Professional Documents

Culture Documents

UT Procedure Rev. A1

Uploaded by

kumaraguruOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UT Procedure Rev. A1

Uploaded by

kumaraguruCopyright:

Available Formats

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

1 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

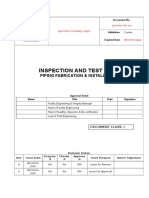

ULTRASONIC TESTING PROCEDURE FOR FABRICATION

AND INSTALLATION OF TEMPORARY & PERMANENT

BRACING MEMBERS, WAILING BEAMS AND TIE RODS

A1 11 June 2017 Issued for Company Review and Approval

RA

Prepared Reviewed Approved Reviewed Approved

Approved by

By By By By By

Rev. Date Description

Sub-contractor Contractor Company

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 1 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

2 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

REVISION RECORD SHEET

NOTES

i) Revisions after Rev. A and after Rev. 0 are denoted by a vertical line in the right

X

hand margin against the revised text, with the revision number (X) displayed next

to the revision line as shown by the example on the right.

ii) All Subcontractor / Vendor documents will be starting from A1 which is issued for

Contractor’s review and approval; subsequent revisions shall be A2, A3, A4, etc till

approval. Contractor approved Subcontractor/Vendor document shall be submitted

to company with Rev. A as per note (iii).

iii) Revision no. A is issued for Company Review and approval; subsequent

revisions shall be B, C, D, etc., for Company approval.

iv) Upon Company approval, Revision no. 0 shall be issued to implementation (for

Engineering, Procurement, and Construction & Fabrication and as applicable).

Subsequent revision thereafter shall be 1, 2, 3, etc.

v) For the details of the Contractor’s Name and Signatory authority for this

document Review and Approval, please refer List of Project Key Personnel,

Designation, Names and Sample Signature (5642-EPC-PA-007) Attachment-1.

Sub-contractor Contractor Company

Rev. Date Description

Prepared Reviewed Approved Reviewed Approved Approved

By By By By By By

11 June Issued for Company Review and

A1 RA

2017 Approval

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 2 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

3 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

TABLE OF CONTENT

SECTION DESCRIPTION PAGE NO.

1 PURPOSE

04

2 SCOPE

04

3 DEFINITIONS/ABBREVIATIONS

04

4 REFERENCE DOCUMENTS

04

5 PERSONNEL QUALIFICATION

05

6 EQUIPMENT

05

7 COUPLING MEDIUM

11

8 SURFACE CONDITION

11

9 CALIBRATION FOR TESTING

11

10 BASE METAL EVALUATION

15

11 SCANNING

16

12 ACCEPTANCE CRITERIA AS PER AWS D1.1

17

13 DOCUMENTATION

17

14 SAMPLE REPORT FORMAT

28

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 3 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

4 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

1. PURPOSE

The purpose of this procedure is desire the minimum requirements performing Ultrasonic

examination as per the applicable code requirement and / or project specification for the

project titled, “Improvement of Fire Fighting Facilities at Abu Dhabi Refinery” Project Number-

5642.

2. SCOPE

This procedure is applicable to direct Ultrasonic examination of welds carried out by Aries

personnel in the workshop & site.

This Ultrasonic Examination procedure is to be used for the testing of groove welds and heat

affected zones between the thickness of 5/16” (8.0mm) and 8” (200mm) when such testing is

required.

For thicknesses less than 8 mm or greater than 200 mm, separate examination

procedure is to be adopted.

During testing of electro slag weld or electro gas weld, if any piping porosity is

suspected, that should be supplemented by Radiographic examination.

Any variation of this procedure with respect to essential variables shall imply re-issue of the

procedure with all the variations incorporated.

Extent of Examination in accordance to contract agreement and Clients Specification.

.

3. DEFINITIONS/ABBREVIATIONS

COMPANY ABUDHABI OIL REFINING COMPANY (TAKREER)

PROJECT

MANAGEMENT Engineer’s India Limited

ASSISTANCE

CONTRACTOR KHARAFI NATIONAL Co. L.L.C

SUBCONTRACTOR TARGET Engineering Const. Co. (L.L.C)

Improvement of Fire Fighting Facilities at Abu Dhabi

PROJECT Refinery

4. REFERENCE DOCUMENTS:

Aries shall use the latest editions for the following;

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 4 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

5 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

The following documents are referred:

AWS D1.1 – 2015 Edition

Personnel Qualification SNT-TC-1A-2011&2016 Edition

Aries Written Practice: Aries-NDT-GQP-01; Rev.10

ISO9712/EN473-Qualification and Certification of NDT Personnel

5. PERSONNEL QUALIFICATION.

All ARIES personnel performing Ultrasonic Examination using this Procedure shall be

qualified to a minimum of UT Level II and qualified by the Aries Written Practice Aries-

NDT-GQP-01;Rev.10 As Per Doc # SNT-TC-1A

Personnel performing Examination shall have vision, with correction if necessary, to

enable to read Jaeger Type No. 1 Standard Chart at a distance of not less than 12 in.,

and differentiate the contrast between the colors or shades of gray, and records of such

vision

Test shall be maintained by ARIES. Vision tests shall be conducted annually and shall be

valid during examination.

Personnel conducting Ultrasonic Examination shall be competent in conducting the

testing as described in this Procedure.

Wherever required, existing Personnel Qualification shall be verified for applicability as to

the Code conditions.

