Professional Documents

Culture Documents

2.8c Risk Assessment - 007 Excavation Work Using Heavy Equipment Rev. July 2019

Uploaded by

smn.ussharOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2.8c Risk Assessment - 007 Excavation Work Using Heavy Equipment Rev. July 2019

Uploaded by

smn.ussharCopyright:

Available Formats

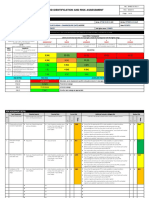

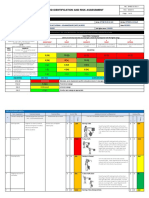

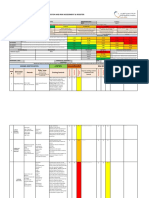

RISK ASSESSMENT AND ANALYSIS

SEVERITY / CONSEQUENCE (Impact/Hazard Effect) (Where an event has more than one ' Loss Type ', choose the ' Consequence' with the highest rating)

Loss Type Additional "Loss Types" may exist for an

event: Identify & rate accordingly (1) Insignificant (2) Minor (3) Moderate (4) Major (5) Catastrophic

Single Fatality or Loss of Quality of Life / Irreversible impact

(S/H) Harm to People (Safety/Health) First Aid Case/Exposure to Minor Health Risk Medical Treatment Case/Exposure to Major Health Risk Loss Time Injury / Reversible Impact on Health on Health Multiple Fatalities / Impact on health Ultimately Fatal

Material Environment harm (RST) Serious environmental harm

(EI) Environmental Impact Minimal environment harm incident with workplace Material Environment harm (RST) incident (RMT) Major environmental incident (RLT) Major environmental harm – Incident Irreversible

(BI/MD) Business Interruption / Material / Fire No disruption to operation / 1000 SR to Less than 10k SR Brief Disruption to Operation / 10k SR to Less Than 100k SR Partial Shutdown/100k SR to Less than 1M SR Partial Loss of Operation/1M SR to Less than10M SR Substantial or Total Loss of Operation / 10M SR and more

Damage & Other Consequential Losses

LIKELIHOOD Examples (Consider Near-Hits as well as actual events) RISK RATING / PROFILE

The unwanted event has occurred frequently : Occurs in order of (1) or more per year & is likely to

(5) ALMOST CERTAIN reoccur within 1 year 5 (L) 10 (M) 15 (H) 20 (Ex) 25 (Ex)

The unwanted event has occurred infrequently : Occurs in order of less than once per year & is

(4) LIKELY likely to reoccur within 5 yrs. 4 (L) 8 (M) 12 (H) 16 (Ex) 20 (Ex)

(3) POSSIBLE The unwanted event has occurred in the business at some time: or could happen within 10 years. 3 (L) 6 (L) 9 (M) 12 (H) 15 (H)

(2) UNLIKELY The unwanted event has occurred in the business at some time: or could happen within 20 years. 2 (L) 4 (L) 6 (L) 8 (M) 10 (M)

The unwanted event has never known to occur in the business or it is highly unlikely to occur

(1) RARE within 20 years. 1 (L) 2 (L) 3 (L) 4 (L) 5 (L)

Stop operation and review controls - Eliminate, Proactively manage & implement specific Actively manage & monitor – Additional Risk acceptable – Monitor & manage as

Project Name : DD-2021-170 – Bujairi Public Realm Wayfinding (Darriyah Riyadh) GUIDELINES FOR RISK MATRIX avoid risk & implement high priority action plans controls/action plans-Review after 7 days controls is advised & review after 30 days appropriate with frequent review

Contract No. : RISK RATING 16 To 25 12 To 15 8 To 10 1 To 6

RA Number: 01:رقم تقييم المخاطر RISK LEVEL (Ex) - Extreme (H) - High (M) - Medium (L) - Low

