Professional Documents

Culture Documents

Adobe Scan ٢٩� - ١٠� - ٢٠٢٢

Uploaded by

Syed AliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adobe Scan ٢٩� - ١٠� - ٢٠٢٢

Uploaded by

Syed AliCopyright:

Available Formats

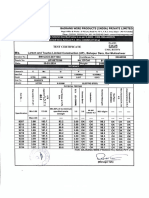

Tel: 011-292 4101 - 2924103

1.0 Lab. TESTREPORT LBy Fax: 011-292 4104, Ext: 149

P.O.Box 53613 Riyadh 11593

Informatio ec Geotechnical & Environmental Co. (GECO) Email: infoageco-ksa.com

7770-KimgAbuluzi: District,Riyadh-12411-4846 KingdomofSaudi Arabia Website: www.geco-ksa.com

2.0 Title of cOMPRESSIVE STRENGTH OF CYLINDERICAL CONCRETE SPECIMENS (ASTM c39IC39M - 20)

Method

PROJECTT

| Construction And Operation Of Phase-1Green Riyadh Nursery DATE REPORT 10 October 2022

CLIENT ALMAJAL Al ARABI COMPANY. DATE OF CAST 12 September 2022

LOCATION/ cONTACT BENBAN DISTRICT,RIYADH,K.SA DATE RECEIVED 13September2022

EST LOCATION GECO, RIYADH HEAD OFFICELAB.(MATERIALLAB) DATE OF TEST 10 October 2022

FACTORY/ B.P UNI BETON READY MIX FACTORY REF. NO. G/S11-1219

TEST APPARATUSUSE COMPRESSIONMACHINE MATEST (S No. CO70PL36/AZ/0001)REPORT NO. 5

ENVIRMET COND. TEMPERATURE:23 °C_ RELATIVE HUMIDITY: 35 % REPORT IssUE# 00

METHOD VARIATION |NIL REVISION # O0 SAMPLED BY CLIENT

TESTED BY AMIR SAEED LAB.CODE. 9609

Sample| End CyI. Unit Cyl. Test Compressive

Fracture

Description Area Mass Mass Age Load Strength,

Types

kg/m Days kN kgf/cm*| MPa

No. mm. mm.

mm kg

738.0 426.0 418 Type4

Bi 300 150| 17671

12.910 243 28

2440 28 791.0 4566 44 8 Type2

B2 300 150 17671 12.988

405.8 39.8 Type3

B3 Trail Mix 299 150 17671 12.895 2440 28 703.0

B4 301| 150 17671 12.891 2440 28 697.0 402.3 394 Type3

B5 301 150 17671 12.906 2430 28 688.0 397.1 38.9 Type2

Average Compressive Strength| 417.5 409

n. s ma

REMARK

S

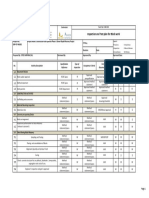

TYPE 1 Lessthan 1inch ofcracking throughcaps han señned cone on oche end

TYPE 2|Vertical cracks running throughcapS

TYPE 3 Columnar Vertical Crackingthrough both ends

TYPE 4Diagonal fracture with no cracking through ends N

TYPE 5Sidefractures at top orbottom

e c t h u r e w i t no

p wUh hamner to wh unture n )

TYPE 6Similar to type 5 but end of cylinder is pointed

Defects occurred in specimien during crushing

ADDITIONAL Anothor information which required for the report acc to ASTM already mentioned in report

INFORMATIO 10 kg/cm*

Result expressed as (Strength as 0.1 Mpa and Density

as

i

1-GECO is not responsible for any deletion, adíition or amendment to the report except through GECO & through an oficial procedure

2- The results in the report are for samples that have been received from the customer only.

3. Samples were collected and all tis data were made known through the ctient. GECO is not responsible for any defect

4 Compression tests were conducted inside GECOs head office Riyadh Laboratory & under its control without any extemal intervention or contact

5- Analysis performed by highly qualified technicians & under their responsibility, opinions & interpretations conformed by technical manager

and final report approved by head of department.