6. EQUIPMENT

Pulse Echo Equipment: - The UT instrument shall be the pulse echo type suitable for use

with transducers oscillating at frequencies between 1 and 6 megahertz. The display shall

be an “A” scan rectified video trace. The equipment shall have valid calibration certificate,

equipment must be calibrated at least every 12 months.

Equipment Requirements. The ultrasonic apparatus to be used shall be pulse echo type

and able to work with both combined and separated transmitter and receiver probe.

The following ultrasonic apparatus having frequency range from 0.5 to 10.0 MHz may be

used.

KRAUTKRAMER - USK 7 / USK 6 / USK 7B / USN 50 / USN 52 / USM 22 / USM 25/

USM 35 DAC/ USM Go/ USM 33.

Olympus-Epoch 600.

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 5 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

6 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

Requirements for Test Instruments. Test instruments shall include internal stabilization

so that after warm up , no variation in response greater than +or- 1 db occurs with a

supply voltage change of 15% nominal or , in the case of a battery, throughout the charge

operating life. There shall be an alarm or meter to signal a drop in battery voltage prior to

instrument shutoff due to battery exhaustion.

Calibration of Test Instruments. The test instrument shall have a calibrated gain control

(attenuator) adjustable in discrete 1 or 2 dB steps over a range of at least 60db. The

accuracy of the attenuator settings shall be within + or- 1 db.

Display Range. The dynamic range of the instrument’s display shall be such that a

difference of 1db of amplitude can be easily detected on the display.

Equipment Qualification

Horizontal Linearity- This qualification procedure is performed with a straight-beam

search unit which produces longitudinal waves with a sound velocity of almost double that

of shear waves, it is necessary to double the shear wave distance ranges to be used in

applying this procedure. The horizontal linearity of the test instrument shall be qualified

over the full sound path distance to be used .Horizontal linearity shall be verified after 40

Hours of instrument use and shall be Performed. A straight-beam search unit shall be

coupled on IIW V1 Block. The first and fifth back reflections shall be adjusted to their

proper locations with use of the distance calibration and zero delay adjustments.

Each indication shall be adjusted to reference level with the gain or attenuation control for

horizontal location examination. Each intermediate trace deflection location shall be

correct within 2% of the screen width.

Gain Control- The test instrument shall have a calibrated gain control (attenuator)

adjustable in discrete 1 or 2 dB steps over a range of at least 60 dB The accuracy of the

attenuator settings shall be within plus or minus 1 dB

In order to attain the required accuracy (± 1%) in reading the indication height, the display

shall be graduated vertically at 2% intervals, or 2.5% for instruments with digital amplitude

readout, at horizontal mid-screen height. These graduations shall be placed on the

display between 60% and 100% of screen height. This may be accomplished with use of

a graduated transparent screen overlay. If this overlay is applied as a permanent part of

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 6 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

7 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

the UT unit, care should be taken that the overlay does not obscure normal testing

displays.

Internal Reflections-Maximum internal reflections from each search unit shall be verified

at a maximum time interval of 40 hours of instrument use in conformance with following

performance. Calibrate the equipment, Remove the search unit from the calibration block

without changing any other equipment adjustments. Increase the calibrated gain or

attenuation 20 dB more sensitive than reference level. The screen area beyond 1/2 in [12

mm] sound path and above reference level height shall be free of any indication.

Calibration of Angle-Beam Search Units.-With the use of an approved calibration

block, each angle beam search unit shall be checked after each eight hours of use to

determine that the contact face is flat, the sound entry point is correct, and that the beam

angle is within the allowed plus or minus 2° tolerance, Search units which do not meet

these requirements shall be corrected or replaced.

Index Point: The transducer sound entry point (index point) shall be located or checked

by the following procedure:

The transducer shall be set in position Index point line on the IIW type block. The

transducer shall be moved until the signal from the radius is maximized. The point on the

transducer which aligns with the radius line on the calibration block is the point of sound

entry.

Angle: The transducer sound-path angle shall be checked or determined by one of the

following procedures:

The transducer shall be set in position B on IIW type block for angles 40° through 60°, or

in position C on IIW type block for angles 60° through 70°

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 7 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

8 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

For the selected angle, the transducer shall be moved back and forth over the line

indicative of the transducer angle until the signal from the radius is maximized. The sound

entry point on the transducer shall be compared with the angle mark on the calibration

block (tolerance ± 2°)

Resolution Requirements: - Angle-Beam - The combination of search unit and instrument

shall resolve three holes in the RC resolution reference test block shown in Figure. The

search unit position is described in below; the resolution shall be evaluated with the

instrument controls set at normal test settings and with indications from the holes brought

to mid screen height. Resolution shall be sufficient to distinguish at least the peaks of

indications from the three holes. Use of the RC resolution reference block for calibration

shall be prohibited. Each combination of instrument search unit (shoe and transducer)

shall be checked prior to its initial use. This equipment verification shall be done initially

with each search unit and UT unit combination. The verification need not be done again

provided documentation is maintained that records

The following items:

(1) UT machine’s make, model and serial number

(2) Search unit’s manufacturer, type, size, angle, and Sr. number

(3) Date of verification and technician’s name

(a) The transducer shall be set on resolution block RC position Q for 70° angle, position R

for 60° angle, or position S for 45° angle.

(b) (2) Transducer and instrument shall resolve the three test holes, at least to the extent

of distinguishing the peaks of the indications from the three holes.

Normal-Beam Transducer

(1) The transducer shall be set in position F on the IIW type block.

(2) Transducer and instrument shall resolve all three distances.

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 8 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

9 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 9 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

10 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

Transducers: - Transducers with following characteristics shall be used. Angle: Shear

wave 70°, 60°, 45° (within plus minus 2°) and Normal (Longitudinal wave).

