 30.5 because rectangular distribution

v1 is assume to be infinite.

10.2.2 ∆ Gauge Block

Effective Date: 20th Dec 2013 Page 6 of 11

Teknicast Sdn. Bhd.

Doc: Title: Caliper Calibration Issue/Rev:

WI-CAL-001 01/00

This is type B because it is obtained from calibration certificate of gauge

block.

S

Standard uncertainty, U 2= 2

k

S2 value is obtained from manufacturer tolerance

k value is 30.5 because rectangular distribution

v2 is assume to be infinite.

10.2.3 ∆ Scale Readability

This is type B because it is obtained from readability judge of person

performing the calibration.

Standard uncertainty, S3

U 3=

k

S3 is obtained from smallest resolution of test instrument scale.

k value is √12 because it is a rectangular distribution and the resolution is

digital type.

V3 is assumed to be 12.5.

10.2.4 ∆ Repeatability

This is type A because it is obtained from calibration data.

Nominal Value Read 1 Read 2 Read 3 Standard Deviation,S

N1

N2

N3

N4

N5

N6

N7

N8

N9

S4

Standard Uncertainty, ESDM =U 4 =

n0. 5

S4 is obtained by getting the maximum value of standard deviation, S

n is obtained from number of repetition.

V4 = n – 1

10.2.5 ∆ Change of temperature effect (Caliper Checker)

Effective Date: 20th Dec 2013 Page 7 of 11

Teknicast Sdn. Bhd.

Doc: Title: Caliper Calibration Issue/Rev:

WI-CAL-001 01/00

This is type B because change of temperature is recorded at the beginning and

end of calibration, not continuously.

S5

Standard uncertainty, U 5 =

k

S5 is the variation of standard length with the change of temperature while

running the calibration.

S5=l × ∆ ℃ ×thermal coefficent

Where l = maximum length

∆˚C = difference temperature from 20˚C, assume as 2˚C

Thermal coefficient = 11.5 x 10-6 for steel

k value is 30.5 because it is a rectangular distribution

v5 is assume to be 12.5 because indicator of thermo hygrometer is in digital

type

10.2.6 ∆ Change of temperature effect (Gauge Block)

This is type B because change of temperature is recorded at the beginning and

end of calibration, not continuously.

S6

Standard uncertainty, U 6 =

k

S6 is the variation of standard length with the change of temperature while

running the calibration.

S6 =l× ∆ ℃ ×thermal coefficent

Where l = maximum length

∆˚C = difference temperature from 20˚C, assume as 2˚C

Thermal coefficient = 4.23 x 10-6 for tungsten carbide

k value is 30.5 because it is a rectangular distribution

v6 is assume to be 12.5 because indicator of thermo hygrometer is in digital

type

10.3 Summary of the uncertainty estimation

Effective Date: 20th Dec 2013 Page 8 of 11

Teknicast Sdn. Bhd.

Doc: Title: Caliper Calibration Issue/Rev:

WI-CAL-001 01/00

Standard

Standard Uncertaint Degree of

Factor Type Uncertainty Assumption

Uncertainty y freedom v

U (µm) U (µm)

S1 Rectangular

∆ Caliper

B S1

Checker k U1 distribution ∞

Rectangular

∆ Caliper S2

B S2 U2 distribution ∞

Checker k

S3 Rectangular

∆ Readability B S3 U3 12.5

√12 distribution

S4

∆ Repeatability A S4 U4 Normal n-1

√n

∆ Temperature

during

B S5

S5 U4

Rectangular

12.5

Calibration Distribution

(caliper √3

checker)

∆ Temperature S6

during Rectangular

calibration

B S6 √3 U6

distribution

12.5

(gauge block)

10.4 Combined Uncertainty, Uc :

√∑ (

n

2

Uc= U i)

i=1

10.5 Effective degree of freedom veff :

Uc

v eff =

( )

n U 4

∑ vi

i

i =1

10.6 Coverage factor k

Effective Date: 20th Dec 2013 Page 9 of 11

Teknicast Sdn. Bhd.

Doc: Title: Caliper Calibration Issue/Rev:

WI-CAL-001 01/00

10.6.1 k is obtained from student t-table, at 95% confidence level corresponds to veff

value calculated from clause 10.5.

10.6.2 It is the policy of this company to report 95% confidence level.

10.7 Expanded Uncertainty U

10.7.1 The expanded uncertainty is based on this formula

U=k×U c

10.7.2 Where Uc is from clause 10.4

10.7.3 k is from clause 10.6

11.0 Presentation

Reporting format shall include:

11.1 The following metrological specification of the caliper

11.2 Measured Value

11.3 Statement of uncertainty at 95% confidence level

12.0 Related document

12.1 JIS B7507:1993

APPENDIX A : PERMISSIBLE VALUE OF INSTRUMENTAL ERROR

Effective Date: 20th Dec 2013 Page 10 of 11

Teknicast Sdn. Bhd.