RA TEAM (NAMES) DESIGNATION SIGNATURES WORKPLACE / TASK / ACTIVITY / PROCESS NAME: DEPARMENT / AREA: Civil

1. R.S.REDDY Safety Engineer DATE:20/12/2023 :

2. Mr. DEBASISH MONDAL Site Manager NEXT REVIEW DATE: 20/12/2024:

EXCAVATION WORK/ Foundation Installation

3. Mr. MANOJ KUMAR MISHRA Operation Manager APPROVED BY MANAGER / SUPERVISOR: MANOJ KUMAR MISHRA

4. SIGNATURE:

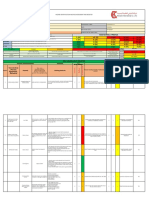

RISK

HAZARD IDENTIFICATION CONTROL ASSESSMENT RISK REDUCTION ACTION PLAN

Consequence

Consequence

Risk Issue

Risk Ranking

Likelihood

Likelihood

(Possible Incident) (What can go wrong) (Improve Existing Controls/ Implement Follow up By Whom (Name) & By

Ranking

Workplace/ Activity/ Process/ Hazards Existing Controls Controls

Item

Equipment/ materials (Accident/ Ill health to person, fire or new controls) When (Date) Implemented (Yes

/ No)

property loss)

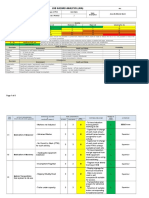

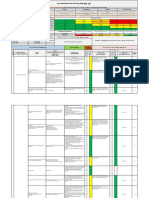

• Permit to Work shall be obtained as a pre- • Permit Receiver shall be trained and

requisite to perform work authorized by the Manager to receive a

• Work shall not be started until duly approved Permit to Work

• Accident resulting serious injury or death to Permit to Work is available at site and that Safety ●Permit Receiver shall be responsible to

Toolbox meeting was conducted 3 2 6 oversee for the safety of all workers under 1 2 2 Supervisor/Engineers/Workers YES

worker

his Permit to Work

• Work shall not proceed without the presence of

approved Permit to Work with the Permit Receiver

• Unathorized work to be performed within overseeing the activity

a defined location and boundary ● A safe work practice shall be implemented to • All workers attending the toolbox meeting

reduce the possibilities of accident / incident shall sign on the attendance sheet attached

to the specific Permit to Work

●Permit Receiver and Permit Issuer shall visit

• Significant property and appurtenances together at the site to ensure that workplace 3 2 1 2 Supervisor/Engineers/Workers YES

damage hazards are adequately identified and mitigating

measure shall be established

● Permit to Work shall be displayed at the ● All workers shall attend the toolbox

worksite meeting on a daily basis conducted by the

● Permit Receiver shall not leave the area for the Supervising Engineer, Foreman and Permit

• Loss of production whole duration of work

2 2 4 Receiver 0 Supervisor/Engineers/Workers YES

1 Obtain Permit to Work

• Uncontrolled personnel entering a

restricted location

●Permit Receiver shall account all workers under

his Permit to Work before the start of work

• Significant cost due to damages

● Manager, Supervisor, Foreman and all workers ●

shall adhere to all requirements set forth in the ●

Permit to Work, Risk Assessment, Method

• Unidentified hazards with unplanned Statement, Job Safety Procedure and other

• Governmental violation relevant safety practices and standards 0 0

safety mitigating measures

1 of Rev. 2 (08 - April - 2019) Project Business Unit

● Site Manager, Supervising Engineer, Foreman ●

shall designate a Permit Receiver competent ●

enough to take responsibility in securing the

• Inadequate coordination and area control Permit to Work

• Environmental complaint 0 0

protocol

• Obtain a valid wok permit • Ensure that Tool Box Talk is conducted

• Ensure that all workers undergo safety induction daily by the Supervisor and Foreman

that discuss safety policies and standards of • Safety trainings must be conducted

• Lack of safety awareness and knowledge • Engage in accident resulting injury to company and Saudi Electricity Company periodically as work requires

for the job personnel due to lack of safety awareness • Conduct Tool box talk and discuss safe work

procedure, RA, and JSP prior to the start of work. 3 2 6 1 2 2 Supervisor/Engineers/Workers YES

• Ensure that all workers are provided with • Close supervision is required. Supervisor

required mandatory PPEs such as: Helmet (ANSI and foreman must be present at site.

Z89.1, CE EN397), Safety Glass, Safety Shoes, Cover • Ensure presence of safety personnel

• Working without wearing appropriate • Hand injury all, Safety Gloves, Dust Mask • Conduct trainings for PPE as per activity.