6- The tests were conducted under appropriate and tight environmental conitions in accordance with the requirements of each test

7- It is not permissible to change the project data after issuing the report.

This report replaces any previous report (s) with this reference

9 The analytical procedures used by GECO material lab. have been developed from established internatuinally recognized procaderes(ASTAD:

10- A symbol preceding any method indicates laboratory or subcontractor non-acredited test in the case when a proced elghg ioap

acredited method was used for non-acredited metrix, would apply that the repoted results are non-acredited.

Concrete Mix Design C-30 MPa

25 TEST Type of Cement Cement Content, Kg_ SPEC. 07 DAYS STRENCTH 22.5 MPa

d

OPINION OPC 380 SPEC.28 DAYS STRENGTH 30 MPa

The average & individual Compression strength of tested concrete Specimens comply the Project Specifications

PASS

4 Y s i l claig

3.0 Authorized signatures for reporting release

Approved By Head of Department Envit

Review By Technical Manager

NAME Eng.Jamil Khan

NAME Eng Faisal Al Baliwy_

SIGNATURE SIGNATURE

DATE 10 October 2022 DATE 10 October 2022

Form# SOP-19-2, issue-2

END OF REPORT

You might also like

- Concrete Compression Test: Cementitious Content Type of CementDocument4 pagesConcrete Compression Test: Cementitious Content Type of Cementmohammed alebiedNo ratings yet

- مدحتDocument14 pagesمدحتHesham MosadNo ratings yet

- Self Consolidating Concrete Mix Design (Aci 237) : MaterialDocument14 pagesSelf Consolidating Concrete Mix Design (Aci 237) : MaterialHishmat Ezz AlarabNo ratings yet

- R CrmnonbistcDocument4 pagesR Crmnonbistcgopuvinu4uNo ratings yet

- QPE002342 - Technical BidDocument136 pagesQPE002342 - Technical BidMuhammed TamerNo ratings yet

- Material Submittal For Al Sarh Trading & Cont. (C20 &C25 Screed) PDFDocument117 pagesMaterial Submittal For Al Sarh Trading & Cont. (C20 &C25 Screed) PDFBikasNo ratings yet

- Dossier Merla - ODB 4604279Document33 pagesDossier Merla - ODB 4604279Indira briceñoNo ratings yet

- Mir 001Document2 pagesMir 001MCCIN L&WNo ratings yet

- The Construction, Commissioning and Maintenance of Infrastructure Works For Electrified Double Track Project Between Seremban and Gemas - Package Ii (KM 502.600 - KM 535.500)Document46 pagesThe Construction, Commissioning and Maintenance of Infrastructure Works For Electrified Double Track Project Between Seremban and Gemas - Package Ii (KM 502.600 - KM 535.500)Suhaidi AliasNo ratings yet

- M4II Family Operation Manual SpanishDocument1 pageM4II Family Operation Manual SpanishLanco SANo ratings yet

- Technical Specification (Medium Voltage) Aaa Covered Conductor & AccesoriesDocument36 pagesTechnical Specification (Medium Voltage) Aaa Covered Conductor & AccesoriesCabcon India100% (1)

- Suhaimi: Summary of Field - TestDocument4 pagesSuhaimi: Summary of Field - Testhammad21No ratings yet

- 9686-6130-FQ-000-0007 Cement Content Higher Than 400Kg Per Cubic Metre 2..Document11 pages9686-6130-FQ-000-0007 Cement Content Higher Than 400Kg Per Cubic Metre 2..ANIL PLAMOOTTILNo ratings yet

- Stirling: Project Masaka RoadsDocument7 pagesStirling: Project Masaka RoadsRonald WaiswaNo ratings yet

- TC PC WireDocument3 pagesTC PC WireSM AreaNo ratings yet

- Inc 800 MTC - FlangeDocument1 pageInc 800 MTC - Flangeranjith_007100% (1)