Doc: Title: Caliper Calibration Issue/Rev:

WI-CAL-001 01/00

Measuring Length Resolution

from to & incl 0.1 0.05 0.02 0.01

0 50 ±0.05 ±0.05 ±0.02 ±0.02

50 100 ±0.06 ±0.06 ±0.03 ±0.03

100 200 ±0.07 ±0.07 ±0.03 ±0.03

200 300 ±0.08 ±0.08 ±0.04 ±0.04

300 400 ±0.09 ±0.09 ±0.04 ±0.04

400 500 ±0.10 ±0.10 ±0.05 ±0.05

500 600 ±0.11 ±0.11 ±0.05 ±0.05

600 700 ±0.12 ±0.12 ±0.06 ±0.06

700 800 ±0.13 ±0.13 ±0.06 ±0.06

800 900 ±0.14 ±0.14 ±0.07 ±0.07

900 1000 ±0.15 ±0.15 ±0.07 ±0.07

*Taken from Table 1 (page 4) in JIS B7507:1993

Effective Date: 20th Dec 2013 Page 11 of 11

You might also like

- Procedure For Caliper Calibration (Rev.1)Document10 pagesProcedure For Caliper Calibration (Rev.1)syisyi87No ratings yet

- Analog Outside Micrometer - 130262486 - 25 MM YDocument15 pagesAnalog Outside Micrometer - 130262486 - 25 MM YishraqaliahsanNo ratings yet

- 04-Dial Micro IndicatorDocument1 page04-Dial Micro IndicatorummarNo ratings yet

- AccreditationDocument40 pagesAccreditationWalid BdeirNo ratings yet

- TSC - 22-23 - 5490-1 TachometerDocument2 pagesTSC - 22-23 - 5490-1 TachometerDebabrata MajhiNo ratings yet

- APL-C7!22!109 Ultrasonic Flow Detector Quality InspectorsDocument2 pagesAPL-C7!22!109 Ultrasonic Flow Detector Quality InspectorsSTEPHEN MIGWINo ratings yet

- Ground Bound Tester. Phoenix Calibration.Document3 pagesGround Bound Tester. Phoenix Calibration.Vladimir DovalNo ratings yet

- 29 Digital Colony Counter 029Document3 pages29 Digital Colony Counter 029ASHOK KUMAR LENKA0% (1)

- Certificación Gammadensimetro. Oct. 2021Document3 pagesCertificación Gammadensimetro. Oct. 2021Vladimir DovalNo ratings yet

- 020-600kN-UTM-CELL COM TELESERVICES PVT. LTD. - 11.03.2023Document1 page020-600kN-UTM-CELL COM TELESERVICES PVT. LTD. - 11.03.2023SwaleheenNo ratings yet

- Laporan Kalibrasi Calliper LatihanDocument24 pagesLaporan Kalibrasi Calliper LatihanMuhammad BurhanuddinNo ratings yet

- Advmet CM 027 Height GaugeDocument6 pagesAdvmet CM 027 Height GaugeMuath FawwazNo ratings yet

- Ultra Sonic Flaw Detector SampleDocument3 pagesUltra Sonic Flaw Detector SampleAAMIRNo ratings yet

- Calibration Laboratory Depth Gauge: Revision Record SheetDocument6 pagesCalibration Laboratory Depth Gauge: Revision Record SheetManivasagan VasuNo ratings yet

- Procedure For Calibration of Welding MachinesDocument8 pagesProcedure For Calibration of Welding MachinesVinayaga MoorthiNo ratings yet

- APT - cc.D.2021.820 (5 Files Merged)Document5 pagesAPT - cc.D.2021.820 (5 Files Merged)umangNo ratings yet

- CFC2023 2398 ML 1Document2 pagesCFC2023 2398 ML 1chandra332No ratings yet

- Calibration CertDocument4 pagesCalibration CertWarn StudioNo ratings yet

- Paramount Calibration Centre Calibrates Sound Level Meter and Infrared ThermometerDocument2 pagesParamount Calibration Centre Calibrates Sound Level Meter and Infrared ThermometerVIKASH RAI50% (2)

- Calibration Certificate Template AnalysisDocument6 pagesCalibration Certificate Template AnalysissmalnifNo ratings yet

- Adobe Scan 02-Jul-2022Document3 pagesAdobe Scan 02-Jul-2022Shamsher SinghNo ratings yet

- Mesuring Tape HE - mt.001Document2 pagesMesuring Tape HE - mt.001Chethan Nagaraju KumbarNo ratings yet

- Caliper Calibration ProcedureDocument4 pagesCaliper Calibration ProcedureVinod KGNo ratings yet