• Use hand gloves for hand protection 3 2 6 1 2 2 Supervisor/Engineers/Workers YES

Personal Protective Equipment (PPE) • Arm injury

• Only up to 20 kg is allowable for each worker to • Ensure that all personnel are trained in

lift. proper manual handling

• Physical injury from slip / trip / fall • Ensure that access has no obstruction

• Improper manual handling • Back injury • If the load is heavier, buddy system is advised 0 0

• Arm injury

• All operators must be trained and certified by a • Only operators that are certified and

third party trained can operate the equipment at the

• All equipment must be inspected and certified by site

• Failure of equipment may lead to accident or a 3rd party • All drivers and operators shall undergo

• Equipment and operator without 3rd party Defensive Driving Safety Training

incident

certificate • Daily tool box talk must be conducted

3 2 6 1 2 2 Supervisor/Engineers/Workers YES

before any work commences

• Daily equipment inspection must be carried out • Equipment Operator shall be oriented on

by the operator how to use and fill out the checklist properly

• All operators must be trained in conducting • Equipment inspection checklist shall be

• Physical / fatal injury inspection of equipment using the checklist provided and conducted in a daily basis

• All equipment must be inspected regularly using 2 3 6 1 2 2 Supervisor/Engineers/Workers YES

• Damage of property

checklists by the operator

• Lack of knowledge in conducting inspection

using checklist

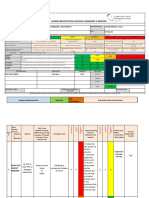

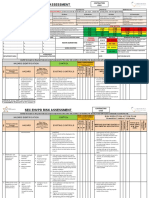

• The equipment to be used shall be in good • Supervising Engineer and Safety Officer

condition shall ensure that inspection was carried out

Mobilization / Inspection of heavy • The equipment must be suitable to perform the thoroughly

2 equipment (excavator and dump • Physical injury from slip, trips and fall task 0 0

trucks) at site

• Establish equipment access and shall be free • Site management plan shall be prepared,

• Vehicular accident from any obstruction approved and implemented to avoid

• Accident resulting Injury to personnel • Designate parking area property damage and personnel accident

0 0

• Struck by moving equipment and vehicle • Designate location for unloading of materials ●

• Designate spotter and flagman to guide all ●

• Property damage of adjacent structure or equipment and personnel movement

0 0

appurtenances

• All heavy equipment and its driver/operator shall • All heavy equipment operator and driver

hold a valid third party certification authorizing shall be oriented with the proper use on how

them on the specified equipment to operate to fill out the daily inspection checklist

• Select and mobilize only good condition • Lease equipment and operator must be

equipment from establish company

• Incompetent equipment operator or driver • Equipment certification and registration must be • All operator and driver must sign the

• Property damage, fatality or injuries during secured and available drivers’ pledge

2 3 6 1 2 2 Supervisor/Engineers/Workers YES

the operation of the equipment. • Operator and driver must have certification and

license

2 of Rev. 2 (08 - April - 2019) Project Business Unit

• All heavy equipment shall be inspected by the • Pre-selection of equipment and operator

authorized operator on a daily basis to ensure that should establish

equipment is in good working condition before

using to the site

• Heavy equipment shall not be used if found any

defects or damage that might affect its safe

• Dilapidated equipment / Damage or • Property damage, fatality or injuries during operation

• Repair of heavy equipment shall not be done on 3 2 6 1 2 2 Supervisor/Engineers/Workers YES

defective condition of equipment the operation of the equipment.

the site. It must be brought to the designated work

shop and only certified mechanic shall make repair

of the equipment

• Implementation of Log-in and Log-out from the • Recording and registry for all equipment,

security post. operator and driver shall be made.

• Unauthorized entry of the equipment to • Equipment / vehicle insurance

• Property damage, fatality or injuries during

the site. 0 0

the operation of the equipment.

• Locate underground services referring to the site • Report accordingly any noticed

• Damage to property map / drawing. underground utility

• Use suitable detectors to check and locate any 3 2 6 1 2 2 Supervisor/Engineers/Workers YES

underground utilities.

• Supervisor and Foreman shall closely monitor to ●

• Damage to underground utlities prior to ensure accurate reading is obtained ●

Checking and verification of any

3 excavation due to failure to perform pre- • Disruption to production 0 0

underground utilities

checks.