- Test Report of BricksDocument1 pageTest Report of BricksKumar Abhishek67% (3)

- Shear Strength by Direct Shear (Small Shear Box) : Client Structure Project Job Sample Test DetailsDocument10 pagesShear Strength by Direct Shear (Small Shear Box) : Client Structure Project Job Sample Test DetailsSocrates Palomino GamboaNo ratings yet

- E/Aod: According To en 10204Document1 pageE/Aod: According To en 10204agungNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-FIT - 186Document2 pagesQ1Co 3000 Q1Co 3620 3620-FIT - 186JHONATAN RODRIGUEZ VENTONo ratings yet

- R Crmnonbistc8302Document2 pagesR Crmnonbistc8302Nelson 2428No ratings yet

- MTC 2257 SPECTRA 304 HR COIL 8mm X 1250Document1 pageMTC 2257 SPECTRA 304 HR COIL 8mm X 1250Amit Kumar OjhaNo ratings yet

- Collapsible Spacer TubeDocument12 pagesCollapsible Spacer TubeMohamed HarisNo ratings yet

- 9686-6130-FQ-000-0007 Cement Content Higher Than 400Kg Per Cubic MetreDocument13 pages9686-6130-FQ-000-0007 Cement Content Higher Than 400Kg Per Cubic MetreANIL PLAMOOTTILNo ratings yet

- تنزيلDocument2 pagesتنزيلShady MohamedNo ratings yet

- CEM 1203 42 BuzzerDocument5 pagesCEM 1203 42 BuzzerEAKIT SPAINNo ratings yet

- Report IDocument1 pageReport IsgewindiaNo ratings yet

- GGG 40.3 Test ReportDocument1 pageGGG 40.3 Test ReportcqigNo ratings yet

- Test Report-Inter Locking Paver BlockDocument9 pagesTest Report-Inter Locking Paver Blockudit shahNo ratings yet

- CMAX-DM20-43-V53: Electrical SpecificationsDocument3 pagesCMAX-DM20-43-V53: Electrical SpecificationsFernando Cuestas RamirezNo ratings yet

- Qap TataDocument5 pagesQap TataDesign VardhNo ratings yet

- Test CetificationDocument1 pageTest CetificationRoy Chavez QuispeNo ratings yet

- Test Ce Tificate: C EMI AL OM OS On PercentDocument2 pagesTest Ce Tificate: C EMI AL OM OS On PercentPravin HonmuteNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOParesh Mehta100% (1)

- BREN DBM Grade-IIDocument12 pagesBREN DBM Grade-IIJoydeep NeogiNo ratings yet

- Apl Apollo Tubes Limited Unit-Iii: Works-Vill-Kudavali Plot No-M-1, Murbad, 421401, Thane (MS)Document1 pageApl Apollo Tubes Limited Unit-Iii: Works-Vill-Kudavali Plot No-M-1, Murbad, 421401, Thane (MS)devanshbhuvansht.823No ratings yet

- Q1Co 3000 Q1Co 3620 3620-FIT - 286Document2 pagesQ1Co 3000 Q1Co 3620 3620-FIT - 286JHONATAN RODRIGUEZ VENTONo ratings yet

- Ultramid A3WG7 IsoDocument3 pagesUltramid A3WG7 IsoRiccardoNo ratings yet

- CMAX DM30 43 V53 - Mimo2 PDFDocument3 pagesCMAX DM30 43 V53 - Mimo2 PDFOrLand ChxNo ratings yet

- CMAX DM30 43 V53 - Mimo2 PDFDocument3 pagesCMAX DM30 43 V53 - Mimo2 PDFOrLand ChxNo ratings yet

- PL Inox 9 MMDocument1 pagePL Inox 9 MMHugo BeltranNo ratings yet

- 21 09 2022 SIKA Mix Load 2Document1 page21 09 2022 SIKA Mix Load 2KENNETH ORJINo ratings yet

- FAT Procedure & ChecklistDocument3 pagesFAT Procedure & ChecklistARSHI ASLAM100% (3)

