Professional Documents

Culture Documents

200 KLD Revised Cylindrical Wall

Uploaded by

raghu kiran0 ratings0% found this document useful (0 votes)

9 views3 pagesOriginal Title

200 Kld Revised Cylindrical Wall

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views3 pages200 KLD Revised Cylindrical Wall

Uploaded by

raghu kiranCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

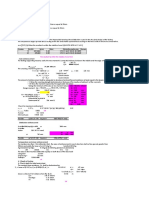

DESIGN OF CYLINDRICAL WALL

The wall is designed based on IS Code 3370 Part 4.

The wall is designed as hinged at base slab, subjected to triangular distributed water pressure.

Diameter of Tank = D 9.00 m

Depth of Water = H 4.45 m

Grade of Concrete = M 30 N/mm2

Grade of Steel = fy 500 N/mm2

Unit wt. of concrete = wc 25000 N/m3

Unit wt. of Water = w 10000 N/m3

Nominal cover = 35 mm

Effective cover = 40 mm

1 Design Constants : For HYSD Bars & Concrete M 30

sst = 130 N/mm2

scbc = 10 N/mm2 m = 9.333

m*c 9.33 x 10

k= = = 0.418

m*c+sst 9.33 x 10 + 130

j=1-k/3 = 1 - 0.418 / 3 = 0.861

R= 1/2xσcbcxkxj = 0.5 x 10 x 0.418 x 0.861 = 1.799

2 Determination of Bending moment and Hoop tension :

Assume thickness of wall = 250 mm

H2 4.45 x 4.45

= = 8.801

Dx T 9 x 0.25

By interpolating the coefficients of 8.338 & 10 we will get the coefficient of 8.801.

Maximum tension occurs at = 0.7 x H = 3.10 m from top and

Coefficient = 0.706

i) Maximum hoop tension at this level = Coefficient x w x H x D/2

= 0.706x10000x4.45x9/2

= 141376.50 N/m

Hydro dynamic force = 2.18 x 1000 x 4.45 / 2

= 4850.50 N/m

Total maximum hoop tension at this level = 141376.5+4850.5

= 146227.000 N/m

ii)

Refer Table 10 of IS 3370 (Part-IV) for coefficient.

Maximum Moment occurs at = 1.0 x H = 4.450 i.e. at base

The -ve sign indicates tension at the inner face.

Coefficient = 0.0100

Maximum cantilever Bending moment M f = Coefficient x w x H3

= 0.01 x 10000 x 4.45^3

= 8812.11 N - m/m

Total bending moment = 8812.11 N - m/m

Maximum +ve moment occurs at 0.7H = 3.115 m From Top

Coefficient = 0.001

Maximum B.M at 0.7 H = Coefficient x w x H3

= 0.001 x 10000 x 4.45^3

= 881.21 N-m/m

3 Design of section for cantilever action :

If t is the effective thickness of the Tank wall

Thickness required for cantilever moment = √ Mf / 1000xR

= √ 8812.11*1000/(1000*1.799)

= 69.99

= 69.99 mm

Overall thickness = t + Cover = 69.99+40

= 110.0 < 250 mm

Wall thickness = 30H +50 = 30 x 4.45+ 50 = 183.5 mm

Effective thickness provided t = 210 mm

i) Area of steel for cantilever bending moment A st = Mf /σst x j x t

= 8812110/(130*0.861*210)

= 374.9 mm²

< Minimum reinforcement

Area of steel for +ve bending moment A st = Mf /σst x j x t

= 881211/(130*0.861*210)

= 37.49 mm²

< Minimum reinforcement

Hence minimum reinforcement be sufficient, calculations are shown below.

ii) Vertical reinforcement :

Minimum reinforcement = 0.35 %

Ash = 0.35*1000*250/100

= 875 mm2

Minimum reinforcement on each face = 437.5 mm3

= 3.14xdia2/4

using 10 mm bars A

=78.54 mm2

Spacing of hoop Bars = 1000*78.54/374.9

= 180

say 75 mm

Hence Provide 10 mm dia bars at 75 mm c/c .on Both the faces.