• Worker who will perform the verification shall be ●

knowledgeable and trained in using and ●

• Accident resulting in injury to worker interpreting the instrument 0 0

• Operator must be competent, trained, and • Flagman training must be conducted

experienced of the task and must be 3rd party • Acquire as-built drawings of underground

certified holder existing facilities prior to any task to be done

• Trained and competent flagman must be • Close supervision is required

assigned for all heavy equipment operation • Supervisor and foreman must be present in

• Impact by a sudden operation of equipment • Heavy equipment shall not be allowed at any the site.

may cause serious injuries or property damage time without the presence of dedicated flagman • Conduct safety toolbox meeting and

• Toolbox meeting must discuss the safe use of discuss the work procedures prior to start of

equipment to be conducted by Foreman work.

• Struck by excavator moving / operating • Only trained competent operators shall be • Supervising Engineer and Safety Officer

assigned to operate any heavy equipment during 4 2 8 shall attend and ensure that toolbox meeting 1 2 2 Supervisor/Engineers/Workers YES

equipment

mechanical excavation works was conducted and discussed according to

the risk assessment of the activity

• All underground utilities must be identified, • At all stages of the excavation, a competent

marked with a visible warning or relocated, fixed person must supervise the work and all

and secure workers must be given clear instructions on

• Area to be excavated must be scanned for working safely in the excavation.

underground services and utilities • Ensure proper and adequate supervision by

• Conduct test pit. Manual excavation is highly supervisor/ foreman.

required to prevent any damages to any existing • Site safety officer must ensure that all

underground utilities due to machine excavation excavations are provided with necessary

• Permit To Excavate must be issued before work safety requirements as per SEC safety

commences standard.

• Spotter must be assigned to guide the heavy • Close supervision is required

equipment operator specially if underground • Supervisor and foreman must be present in

utility is found the site

• Impact and damage to existing plant / • Hand digging only in the vicinity of underground • Training for excavation works must be

• Presence of plant / underground services services 3 2 6 conducted 1 2 2 Supervisor/Engineers/Workers YES

underground facilities

• Properly monitor when hand digging the vicinity • Tool Box Talk shall be provided to the

of underground services workers prior to the start of work

• Electrical cables adjacent to excavation shall be

isolated by electrician using permit to isolate

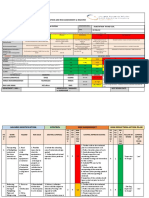

3 of Rev. 2 (08 - April - 2019) Project Business Unit

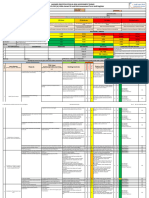

• All underground utilities must be identified, ● • Ensure proper housekeeping to avoid

marked with a visible warning or relocated, fixed unnecessary materials

and secure ●

• Area to be excavated must be scanned for

underground services and utilities

• Conduct test pit. Manual excavation is highly

required to prevent any damages to any existing

underground utilities due to machine excavation

• Permit To Excavate must be issued before work

commences

• Spotter must be assigned to guide the heavy

equipment operator specially if underground

utility is found

• Hand digging only in the vicinity of underground

services

• Properly monitor when hand digging the vicinity

of underground services

• Falling of workers / equipment / tools into • Electrical cables adjacent to excavation shall be

• Unprotected edges of excavation excavation resulting to personnel injury, isolated by electrician using permit to isolate 3 2 6 1 2 2 Supervisor/Engineers/Workers YES

fatality, property damage • Fall prevention barriers (barricades) with signs

shall be erected around excavation at least 1

meter away

• Concrete Jersey barrier installed at a safe

distance from excavation, preventing vehicles from

falling into the excavation. Standard barricading

for UG shall be complied accordingly.

• Wear appropriate PPE – hard hats, safety glasses,

safety mask, safety gloves and safety shoes

• Check the condition of excavation at all times for • Report any signs of cave-in to supervisor.

possibility of collapse or cave in • Excavation training must be conducted

• Excavation walls that are deeper than 1.5 meter prior to start of activity

must be sloped / benched or shored depending on • Hazard awareness and best practices

Perform excavation using heavy the type of materials being excavated relevant to excavation must be conducted.