Transducers shall be as specified as below

Straight Beam (Longitudinal Wave) Search Units. Straight beam search unit transducers

shall have an active area of not less than ½ in² (323 mm²) nor more than 1 in² (645

mm²).The transducer shall be round or square. Transducers shall be capable of resolving

the three reflections from the IIW block.

Angle Beam Search Units. Angle beam search units shall consist of a transducer and an

angle wedge. The unit may be compromised of the two separate elements or may be an

integral unit

Type: Single Crystal for shear wave probes.

Single Crystal or Twin Crystal for compressional wave probes.

Frequency: The nominal probe frequencies shall be 2 to 2.5 MHz

Other probe frequencies may be used if material variable such as material grain structure

or size dictates.

The Transducer crystal shall be square or rectangular in shape and may vary from

15mm to 25mm in width and in height 15mm to 20mm.

Coaxial Cables: - Minimum 6 feet (1830 mm) and a maximum of 15feet (4772 mm) in

length with suitable connections shall be used.

Calibration Blocks: - IIW / V1block shall be the standard for both distance and sensitivity

calibration. Other portable blocks may be used provided the reference level sensitivity for

instrument / search unit combination is adjusted to be equivalent of that achieved with IIW

block. Only IIW V1 Block shall be used for Sensitivity setting.

Discontinuity Plotting Aids: - An array of devices are available for the ultrasonic

operator to be able to plot and verify where indications are coming from, the technician

may utilize the following.

Magnetic strips, Electronic calculators, Mimic gauges (wire type), Soldering wire, Perspex

slides, Cursors

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 10 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

11 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

Plotting cards, Protractor, Compass, 150MM Stainless steel rulers, measuring tapes,

indelible markers.

7. COUPLING MEDIUM.

Oil, Polycell jelly, grease, water or equivalent Couplant that shall provide satisfactory

transmission of Ultrasonic sound waves. Couplant used for Calibration, the same

Couplant shall be used for Examination.

8. SURFACE CONDITION.

Scanning surface shall be free of weld spatters surface irregularities or foreign materials

that might interfere with the scanning during examination.

9. CALIBRATION FOR TESTING.

All calibrations and tests shall be made with the reject (clipping or suppression) control

turned off.

Calibration for sensitivity and horizontal sweep (distance) shall be made by the ultrasonic

operator just prior to and at the location of testing of each weld.

Recalibration shall be made after a change of operators, each 30-minute maximum time

interval, or when the electrical circuitry is disturbed in any way, which includes the

following:

(1) Transducer change

(2) Battery change

(3) Electrical outlet change

(4) Coaxial cable change

(5) Power outage (failure).

Calibration for straight beam testing of base metal shall be made with the search unit

applied to Face A OR B of the base metal. The examination is to be performed in order to

reveal possible imperfections, which might influence the angle probe testing.

The whole of the area (1.5 × S) which will transfer ultrasound when using angle probes

shall be tested. The gain setting shall be calibrated on a defect free place on the parent

material. The second back wall echo shall be set to 75% of FSH Imperfections with a

cross section larger than the sound beam (loss of back wall echo) shall be reported. The

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 11 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

12 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

extent of the imperfections is measured with the aid of the 6 dB-drop method when

complete loss of back wall echo occurs.

The horizontal sweep shall be adjusted for distance calibration to present the equivalent

of at least two-plate thickness on the CRT screen.

The sensitivity shall be adjusted at a location free of indications so that the first back

reflection from the far side of the plate will be minimum 75% of full screen height.

Calibration for angle beam testing shall be performed as follows.

1) The horizontal sweep shall be adjusted to represent the actual sound path distance by

using the IIW V1 block or alternative blocks. The distance calibration shall be made

using either the 125mm scale or 250mm scale on the CRT screen, whichever is

appropriate. If, however, the joint configuration or thickness prevents full examination

of the weld at either of these settings, the distance calibration shall be made using

500mm scale as required,

2) The zero reference level sensitivity used for flaw evaluation is attained by adjusting

the calibrated gain control (attenuator) of the flaw detector, so that a maximized

horizontal reference level trace deflection results on the CRT screen. For calibration

reflector with 1.6 mm dia of IIW V1 block shall be used.

3) Welds shall be tested using an angle beam search unit using the angle as shown in

Table 6.7Attached. Following calibration and during testing, the only instrument

adjustment permitted is the sensitivity level adjustment with the calibrated gain control

(attenuator). The reject (clipping or suppression) control shall be turned off. Sensitivity

shall be increased from the reference level for weld scanning in accordance with

Tables 6.2 or 6.3 (see attached) as applicable.

4) The testing angle and scanning procedure shall be in accordance with those shown in

Table 6.7 (see attached).

5) All butt joint welds shall be tested from each side of the weld axis. Corner and T- joint

welds shall be primarily tested from one side of the weld axis only. All welds shall be

tested using the applicable scanning pattern exhibit as necessary to detect both

longitudinal and transverse flaws. It is intended that, as a minimum, passing sound

through the entire volume of the weld and the heat-affected zone in two crossing

directions test all welds, wherever practical.

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 12 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

13 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

6) Scanning Patterns:

Longitudinal Discontinuities- Scanning Movement A. Rotation angle a =10°

Scanning Movement B. Scanning distance b shall be such that the section of weld being

tested is covered.

Scanning Movement C. Progression distance c shall be approximately one-half the

transducer width.

NOTE: Movements A, B, and C may be combined into one scanning pattern.