Provided Ast= 1047 > 374.9 mm2 OK

5 Design of section for hoop action :

i) Hoop reinforcement

146227

Area of hoop steel for both faces A sh = = 1125 mm2 / m

130

> Minimum reinforcement

Area of steel on Each face = 1124.8 / 2 = 562 mm2 / m

= 3.14xdia2/4

using 10 mm bars A

=

78.54 mm2

Spacing of hoop Bars = 1000*78.54/562.4

= 140

say 100 mm

Hence Provide 10 mm dia bars at 100 mm c/c .on Both the faces.

wHD/2

If T is thickness of wall, we have, sct =

1000 T+(m-1)Ash

where s ct= permissible direct tensile

stress of concrete 1.5 N/mm2 for M-30 concrete

T = thickness of wall in mm m = modular ratio = 9.333

T= 1.5 = 146227/1000T+(9.333-1) x 1124.8

T = 88 mm

< 250 mm SAFE

You might also like

- DESIGN OF CIRCULAR WATER TANKDocument6 pagesDESIGN OF CIRCULAR WATER TANKPRAKASHNo ratings yet

- 2018 May 29 Circular Tank With WaterDocument4 pages2018 May 29 Circular Tank With WaterPRAKASHNo ratings yet

- Desing of 200 Cubic Metre Reinforced Rectangular Clear Water Storage Tank For Rumphi Tank Geometry and DimensionsDocument23 pagesDesing of 200 Cubic Metre Reinforced Rectangular Clear Water Storage Tank For Rumphi Tank Geometry and DimensionsWjz WjzNo ratings yet

- Roof & WallDocument3 pagesRoof & WallcivilceejiNo ratings yet

- 11 RECT TANK 4.0M X 3.0M X 3.3M H - Flocculator PDFDocument3 pages11 RECT TANK 4.0M X 3.0M X 3.3M H - Flocculator PDFaaditya chopadeNo ratings yet

- Circular Water Tank (Flexible Joint)Document7 pagesCircular Water Tank (Flexible Joint)PUNARVI INFRASTRUCTURENo ratings yet

- RC Tank Design CalculationDocument8 pagesRC Tank Design CalculationNicholas ThompsonNo ratings yet

- 1 Design Constants: Maximum Hoop Tension atDocument15 pages1 Design Constants: Maximum Hoop Tension atMiko AbiNo ratings yet

- Design of BearingsDocument24 pagesDesign of BearingsFarrukh RizwanNo ratings yet

- Sump Well 20 KLDocument3 pagesSump Well 20 KLANKESH SHRIVASTAVA100% (1)

- 3Document8 pages3Yousif R. AljNo ratings yet

- Design of Walkway Slab (WS1) ReinforcementDocument2 pagesDesign of Walkway Slab (WS1) ReinforcementRaju SainiNo ratings yet

- Design For Water TankDocument9 pagesDesign For Water TankHarmeetNo ratings yet

- SMS slab reinforcement designDocument6 pagesSMS slab reinforcement designJamie MartinezNo ratings yet

- Design of Rectangular Underground Water Tank: S S M C+ SSTDocument6 pagesDesign of Rectangular Underground Water Tank: S S M C+ SSTRatul PalodhiNo ratings yet

- Staging and Scaffolding of Bridge Deck SlabDocument3 pagesStaging and Scaffolding of Bridge Deck SlabPhanindra Nath100% (1)

- All Type of Footing DesignDocument26 pagesAll Type of Footing DesignDilon FernandoNo ratings yet

- Design of Flash Mixer at Kurawar - 1ADocument13 pagesDesign of Flash Mixer at Kurawar - 1AAnonymous RREG0QJWNo ratings yet

- Over Head ResevoirDocument8 pagesOver Head ResevoirPoulomi BiswasNo ratings yet

- Design of R.C.C. Beam Bottom Ast: 567 MM Check D'/D Ratio Design As Singly BeamDocument2 pagesDesign of R.C.C. Beam Bottom Ast: 567 MM Check D'/D Ratio Design As Singly BeamJayNo ratings yet

- Design calculations for skin plate and stiffener of pier and piercapDocument4 pagesDesign calculations for skin plate and stiffener of pier and piercapraghuveer11No ratings yet

- 1410 113 DL+LL+ MATL. LOAD+SL Z-: Bagging Tower Support - JPLDocument3 pages1410 113 DL+LL+ MATL. LOAD+SL Z-: Bagging Tower Support - JPLAshlin AarthiNo ratings yet

- Design CalculationsDocument8 pagesDesign CalculationsJIBEESH01No ratings yet

- Design of Two-Way Slab for Residential UnitDocument235 pagesDesign of Two-Way Slab for Residential Unitramel sigueNo ratings yet

- FOOTING DESIGN TITLEDocument1 pageFOOTING DESIGN TITLEtewele brhaneNo ratings yet

- DN 600m Amirabad 2Document5 pagesDN 600m Amirabad 2anirbanpwd76No ratings yet

- Design of combined footing and strap beamDocument4 pagesDesign of combined footing and strap beamSakar ShresthaNo ratings yet