4 equipment such as skid loader, • Erosion control measures must be considered • Provide hole watcher to monitor the entry

backhoe, Excavator when using dewatering operations & exit of entrant

• Provide temporary sum pit and sub pump to • Practice good housekeeping while working

remove water inside excavation in and around excavations and trenches

• Unstable soil condition (due to type, • If equipment is being used above the trench,

• Cave-in (sudden collapse of soil) 0 0

vibration, and water) then no operatives should be in the trench when

the machine is in use • Stability of

soil must be ensured

• All excavated materials must be a minimum of 1 • Provide Gas Test equipment and conduct

meter away from the edges of excavation or gas test by competent persons if suspected

totally removed from the site. to have a buildup of unknown gas

• Excavation must be properly barricaded • Contact the site area

physically, and DANGER DEEP EXCAVATION signs in advance and agree that access to the

must be provided specific area is acceptable

• Heavy equipment parking must be a minimum of • Follow safe work practices

• Buildup of harmful gases in the excavation • Health hazards (asphyxiation / collapse due 3 meters away from the edges of excavation • Conduct confined space training for the

• Excavations > 4 ft. deep (1.20 m) that may 3 2 6 involved personnel 1 2 2 Supervisor/Engineers/Workers YES

for 1.2 meters confined space to inhalation of hazardous gases)

develop hazardous atmospheres shall be

considered a confined space

4 of Rev. 2 (08 - April - 2019) Project Business Unit

• Use safe access while entering and exiting • Hoses / cables shall be positioned in such a

excavations and trenches way that it will not create obstruction on the

• Each excavation must be provided with proper access and work areas

access and egress • Warning signs and safety barricades shall

• Ladders must be secured when workers are be used whenever a slip, trip or fall hazard

required to work inside the excavation for manual has been identified but cannot be corrected

excavation or removed immediately

• Avoid taking short cuts or jumping in and out of

excavation

• Aisles, stairs, and passageways shall be kept clear

• Materials must not be carried in a manner that

will provide obstruction in the way ahead

• Materials shall be stored in designated areas

• Materials and tools shall be stored away from

exposed edges

• Ensure proper access and egress in the

• Personal injury due to slip and trip hazards excavation

• Poor access and egress from the obstruction of materials on access / • Provide proper illumination or blinker lights

3 2 6 1 2 2 Supervisor/Engineers/Workers YES

egress along the excavation in order to be identified

during night time.

• No tools and equipment shall be stored close to

the edge of excavation.

• Modify work schedules and arrange frequent • Establish a complete heat illness

rest periods with water breaks in shaded area prevention program

• Provide adequate cool water to workers close to • Provide heat stress training, and its

the work area. prevention

• Ensure workers drink at least a pint of

water every hour

• Workers must be advised to drink plenty of

fluids

• Workers must be advised to drink water

more often and even before they feel thirsty

• Working under direct sunlight • Heat exhaustion/ stress 3 2 6 • Workers must avoid beverages that contain 1 2 2 Supervisor/Engineers/Workers YES

alcohol or caffeine.

• Workers must wear light-weight, light-

colored, and loose-fitting clothes

• Use an approved dusk mask (such as 3M, etc.) • Water sprinkling shall be carried out to

• Dust control must be thoroughly done around avoid dust emissions, where necessary

• Exposure to dust the excavation area • Supervisor and foreman must ensure

• Respiratory illness 0 adequate monitoring of activities 0

• Provide trained flagman equipped with green • All heavy equipment operator including

and red flags to control the moving equipment rentals shall attend Defensive Driving

• Serious accident and even death to personnel • There shall be no working personnel inside the Training for the driver

• Struck by moving equipment (such as excavation while excavation and loading of soils is

dump truck, etc.) ongoing 2 3 6 1 2 2 Supervisor/Engineers/Workers YES

• Conduct tool box talk prior start to work.

• Establish safe distance from equipment to the • Equipment must have back-up alarms

edge of excavation

• Concrete Jersey barrier shall be maintained and

• Falling of heavy equipment into the installed at a safe distance from excavation,

• Significant property damage preventing vehicles from falling into the excavation 3 2 6 1 2 2 Supervisor/Engineers/Workers YES

excavation

• Provide adequate shoring with approve shoring • Supervisor and foreman must ensure

Loading of excavated soils to a materials on an excavated area adequate monitoring of activities