Transverse Discontinuities- Ground Welds. Scanning pattern D shall be used when welds

are ground flush.

Unground Welds. Scanning pattern E shall be used when the weld reinforcement is not

ground flush Scanning angle e = 15° max.

NOTE: The scanning pattern shall cover the full weld section.

ESW or EGW Welds (Additional Scanning Pattern) - Scanning Pattern E Search unit

rotation angle e between 45° and 60°.

NOTE: The scanning pattern shall cover the full weld section.Fig.6.15

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 13 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

14 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

Indication rating method:

The transducer shall be set in the position of IIW V1blockso that the maximum reflection

from 1.59 mm hole is received. The maximized signal shall then be adjusted to attain a

horizontal reference line height indication.

The maximum decibel reading shall be used as the reference level, “b” in the calculation

of the indication rating. This shall be ref.sensitivity and ‘dB shall be recorded for level ‘’b’’.

Indication rating, d = a-b-c

Where “a” – Instrument reading in decibels, when the indication from the discontinuity is

adjusted to the amplitude source as the indication from 1.59mm Ȃ hole at primary

reference level.

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 14 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

15 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

“c”- Attenuation factor is attained by subtracting 1 inch (25mm) from the sound – path

distance and multiplying the remainder by 2. The factor shall be rounded out to the

nearest dB value.

10. BASE METAL EVALUATION

The area adjacent to the weld from which scanning is to be conducted shall be scanned

with a 0° compressional probe and the thickness shall be recorded. Areas where laminar

type defects are together with other reflectors that may interfere with the shear wave scan

shall be reported.

Discontinuity Size Evaluation:-

Straight-Beam (Longitudinal) Testing. The size of lamellar discontinuities is not always

easily determined, especially those that are smaller than the transducer size. When the

discontinuity is larger than the transducer, a full loss of back reflection will occur and a 6

dB loss of amplitude and measurement to the centerline of the transducer is usually

reliable for determining dis continuity edges. However, the approximate size evaluation of

those reflectors, which are smaller than the transducer, shall be made by beginning

outside of the discontinuity with equipment calibrated in and moving the transducer

toward the area of discontinuity until an indication on the display begins to form. The

leading edge of the search unit at this point is indicative of the edge of the discontinuity.

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 15 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

16 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

Angle-Beam (Shear) Testing. The following procedure shall be used to determine lengths

of indications which have dB ratings more serious than for a Class D indication. The

length of such indication shall be determined by measuring the distance between the

transducer centerline locations where the indication rating amplitude drops50% (6 dB)

below the rating for the applicable discontinuity classification. This length shall be

recorded under “discontinuity length” on the test report. Where warranted by discontinuity

amplitude, this procedure shall be repeated to determine the length of Class A, B, and C

discontinuities.

11. SCANNING

Scanning shall be by contact method using A Scan presentation. Recording may be

carried out using automatic alarm recording system or by manual method.

Scanning shall be carried out such that entire volume of weld is tested for longitudinal and

transverse discontinuities. Ref. fig 1 attached.

The volume to be scanned shall be examined by moving the search unit over the

scanning surface so as to scan the entire examination volume for each required search

unit. Each pass of the search unit shall overlap a minimum of 10% of the active

transducer (piezoelectric element) dimension perpendicular to the direction of scan.

Where mandated by code requirements, the percent minimum overlap may be increased.

Alternatively, each pass of the search unit may overlap a dimension less than the

minimum beam dimension (beam spread) if the same is already known. Oscillation of the

search unit is permitted provided improved coverage is demonstrated.

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 16 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

17 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

The pulse Repetition rate shall be small enough to assure that a signal from a reflector

located at the maximum distance in the examination volume will arrive back at the search

unit before the next pulse is placed on the transducer.

The rate of search unit movement (scanning speed) shall not exceed 6 inch /s (152

mm/s) Scanning shall be performed from the branch connection.

12. ACCEPTANCE CRITERIA.

Each weld discontinuity shall be accepted or rejected on the basis of its indication rating

and its length, in accordance with AWS D1.1 for statically Table 6.2(Attachment I) or

cyclically loaded structures Table 6.3 (Attachment II respectively.

Each rejected discontinuity shall be indicated on the weld by a mark directly over the

discontinuity for its entire length and depth from the surface shall be noted on nearby

base metal

Evaluation of the defects shall be performed from both the branch and the main branch.

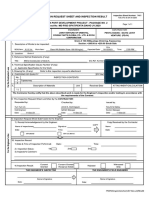

13. DOCUMENTATION

UT examination conducted as per this procedure shall be reported on AWS D1.1

reporting format with standard Ultrasonic Examination report refer attached and shall

contain the following information as a minimum.

a. Client

b. Job No.

c. Drawing /Line

d. Location

e. Repair

f. Date

g. Weld Type

h. Flaw detector type, Serial No.

i. Probe, Frequency, Sensitivity, Transfer Correction

j. Technician’s Name with personnel qualification and signature. k. Test limitations /

Restrictions

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 17 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

18 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

Attachment – I Acceptance Criteria as per AWS D1.1

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 18 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

19 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

Attachment – II Acceptance Criteria as per AWS D1.1

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 19 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

20 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

Attachment – III Table 6.7 Testing Angle

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 20 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

21 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 21 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

22 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

Annexure I

Technique sheet-01

BUTT WELD – SINGLE “V” Scanning Pattern

Technique sheet-02

a. Parent Metal Examination

Scanning Positions : 1 & 2 over 2.5 times the parent

Metal thickness each side of the weld toes.

