Professional Documents

Culture Documents

ITP - Concrete Work

Uploaded by

Syed AliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ITP - Concrete Work

Uploaded by

Syed AliCopyright:

Available Formats

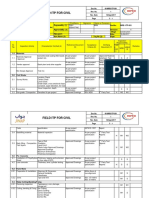

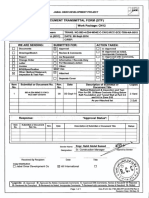

Client: Consultant: Contractor: Form No. 3-QC-03.

Inspection and Test plan for cast in place concreting

Project No.: Project Name: Construction and Operate Phase-1 Green Riyadh Nursery Project Legend:

ITP No.:CIV-MTS-00006

P-Perform H-Hold Point

I-Inspection R-Record Review

Revision: Date:

S-Surveillance W-Witness

Prepared By: Reviewed By: Approved By: Aprroved Date:

Type of Verifying Responsibility

No. Activity Description Specification Reference Acceptance Criteria Contracto

Inspection Document Dorsch TPI Client

r

1 Document Review

Material approval Approved material Approved

1 R Approved material submittal R R R

submittal material

Methode statement Approved method Approved method

2 R R R R

statement statement

Approved structural drawings Approved structural Approved structural

4 R R R R

drawings drawings

2 material Reciewing

Concrete, Reinforcement, Formwork and Embeds etc. Approved material Approved material

1 W MIR H W W

submittal/MS submittal/MS

3 Installation

Concrete delivery ticket shall be checked and verifiy the grade

of concrete, should be accordance with the TRSDC approved

3.1 W W W S

Mix Design..

Approved mix

Concrete delivery Concrete delivered at a temperature in excess of 32°C or that Approved mix design/MS W Approved mix design/MS

design/MS

fails to maintain a temperature of 32°C until used, shall be

rejected. (Except Non- structural concrete) W W W S

Fresh concrete-Slump Test

3.2 Frequency – – 1 Test for 1 mix 1

Approved mix

Field testing Hardened Concrete-Compressive strength @7 & 28days Methode statement W Methode statement design/TEST W W P S

Frequency as per ASTM REPORT

Forms shall result in a final structure that conforms to shapes,

lines, and dimensions of the members as required by the

3.3

Approved Structural drawings.

Forms shall be substantial and sufficiently tight to prevent

leakage of mortar from the concrete. Approved structural

Formwork H Approved drawings/WIR Check list/WIR H W S

drawings

Forms are properly braced or tied together to maintain

position and shape.

Formwork shall be anchored to the shores below so that

movement of any part of the formwork system will be

prevented

Page 1

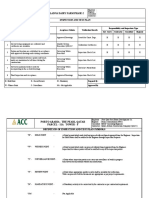

Client: Consultant: Contractor: Form No. 3-QC-03.0

Inspection and Test plan for cast in place concreting

Project No.: Project Name: Construction and Operate Phase-1 Green Riyadh Nursery Project Legend:

ITP No.:CIV-MTS-00006

P-Perform H-Hold Point

I-Inspection R-Record Review

Revision: Date:

S-Surveillance W-Witness

Prepared By: Reviewed By: Approved By: Aprroved Date:

Type of Verifying Responsibility

No. Activity Description Specification Reference Acceptance Criteria Contracto

Inspection Document Dorsch TPI Client

r

Reinforcement Reinforcing steel bars conform to high strength steel with

3.4 yield strength Fy 415 Mpa.

Reinforcing steel lap splice lengths for each bar size shall be as

detailed for each size as shown on the approved drawings. Approved structural

H Approved drawings/WIR Check list/WIR H H S

drawings

The inside diameter of bends for stirrups and ties shall be no

less than 4 bar diameter for sizes

Embeded items All sleeves, inserts, anchor bolts, waterstops and other Approved drawings Approved drawings

embedded items shall be installed in accordance with the

3.5 design drawings and supported against displacement. H Check list/WIR H W S

3.6 concrete pouring Methode statement W Methode statement Check list/WIR H W S

3.7 Curing Methode statement S Methode statement Check list/WIR S S S

Methode Methode

3.8 Damp proofing statement/manufacturer W statement/manufacturer WIR W W W

recommendation recommendation

Page 2

You might also like

- Inspection and Test Plan Piping Work ActivitiesDocument2 pagesInspection and Test Plan Piping Work ActivitiesAbram Berkat100% (2)

- Itp For Pipeline at SiteDocument3 pagesItp For Pipeline at Siteanang_pri100% (2)

- 13 Checklist ARCH Plastering Works (General)Document6 pages13 Checklist ARCH Plastering Works (General)Puteri Indah Achmad HasyimNo ratings yet

- Inspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak RiauDocument4 pagesInspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak Riauanang_priNo ratings yet

- Quality Control Plan: ClientDocument7 pagesQuality Control Plan: ClienteliiiiiiNo ratings yet

- Seismic Analysis of Reinforced Concrete High Rise Multi-Storey BuildingDocument59 pagesSeismic Analysis of Reinforced Concrete High Rise Multi-Storey BuildingSayan Deb100% (1)

- ITP For Installation & Leakage Test For HVAC Ducts and AccessoriesDocument1 pageITP For Installation & Leakage Test For HVAC Ducts and AccessoriesDong VanraNo ratings yet

- Contractor: Client:: Project TitleDocument2 pagesContractor: Client:: Project TitlePrasanna Kumar100% (1)

- Inspection and Test Plan: Activity: ITP For Inspection of Piling WorksDocument5 pagesInspection and Test Plan: Activity: ITP For Inspection of Piling WorksjitendraNo ratings yet

- Quantity Surveying - Earthworks, Concrete Etc...Document18 pagesQuantity Surveying - Earthworks, Concrete Etc...Cole Jade DayoNo ratings yet

- ITP CIVIL WORK-Rev-1Document6 pagesITP CIVIL WORK-Rev-1Ateeq Rahman100% (1)

- ITP For PlasteringDocument2 pagesITP For PlasteringPrasanna KumarNo ratings yet

- Inspection Test Plan (Itp) at Site: Disciplin RevDocument5 pagesInspection Test Plan (Itp) at Site: Disciplin RevEnryan Oreski RiyadiNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNo ratings yet

- Itp For Ug PipelineDocument3 pagesItp For Ug PipelineJustin Alwar100% (1)

- Inspection Test Plan (Itp) at Shop: Remark No DescriptionDocument2 pagesInspection Test Plan (Itp) at Shop: Remark No Descriptionanang_pri100% (1)

- Inspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak RiauDocument10 pagesInspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak Riauanang_priNo ratings yet

- ITP For Structural Cabling System Testing and CommissioningDocument1 pageITP For Structural Cabling System Testing and CommissioningRommel Espinosa ParasNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNo ratings yet

- ITP For CCTV System Testing & CommissioningDocument1 pageITP For CCTV System Testing & CommissioningTamer EidNo ratings yet

- 18.9 ITP SUB BASE Rev01Document2 pages18.9 ITP SUB BASE Rev01YEHIA100% (1)

- Bed 2381 Q Itp XX 000 00 PDFDocument1 pageBed 2381 Q Itp XX 000 00 PDFKareem GhazyNo ratings yet

- Aci 207.1R-96Document45 pagesAci 207.1R-96hasan_676489616100% (1)

- Inspection and Test Plan Suspension ClampsDocument2 pagesInspection and Test Plan Suspension ClampsAvinash Lal0% (1)

- 2004 - Khundia y Gosh - Flexural Stiffness of Reinforced Concrete Columns and Beams - ExperimentalDocument11 pages2004 - Khundia y Gosh - Flexural Stiffness of Reinforced Concrete Columns and Beams - ExperimentalpaulkohanNo ratings yet

- 9686-6150-ITP-000-0006 - A1 ITP For Piping Fabrication and ErectionDocument23 pages9686-6150-ITP-000-0006 - A1 ITP For Piping Fabrication and Erectionvenkatesh100% (1)

- PC-ITP-001 - Backfilling and ExcavationDocument2 pagesPC-ITP-001 - Backfilling and ExcavationHusam zayed100% (1)

- Ground Floor Slab Design CalculationsDocument7 pagesGround Floor Slab Design CalculationsArindam RoyNo ratings yet

- Itp WeldDocument2 pagesItp WeldHarshaVeeragandhamNo ratings yet

- Lps 01 Hti Itp Me 022 Chemical Dosing SystemDocument9 pagesLps 01 Hti Itp Me 022 Chemical Dosing SystemJomy JohnyNo ratings yet

- Project Internal Audit Procedure: Name Position Signature Date Prepared byDocument7 pagesProject Internal Audit Procedure: Name Position Signature Date Prepared byTwin Bulls100% (1)

- Natural Gas Transportation Development Project - Siak Riau: Inspection Test Plan (Itp) at ShopDocument3 pagesNatural Gas Transportation Development Project - Siak Riau: Inspection Test Plan (Itp) at Shopanang_priNo ratings yet

- ITP - T&C Fire Alarm SystemDocument1 pageITP - T&C Fire Alarm SystemAmirul Amri HashimNo ratings yet

