Professional Documents

Culture Documents

Pacs Lower Pin PJ Burry (2 November 2023)

Uploaded by

Putra BangunOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pacs Lower Pin PJ Burry (2 November 2023)

Uploaded by

Putra BangunCopyright:

Available Formats

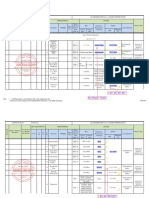

PREPARED CHECKED APPROVED

PROBLEM ANALYSIS AND COUNTERMEASURE SHEET

Control no :/.../PACS/INT-EKS / III / ALREADY SIGN

DISPOSISI : DEPT. / DIV. : QA / QC

PART NO : TYPE DEMERIT POINT SELECTION POINT DEFECTIVE DATE DEFECT QTY 156 Pcs

PART NAME : LOWER PIN PROBLEM ISSUE DATE ENGINE NO.

CLASS PART 1. SAFETY PART 2. FUNCTION PART 3. GENERAL PART BURRY ACCEPTED DATE FRAME NO.

DETAIL OF PROBLEM ( Rincian Masalah ) PROBLEM ANALYSIS ( Analisa Masalah ) 5W PREVENTIVE ACTION ( Tindakan Pencegahan ) ACTION DATE

Kenapa terbuat ?

Inspection Standard

~ Pada ujung part lower pin burry

~ Pada saat proses cutting, dies shearing gompal sehingga

menyebabkan hasil potongan burry

~ Belum adanya kontrol dies shearing pada proses cutting yang

QCPC

menyebabkan kondisi gompal tidak terdeteksi

Kenapa terkirim? Work Instruction

~ Penanganan lot bermasalah tidak dilakukan sesuai dengan

standard.

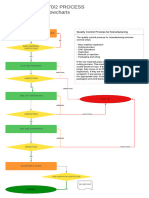

~ Terdapat part suspect yang tidak diberikan identitas untuk FLOW PROCESS ( Arus Proses )

dilakukan repair.

Before Improvement (Sebelum Perbaikan ) After Improvement (Setelah Perbaikan )

MAIN NATURE OF CAUSES ( Penyebab Utama Masalah )

Mohon kirim analisa & jawaban masalah max 4 hari setelah terima PACS !

Investigation (4 M) Fish Bone Diagram ( Investigasi Diagram Tulang Ikan )

Man Mesin

CORRECTIVE/TEMPORARY ACTION DATE

Repair area chamfer dengan machining NOTE :

Delivery After Improvement

BURRY DATE

LOT. CODE

DATE PREPARED CHECKED APPROVED

DEPT.

Methode Material

EVALUATION : HORIZONTAL DEVELOPMENT Inspection Standard DATE CHECKED APPROVED

QCPC

Similar part

SAME GENERAL

NOTIFICATION : The Report must be follow up by incharge and ANALISYS

sent in 4 days after received with support data for preventive Similar process Work Instruction

and corrective action

You might also like

- DSM-IV Adult ADHD Symptom Checklist-Self Report Version # 6182Document1 pageDSM-IV Adult ADHD Symptom Checklist-Self Report Version # 6182Chris0% (1)

- 6.ITP For RebarDocument1 page6.ITP For RebarDaniel Sinaga100% (1)

- DS-09-02 R0 Change Implementation MatrixDocument3 pagesDS-09-02 R0 Change Implementation MatrixDhinakaran100% (1)

- PFMEA&control Plan LinkageDocument7 pagesPFMEA&control Plan LinkageToni HimawanNo ratings yet

- OutgoingDocument4 pagesOutgoingEri ParihahNo ratings yet

- Potential Failure Mode and Effect Analysis (Process Fmea) : Opn - NoDocument1 pagePotential Failure Mode and Effect Analysis (Process Fmea) : Opn - Noprasad sapareNo ratings yet

- Standard Operation ProcedureDocument3 pagesStandard Operation ProcedureAnand KesarkarNo ratings yet