Thickness Range : 8mm to 20mm Single V Butt welds

Sensitivity : Sensitivity setting shall be 1.6mmSDH for straight

beam probe

(Single /Twin) when used for discontinuity detection

of weld metal.

BWE shall be used for base metal scanning only for

laminar discontinuity.

Probes : 0° - 2 MHz to 2.5 MHz T/C or S/C

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 22 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

23 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

b. Weld Metal Examination:

Scanning Pattern : 10% Overlapping Scans

Probes Scanning Options Scanning Sensitivity

0° HAZ (1&2) II’nd BWE set to 80%+6 dB

70° 1&2 1.6mm Reference side drilled hole

set to 50%FSH

Sizing Technique : 6 dB drop, max amplitude and similar recognized technique.

Scanning dB : Refer attachment I & II AWS D1.1 Table 6.2 / 6.3.

Note: 45°&60° Angle Beam not required as Per Code Specification Ref: attachment I & II

AWS D1.1 Table 6.2 / 6.3.

Annexure I

Technique sheet-02

BUTT WELD – Double “V” Scanning Pattern

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 23 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

24 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

a. Parent Metal Examination

Scanning Positions : 1 & 2or 3 & 4 over 2.5 times the parent

Metal thickness each side of the weld toes.

Thickness Range : 20mm and above Double V Butt weld

Sensitivity : Sensitivity setting shall be 1.6mmSDH for straight

beam probe

(Single /Twin) when used for discontinuity

detection of weld metal.

BWE shall be used for base metal scanning only

for laminar discontinuity.

Probes : 0° - 2 MHz to 2.5 MHz T/C or S/C

b. Weld Metal Examination:

Scanning Pattern : 10% Overlapping Scans

Probes Scanning Options Scanning Sensitivity

0° 1& 2 II’nd BWE set to 80%+6 dB

70° 1 &2/3&4 1.6mm Reference side

drilled hole set to 50%FSH

Sizing Technique : 6 dB drop / max amplitude or similar recognized technique.

Scanning dB : Refer attachment I & II AWS D1.1 Table 6.2 / 6.3.

Note: 45°&60° Angle Beam not required as Per Code Specification Ref: attachment I & II

AWS D1.1 Table 6.2 / 6.3.

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 24 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

25 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

Annexure I

Technique sheet-03

T- WELD – (Single Bevel T) Scanning Pattern

a. Parent Metal Examination

Scanning Positions : 1 over 2.5 times the parent

Metal thickness each side of the weld toes.

Thickness Range : 8mm to 20mm Single Bevel T weld

Sensitivity : Sensitivity setting shall be 1.6mmSDH for straight

beam probe

(Single /Twin) when used for discontinuity detection

of weld metal.

BWE shall be used for base metal scanning only for

laminar discontinuity.

Probes : 0° - 2 MHz to 2.5 MHz T/C or S/C

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 25 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

26 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

b. Weld Metal Examination:

Scanning Pattern : 10% Overlapping Scans

Probes Scanning Options Scanning Sensitivity

0° 1 II’nd BWE set to 80%+6 dB

0° 2(if required) 1.6mm Reference side drilled

hole set to 50%FSH hole set to 80%FSH

70° 1 1.6mm Reference side

drilled whole set to 50%FSH hole set to 50%FSH

Sizing Technique : 6 dB drop / max amplitude or similar recognized technique.

Scanning dB : Refer attachment I & II AWS D1.1 Table 6.2 / 6.3.

Note: 45°&60° Angle Beam not required as Per Code Specification Ref: attachment I & II

AWS D1.1 Table 6.2 / 6.3.

Annexure I

Technique sheet-04

T- WELD – (Double Bevel T) Scanning Pattern

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 26 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

27 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

a. Parent Metal Examination

Scanning Positions : 1 & 2 over 2.5 times the parent metal thickness each side of

the weld toes.

Thickness Range : Above 20mm Double Bevel T weld

Sensitivity : Sensitivity setting shall be 1.6mmSDH for straight beam probe

(Single /Twin) when used for discontinuity detection of weld

metal.

BWE shall be used for base metal scanning only for laminar

discontinuity.

Probes : 0° - 2 MHz to 2.5 MHz T/C or S/C

b. Weld Metal Examination:

Scanning Pattern : 10% Overlapping Scans

Probes Scanning Options Scanning Sensitivity

0° 1 II’nd BWE set to 80%+6 dB

0° 3(if required) 1.6mm Reference side drilled

hole set to 50%FSH hole set to 80%FSH

70° 1&2 1.6mm Reference side

drilled whole set to 50%FSH hole set to 50%FSH

Sizing Technique : 6 dB drop / max amplitude or similar recognized technique.

Scanning dB : Refer attachment I & II AWS D1.1 Table 6.2 / 6.3.

Note: 45°&60° Angle Beam not required as Per Code Specification Ref: attachment I & II

AWS D1.1 Table 6.2 / 6.3.

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 27 of 28

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

Co. (L.L.C)

Document No.: xxxxxxxxxxxx Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Procedure for Project No.: 5642

Fabrication and Installation of

Page

Document Title: Temporary & Permanent Bracing

28 of 28 KN Project No.: 005007900

Members, Wailing Beams and Tie

Rods

Subcon. Doc. No.: xxxxxxxxxxxx

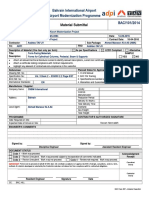

14. Sample Report format

Project : Improvement of Fire Fighting Facilities at

Abu Dhabi Refinery

Kharafi National Co.

