Professional Documents

Culture Documents

Template MRFW

Uploaded by

Dylan TriggCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Template MRFW

Uploaded by

Dylan TriggCopyright:

Available Formats

Company Name

LOGO Address Line 1

Address Line 2

Town, County

Postcode

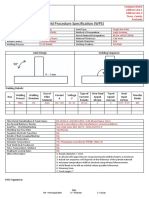

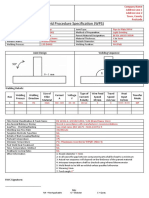

Weld Procedure Specification (WPS)

Location: Workshop Joint Type: Multi Run Fillet

Manufacturer’s WPS No: MRFW-WPS001 Method of Preparation: Light Grinding

WPQR: MRFW Parent Material Designation: BS EN 10025 S355JR

Manufacture: Company Name Material Thickness: X to Xmm

Welders Name: Welders Name Outside Diameter: N/A

Welding Process: 135 (MAG) Welding Position: PA (Flat)

Joint Design Welding Sequence

Welding Details:

Size of Type of Wire Feed Travel Heat

Welding Welding Current Voltage Transfer

Run Filler Current/ Speed Speed Input

Process Direction A V Mode

Material Polarity M/min mm/sec KJ/min

1 MAG PA Xmm XXX - XXX XX - XX DC+ve X X 0.XXX – 0.XXX DIP

2 MAG PA Xmm XXX - XXX XX - XX DC+ve X X 0.XXX – 0.XXX DIP

3 MAG PA Xmm XXX - XXX XX - XX DC+ve X X 0.XXX – 0.XXX DIP

Filler Metal Classification & Trade Name EN 14341-A: G38 4M G3SI1 / G38 (Brand Name Wire)

Any Special Baking or Drying Stored in accordance with manufacturers recommendations.

Gas/Flux: - Shielding/Backing Gas retail name (ISO 14175 – M24 ArCO7/2.5

Shielding Gas Flow Rate 15L/Minute

Tungsten Electrode Type/Size NA

Details of Back Gouging/Backing NA

Preheat Temperature X℃

Interpass Temperature (℃) ‘Maximum recorded in WPQR’ (Note 4)

Post Weld Heat Treatment NA

Time, Temperature, Method NA

Heating & Cooling Rates NA

Other Information 1: Nozzle diameter = Xmm

2: In all cases the gap between component parts shall be kept to a minimum

3: Actual run sequence will depend on the thickness of the parent material

4: Interpass temperature shall be checked using infrared thermometer

5: Weld finish to be left as-welded unless specified otherwise

6: Weaving Xmm

7: Torch angle X°

RWC Signature:

Key:

NA = Not Applicable G = Globular S = Spray

You might also like

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationGodwin A.udo-akanNo ratings yet

- Motor CAT C13 AcertDocument3 pagesMotor CAT C13 AcertJosé Gonzalez100% (4)

- Aws D1.6 - SS316 WPSDocument1 pageAws D1.6 - SS316 WPSBoby Thomas0% (1)

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Orofacial Complex: Form and FunctionDocument34 pagesOrofacial Complex: Form and FunctionAyushi Goel100% (1)

- Template BUTTDocument1 pageTemplate BUTTDylan TriggNo ratings yet

- Template SRFWDocument1 pageTemplate SRFWDylan TriggNo ratings yet

- Template Pipe PlateDocument1 pageTemplate Pipe PlateFarhan AmzarNo ratings yet

- DraftDocument32 pagesDraftAnilkumarNo ratings yet

- 01 - WPS - Welder Qualification and WPQR For MS 5.0 MM RAKESH Fillet T JointDocument5 pages01 - WPS - Welder Qualification and WPQR For MS 5.0 MM RAKESH Fillet T JointssqiindiapvtltdNo ratings yet

- Draft WPSDocument32 pagesDraft WPSAnilkumar G NairNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (2)

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- HRP Ii WPS LGP 50aDocument2 pagesHRP Ii WPS LGP 50aRohiNo ratings yet

- Welding Procedure Specification (WPS) (As Per EN / ISO 15609-1)Document1 pageWelding Procedure Specification (WPS) (As Per EN / ISO 15609-1)ramesh rajaNo ratings yet