- Arc 2Document2 pagesArc 2chandrabhushan kushwahaNo ratings yet

- 249-317 Tec Aero Tue-C-100-293Document1 page249-317 Tec Aero Tue-C-100-293KiranNo ratings yet

- Cathye@repmet - Co.za: Calibrated by MJ. Frade Checked by SP. Mare SANAS Technical Signatory MJ. FradeDocument6 pagesCathye@repmet - Co.za: Calibrated by MJ. Frade Checked by SP. Mare SANAS Technical Signatory MJ. FradeTsiory RandriaNo ratings yet

- Ministry of Works and Transport-01220745 - 20220929051602Document1 pageMinistry of Works and Transport-01220745 - 20220929051602Okello StevenNo ratings yet

- Single Gas Detector (Msa Altair Pro)Document10 pagesSingle Gas Detector (Msa Altair Pro)MANIVASAGANNo ratings yet

- Adobe Scan 06-Aug-2023Document2 pagesAdobe Scan 06-Aug-2023meerut nazibabad projectNo ratings yet

- Oiml R035-1-E07Document6 pagesOiml R035-1-E07Juan Sebastián Martinez NunciNo ratings yet

- UV Light Meter-23 To 24Document2 pagesUV Light Meter-23 To 24monwar hosenNo ratings yet

- Arc 1Document2 pagesArc 1chandrabhushan kushwahaNo ratings yet

- Standard Calibration Procedure Dial Gauge Doc. No. Call/SCP/007 Rev. 00 May 01, 2015Document4 pagesStandard Calibration Procedure Dial Gauge Doc. No. Call/SCP/007 Rev. 00 May 01, 2015Ajlan KhanNo ratings yet

- Laboratory Equipment Calibration SOPDocument12 pagesLaboratory Equipment Calibration SOPmiracle projectNo ratings yet

- Cal Cert FormatDocument6 pagesCal Cert FormatINSTRUCAL CALIBRATION SERVICESNo ratings yet

- Calibrate MSA ALTAIR 2X Single Gas DetectorDocument10 pagesCalibrate MSA ALTAIR 2X Single Gas DetectorMANIVASAGANNo ratings yet

- Water Flow Meter OkDocument3 pagesWater Flow Meter OkAaron Matthew BasteNo ratings yet

- KapDocument29 pagesKapRajesh KumarNo ratings yet

- AMS CAL 0153 11 Dial Indicator (AutoRecovered)Document2 pagesAMS CAL 0153 11 Dial Indicator (AutoRecovered)Muhammad RahimNo ratings yet

- 1 NablDocument11 pages1 NablNeha SharmaNo ratings yet

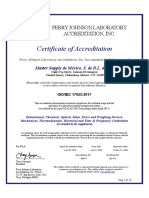

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDocument32 pagesCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncOSCAR YOBANY VEGA HERNANDEZNo ratings yet

- Calibration Certificates.Document48 pagesCalibration Certificates.Erfan KhanNo ratings yet

- Calibration Certificate Pressure Gauge ID PG-21Document1 pageCalibration Certificate Pressure Gauge ID PG-21Tinotenda MazhoweNo ratings yet

- Vernier and Measuring Tape CalibrationDocument2 pagesVernier and Measuring Tape CalibrationVIKASH RAI50% (2)

- Godrej Calibration Certificate for Digital Weighing BalanceDocument16 pagesGodrej Calibration Certificate for Digital Weighing BalancemaniNo ratings yet

- Dial Calibration TesterDocument2 pagesDial Calibration TesterAdityaKochar100% (1)

- FF - 01 - Vernier CaliperDocument2 pagesFF - 01 - Vernier CaliperMechtek LabNo ratings yet

- Adobe Scan 03 Aug 2022Document1 pageAdobe Scan 03 Aug 2022Subasini Biswajit Narayan NayakNo ratings yet

- Diplomate ServivveDocument1 pageDiplomate ServivveSunil Kumar GoudaNo ratings yet

- Master Supply Lab Earns ISO AccreditationDocument24 pagesMaster Supply Lab Earns ISO AccreditationOSCAR YOBANY VEGA HERNANDEZNo ratings yet

- 4250 Performance Verification Manual 2021.2.0Document16 pages4250 Performance Verification Manual 2021.2.0Ana Gabriela OjedaNo ratings yet

- Lumax Quality System: Gauge TypeDocument4 pagesLumax Quality System: Gauge TypeHarkesh KumarNo ratings yet

- RDS - TTR 1887Document1 pageRDS - TTR 1887emc roorkee59No ratings yet

- Standard Densitometer Calibration ProcedureDocument4 pagesStandard Densitometer Calibration ProcedureAjlan Khan100% (2)

- TESTO 104 Digital Thermometer OKDocument3 pagesTESTO 104 Digital Thermometer OKAaron Matthew BasteNo ratings yet

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDocument11 pagesCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncJoel MelendezNo ratings yet

