Professional Documents

Culture Documents

UMS Checklist DCM 01.03.h-91 Rev 06

Uploaded by

Austin UdofiaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UMS Checklist DCM 01.03.h-91 Rev 06

Uploaded by

Austin UdofiaCopyright:

Available Formats

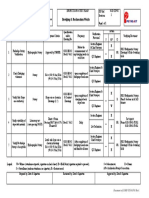

E0 / UMS Check list

Vessel:LNG River Orashi

Date: 2023

Chief Engineer’s Standing Instructions for E0 / UMS

Time:

Items below have to be positively checked out before commencing E0 / UMS OK OK OK OK

Have instructions for Duty Engineer’s tasks when going unmanned been read?

Check standby alternators are ready for auto start

Check main fire pumps set for remote operation

Check Main Turbine lub oil system and tank levels

Check domestic fresh water system and tank levels

Check main engine and generator expansion tanks

Drain water off all setting and service tanks

Inspect oil purification plant and check levels

Check and drain compressed air bottles

Check intermediate shaft bearing and oil level

Check bilge spaces

Check all spare gears and engine room cranes are secured

Ensure all fire doors closed

Check exits are free from obstructions

Check illumination on all alarm panels

Are all machinery spaces and steering gear in clean and safe condition

for E0 / UMS operation?

Check relevant stand-by equipment in stand-by position

Check fire alarm is operational and that fire loops are connected in machinery spaces.

AHU Temperature

Check Tank Protection set point (20mbar)

Bridge / Duty Officer notified and UMS acknowledged

Duty Engineers Signature

Duty Engineer

Duty Engineer

Duty Engineer

Duty Engineer

Signature

Signature

Signature

Signature

DCM 01.03.h-91 rev 06

E0 / UMS Check list

Vessel:LNG River Orashi

Date 2023

Chief Engineer’s Standing Instructions for E0 / UMS

Time:

Items below have to be positively checked out before commencing E0 / UMS OK OK OK OK

Have instructions for Duty Engineer’s tasks when going unmanned been read?

Check standby alternators are ready for auto start

Check main fire pumps set for remote operation

Check main Turbine lub oil system and tank levels

Check domestic fresh water system and tank levels

Check main engine and generator expansion tanks

Drain water off all setting and service tanks

Inspect oil purification plant and check levels

Check and drain compressed air bottles

Check intermediate shaft bearing and oil level

Check bilge spaces

Check all spare gears and engine room cranes are secured

Ensure all fire doors closed

Check exits are free from obstructions

Check illumination on all alarm panels

Are all machinery spaces and steering gear in clean and safe condition

for E0 / UMS operation?

Check relevant stand-by equipment in stand-by position

Check fire alarm is operational and that fire loops are connected in machinery spaces.

AHU Temperature

Check Tank Protection set point (20mbar)

Bridge / Duty Officer notified and UMS acknowledged

Duty Engineers Signature

Duty Engineer

Duty Engineer

Duty Engineer

Duty Engineer

Signature

Signature

Signature

Signature

DCM 01.03.h-91 rev 06

You might also like

- East Coast Yacht's Expansion Plans-06!02!2008 v2Document3 pagesEast Coast Yacht's Expansion Plans-06!02!2008 v2percyNo ratings yet

- A320 Exterior Placards Catalogue (Approved)Document375 pagesA320 Exterior Placards Catalogue (Approved)Jan kopáček100% (1)

- Testing and Commissioning Procedure For ElevatorsDocument11 pagesTesting and Commissioning Procedure For ElevatorsWinNo ratings yet

- ITP-Refrac 03B001&02B001-1Document2 pagesITP-Refrac 03B001&02B001-1มิตร อันมา100% (2)

- US Dollar Store Consumer BehaviourDocument10 pagesUS Dollar Store Consumer BehaviourTryden Royce D'SouzaNo ratings yet

- Ebf Rehearsal RubricDocument1 pageEbf Rehearsal Rubricapi-518770643No ratings yet

- Lguvisitation-Municipality of CaintaDocument23 pagesLguvisitation-Municipality of CaintaDaniel BulanNo ratings yet