- Spot Detail Section: (Roofing Sheets and Corbel Conn.)Document1 pageSpot Detail Section: (Roofing Sheets and Corbel Conn.)Robert Christopher NiebresNo ratings yet

- Inspection and Testing Plan For Cable TrayDocument2 pagesInspection and Testing Plan For Cable TrayJohn Rey Perlas100% (2)

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURK100% (1)

- EABASSOC Lightweight Foamed ConcreteDocument4 pagesEABASSOC Lightweight Foamed ConcreteAr Aayush GoelNo ratings yet

- Construction TechniquesDocument8 pagesConstruction TechniquesManasAroraNo ratings yet

- ITP BlockDocument1 pageITP BlockSyed AliNo ratings yet

- ITP RoadDocument2 pagesITP RoadSyed AliNo ratings yet

- Sample of ITP For RO-FEDocument1 pageSample of ITP For RO-FEDaniel DuongNo ratings yet

- ITP For Access Control System InstallationDocument1 pageITP For Access Control System InstallationTamer EidNo ratings yet

- ITP For Installation of Structured Cabling For CommunicationDocument1 pageITP For Installation of Structured Cabling For CommunicationInfas YahyaNo ratings yet

- Alumnium Windows ITPDocument1 pageAlumnium Windows ITPahmed samirNo ratings yet

- ITP PaintingDocument2 pagesITP PaintingWalidNo ratings yet

- Inspection & Test Plan: LFC-AUHMM-E-MST-00001 Inspection & Testing - LV PanelsDocument1 pageInspection & Test Plan: LFC-AUHMM-E-MST-00001 Inspection & Testing - LV PanelsejohnNo ratings yet

- Fabrication & Certification LPG Tank:: 0: 10-Feb-20:::: Field Inspection & Test Plan (Itp)Document3 pagesFabrication & Certification LPG Tank:: 0: 10-Feb-20:::: Field Inspection & Test Plan (Itp)Rifki HasyaNo ratings yet

- Inspected by QCP Approval 1-APC 1 - APC 2 - DAR 2 - DAR Al-Handeseh 3 - Negemco 4 - Vendor 5 - Third PartyDocument6 pagesInspected by QCP Approval 1-APC 1 - APC 2 - DAR 2 - DAR Al-Handeseh 3 - Negemco 4 - Vendor 5 - Third PartyAhmad DagamsehNo ratings yet

- Weir Projects QCPDocument1 pageWeir Projects QCPJessicaNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNo ratings yet

- ITP For Testing & Commissioning SwitchgearDocument1 pageITP For Testing & Commissioning SwitchgearguspriyNo ratings yet

- Project and Location: 65 MW Noor Laayoune Solar PV Project at LaayouneDocument1 pageProject and Location: 65 MW Noor Laayoune Solar PV Project at LaayouneOussama BourimNo ratings yet

- Pumps ItpDocument3 pagesPumps Itpkokod9757No ratings yet

- Itp For Installation of Pressurization UnitDocument1 pageItp For Installation of Pressurization UnitvictorNo ratings yet

- 3.6 Quality Control Plan - Container ManufacturingDocument2 pages3.6 Quality Control Plan - Container ManufacturingJean-Pierre Awu100% (1)

- Inspection & Test Plan: Project Name: Main Activity: Date: W Witness H Hold Point T Test R RandomDocument1 pageInspection & Test Plan: Project Name: Main Activity: Date: W Witness H Hold Point T Test R RandomKasinadh KarraNo ratings yet

- QIP Boiler ErectionDocument1 pageQIP Boiler Erectionshahroze mustafaNo ratings yet

- QCP Smoking SheltersDocument1 pageQCP Smoking SheltersMantshaNo ratings yet

- 00257650-0000-33EG-0001 - Rev PB - Attachment A - ITP ExampleDocument4 pages00257650-0000-33EG-0001 - Rev PB - Attachment A - ITP ExampleSubrata Das100% (1)

- ITP For Fire Protection SystemDocument19 pagesITP For Fire Protection SystemBibin Chacko MammenNo ratings yet

- Quality Control Plan: ClientDocument7 pagesQuality Control Plan: ClienteliiiiiiNo ratings yet

- SFDSF PDFDocument3 pagesSFDSF PDFbishnu sahNo ratings yet

- 149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Document58 pages149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Cable Ladder InstallationDocument5 pagesCable Ladder InstallationAhmad DagamsehNo ratings yet

- Toaz - Info Itp For PVC Conduits PRDocument6 pagesToaz - Info Itp For PVC Conduits PRehtesham khanNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument4 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNo ratings yet