- Gpe-Fat OverviewDocument5 pagesGpe-Fat Overviewn.hartonoNo ratings yet

- 3 WH Drum Process ProjectDocument28 pages3 WH Drum Process ProjectBrandvision AdvertisementNo ratings yet

- A3 Report RustyDocument7 pagesA3 Report RustyMarketing BonecomNo ratings yet

- JAPL-F-HE-019 Scraper CheckDocument1 pageJAPL-F-HE-019 Scraper CheckAli HassanNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document3 pagesPotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- Supplier Quality Issues Report: Stud Tilt MoldedDocument5 pagesSupplier Quality Issues Report: Stud Tilt MoldedJ P ENTERPRISESNo ratings yet

- Process Flow ChartDocument11 pagesProcess Flow Chartsudar1477No ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document1 pagePotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- Attachment 1 - Process-Audit-form - v1.3 - March-2021Document22 pagesAttachment 1 - Process-Audit-form - v1.3 - March-2021samuel.barbosa.proNo ratings yet

- Cover 5W1H SheetDocument1 pageCover 5W1H Sheetpurchase.electricals2No ratings yet

- 447 Final Inspn Edited PDFDocument3 pages447 Final Inspn Edited PDFATHIBAN VNo ratings yet

- Inspection Sheet GensetDocument2 pagesInspection Sheet GensetDwiNo ratings yet

- Failure Indication Tag (Pink)Document2 pagesFailure Indication Tag (Pink)PalNo ratings yet

- Essae 20.06.20Document3 pagesEssae 20.06.20Parthiban DNo ratings yet

- Control Plan - 608 2RS C3Document28 pagesControl Plan - 608 2RS C3trandangbkNo ratings yet

- FlowchartsDocument1 pageFlowchartsChithralekha AnanthNo ratings yet

- Problem (Orange Peel & Dented)Document2 pagesProblem (Orange Peel & Dented)Marketing TanajawaNo ratings yet

- Control (Quality) PlanDocument1 pageControl (Quality) PlanRabia ZulqarnainNo ratings yet

- Etech Automation Mr. Varun Dev FMEA / 26221839 05.10.2012 Mr. Sethupathi Terminal BendingDocument4 pagesEtech Automation Mr. Varun Dev FMEA / 26221839 05.10.2012 Mr. Sethupathi Terminal BendingMadan PrakashNo ratings yet

- Without Punch Part Mix: Customer/Supplier / in Plant Quality Problem Analysis and Countermeasure Sheet (5 - Rule)Document13 pagesWithout Punch Part Mix: Customer/Supplier / in Plant Quality Problem Analysis and Countermeasure Sheet (5 - Rule)Rohtash fastnerNo ratings yet

- PFDPFMEACP Linkages PDFDocument1 pagePFDPFMEACP Linkages PDFsateeshkoriNo ratings yet

- Itp Transfer Tower - Xls (Bvi Comment)Document52 pagesItp Transfer Tower - Xls (Bvi Comment)Alif Rahmat FebriantoNo ratings yet

- Inspection Testing Repair FormDocument1 pageInspection Testing Repair FormVajid MadathilNo ratings yet

- Product Quality Plan (PQP)Document2 pagesProduct Quality Plan (PQP)Jolene JourneNo ratings yet

- Problem (Orange Peel & Dented)Document2 pagesProblem (Orange Peel & Dented)azmi fasyaNo ratings yet

- SMT Generic Control PlanDocument3 pagesSMT Generic Control Plantuan mai vanNo ratings yet

- 3 WH Drum Process ProjectDocument28 pages3 WH Drum Process ProjectBrandvision AdvertisementNo ratings yet

- Kunstocom India Pvt. LTD.: Format No: Issue No./Date: Qav-Check Sheet Rev - No/Rev. Date: Control Item Check ItemsDocument2 pagesKunstocom India Pvt. LTD.: Format No: Issue No./Date: Qav-Check Sheet Rev - No/Rev. Date: Control Item Check ItemsSandeep VermaNo ratings yet