- 0183-Itp-02 R1Document1 page0183-Itp-02 R1Belal hassanNo ratings yet

- 050723HC TowerDocument8 pages050723HC TowerNahom AnaniyaNo ratings yet

- Project Name Daily Report: WeatherDocument1 pageProject Name Daily Report: WeatherMohamed ELrasheedNo ratings yet

- Organizational StructureDocument2 pagesOrganizational StructureEmelda PalangdaoNo ratings yet

- Overseas Assignments: For More Overseas Ads See Page Nos. 3 & 4Document3 pagesOverseas Assignments: For More Overseas Ads See Page Nos. 3 & 4Brodsky RjNo ratings yet

- M-0043-01-CL - Installation of Above GroundDocument1 pageM-0043-01-CL - Installation of Above GroundhassanabunafeesahNo ratings yet

- 250H FDC 25 K8 FantuzziDocument1 page250H FDC 25 K8 FantuzziMonir MekkaouiNo ratings yet

- M-0079-01 CL - Domestic & Grey Water Supply Piping at Tunnel AreaDocument1 pageM-0079-01 CL - Domestic & Grey Water Supply Piping at Tunnel AreahassanabunafeesahNo ratings yet

- M-0078-01-CL - Underground CPVC Water Supply Piping SystemDocument2 pagesM-0078-01-CL - Underground CPVC Water Supply Piping SystemhassanabunafeesahNo ratings yet

- High Risk Job Safety Analysis: Contractor ArgonneDocument11 pagesHigh Risk Job Safety Analysis: Contractor Argonnehalfy safitriNo ratings yet

- M-0072-01 Check List For Pipe InsulationDocument2 pagesM-0072-01 Check List For Pipe InsulationhassanabunafeesahNo ratings yet

- M-0075-01 - Check List - Identification of Electrical SystemsDocument1 pageM-0075-01 - Check List - Identification of Electrical SystemshassanabunafeesahNo ratings yet

- 16052-TGC-MTH-ARC-00021 - Engineer's Comments - Rev.03Document1 page16052-TGC-MTH-ARC-00021 - Engineer's Comments - Rev.03Mohammad MohammadNo ratings yet

- Nav Ii Phase 3Document30 pagesNav Ii Phase 3carl reevesNo ratings yet

- CD-09 (DSA-03) List of Daily Manpower & EquipmentDocument1 pageCD-09 (DSA-03) List of Daily Manpower & EquipmentDianalyn DescotidoNo ratings yet

- UMS Changeover ProcedureDocument1 pageUMS Changeover ProcedureSrini VasanNo ratings yet

- Testing and Commissioning Procedure For Moving WalksDocument14 pagesTesting and Commissioning Procedure For Moving WalksWinNo ratings yet

- Gate Installation ReportDocument3 pagesGate Installation ReportKumar AbhishekNo ratings yet

- P-0008-01 Installation of Above Ground Water Supply PipingDocument1 pageP-0008-01 Installation of Above Ground Water Supply PipinghassanabunafeesahNo ratings yet

- M-0057-01 - Check List - Power & Lighting WiringDocument1 pageM-0057-01 - Check List - Power & Lighting WiringhassanabunafeesahNo ratings yet

- Site DiaryDocument1 pageSite Diaryimpak sensasiNo ratings yet

- Nav Ii Phase 2Document24 pagesNav Ii Phase 2carl reevesNo ratings yet

- Construction Delay Analysis TechniquesDocument1 pageConstruction Delay Analysis TechniquesAddisNo ratings yet

- Cm-Elec - (47 To 47) - Send To MGPS at (03-08-2020)Document1 pageCm-Elec - (47 To 47) - Send To MGPS at (03-08-2020)ali morisyNo ratings yet

- Cm-Mech - (49 To 50) - Send To MGPS at (13-08-2020)Document3 pagesCm-Mech - (49 To 50) - Send To MGPS at (13-08-2020)ali morisyNo ratings yet

- DPW Onshore Port Terminal: Project ManagerDocument1 pageDPW Onshore Port Terminal: Project Managerهيثم سميرNo ratings yet

- Daily Service: Komatsu Small ExcavatorDocument9 pagesDaily Service: Komatsu Small ExcavatorHebert SozinyuNo ratings yet