Company: Abu Dhabi Oil Refining Company (TAKREER) Contractor:

(L.L.C)

Document No.: Rev.: A1 Agreement No.: 14ETETE11210

Ultrasonic Testing Examination Procedure for Project No.: 5642

Fabrication and Installation of Temporary &

Document Title:

Permanent Bracing Members, Wailing Beams and KN Project No.: 005007900

Tie Rods

Document No xxxxxxxxxxxx /Rev .A Date 11 June 17 Page 28 of 28

You might also like

- Work Method Statement For Constructing New RC Plinth & Top Up SlabDocument9 pagesWork Method Statement For Constructing New RC Plinth & Top Up SlabMohd Hafizi Azlan100% (1)

- Sir Syed Ahmed Khan and Two Nation TheoryDocument11 pagesSir Syed Ahmed Khan and Two Nation TheoryZeeshan Saeed100% (5)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Field & Shop Inspection and Test Plan (Itp) With Prefabrication, Painting of Spools and Field Activities After InstallationDocument8 pagesField & Shop Inspection and Test Plan (Itp) With Prefabrication, Painting of Spools and Field Activities After Installationvishnu300022No ratings yet

- Employee Safety Training Matrix Template ExcelDocument79 pagesEmployee Safety Training Matrix Template Excelشاز إياسNo ratings yet

- Brand Awareness Questionnaire SampleDocument2 pagesBrand Awareness Questionnaire SampleYogesh Sangani77% (13)

- MPI Procedure Rev.A1Document17 pagesMPI Procedure Rev.A1kumaraguruNo ratings yet

- Inspection & Test Plan TemplateDocument11 pagesInspection & Test Plan Templatefanghao5345No ratings yet

- Engineering Cover Sheet-ExcelDocument1 pageEngineering Cover Sheet-ExcelRAMKRISHNA DASNo ratings yet

- AozayDocument11 pagesAozayheryfiononanapierrette01No ratings yet

- Prediction of CO2 Corrosion Rate TZK Gas Line Rev0Document14 pagesPrediction of CO2 Corrosion Rate TZK Gas Line Rev0Mohamed KAICH100% (1)

- QAQC Procedure For Fabrication - Flare KOD Rev ADocument9 pagesQAQC Procedure For Fabrication - Flare KOD Rev ARajesh K Pillai100% (1)

- Binded Hook Up & InstallationDocument44 pagesBinded Hook Up & InstallationrajNo ratings yet

- OZ Compressors As-Built - Site Survey ReportDocument19 pagesOZ Compressors As-Built - Site Survey ReportAshraf AmmarNo ratings yet

- 2.ITP For Excavation & Laying of 33kV & FO CableDocument2 pages2.ITP For Excavation & Laying of 33kV & FO Cabletahirsaleem100% (1)

- Work Method Statement For Constructing RC FoundationDocument16 pagesWork Method Statement For Constructing RC FoundationMohd Hafizi AzlanNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- 00331600CACP16006 - EXCO00 - 44 - Piping Support CNDocument45 pages00331600CACP16006 - EXCO00 - 44 - Piping Support CNchiheb ben dahsenNo ratings yet

- N15907-PIL-HYD-NCR-I016 Fire Alarm Installation Non Conformity TAP X (For Approval)Document11 pagesN15907-PIL-HYD-NCR-I016 Fire Alarm Installation Non Conformity TAP X (For Approval)unnicyriacNo ratings yet

- 00257650-0000-33EG-0001 - Rev PB - Attachment A - ITP ExampleDocument4 pages00257650-0000-33EG-0001 - Rev PB - Attachment A - ITP ExampleSubrata Das100% (1)

- Request For Inspection: QC Rfi No.Document1 pageRequest For Inspection: QC Rfi No.KarthikNo ratings yet

- Ms-Target Engg.-Mubarraz Island - Pile Load TestDocument20 pagesMs-Target Engg.-Mubarraz Island - Pile Load TestWilander XavierNo ratings yet

- ITP For Pipeline Repair Works - by Using Belzona Superwrap IIDocument4 pagesITP For Pipeline Repair Works - by Using Belzona Superwrap IIAhmedNo ratings yet

- 4201-106-V2-0000-00001 - 001 - Particular Specs - AllDocument182 pages4201-106-V2-0000-00001 - 001 - Particular Specs - AllAneesNo ratings yet

- Sample Template Itp For Piping Fabrication and InstallationDocument16 pagesSample Template Itp For Piping Fabrication and InstallationEyoh EffiongNo ratings yet

- F07 - RFA - Form No. AC-PR-NCR-01-F07 Dated 15.06.2017 30Document2 pagesF07 - RFA - Form No. AC-PR-NCR-01-F07 Dated 15.06.2017 30Razi KhanNo ratings yet

- TEC-014326 - PQF-CLT-Rev01 - Prequalification Cheklist For Testing Laboratory ServiceDocument4 pagesTEC-014326 - PQF-CLT-Rev01 - Prequalification Cheklist For Testing Laboratory ServiceKhaled NaguibNo ratings yet

- Pre-Bid Clarification-01Document1 pagePre-Bid Clarification-01pavanNo ratings yet

- Vendor Documents AND Delivery Schedule FOR XXXXXDocument3 pagesVendor Documents AND Delivery Schedule FOR XXXXXPinak ProjectsNo ratings yet