5 • Soil cave in and collapse • Physical injury / property damage • Provide complete physical barricades with 2 3 6 1 2 2 Supervisor/Engineers/Workers YES

dump truck

flagman standing outside the barricades

5 of Rev. 2 (08 - April - 2019) Project Business Unit

• All drivers must be trained and have a driving • Proper training must be provided to the

license operator / driver

• Filled dump trucks shall be covered with screen

or equivalent materials to prevent spoils from

spilling on the road while transporting to dump

• Incompetent driver • Disruption to activity and productivity site 2 3 6 1 2 2 Supervisor/Engineers/Workers YES

• Foreman shall ensure that cover is installed

properly

• Use an approved dusk mask (such as 3M, etc.) • Water sprinkling shall be carried out to

• Dust control must be thoroughly done around avoid dust emissions, where necessary

• Respiratory illness the excavation area

• Exposure to dust 0 0

• Provide trained flagman equipped with green

• Struck by moving equipment (such as and red flags to control the movement of

• Vehicular accident resulting to injury or ill equipment.

dump truck, etc)

health to worker or bystander • Suitable traffic management plan shall be

established such as segregation of pedestrian lanes 2 3 6 0 Supervisor/Engineers/Workers YES

from vehicle access ways.

• Slowly dump the soil to minimize the airborne of • Check surrounding for any equipment or

dust materials that might be covered during

• Exposure to Dust • Ill health to worker due to inhalation of dust 3 2 6 dumping of excavated soil 1 2 2 Supervisor/Engineers/Workers YES

• Driver shall follow instruction from the foreman • Driver shall be trained and follow defensive

Shifting and offloading of excavated • Reckless driving driving technique

6 • Significant damage to property 0 0

soils into the designated area

• Filled dump trucks shall be covered with screen • Driver shall follow designated route going

or equivalent materials to prevent spoils from to the dumping area

spilling on the road while transporting to dump

• Vehicular accident resulting to injury or ill site

• Busy traversed road • Foreman shall ensure that cover is installed

2 3 6 1 2 2 Supervisor/Engineers/Workers YES

health to worker or bystander

properly.

• Designated offloading (dump site) shall be • Designated dumping area shall be away

established with suitable demarcation and signs from residential area

posted.

• Populated area • Ill health to worker due to inhalation of dust 2 3 6 1 2 2 Supervisor/Engineers/Workers YES

• Conduct and maintain daily housekeeping ●

• Foreman must designate 1 or 2 persons to ●

• Unwanted materials laid inside and outside maintain good housekeeping.

the excavation area

• Physical injuries from slip, trips and fall 2 0 0

• Maintain daily proper housekeeping ●

• Additional person for housekeeping must be ●

provided if necessary.

• Ladder and hand tools that block in the • Provide designated trash disposal area so

• Physical injuries from slip, trips and fall 0 0

walkway anybody can perform housekeeping

• Manual handling can lead to musculoskeletal • Facilitate training for manual handling.

• Manual handling disorder • Observe proper posture during manual lifting,

pushing, pulling, etc. 2 3 6 0 Supervisor/Engineers/Workers YES

Housekeeping, Clearing the area

with all used materials, tools and

7 equipment and brought to the

designated storage and disposal • Provide storage box for cables • • Daily inventory of the equipment •

area Labeling of storage box (good items, scrap / Training / awareness regarding the

• Materials lying on the ground • Property damage 3 2 6 1 2 2 Supervisor/Engineers/Workers YES

damage items, by capacity, etc.) segregation of waste

• Immediate disposal or sending the damage one

•toRemove

the storeallkeeper

unwanted / protruding materials / • Good housekeeping at the site

object at the site • Daily toolbox meeting

• Protruding object / materials at the site • Accident resulting injury to worker 0 0

• Provision of standby fire extinguisher • Records and registry for fire extinguisher

• Periodical inspection and / or color coding for • Records /

fire extinguisher registry for the quantity of waste disposed

• Provision of waste skip in the strategic location

• Uncollected / scattered rubbish • Fire at the site with marking 2 3 6 1 2 2 Supervisor/Engineers/Workers YES

• Provision of color coded waste bins at the site

6 of Rev. 2 (08 - April - 2019) Project Business Unit

• Permit Receiver shall ensure that housekeeping

• Significant property and appurtenances in done before, during and after the work

damage • Electrical equipment shall be properly secured,

• Unsecured electrical equipment, energized distribution board closed and padlocked

equipment 2 2 4 0 Supervisor/Engineers/Workers YES

• All waste materials generated from the work • Supervising Engineer and Foreman shall

shall be disposed properly and shall not be left adhere to the proper housekeeping and