- Welding Procedure For Plate - WPSDocument1 pageWelding Procedure For Plate - WPSCristian ZidarescuNo ratings yet

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- WPS & PQR - LTM - QW - PipeDocument7 pagesWPS & PQR - LTM - QW - PipeKAMALNo ratings yet

- Client: Hindustan Petroleum Corporation Ltd. Contractor: Narmada Offshore Constructions Pvt. Ltd. Doc. No.: NOCPL/HPCL/NWOT/RK/WPS/JP/01 Rev. 00Document7 pagesClient: Hindustan Petroleum Corporation Ltd. Contractor: Narmada Offshore Constructions Pvt. Ltd. Doc. No.: NOCPL/HPCL/NWOT/RK/WPS/JP/01 Rev. 00Bhargav BbvsNo ratings yet

- PQR Saw ProcessDocument1 pagePQR Saw ProcessARUL ARON JOSENo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- Arl-Al - WPS-001 PDFDocument2 pagesArl-Al - WPS-001 PDFrajuajiNo ratings yet

- Procedure Qualification Record (PQR) : Annex N AWS D1.1/D1.1M:2010Document2 pagesProcedure Qualification Record (PQR) : Annex N AWS D1.1/D1.1M:2010Menad SalahNo ratings yet

- Wps Blank Form 2sheetDocument4 pagesWps Blank Form 2sheetdidi sudiNo ratings yet

- MHC Conveying System Private Limited: JOINTS (QW-402)Document3 pagesMHC Conveying System Private Limited: JOINTS (QW-402)Lipika GayenNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- SPL - PQR-WPS-SWPS SmawDocument7 pagesSPL - PQR-WPS-SWPS Smawgopuvinu4uNo ratings yet

- HRP Ii WPS STR 225Document4 pagesHRP Ii WPS STR 225RohiNo ratings yet

- Welding Procedure SpecificationDocument101 pagesWelding Procedure SpecificationNhien ManNo ratings yet

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Document3 pagesWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNo ratings yet

- WPS 84281 R06Document1 pageWPS 84281 R06Ritesh kumarNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 pagesWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- PQR Babbit SCDocument34 pagesPQR Babbit SCagustinusNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- Welding Procedure SpecificationDocument4 pagesWelding Procedure SpecificationBhargav BbvsNo ratings yet

- Lampiran 3. WPS of Pile JointDocument3 pagesLampiran 3. WPS of Pile JointDoni TriatmojoNo ratings yet

- WPS - 0601 00112 01 PDFDocument1 pageWPS - 0601 00112 01 PDFAnonymous zzMwR2aNNo ratings yet

- Welding Procedure Specifications (Wps - 6G) : 2mm (Max)Document2 pagesWelding Procedure Specifications (Wps - 6G) : 2mm (Max)Gbenga Mobolade100% (1)

- Pessing Libya INC: SA 312 TP 316 TO SA 312 TPDocument1 pagePessing Libya INC: SA 312 TP 316 TO SA 312 TPMahmoud HaggagNo ratings yet

- WPS 7018+70S2Document8 pagesWPS 7018+70S2rajuNo ratings yet

- PWPS Vahali 26 - 136 PD - FWDocument1 pagePWPS Vahali 26 - 136 PD - FWVasiljka Đordan JelacaNo ratings yet

- PQR - Gmaw BCCDocument2 pagesPQR - Gmaw BCCBasel MohammadNo ratings yet

- Swathi Industries: JOINT (QW 402)Document10 pagesSwathi Industries: JOINT (QW 402)Mustu AkolawalaNo ratings yet

- Welding Insection ReportDocument4 pagesWelding Insection ReportRanjeet MouryaNo ratings yet

- Document Title: Welding Procedure Specification: Champion West Phase Iii Dev. Project C030005/ESP MSE BSP (ESP/2)Document1 pageDocument Title: Welding Procedure Specification: Champion West Phase Iii Dev. Project C030005/ESP MSE BSP (ESP/2)Ed FangNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit GhoshNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (1)

- Procedure Qualification Record (PQR) FormDocument1 pageProcedure Qualification Record (PQR) FormEarl HarbertNo ratings yet