- Wt2201 RWD CW MST XXXX XXXX XX - Mos For Deep Excavation - RemovedDocument6 pagesWt2201 RWD CW MST XXXX XXXX XX - Mos For Deep Excavation - RemovedJuber JamshedNo ratings yet

- Cost Report Rev.00Document16 pagesCost Report Rev.00Ahmed al-sheaikhNo ratings yet

- 017-ITC-056 (1) Reinforced Concrete Works For BridgesDocument11 pages017-ITC-056 (1) Reinforced Concrete Works For BridgesJuan Morales0% (1)

- (Itp For Cast Insitu Foundation) 4172-Genon-1!25!0002-ADocument45 pages(Itp For Cast Insitu Foundation) 4172-Genon-1!25!0002-ARajesh SinghNo ratings yet

- QCP Overall File...Document66 pagesQCP Overall File...Lenny NaidooNo ratings yet

- VD 1233 330 Dig 001 1Document12 pagesVD 1233 330 Dig 001 1Reza AranNo ratings yet

- Checklist-EDC TANKDocument14 pagesChecklist-EDC TANKPartheeban SkpNo ratings yet

- MAT-AAC-NT-ARCH-070 R00 - Data Sheet For Clustera (Aluminum Works)Document6 pagesMAT-AAC-NT-ARCH-070 R00 - Data Sheet For Clustera (Aluminum Works)eromax1No ratings yet

- BorWin6 Page 5Document1 pageBorWin6 Page 5Kiran VargheseNo ratings yet

- XXXXXXXXXXXXXXXXXXXXXXXXXXXXXX: Method Statement: Construstion of ManholeDocument10 pagesXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX: Method Statement: Construstion of ManholeJunaid MirNo ratings yet

- Loop Test ProcedureDocument13 pagesLoop Test ProcedureAlia RedhaNo ratings yet

- Steel Submittal - JPR3VL002Document20 pagesSteel Submittal - JPR3VL002MUQEET ahmedNo ratings yet

- Inspection and Test Plan: Piping Fabrication & InstallationDocument11 pagesInspection and Test Plan: Piping Fabrication & Installationmohd as shahiddin jafriNo ratings yet

- Plant: Tan Thang Cement Plant: Approved Information Commented Comment As Built Approval Final ConstructionDocument14 pagesPlant: Tan Thang Cement Plant: Approved Information Commented Comment As Built Approval Final ConstructiongacongnghiepNo ratings yet

- Toaz - Info Itp For PVC Conduits PRDocument6 pagesToaz - Info Itp For PVC Conduits PRehtesham khanNo ratings yet

- P742 RCC So 0001Document36 pagesP742 RCC So 0001Danish MohammedNo ratings yet

- Material Submittal For LouverDocument42 pagesMaterial Submittal For LouverYusuf Ziya DilbazNo ratings yet

- Method Statement With Jsa For Piping Work (Rev 1) (28!08!2019)Document55 pagesMethod Statement With Jsa For Piping Work (Rev 1) (28!08!2019)Pradip PaulNo ratings yet

- VP-2025JV0P10147-000-P82-002 - 3 - (Actuator PAINTING PROCEDURE)Document18 pagesVP-2025JV0P10147-000-P82-002 - 3 - (Actuator PAINTING PROCEDURE)Vasilica BArbarasaNo ratings yet

- Welder Qualification GUIDLINES1Document33 pagesWelder Qualification GUIDLINES1CPFormanNo ratings yet

- Maamoura and Baraka Development Project 3314.02.DACC.15059Document18 pagesMaamoura and Baraka Development Project 3314.02.DACC.15059AHMED AMIRANo ratings yet

- FINAL-ITP For Concreting Work Rev.2 25-Oct-2014Document12 pagesFINAL-ITP For Concreting Work Rev.2 25-Oct-2014Mohammed MujahidNo ratings yet

- Volume 1 Form of Subcontract Agreement - RevADocument4 pagesVolume 1 Form of Subcontract Agreement - RevAOfer GardenNo ratings yet

- Waterproofing BldgsDocument17 pagesWaterproofing BldgssakrakirfanNo ratings yet

- M-0079-01 CL - Domestic & Grey Water Supply Piping at Tunnel AreaDocument1 pageM-0079-01 CL - Domestic & Grey Water Supply Piping at Tunnel AreahassanabunafeesahNo ratings yet

- OU500764928 - R0 - Quality Assurance-Manufacturing IDSDocument13 pagesOU500764928 - R0 - Quality Assurance-Manufacturing IDSbecemNo ratings yet

- Inspection Test Plan For Stat XDocument4 pagesInspection Test Plan For Stat XGinish KumarNo ratings yet

- 1-M-C-CI09-ATC-AD-MS-0064 - Forms For Cylindrical Columns, Pedestals & Supports (AMA)Document1 page1-M-C-CI09-ATC-AD-MS-0064 - Forms For Cylindrical Columns, Pedestals & Supports (AMA)rthomsanNo ratings yet

- MPFMDocument5 pagesMPFMmusaveerNo ratings yet

- Engineering Department: Piper Aircraft IncDocument7 pagesEngineering Department: Piper Aircraft Inccarlos martinezNo ratings yet

- PF0009 SLB CV SPC 0002Document12 pagesPF0009 SLB CV SPC 0002bmanojkumar16No ratings yet

- Material Receiving Inspection Report Discipline: Quality Control FormDocument15 pagesMaterial Receiving Inspection Report Discipline: Quality Control FormSREENATH SOMANATHAN NAIRNo ratings yet