- Pier Cap Corbel 30m SGDocument3 pagesPier Cap Corbel 30m SGSM ConsultantsNo ratings yet

- Design of Water Tank On The Ground According To Bs 8007:1987Document109 pagesDesign of Water Tank On The Ground According To Bs 8007:1987minov minovitchNo ratings yet

- U-shaped retaining wall design parametersDocument4 pagesU-shaped retaining wall design parametersAshish G100% (1)

- Design of Staircase: 3179 MM 3179 MM 10370 MM 3800 MM 150 MM 280 MM 500 Mpa 20 Mpa 1.5 KN/M 3.0 KN/M 0 MM 1100 MMDocument7 pagesDesign of Staircase: 3179 MM 3179 MM 10370 MM 3800 MM 150 MM 280 MM 500 Mpa 20 Mpa 1.5 KN/M 3.0 KN/M 0 MM 1100 MMSudip ShresthaNo ratings yet

- Design of Water Tank On The Ground According To Bs 8007:1987Document77 pagesDesign of Water Tank On The Ground According To Bs 8007:1987juliyet strucNo ratings yet

- Design of Flash Mixer at Aron - 4DDocument10 pagesDesign of Flash Mixer at Aron - 4DSougata MondalNo ratings yet

- Open Well Staircase: 1. Design DataDocument7 pagesOpen Well Staircase: 1. Design DataEr Saroj Paudel100% (1)

- Design of Stair CaseDocument3 pagesDesign of Stair CaseVijay VijayNo ratings yet

- Design of CWR WallDocument3 pagesDesign of CWR WallTarun SharmaNo ratings yet

- Pad Footing Design for 3m x 3m ColumnDocument4 pagesPad Footing Design for 3m x 3m ColumnAlly KhooNo ratings yet

- Revised Pad Footing Rev.1 (10.7.2018)Document4 pagesRevised Pad Footing Rev.1 (10.7.2018)Ally Khoo100% (1)

- Return WallDocument4 pagesReturn WallAshish GNo ratings yet

- Strip Footing and Beam Design at Grid C-CDocument3 pagesStrip Footing and Beam Design at Grid C-CSujal MaharjanNo ratings yet

- Isolated Footing - MomentsDocument1 pageIsolated Footing - MomentsKaushlendra KumarNo ratings yet

- Overhead Water Intze Tank DesignDocument19 pagesOverhead Water Intze Tank Designiqramoyale022No ratings yet

- STRAP FOOTING DESIGN FOR MULTI-STOREY BUILDINGDocument5 pagesSTRAP FOOTING DESIGN FOR MULTI-STOREY BUILDINGNabin Acharya100% (1)

- Sequential Batch Reactor Design DataDocument6 pagesSequential Batch Reactor Design Dataankkeshmundra1No ratings yet

- Calculation For 1.4m X 1.5m RCC Box CulvertDocument4 pagesCalculation For 1.4m X 1.5m RCC Box CulvertManish BhatkarNo ratings yet

- FOOTING DESIGN TITLEDocument1 pageFOOTING DESIGN TITLEtewele brhaneNo ratings yet

- Design of BeamsDocument19 pagesDesign of BeamssnsatyanarayanaNo ratings yet

- 500cubic Metre Concrete Tank DesignDocument18 pages500cubic Metre Concrete Tank DesignWjz WjzNo ratings yet

- Intze Tank 1 Moin 25-1-23Document17 pagesIntze Tank 1 Moin 25-1-23MOIN UDDINNo ratings yet

- Underground Tank Design and Reinforcement DetailsDocument2 pagesUnderground Tank Design and Reinforcement Detailsaaditya chopadeNo ratings yet

- Design of Bottom Reaction Beam ISMB 150Document2 pagesDesign of Bottom Reaction Beam ISMB 150ketanNo ratings yet

- Circular Water Tank Flexible Joint - CompressDocument45 pagesCircular Water Tank Flexible Joint - CompressFrank XwalaNo ratings yet

- Design Example - Cantilever Retaining WallDocument14 pagesDesign Example - Cantilever Retaining WallJumma AbualgasemNo ratings yet

- Design of Bank Building in MSECDocument82 pagesDesign of Bank Building in MSECjahanger ali SNo ratings yet

- Annexure-2 (Section Design Calcs)Document107 pagesAnnexure-2 (Section Design Calcs)blisscutest beagleNo ratings yet