- DGA-53H Drilling Fluid Report No 28Document1 pageDGA-53H Drilling Fluid Report No 28Over KeelNo ratings yet

- RT Report Format Rev.1 17-3-19Document6 pagesRT Report Format Rev.1 17-3-19mohd as shahiddin jafriNo ratings yet

- K M G CollegeDocument2 pagesK M G CollegeSugumar MuthusamyNo ratings yet

- Appcom HC 5000 BK UvDocument1 pageAppcom HC 5000 BK UvabinayaNo ratings yet

- 9.marshall Trial Compaction Ac WC25092020Document20 pages9.marshall Trial Compaction Ac WC25092020Ramdan Pramedis SetyaNo ratings yet

- 2324MTC037 11362Document1 page2324MTC037 11362Shrikrushna DalviNo ratings yet

- Test Certificate-ER347-lot 563092-75344Document1 pageTest Certificate-ER347-lot 563092-75344Mohammad HassanNo ratings yet

- Concure A99 AS3799 Aug 2020Document2 pagesConcure A99 AS3799 Aug 2020malak hindiNo ratings yet

- Hasil LabDocument4 pagesHasil LabHanafi Yusuf AviansyahNo ratings yet

- Certificate of Analysis: Parameter Specification Analysis Chemical RequirementsDocument1 pageCertificate of Analysis: Parameter Specification Analysis Chemical RequirementsAnkur BarsainyaNo ratings yet

- FDT 19728 Civil 43025Document1 pageFDT 19728 Civil 43025Mohamed RamadanNo ratings yet

- Sertifikat Produksi Caa-2212-00097Document1 pageSertifikat Produksi Caa-2212-00097figo zaliNo ratings yet

- Test Certificate: (, Phone: 26751763 MillDocument1 pageTest Certificate: (, Phone: 26751763 MillQc QatarNo ratings yet

- Varilla B7 3-8 X 144 MT (B7)Document1 pageVarilla B7 3-8 X 144 MT (B7)Carlos Lluen AquinoNo ratings yet

- DZ1610Document1 pageDZ1610Dany LeaNo ratings yet

- List of Recommended Manufacturers (Or Approved Equal) HvacDocument7 pagesList of Recommended Manufacturers (Or Approved Equal) HvacSyed AliNo ratings yet

- Staff HousingDocument5 pagesStaff HousingSyed AliNo ratings yet

- ITP - Concrete WorkDocument2 pagesITP - Concrete WorkSyed AliNo ratings yet

- HERA-concrete Works - REV-00Document6 pagesHERA-concrete Works - REV-00Syed AliNo ratings yet

- Method Statement For Concrete WorkDocument11 pagesMethod Statement For Concrete WorkSyed AliNo ratings yet

- ChecklistsDocument1 pageChecklistsSyed AliNo ratings yet

- ChecklistsDocument1 pageChecklistsSyed AliNo ratings yet

- Msra-For Block WorksDocument13 pagesMsra-For Block WorksSyed AliNo ratings yet

- ITP BlockDocument1 pageITP BlockSyed AliNo ratings yet

- ITP RoadDocument2 pagesITP RoadSyed AliNo ratings yet

- Adobe Scan ١٠� - ٠٨� - ٢٠٢٢Document1 pageAdobe Scan ١٠� - ٠٨� - ٢٠٢٢Syed AliNo ratings yet

- M1 Questions REV SP23Document2 pagesM1 Questions REV SP23Melia MorrisNo ratings yet

- Maldigestion/malabsorption Syndromes: Fecal AnalysisDocument2 pagesMaldigestion/malabsorption Syndromes: Fecal AnalysisMonica DomingoNo ratings yet

- Soc6 - Advanced Social TheoryDocument10 pagesSoc6 - Advanced Social Theoryrabarber1900No ratings yet

- Teaching Third World Cinema Screen by Teshome H. GabrielDocument6 pagesTeaching Third World Cinema Screen by Teshome H. GabrielBunmi OloruntobaNo ratings yet