- 3225.XX - dfrv.10XXX - 00 - P&ID Desktop Reveiw ReportDocument74 pages3225.XX - dfrv.10XXX - 00 - P&ID Desktop Reveiw ReportMorgan SidesoNo ratings yet

- VD 1233 330 DPH 001 0Document11 pagesVD 1233 330 DPH 001 0Reza AranNo ratings yet

- Register Punchlist of Pre-AuditDocument2 pagesRegister Punchlist of Pre-AuditkumaraguruNo ratings yet

- Project Quality PlanDocument15 pagesProject Quality PlankumaraguruNo ratings yet

- Project Quality PlanningDocument23 pagesProject Quality PlanningkumaraguruNo ratings yet

- Oil Leak Test ProcedureDocument5 pagesOil Leak Test ProcedurekumaraguruNo ratings yet

- Pneumatic ProcedureDocument5 pagesPneumatic ProcedurekumaraguruNo ratings yet

- Report of Eddy Current Inspection - Indiana AirportDocument45 pagesReport of Eddy Current Inspection - Indiana AirportkumaraguruNo ratings yet

- Material Submittal FOR Welding Consumables: 2100184/AJPEC/CPMD/MAR-0009Document8 pagesMaterial Submittal FOR Welding Consumables: 2100184/AJPEC/CPMD/MAR-0009kumaraguruNo ratings yet

- Professional StandardsDocument28 pagesProfessional StandardskumaraguruNo ratings yet

- Easa Ad F-1998-537-124R1 1Document1 pageEasa Ad F-1998-537-124R1 1lakshmimurugesanNo ratings yet

- Assignment 3: Course Title: ECO101Document4 pagesAssignment 3: Course Title: ECO101Rashik AhmedNo ratings yet

- SKV-FM-QA-12 Non Conformity and Corrective ActionDocument1 pageSKV-FM-QA-12 Non Conformity and Corrective ActionSaurabh BhadouriyaNo ratings yet

- Lesson 2 - Língua Inglesa 7Document21 pagesLesson 2 - Língua Inglesa 7Shara Maria Venâncio SilvaNo ratings yet

- EBOOK6131f1fd1229c Unit 3 Ledger Posting and Trial Balance PDFDocument44 pagesEBOOK6131f1fd1229c Unit 3 Ledger Posting and Trial Balance PDFYaw Antwi-AddaeNo ratings yet

- Grammar Translation MethodDocument22 pagesGrammar Translation MethodCeyinNo ratings yet

- Introduction To Public Policy: Course DescriptionDocument15 pagesIntroduction To Public Policy: Course DescriptionJericko Perez AvilaNo ratings yet

- STP280 - 24Vd - UL (H4 Connector) - AZDocument2 pagesSTP280 - 24Vd - UL (H4 Connector) - AZkiranpandey87No ratings yet

- Snigdha Chaturvedi PDFDocument5 pagesSnigdha Chaturvedi PDFHitesh KohliNo ratings yet

- Pms 500 - International Mechanics KitDocument0 pagesPms 500 - International Mechanics KitArsul RNo ratings yet

- CV TemplateDocument1 pageCV TemplateHimanshu RaghuwanshiNo ratings yet

- Rasi Navamsa: As Mo Ke Su Ve Mo JuDocument11 pagesRasi Navamsa: As Mo Ke Su Ve Mo JuRavan SharmaNo ratings yet

- Pyneng Readthedocs Io en LatestDocument702 pagesPyneng Readthedocs Io en LatestNgọc Duy VõNo ratings yet

- The Enemy Within - v18Document8 pagesThe Enemy Within - v18Matt WillisNo ratings yet

- Digital SAT Skills Insight Tool - MathDocument61 pagesDigital SAT Skills Insight Tool - MathSianitus La Tour D'AuvergneNo ratings yet

- SHPL Product Order Form 2021Document4 pagesSHPL Product Order Form 2021anuradha100% (3)

- Analytic Solutions of A Two Dimensional Rectangular Heat Equation PDFDocument5 pagesAnalytic Solutions of A Two Dimensional Rectangular Heat Equation PDFreff1694No ratings yet

- Fender Re-Issue 62 Jazzmaster Wiring DiagramDocument1 pageFender Re-Issue 62 Jazzmaster Wiring DiagrambenitoNo ratings yet

- 4194-Article Text-11162-1-10-20190903Document6 pages4194-Article Text-11162-1-10-20190903Akhsana SantosoNo ratings yet

- Weekly Home Learning Plan - KindergartenDocument3 pagesWeekly Home Learning Plan - KindergartenPrecious ArniNo ratings yet

- Ferrites For Linear Appl - Properties - SnellingDocument10 pagesFerrites For Linear Appl - Properties - SnellingTom SebastianNo ratings yet

- Geologic Report Arches NationalDocument9 pagesGeologic Report Arches NationalJacob AndersonNo ratings yet

- 01-13 PWE3 ConfigurationDocument97 pages01-13 PWE3 ConfigurationRoger ReisNo ratings yet

- UntitledDocument385 pagesUntitledDelta BravoNo ratings yet

- Purification of Wastewater by Metal Oxide NanoparticlesDocument12 pagesPurification of Wastewater by Metal Oxide NanoparticlesEditor IJTSRDNo ratings yet

- 1908 The Watchower and Herald of Christ's PresenceDocument193 pages1908 The Watchower and Herald of Christ's PresenceTimothy RichesNo ratings yet

- Eyu-Ethiopia FinanceOperations Manual January2020 v1 EnglishDocument104 pagesEyu-Ethiopia FinanceOperations Manual January2020 v1 EnglishHenockNo ratings yet