- Technical Delay Report: Form No. SJ/TSD/014 Issue 1 Revision - 2 (Aug. 2005)Document1 pageTechnical Delay Report: Form No. SJ/TSD/014 Issue 1 Revision - 2 (Aug. 2005)Naresh Kumar PrajapatNo ratings yet

- Nom de Technicien Signature Durée D'intervention: Ordinary Maintenance 250 H For Forklift Fantuzzi (FDC 25 K8)Document1 pageNom de Technicien Signature Durée D'intervention: Ordinary Maintenance 250 H For Forklift Fantuzzi (FDC 25 K8)Peix HichamNo ratings yet

- Today's Work) Ompleted Location Level ActivityDocument12 pagesToday's Work) Ompleted Location Level ActivityChetan GohilNo ratings yet

- For Chief Engineer Only: Page 1 of 2Document3 pagesFor Chief Engineer Only: Page 1 of 2ODEN SAMANo ratings yet

- Itp-Internals R2Document2 pagesItp-Internals R2Delta akathehuskyNo ratings yet

- M-0076-01-Check List - Installation of Lighting Control SystemDocument2 pagesM-0076-01-Check List - Installation of Lighting Control SystemhassanabunafeesahNo ratings yet

- QC Forms For EarthworksDocument9 pagesQC Forms For EarthworksikhlaslivingNo ratings yet

- Project: Etlal Residence Submittal: M/s. Projacs InternationalDocument1 pageProject: Etlal Residence Submittal: M/s. Projacs Internationalghassan ayeshNo ratings yet

- LF - e 000 Chief Engineers Standing OrdersDocument1 pageLF - e 000 Chief Engineers Standing Ordersmiswanto antoNo ratings yet

- Response Submittal - GD01-PIV-ALG-MAT-ARC-0033-01 - Roof Access Hatch & LadderDocument117 pagesResponse Submittal - GD01-PIV-ALG-MAT-ARC-0033-01 - Roof Access Hatch & LadderAhmadMughalNo ratings yet

- ASE-Inspection Test PlanDocument2 pagesASE-Inspection Test PlanAdnanNo ratings yet

- E-0054 - Check List - Installation of EMT ConduitDocument2 pagesE-0054 - Check List - Installation of EMT ConduithassanabunafeesahNo ratings yet

- The ACME Laboratories LTD. Demand Report: February 8, 2021 Report Printed oDocument1 pageThe ACME Laboratories LTD. Demand Report: February 8, 2021 Report Printed oyNo ratings yet

- P - 0080 - Installation of Plumbing InsulationDocument1 pageP - 0080 - Installation of Plumbing InsulationhassanabunafeesahNo ratings yet

- ITP - Beams-R1Document1 pageITP - Beams-R1Anonymous zsBCtskzNo ratings yet

- QA-03 Appr - Chit Site ClearingDocument1 pageQA-03 Appr - Chit Site ClearingdominicNo ratings yet

- Confined Space Permit Rev 00Document3 pagesConfined Space Permit Rev 00Arunava BasakNo ratings yet

- ITP-00010 Pavement Road WorksDocument3 pagesITP-00010 Pavement Road WorksIsmail MydeenNo ratings yet

- Site OrganizationDocument1 pageSite OrganizationhannykhawajaNo ratings yet

- CM-ELEC - (61 and 73) - SEND TO MGPS AT (04-11-2020) ReprintDocument2 pagesCM-ELEC - (61 and 73) - SEND TO MGPS AT (04-11-2020) Reprintali morisyNo ratings yet

- Work Inspection Request: Contract Number: MDC/2471374 - 2 Wir Reference: Revision: 00 Date & Time of InspectionDocument10 pagesWork Inspection Request: Contract Number: MDC/2471374 - 2 Wir Reference: Revision: 00 Date & Time of Inspectionamith_kmNo ratings yet

- Organisation Chart: Project ManagerDocument1 pageOrganisation Chart: Project ManagerDinesh KumarNo ratings yet

- Cm-Inst - (25 To 25) - Send To MGPS at ( 03-08-2020)Document1 pageCm-Inst - (25 To 25) - Send To MGPS at ( 03-08-2020)ali morisyNo ratings yet

- RS05 - RS06Document15 pagesRS05 - RS06ChNo ratings yet

- Field Inspection Request (FIR) : Project Project No. 1702 Employer Package No. 02Document4 pagesField Inspection Request (FIR) : Project Project No. 1702 Employer Package No. 02Malek MahmoudNo ratings yet