- Process Audit Check SheetDocument5 pagesProcess Audit Check SheetaliNo ratings yet

- Appendix A: Sam Ple in SP e Ctio N An D Test Plan (ITP)Document7 pagesAppendix A: Sam Ple in SP e Ctio N An D Test Plan (ITP)peterandreaNo ratings yet

- E-01 Form Non Conformance & Withdrawal Control (NCWC)Document1 pageE-01 Form Non Conformance & Withdrawal Control (NCWC)diah Puspita sariNo ratings yet

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument3 pagesInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiNo ratings yet

- FM - MKT - 02 Quality Control Process ChartDocument4 pagesFM - MKT - 02 Quality Control Process Chartbarja subarjaNo ratings yet

- Pt. Prestasi Inti Rubber: Control PlanDocument1 pagePt. Prestasi Inti Rubber: Control PlanHardjonoNo ratings yet

- Flange FacingDocument1 pageFlange FacingChiller PartyNo ratings yet

- 8D Wheel WobblingDocument2 pages8D Wheel Wobblingmunireddy.vNo ratings yet

- NCR - CMF-4010A-001A - NG Burry Mulut, Burry Injector, Burry Hole, Sisa RepairDocument1 pageNCR - CMF-4010A-001A - NG Burry Mulut, Burry Injector, Burry Hole, Sisa RepairElfas SyahraniNo ratings yet

- Ih Setup 38tDocument1 pageIh Setup 38tmuthuselvanNo ratings yet

- Audit KRADocument2 pagesAudit KRAtre coolNo ratings yet

- Standard Operating Procedure: Record of RevisionDocument6 pagesStandard Operating Procedure: Record of RevisionEldhose PaulNo ratings yet

- Kick Off Meeting InternalDocument26 pagesKick Off Meeting Internaldeden ibnuNo ratings yet

- First Article Inspection Report Approval Sheet: Inspection Record For Manufacture of Electrical Harnesses OnlyDocument1 pageFirst Article Inspection Report Approval Sheet: Inspection Record For Manufacture of Electrical Harnesses OnlyCE CERTIFICATENo ratings yet

- Bhagod Navinagri Naykiwad Road.: ValsadDocument12 pagesBhagod Navinagri Naykiwad Road.: ValsadARTI PALEKARNo ratings yet

- Quality PLan Fabrication of Expansion Spool For BN8Document1 pageQuality PLan Fabrication of Expansion Spool For BN8Aldrin HernandezNo ratings yet

- Quality PLan Fabrication of Expansion Spool For BN8Document1 pageQuality PLan Fabrication of Expansion Spool For BN8Aldrin HernandezNo ratings yet

- Non Conformity Report: Part Name:-Clamp Bolt Model: M4 Clamp Bolt Supplier:-Paradise Indus. Customer: PICLDocument1 pageNon Conformity Report: Part Name:-Clamp Bolt Model: M4 Clamp Bolt Supplier:-Paradise Indus. Customer: PICLAyush NarangNo ratings yet

- Essae 8.03.23Document4 pagesEssae 8.03.23Parthiban DNo ratings yet

- NCR - CKM-4060L-02HK - NG XRF BR&CL OUTSPECDocument1 pageNCR - CKM-4060L-02HK - NG XRF BR&CL OUTSPECElfas SyahraniNo ratings yet

- Inspection and Test Plan Piling: 1. Document ReviewDocument3 pagesInspection and Test Plan Piling: 1. Document ReviewZara BhaiNo ratings yet

- F-PD-01 Process Flow DiagramDocument1 pageF-PD-01 Process Flow DiagramTrivesh SharmaNo ratings yet

- Quality Control Plan CoatingDocument3 pagesQuality Control Plan CoatingtonierlandaNo ratings yet

- Process Robustness1Document14 pagesProcess Robustness1Rakesh SNo ratings yet

- Standard Operasional Prosedur Departemen ElektrikalDocument1 pageStandard Operasional Prosedur Departemen ElektrikalAgungNo ratings yet