• Undisposed waste materials • Governmental violation unattended at the worksite 2 3 6 storage of materials at the designated 1 2 2 Supervisor/Engineers/Workers YES

location

• Permit Receiver shall account all worker under ●

his Permit to Work and ensure all have signed out ●

• Accident resulting serious injury or death to on the attendance sheet and clear of the area

• Unaccounted workers 2 3 6 0 Supervisor/Engineers/Workers YES

8 Closing of Permit to Work worker

• Site Manager shall be responsible on the ●

effective implementation of the Permit to Work ●

• Inadequate communication • Loss of production 2 2 4 0 Supervisor/Engineers/Workers YES

• All materials used at the site such as chemicals, ●

flammable and combustible materials shall be ●

• Poor storage of chemical, flammable and stored at the designated storage at the end of

• Environmental complaint 0 0

combustible materials and etc. each day

• Permit Issuer shall visit the work location to • Mobile equipment shall properly parked on

verify good housekeeping was conducted before a designated equipment laydown

• Unattended unsafe condition • Significant cost due to damages closing the Permit to Work 2 2 4 1 2 2 Supervisor/Engineers/Workers YES

● 0 ● 0

●

● ●

●

0 0

●

● ●

●

0 0

● ●

7 of Rev. 2 (08 - April - 2019) Project Business Unit

RA Prepared by : RA Accepted by : RA Approved by SEC / Safety Rep: RA Aprroved by SEC-HV&EHVPD:

Name & Sign Name & Sign Name & Sign Name & Sign

Desgination Desgination Desgination Desgination

Date Date Date Date

You might also like

- 31.0.11 ALR - Temporary Electrical InstallationDocument3 pages31.0.11 ALR - Temporary Electrical InstallationGerritNo ratings yet

- UG RA 007 - Asphalt Cutting Using Roto MillDocument5 pagesUG RA 007 - Asphalt Cutting Using Roto MillshamshuddinNo ratings yet

- Job Risk Asessment. Excavation 8-6-22Document3 pagesJob Risk Asessment. Excavation 8-6-22Mohammed Ali Qazi100% (1)

- Excavation Risk AssessmentDocument3 pagesExcavation Risk Assessmentkhalef100% (1)

- Insignificant (2) Minor (3) Moderate (4) Major (5) CatastrophicDocument6 pagesInsignificant (2) Minor (3) Moderate (4) Major (5) Catastrophicabhinav dj50% (2)

- Job Hazard Analysis (Jha)Document8 pagesJob Hazard Analysis (Jha)Selamat NdtNo ratings yet

- 31.0.10 LLA - Manual HandlingDocument4 pages31.0.10 LLA - Manual HandlingGerritNo ratings yet

- 02-F02 HIRA-Hazard ID and Risk Assessment Form and RegisterDocument5 pages02-F02 HIRA-Hazard ID and Risk Assessment Form and Registershaibaz chafekarNo ratings yet

- 2.8c Risk Assessment - 005 Light Materials and Equipment Loading - Unloading Rev. July 2019Document9 pages2.8c Risk Assessment - 005 Light Materials and Equipment Loading - Unloading Rev. July 2019Wasim KhanNo ratings yet

- Ra FormDocument5 pagesRa FormEngrHazrat MaazNo ratings yet

- UG RA 009 - Light Materials and Equipment Loading and UnloadingDocument6 pagesUG RA 009 - Light Materials and Equipment Loading and Unloadingshamshuddin100% (1)

- 2.8c Risk Assessment - 023 Scaffolding Erection, Dismantling, Modification Rev. July 2019Document9 pages2.8c Risk Assessment - 023 Scaffolding Erection, Dismantling, Modification Rev. July 2019Shah MuzzamilNo ratings yet

- Shutdown - Ra - RiyadhDocument4 pagesShutdown - Ra - RiyadhRais BurondkarNo ratings yet

- Ra - Riyadh ProjectDocument13 pagesRa - Riyadh ProjectRais BurondkarNo ratings yet