- 02 Contractor Daily Report - CDRDocument1 page02 Contractor Daily Report - CDRPERVEZ AHMAD KHANNo ratings yet

- Ewc Atc 3.5.1.16 Tut JR 07 0058Document11 pagesEwc Atc 3.5.1.16 Tut JR 07 0058francisbautistaNo ratings yet

- Tender: Organisation ChartDocument2 pagesTender: Organisation ChartAbhishek PathakNo ratings yet

- 31.HIRA - Boom Placer OperationDocument3 pages31.HIRA - Boom Placer OperationMMRDACA07 SAFETYNo ratings yet

- OXYGEN CONTROL EnglishDocument4 pagesOXYGEN CONTROL EnglishAustin UdofiaNo ratings yet

- Dieselgaurd NBDocument13 pagesDieselgaurd NBAustin UdofiaNo ratings yet

- Carbon Remover SP EnglishDocument5 pagesCarbon Remover SP EnglishAustin UdofiaNo ratings yet

- Chevron Texclad PDS1 LoDocument1 pageChevron Texclad PDS1 LoAustin UdofiaNo ratings yet

- Cetus de 100 UsDocument6 pagesCetus de 100 UsAustin UdofiaNo ratings yet

- Texclad 2 EUDocument6 pagesTexclad 2 EUAustin UdofiaNo ratings yet

- Cooling Sea Water Service SystemDocument3 pagesCooling Sea Water Service SystemAustin UdofiaNo ratings yet

- Major Works To Be DoneDocument6 pagesMajor Works To Be DoneAustin UdofiaNo ratings yet

- Capella HFC 55 EuDocument5 pagesCapella HFC 55 EuAustin UdofiaNo ratings yet

- Chevron Texatherm PDS1 LoDocument1 pageChevron Texatherm PDS1 LoAustin UdofiaNo ratings yet

- Funnel DiagramDocument1 pageFunnel DiagramAustin UdofiaNo ratings yet

- Retrofitting Marine Dual Fuel Diesel EngineDocument5 pagesRetrofitting Marine Dual Fuel Diesel EngineAustin UdofiaNo ratings yet

- Economic, Environmental, and Societal Issues in Materials Science and EngineeringDocument7 pagesEconomic, Environmental, and Societal Issues in Materials Science and EngineeringAustin UdofiaNo ratings yet

- Managing Successful Projects: So What Is A Project?Document15 pagesManaging Successful Projects: So What Is A Project?Austin UdofiaNo ratings yet

- Project Management: CLASSIFICATION: 2 - Internal or Non-ConfidentialDocument10 pagesProject Management: CLASSIFICATION: 2 - Internal or Non-ConfidentialAustin UdofiaNo ratings yet

- LNG Imo FamiliarizationDocument32 pagesLNG Imo FamiliarizationAustin UdofiaNo ratings yet

- Electrical Power HJ4F 34: Operations of P and N Type DiodeDocument3 pagesElectrical Power HJ4F 34: Operations of P and N Type DiodeAustin UdofiaNo ratings yet

- HND HJ4A 35 Heat Engines Oc3Document20 pagesHND HJ4A 35 Heat Engines Oc3Austin UdofiaNo ratings yet

- Transistors As Switches OC4 Ex 4Document2 pagesTransistors As Switches OC4 Ex 4Austin UdofiaNo ratings yet

- Examples of SMART TargetsDocument2 pagesExamples of SMART TargetsAustin UdofiaNo ratings yet

- 1a Direct Stress & Strain With Solutions - Sep 2020Document17 pages1a Direct Stress & Strain With Solutions - Sep 2020Austin UdofiaNo ratings yet

- Cooling Sea Water Service SystemDocument3 pagesCooling Sea Water Service SystemAustin UdofiaNo ratings yet

- Lubication Oil SystemDocument3 pagesLubication Oil SystemAustin UdofiaNo ratings yet

- Boiler Questions and AnswersDocument10 pagesBoiler Questions and AnswersAustin UdofiaNo ratings yet

- Fire Prevention - 1Document24 pagesFire Prevention - 1Austin UdofiaNo ratings yet