- 5.3 Design of Crash BarrierDocument3 pages5.3 Design of Crash BarrierMd BIN HASANNo ratings yet

- Design of Pier For Minor Bridge at Ch. 11+120Document69 pagesDesign of Pier For Minor Bridge at Ch. 11+120siddharth yadavNo ratings yet

- Design of StaircaseDocument4 pagesDesign of StaircaseahmedNo ratings yet

- SESIMIC & WIND LoadDocument4 pagesSESIMIC & WIND Loadraghu kiranNo ratings yet

- CRW 13MRDocument25 pagesCRW 13MRraghu kiranNo ratings yet

- Reserach Design SheetsDocument57 pagesReserach Design Sheetskiran raghukiranNo ratings yet

- CRW 13MRDocument25 pagesCRW 13MRraghu kiranNo ratings yet

- Thressing Shed and Mannure Stock Shed PalamneruDocument75 pagesThressing Shed and Mannure Stock Shed Palamneruraghu kiranNo ratings yet

- Design of Combined Footing Cf5: 5742 C1 C2 620 C.G 3000 0.75 X 0.75 0.6 X 0.6 2250 2242 1250Document5 pagesDesign of Combined Footing Cf5: 5742 C1 C2 620 C.G 3000 0.75 X 0.75 0.6 X 0.6 2250 2242 1250kiran raghukiranNo ratings yet

- Reserach Design SheetsDocument57 pagesReserach Design Sheetskiran raghukiranNo ratings yet

- Zone 2 and 3 - Water Requirement (Final)Document10 pagesZone 2 and 3 - Water Requirement (Final)raghu kiranNo ratings yet

- VZM MC Portico Slope Slab DesignDocument204 pagesVZM MC Portico Slope Slab Designraghu kiranNo ratings yet

- SLABS RefDocument2 pagesSLABS Refraghu kiranNo ratings yet

- SLABS RefDocument2 pagesSLABS Refraghu kiranNo ratings yet

- Gabion Retaing Wall-1Document1 pageGabion Retaing Wall-1raghu kiranNo ratings yet

- Water Tank CLPMDocument3 pagesWater Tank CLPMkiran raghukiranNo ratings yet

- Box Culvert Designs-2Document20 pagesBox Culvert Designs-2raghu kiranNo ratings yet

- 250kLD STP STR DesignDocument68 pages250kLD STP STR Designraghu kiranNo ratings yet

- Cf3-Without Beam NTSDocument4 pagesCf3-Without Beam NTSraghu kiranNo ratings yet

- 200 KLD Revised Cylindrical WallDocument3 pages200 KLD Revised Cylindrical Wallraghu kiranNo ratings yet

- 1800 KLD Revised Cylindrical Wall 1Document2 pages1800 KLD Revised Cylindrical Wall 1raghu kiranNo ratings yet

- Construction of Proposed Hospital Fire Fighting System EstimateDocument137 pagesConstruction of Proposed Hospital Fire Fighting System Estimateraghu kiranNo ratings yet

- 200 KLD Revised Cylindrical WallDocument3 pages200 KLD Revised Cylindrical Wallraghu kiranNo ratings yet

- Sattvic Revolution: M.Sc. in Environmental Management National University of SingaporeDocument35 pagesSattvic Revolution: M.Sc. in Environmental Management National University of SingaporeDanivian HigginsNo ratings yet

- 1800 KLD Revised Cylindrical Wall 1Document2 pages1800 KLD Revised Cylindrical Wall 1raghu kiranNo ratings yet

- Mangalagiri Final StaircaseDocument12 pagesMangalagiri Final Staircaseraghu kiranNo ratings yet

- Revised BoqDocument6 pagesRevised Boqraghu kiranNo ratings yet

- Vijayanagaram Elec Abcd Sor 20-21 Final 15-03-2021 For JPDocument656 pagesVijayanagaram Elec Abcd Sor 20-21 Final 15-03-2021 For JPraghu kiranNo ratings yet

- Final Fire FightingDocument52 pagesFinal Fire Fightingraghu kiranNo ratings yet

- Mbbrmedia Virgin Technicaldetails Hd1582Document1 pageMbbrmedia Virgin Technicaldetails Hd1582raghu kiranNo ratings yet

- MBBR Technical BreifDocument12 pagesMBBR Technical Breifraghu kiran100% (1)

- Hvac EstimateDocument18 pagesHvac Estimateraghu kiranNo ratings yet

- Unit 1 CH 07 Exergy Analysis - ReidDocument31 pagesUnit 1 CH 07 Exergy Analysis - ReidLorenzo Galindo Jr.No ratings yet