- Preliminary Welding Procedure Specification (PWPS)Document2 pagesPreliminary Welding Procedure Specification (PWPS)Maneesh0% (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- History of Flash Part - 2Document7 pagesHistory of Flash Part - 2YOGESHWER NATH SINGHNo ratings yet

- JHS 182Document137 pagesJHS 182harbhajan singhNo ratings yet

- Generative Shape DesignDocument195 pagesGenerative Shape DesignAdi Fiera100% (1)

- CAC Bubble DiagramsDocument12 pagesCAC Bubble Diagramsangst6250No ratings yet

- Stanley B. Alpern - Amazons of Black Sparta - The Women Warriors of Dahomey-New York University Press (2011)Document308 pagesStanley B. Alpern - Amazons of Black Sparta - The Women Warriors of Dahomey-New York University Press (2011)georgemultiplusNo ratings yet

- Crashing Is A Schedule Compression Technique Used To Reduce or Shorten The Project ScheduleDocument1 pageCrashing Is A Schedule Compression Technique Used To Reduce or Shorten The Project ScheduleRaymart BulagsacNo ratings yet

- Dell W2306C LCD Monitor Service ManualDocument104 pagesDell W2306C LCD Monitor Service ManualIsrael B ChavezNo ratings yet

- Yadea User Manual For e Scooter 1546004910Document44 pagesYadea User Manual For e Scooter 1546004910Danthe ThenadNo ratings yet

- Astm 2017-F2059Document5 pagesAstm 2017-F2059laythNo ratings yet

- Active Faults in MalaysiaDocument52 pagesActive Faults in MalaysiaHazim HaNo ratings yet

- ODA X9 2SL DatasheetDocument8 pagesODA X9 2SL DatasheetYudy UtamaNo ratings yet

- Plato: Epistemology: Nicholas WhiteDocument2 pagesPlato: Epistemology: Nicholas WhiteAnonymous HCqIYNvNo ratings yet

- Quarter 4 English As Grade 4Document28 pagesQuarter 4 English As Grade 4rubyneil cabuangNo ratings yet

- Natural Disasters Vocabulary Exercises Fun Activities Games Icebreakers Oneonone Activiti 42747Document2 pagesNatural Disasters Vocabulary Exercises Fun Activities Games Icebreakers Oneonone Activiti 42747Andrea Tercero VillarroelNo ratings yet

- Reactive Dyes For Digital Textile Printing InksDocument4 pagesReactive Dyes For Digital Textile Printing InksDHRUVNo ratings yet

- Milviz F-15e Poh V 2Document499 pagesMilviz F-15e Poh V 2Jose Ramon Martinez GutierrezNo ratings yet

- Product Stock Exchange Learn BookDocument1 pageProduct Stock Exchange Learn BookSujit MauryaNo ratings yet

- Sudip Praposal - 1Document20 pagesSudip Praposal - 1Usha BbattaNo ratings yet

- The Wilson Quarterly: The World's New Numbers by Martin WalkerDocument13 pagesThe Wilson Quarterly: The World's New Numbers by Martin WalkerDavid WeekNo ratings yet

- Maths All FormulasDocument5 pagesMaths All FormulasVishnuNo ratings yet

- Manual Nice9000v A04Document151 pagesManual Nice9000v A04hoang tamNo ratings yet

- 3161 GIS Data ModelsDocument13 pages3161 GIS Data Modelsapi-3788255No ratings yet

- BECO UACE Chem2Document6 pagesBECO UACE Chem2EMMANUEL BIRUNGINo ratings yet

- Easergy PS100 48VDC Power SupplyDocument2 pagesEasergy PS100 48VDC Power SupplyRichard SyNo ratings yet

- 1ST SUMMATIVE TEST FOR G10finalDocument2 pages1ST SUMMATIVE TEST FOR G10finalcherish austriaNo ratings yet

- L GH Catalog PullingDocument60 pagesL GH Catalog PullingLuis LuperdiNo ratings yet

- Vehicle Intercom Systems (VIS)Document4 pagesVehicle Intercom Systems (VIS)bbeisslerNo ratings yet