- TRN 0515Document2 pagesTRN 0515rayNo ratings yet

- ITP For Structural Concrete Works at Birkat Al Awamer Logistic ParkDocument1 pageITP For Structural Concrete Works at Birkat Al Awamer Logistic ParkAshir RIZNo ratings yet

- List of Recommended Manufacturers (Or Approved Equal) HvacDocument7 pagesList of Recommended Manufacturers (Or Approved Equal) HvacSyed AliNo ratings yet

- Method Statement For Concrete WorkDocument11 pagesMethod Statement For Concrete WorkSyed AliNo ratings yet

- Staff HousingDocument5 pagesStaff HousingSyed AliNo ratings yet

- HERA-concrete Works - REV-00Document6 pagesHERA-concrete Works - REV-00Syed AliNo ratings yet

- ChecklistsDocument1 pageChecklistsSyed AliNo ratings yet

- Msra-For Block WorksDocument13 pagesMsra-For Block WorksSyed AliNo ratings yet

- ChecklistsDocument1 pageChecklistsSyed AliNo ratings yet

- Adobe Scan ١٠� - ٠٨� - ٢٠٢٢Document1 pageAdobe Scan ١٠� - ٠٨� - ٢٠٢٢Syed AliNo ratings yet

- Adobe Scan ٢٩� - ١٠� - ٢٠٢٢Document1 pageAdobe Scan ٢٩� - ١٠� - ٢٠٢٢Syed AliNo ratings yet

- Bridge Design RCDG Service Load MethodDocument17 pagesBridge Design RCDG Service Load Methodbart porquiadoNo ratings yet

- Handover of Layout Smoke Extraction.Document5 pagesHandover of Layout Smoke Extraction.Kevin JohnNo ratings yet

- Pilecap Additional WorksDocument62 pagesPilecap Additional WorksLiew Kuet KongNo ratings yet

- Comparative Cost Study of Reinforced Concrete Flat Slab and Slab With Beam Floor SystemsDocument79 pagesComparative Cost Study of Reinforced Concrete Flat Slab and Slab With Beam Floor SystemsFreizerNo ratings yet

- 4 - Earthquake Resistant Behavior of Prestressed ConcreteDocument5 pages4 - Earthquake Resistant Behavior of Prestressed ConcreteHemal MistryNo ratings yet

- Cfa Piling Guidance 0Document9 pagesCfa Piling Guidance 0hugojameswoodNo ratings yet

- New Rich Text DocumentDocument23 pagesNew Rich Text DocumentRubina FatimaNo ratings yet

- Cotm 2103 HandoutDocument116 pagesCotm 2103 Handoutfitsum tesfayeNo ratings yet

- URS Fatigue Evaluation and Redundancy AnalysisDocument2 pagesURS Fatigue Evaluation and Redundancy Analysismadhu.nandha9285No ratings yet

- Mathcad - C06-C10 PDFDocument7 pagesMathcad - C06-C10 PDFKrish ChandNo ratings yet

- Thrust Line & Pressure Line ExplanationDocument11 pagesThrust Line & Pressure Line ExplanationTanvir A MridhaNo ratings yet

- Submitted To The Department of Civil Engineering of CGC Technical Campus Jhanjeri, MohaliDocument46 pagesSubmitted To The Department of Civil Engineering of CGC Technical Campus Jhanjeri, MohaliBipinNo ratings yet

- Estimate Details: Work InformationDocument2 pagesEstimate Details: Work Informationatul patilNo ratings yet

- Civ 300Document70 pagesCiv 300johney2No ratings yet

- Consolidation and Strengthening of Historical Masonry by Means of Mineral Grouts - Kanchi ChoudharyDocument3 pagesConsolidation and Strengthening of Historical Masonry by Means of Mineral Grouts - Kanchi ChoudharyKanchi ChoudharyNo ratings yet

- CSE513 Tall Building Structures:: Coupled Shear WallsDocument104 pagesCSE513 Tall Building Structures:: Coupled Shear WallsVincent YeungNo ratings yet

- U Boot BetonDocument23 pagesU Boot BetonMegha KallihalNo ratings yet

- Ce0061 Professional Course 4 - (Specialized 2) Ste Track: Prestressed Concrete DesignDocument40 pagesCe0061 Professional Course 4 - (Specialized 2) Ste Track: Prestressed Concrete DesignjerichoNo ratings yet

- 2152-1.3LL Sump-Str-Cal-01Document33 pages2152-1.3LL Sump-Str-Cal-01sssmitNo ratings yet

- BeamDocument14 pagesBeamLong Live TauNo ratings yet

- Deep Beam STMDocument98 pagesDeep Beam STMManjula Unnikrishnan N K100% (3)