- Mathematics (Question Paper)Document5 pagesMathematics (Question Paper)B GALANo ratings yet

- 3 Disability ModelsDocument28 pages3 Disability ModelszainbNo ratings yet

- Cancer HandbookDocument15 pagesCancer Handbookdaddytrill777No ratings yet

- Nursing Care of Child With LIFE THREATENING CONDITIONSDocument70 pagesNursing Care of Child With LIFE THREATENING CONDITIONSinno so qtNo ratings yet

- NMAT Sample Paper With Answer KeyDocument4 pagesNMAT Sample Paper With Answer KeyBATHULA MURALIKRISHNA CSE-2018 BATCHNo ratings yet

- BBM11411 Final Exam 2022 S1Document5 pagesBBM11411 Final Exam 2022 S1bonaventure chipetaNo ratings yet

- A Detailed Lesson Plan in English 1Document9 pagesA Detailed Lesson Plan in English 1Veronica Santiago100% (5)

- New Microsoft Word DocumentDocument7 pagesNew Microsoft Word DocumentOrigamiGalati BrailaNo ratings yet

- Fiona FamousDocument10 pagesFiona FamousAdriana EneNo ratings yet

- Contribution of PHD ProposalDocument2 pagesContribution of PHD ProposalAnirban BanikNo ratings yet

- Proposal On Comparative Study On TVS and HondaDocument7 pagesProposal On Comparative Study On TVS and HondaSatish KumarNo ratings yet

- READINGDocument16 pagesREADINGRonalyn Tulabot - PasamaneroNo ratings yet

- 6QQMN969 Module OutlineDocument4 pages6QQMN969 Module OutlineyuvrajwilsonNo ratings yet

- Happy Orere-Amadu 7&17 Professional CVDocument4 pagesHappy Orere-Amadu 7&17 Professional CVapi-284326863No ratings yet

- English PresentationDocument4 pagesEnglish PresentationEmptygal Ling YamNo ratings yet

- ACCT3014 Lecture01 s12013Document40 pagesACCT3014 Lecture01 s12013thomashong313No ratings yet

- Application For A Social Security Card Applying For A Social Security Card Is Free!Document5 pagesApplication For A Social Security Card Applying For A Social Security Card Is Free!Edward McNattNo ratings yet

- Assessment of Critical Success Factors For Construction Projects in PakistanDocument13 pagesAssessment of Critical Success Factors For Construction Projects in PakistanAbdul Qayoom Memon100% (1)

- UCPB Vs Secretary of Justice, GR 209601, Jan. 12, 2021Document11 pagesUCPB Vs Secretary of Justice, GR 209601, Jan. 12, 2021Mikee ClamorNo ratings yet

- United States v. Troy Stephens, 7 F.3d 285, 2d Cir. (1993)Document8 pagesUnited States v. Troy Stephens, 7 F.3d 285, 2d Cir. (1993)Scribd Government DocsNo ratings yet

- Rizal Report - 19TH CenturyDocument25 pagesRizal Report - 19TH CenturyNamja PyosiNo ratings yet

- International Relations Dissertation TopicsDocument5 pagesInternational Relations Dissertation TopicsPaySomeoneToWriteYourPaperHighPoint100% (1)

- Tools Surveilans Hais Pencegahan & Pengendalian Infeksi 2021Document127 pagesTools Surveilans Hais Pencegahan & Pengendalian Infeksi 2021Yohana AnjaNo ratings yet

- Ibps Po Prelims Day - 36 e 170313469722Document41 pagesIbps Po Prelims Day - 36 e 170313469722chowdhuryarpita2No ratings yet

- Effect of Audit Findings and Audit RecommendationDocument25 pagesEffect of Audit Findings and Audit RecommendationDwi Puspita SariNo ratings yet

- Lesson Plan FoodDocument3 pagesLesson Plan FoodNur Aliyah Abdul RazakNo ratings yet