- Ship Name: LNG River Orashi TASK: C34.1 DATE: 03/09/2019Document3 pagesShip Name: LNG River Orashi TASK: C34.1 DATE: 03/09/2019Austin UdofiaNo ratings yet

- Time Series and Trend Analysis: Presented byDocument11 pagesTime Series and Trend Analysis: Presented byRishabh RajNo ratings yet

- Global Forecasts DiscussionDocument10 pagesGlobal Forecasts DiscussionkareemarfaNo ratings yet

- Marxist - Political Science IGNOUDocument15 pagesMarxist - Political Science IGNOUDesi Boy100% (2)

- UNIT-5 ppspNOTESDocument29 pagesUNIT-5 ppspNOTESEverbloom EverbloomNo ratings yet

- Walt Disney BiographyDocument8 pagesWalt Disney BiographyIsaacRodríguezNo ratings yet

- Regulations ON Academic Matters: Tezpur UniversityDocument21 pagesRegulations ON Academic Matters: Tezpur UniversitybishalNo ratings yet

- Forest Field Trip ReportDocument8 pagesForest Field Trip Reportapi-296213542100% (2)

- Villaseñor vs. AbanoDocument2 pagesVillaseñor vs. AbanoFrancess PiloneoNo ratings yet

- Pengembangan Transferable Skills Dalam PembelajaraDocument12 pagesPengembangan Transferable Skills Dalam PembelajaraKesat RiyanNo ratings yet

- A Short Guide For Feature Engineering and Feature SelectionDocument32 pagesA Short Guide For Feature Engineering and Feature SelectionjainnitkNo ratings yet

- Long Quiz 1 Eim Tools, MaterialsDocument1 pageLong Quiz 1 Eim Tools, MaterialsLea Ann PalaciosNo ratings yet

- Solar Geometry FinalDocument17 pagesSolar Geometry Finalsarvesh kumarNo ratings yet

- CDBFRDDocument88 pagesCDBFRDmarcol99No ratings yet

- The Wise Old WomenDocument2 pagesThe Wise Old WomenLycoris FernandoNo ratings yet

- Euphoria 2021 F K Anyone Whos Not A Sea Blob Part 2 Jules Script Teleplay Written by Sam Levinson and Hunter SchaferDocument40 pagesEuphoria 2021 F K Anyone Whos Not A Sea Blob Part 2 Jules Script Teleplay Written by Sam Levinson and Hunter SchaferMadalena Duarte7No ratings yet

- Music For BandDocument143 pagesMusic For BandTedTerroux604No ratings yet

- Machinery's Handbook 27th Edition: Tooling and ToolmakingDocument3 pagesMachinery's Handbook 27th Edition: Tooling and ToolmakingOmkar KshirsagarNo ratings yet

- 8 Extraordinary Qi VesselsDocument6 pages8 Extraordinary Qi VesselsRiccardo Lautizi100% (1)

- Present Tenses RevisionDocument1 pagePresent Tenses RevisionJasmina LatinovicNo ratings yet

- Assignment Marks: 30: InstructionsDocument2 pagesAssignment Marks: 30: InstructionsbishtamitdipNo ratings yet

- Welcome Olusegun Ajayi: Faqs Contact UsDocument3 pagesWelcome Olusegun Ajayi: Faqs Contact UsOlusegun AjayiNo ratings yet

- Catalogue2019 PDFDocument12 pagesCatalogue2019 PDFlakavath arthiNo ratings yet

- U59cbu5f97u897fu5c71u5bb4u904au8a18-U6307u5b9au6587u8a00u7d93u5178u7cbeu7de8u53c3u8003u7b54u6848.docx - 1 10 (Document1 pageU59cbu5f97u897fu5c71u5bb4u904au8a18-U6307u5b9au6587u8a00u7d93u5178u7cbeu7de8u53c3u8003u7b54u6848.docx - 1 10 (Yo YuuiNo ratings yet

- The Need For Culturally Relevant Dance EducationDocument7 pagesThe Need For Culturally Relevant Dance Educationajohnny1No ratings yet

- Moskvin Eng FibromialgiaDocument218 pagesMoskvin Eng FibromialgiaWebster LimNo ratings yet

- LY Adverbs Combined ListDocument1 pageLY Adverbs Combined ListcarmencrisanNo ratings yet