- Certificado de Calibração - Validador 2023Document2 pagesCertificado de Calibração - Validador 2023Edson RamosNo ratings yet

- SARENS HEAVY CalibarationDocument2 pagesSARENS HEAVY CalibarationSusil Kumar SahooNo ratings yet

- ARTIKEL - Baby Talk Hinders LearningDocument2 pagesARTIKEL - Baby Talk Hinders LearningZ E V A N Y ANo ratings yet

- PROF ED 8 Assessment Learning 1Document5 pagesPROF ED 8 Assessment Learning 1Mirabel ManucducNo ratings yet

- Non Imaging Fresnel Lenses Design and Performance of Solar ConcentartorDocument278 pagesNon Imaging Fresnel Lenses Design and Performance of Solar ConcentartorYoya LawiNo ratings yet

- Medieval Musical Notation: Neumatic Signs and ClefsDocument1 pageMedieval Musical Notation: Neumatic Signs and ClefsAntonieta Monica PalominoNo ratings yet

- Test Bank For Sociology A Brief Introduction 9th Edition by SchaeferDocument35 pagesTest Bank For Sociology A Brief Introduction 9th Edition by Schaefercashiersulphidetmvsc0100% (41)

- Ref1 Tc-211 Eng Ver2Document10 pagesRef1 Tc-211 Eng Ver2Naim ParvejNo ratings yet

- 2012 HCO Oriented Core ProceduresDocument30 pages2012 HCO Oriented Core ProceduresPancho Perez100% (1)

- Finning CAT Event CodesDocument20 pagesFinning CAT Event CodesSebastian Rodrigo Octaviano100% (2)

- Evolution of Crops - D.Tay-2Document27 pagesEvolution of Crops - D.Tay-2liam peinNo ratings yet

- Self Healing ConcreteDocument20 pagesSelf Healing ConcreteshivangNo ratings yet

- Macho Drum Winches Data v1.4Document2 pagesMacho Drum Winches Data v1.4AdrianSomoiagNo ratings yet

- Inverse Trigo and Functions BansalDocument28 pagesInverse Trigo and Functions BansalYagyank ChadhaNo ratings yet

- TX AsiaDemandForecast 2018Document12 pagesTX AsiaDemandForecast 2018Muhammad AsadNo ratings yet

- eGr13OM BioResoBookDocument137 pageseGr13OM BioResoBookJanath AnthonyNo ratings yet

- Echotrac Mkiii: Model DFDocument2 pagesEchotrac Mkiii: Model DFjonathansolverNo ratings yet

- Chapter 9 & Chapter 10 SolutionsDocument7 pagesChapter 9 & Chapter 10 SolutionsSaeed IqbalNo ratings yet

- Identifikasi Risiko Pada Proyek KonstruksiDocument6 pagesIdentifikasi Risiko Pada Proyek Konstruksiair_langgNo ratings yet

- Technical Datasheet 0027141131 003Document4 pagesTechnical Datasheet 0027141131 003Faizal SetiawanNo ratings yet

- BBC Learning English 6 Minute English Day-Trip With A DifferenceDocument4 pagesBBC Learning English 6 Minute English Day-Trip With A DifferenceAsefeh KianiNo ratings yet

- Bypass Sony KDL-55W900A 4X LED Blinking ErrorDocument7 pagesBypass Sony KDL-55W900A 4X LED Blinking ErroruzenNo ratings yet

- Treadmill Error Code GuideDocument19 pagesTreadmill Error Code GuideŞener MutluNo ratings yet

- CNC USB Controller API: User ManualDocument29 pagesCNC USB Controller API: User ManualVisajientoNo ratings yet

- Sample Securitiser: Pressure Facility Re-InventedDocument4 pagesSample Securitiser: Pressure Facility Re-InventedMiguelNo ratings yet

- Questionnaire DesignDocument16 pagesQuestionnaire DesignCriss James AnsunNo ratings yet

- 18 Empathy Statements That Help Improve CustomerDocument4 pages18 Empathy Statements That Help Improve Customeriammiguelsalac100% (3)

- Humour and IdentityDocument12 pagesHumour and IdentityLyann MartinezNo ratings yet

- PDF Investigating Heat - Practical ReportDocument5 pagesPDF Investigating Heat - Practical Reportapi-292599931No ratings yet

- Concept of Nation and Nationalism: Imagined Communities by Benedict AndersonDocument11 pagesConcept of Nation and Nationalism: Imagined Communities by Benedict AndersonANDREA TANNo ratings yet

- Politics of Pedestrian Level Urban Wind ControlDocument5 pagesPolitics of Pedestrian Level Urban Wind ControlEnrico NardiNo ratings yet

- KIA Motors Corporation ProfileDocument3 pagesKIA Motors Corporation ProfileIlham K GustavakuanNo ratings yet