- Restuarant KolkataDocument9 pagesRestuarant KolkataSulagna Basu DasNo ratings yet

- Safety Data Sheet: Valvoline Valplex EP GreaseDocument7 pagesSafety Data Sheet: Valvoline Valplex EP Greasediah ayuNo ratings yet

- FAMOTIDINEDocument3 pagesFAMOTIDINECay Sevilla100% (1)

- SpectrolyserDocument4 pagesSpectrolysernirpred20No ratings yet

- Series: Dual Rod CylinderDocument22 pagesSeries: Dual Rod CylinderAnonymous A55PY1bNo ratings yet

- Soal Pas G-3 2020 GasalDocument13 pagesSoal Pas G-3 2020 Gasalgusti annisaNo ratings yet

- Simple Past ExcDocument1 pageSimple Past ExcHa H. MuhammedNo ratings yet

- ChargesDocument1 pageChargesshenNo ratings yet

- Case 04 Kraft FoodsDocument18 pagesCase 04 Kraft FoodsKad Saad100% (2)

- V 23148Document3 pagesV 23148nelucurtaNo ratings yet

- PRIYANKA S Thesis On Probiotic Shrikhand Very Importand PDFDocument230 pagesPRIYANKA S Thesis On Probiotic Shrikhand Very Importand PDFAshutosh MasihNo ratings yet

- Mte 4 ReportDocument8 pagesMte 4 ReportZeke KazamiNo ratings yet

- Oral Presentation Engllish SBADocument1 pageOral Presentation Engllish SBAKALI LAWRENCE100% (1)

- Effective Supervision (Module 6 Requirement)Document34 pagesEffective Supervision (Module 6 Requirement)joshua_buyserNo ratings yet

- Internal Audit ProcedureDocument6 pagesInternal Audit ProcedureUsaid KhanNo ratings yet

- Water Cycle E-BookDocument13 pagesWater Cycle E-Bookapi-322786693No ratings yet

- U4 - Study Guide - CELL DIVISION & GROWTHDocument7 pagesU4 - Study Guide - CELL DIVISION & GROWTHJuan CastellanosNo ratings yet

- Mental Status ExaminationDocument8 pagesMental Status ExaminationanisaNo ratings yet

- Altivar 71 ATV71HU75N4Document4 pagesAltivar 71 ATV71HU75N4electrosysro8560No ratings yet

- Manual de Partes Thmig 500Document3 pagesManual de Partes Thmig 500Alexander HernandezNo ratings yet

- Climate Master Tranquility TCV Series MANUALDocument52 pagesClimate Master Tranquility TCV Series MANUALRitajaiswal0% (1)

- Multiple Myeloma Case Studies (Tandem 2017) (Final)Document52 pagesMultiple Myeloma Case Studies (Tandem 2017) (Final)Syed Ali Akbar100% (2)

- M007-CCC-STR-MES-00005 Rev. 2.0Document102 pagesM007-CCC-STR-MES-00005 Rev. 2.0Mikku KattaNo ratings yet

- Rizal Technological University Pasig Senior High SchoolDocument14 pagesRizal Technological University Pasig Senior High SchoolCj SernaNo ratings yet

- CCNA Cyber Ops (Version 1.1) - Chapter 6 Exam Answers FullDocument20 pagesCCNA Cyber Ops (Version 1.1) - Chapter 6 Exam Answers FullRawan AlharbiNo ratings yet

- LESSON 8: Emotions and FeelingsDocument2 pagesLESSON 8: Emotions and FeelingsBusiness PsychologistNo ratings yet

- Algoritma TBIDocument3 pagesAlgoritma TBIravenskaNo ratings yet

- 10 Science Life Processes Test 04Document1 page10 Science Life Processes Test 04asuhassNo ratings yet

- SuperFlo High Performance Pump Owners Manual EnglishDocument16 pagesSuperFlo High Performance Pump Owners Manual EnglishAldiNo ratings yet