- HPLC Nexera PHDocument2 pagesHPLC Nexera PHhectorNo ratings yet

- Periodic Table Stories PDFDocument47 pagesPeriodic Table Stories PDFErra Peñaflorida100% (1)

- IJPPR, Vol 8, Issue 5, Article 16Document7 pagesIJPPR, Vol 8, Issue 5, Article 16Idha KurniawatiNo ratings yet

- PhysicscaDocument19 pagesPhysicscabishal2632No ratings yet

- Concise Physics Solutions for MachinesDocument18 pagesConcise Physics Solutions for MachinesBharati GulajkarNo ratings yet

- Che10108 PDFDocument68 pagesChe10108 PDFChristian Del Barco100% (1)

- Fundamentals of Process Intensification: A Process Systems Engineering ViewDocument28 pagesFundamentals of Process Intensification: A Process Systems Engineering Viewkumar_chemicalNo ratings yet

- Solidworks Flow Simulation Project ReportDocument11 pagesSolidworks Flow Simulation Project ReportIpx KangkangNo ratings yet

- Freek J. M. Hoeben, Pascal Jonkheijm, E. W. Meijer and Albertus P. H. J. Schenning - About Supramolecular Assemblies of Pi-Conjugated SystemsDocument56 pagesFreek J. M. Hoeben, Pascal Jonkheijm, E. W. Meijer and Albertus P. H. J. Schenning - About Supramolecular Assemblies of Pi-Conjugated SystemsCogsmsNo ratings yet

- Heat Exchanger Handbook - Heat Exchangers PDFDocument66 pagesHeat Exchanger Handbook - Heat Exchangers PDFhonghai_dl100% (3)

- A Heterocylic (212 C Part 2)Document138 pagesA Heterocylic (212 C Part 2)Moamen MohamedNo ratings yet

- Astm D1160 - 18Document20 pagesAstm D1160 - 18Metrologia Piedecuesta Solumed Ingenieria Ltda100% (2)

- Malt Extract MsdsDocument7 pagesMalt Extract MsdsSorin LazarNo ratings yet

- KineticsDocument26 pagesKineticsMelissa M. Abansi-BautistaNo ratings yet

- Differential Scanning Calorimetry (DSC)Document9 pagesDifferential Scanning Calorimetry (DSC)DanielNo ratings yet

- Cie - 462 - Test One.09.05.2022Document2 pagesCie - 462 - Test One.09.05.2022Chris KapendaNo ratings yet

- Selection of Materials For Prototype Fast Breeder Reactor S.L.Mannan, S.C.Chetal, Baldev Raj and S.B.BhojeDocument35 pagesSelection of Materials For Prototype Fast Breeder Reactor S.L.Mannan, S.C.Chetal, Baldev Raj and S.B.BhojeSatish Kumar GautamNo ratings yet

- Science of The Egg Drop1Document2 pagesScience of The Egg Drop1Virginia FernandezNo ratings yet

- Diffusion Explained: Movement of MoleculesDocument3 pagesDiffusion Explained: Movement of MoleculesJames TangNo ratings yet

- Pharmaceutical EmulsionsDocument28 pagesPharmaceutical EmulsionsEph RemNo ratings yet

- Ap4073 Sensors and Actuators L T P CDocument1 pageAp4073 Sensors and Actuators L T P Cjames RNo ratings yet

- Physics I Problems PDFDocument1 pagePhysics I Problems PDFBOSS BOSSNo ratings yet

- Bitumen modifiers introductionDocument5 pagesBitumen modifiers introductiondesalegn aberaNo ratings yet

- IEC 60891 Procedures For Temperature and Irradiance Corrections To Measure I-V CharacteristicsDocument18 pagesIEC 60891 Procedures For Temperature and Irradiance Corrections To Measure I-V CharacteristicsMichel GomesNo ratings yet

- CH 1 S Cbse BDocument14 pagesCH 1 S Cbse BIchigo KurosakiNo ratings yet

- Smart Materials BookDocument304 pagesSmart Materials BookemonetoNo ratings yet

- Phys101 Lecture 6 Circular Motion: Key PointsDocument11 pagesPhys101 Lecture 6 Circular Motion: Key PointsJoby Jobzz SebellinoNo ratings yet

- Pre Lab!Document4 pagesPre Lab!Lamirah ThomasNo ratings yet

- Module Two Lesson Three Guided Notes PDFDocument4 pagesModule Two Lesson Three Guided Notes PDFMadera HarrisNo ratings yet