- UG RA 008 - Asphalt Cutting by Using Concrete BreakingDocument5 pagesUG RA 008 - Asphalt Cutting by Using Concrete BreakingshamshuddinNo ratings yet

- Atp 45 (D) PDFDocument450 pagesAtp 45 (D) PDFKerry O'Connell0% (1)

- UG RA 001 - Mobilization and Preparation of Site OfficesDocument5 pagesUG RA 001 - Mobilization and Preparation of Site Officesshamshuddin100% (1)

- UG RA 006 - Installation of Road BarricadesDocument4 pagesUG RA 006 - Installation of Road BarricadesshamshuddinNo ratings yet

- 31.0.12 ALR - Traffic Control by FlagmanDocument3 pages31.0.12 ALR - Traffic Control by FlagmanGerrit100% (1)

- OHS-PR-09-03-F02 (A) HIRA-Hazard ID and Risk Assessment Form and RegisterDocument8 pagesOHS-PR-09-03-F02 (A) HIRA-Hazard ID and Risk Assessment Form and RegisterShafie ZubierNo ratings yet

- 31.0.9 ALR - Loading & Off-Loading TruckDocument5 pages31.0.9 ALR - Loading & Off-Loading TruckGerrit100% (1)

- UntitledDocument6 pagesUntitledshaibaz chafekarNo ratings yet

- 2.8c Risk Assessment - 007 Excavation Work Using Heavy Equipment Rev. HSE AsadDocument9 pages2.8c Risk Assessment - 007 Excavation Work Using Heavy Equipment Rev. HSE AsadAsad Raza100% (1)

- Ra - Traning CeneterDocument12 pagesRa - Traning CeneterRais BurondkarNo ratings yet

- OHS-PR-09-03-F02 RISK ASSESSMENT For INSTALLATION OF WALL MOUNTED JIB CRANEDocument21 pagesOHS-PR-09-03-F02 RISK ASSESSMENT For INSTALLATION OF WALL MOUNTED JIB CRANEmohammed tofiqNo ratings yet

- 2.8c Risk Assessment - 074 Construction of Substation Floor, Wall, Stairs by Casting in Place Rev. July 2019Document7 pages2.8c Risk Assessment - 074 Construction of Substation Floor, Wall, Stairs by Casting in Place Rev. July 2019kamranshamoo1No ratings yet

- Fall Protection Rescue PlanDocument4 pagesFall Protection Rescue PlansimoneNo ratings yet

- UG RA 004 - Test Pit Manual ExcavationDocument5 pagesUG RA 004 - Test Pit Manual ExcavationshamshuddinNo ratings yet

- UG RA 003 - Test Pit Markings and Asphalt CuttingDocument6 pagesUG RA 003 - Test Pit Markings and Asphalt CuttingshamshuddinNo ratings yet

- Risk Assessment For Ceramic & Porcelain Tile WorksDocument6 pagesRisk Assessment For Ceramic & Porcelain Tile WorksFaizan Tanveer100% (1)

- Risk Assessment - Concrete PouringDocument6 pagesRisk Assessment - Concrete Pouringabdullah ashrafNo ratings yet

- Risk Assessment - Hot WorkDocument6 pagesRisk Assessment - Hot Workabdullah ashrafNo ratings yet

- Baseline Risk AssessmentDocument6 pagesBaseline Risk AssessmentPHUMZILENo ratings yet

- HVAC Risk AssesmentDocument8 pagesHVAC Risk Assesmentaaktgt MepNo ratings yet

- #27-Ra For Concrete Block Mesonry WorkDocument5 pages#27-Ra For Concrete Block Mesonry WorkPandiaraj VNo ratings yet

- UG RA 005 - Thermal Integrity and Resistivity TestingDocument6 pagesUG RA 005 - Thermal Integrity and Resistivity TestingshamshuddinNo ratings yet

- Circular Saw-Ra 015Document4 pagesCircular Saw-Ra 015Azhar MehamoodNo ratings yet

- Sample of JHA - Roofing Top Installation Rev 2Document5 pagesSample of JHA - Roofing Top Installation Rev 2vajiravel407No ratings yet

- RA - Foundation (Formwork & Reinforcement)Document7 pagesRA - Foundation (Formwork & Reinforcement)abhinav djNo ratings yet

- Risk Assessment - Foundation and Ground Works Concrete PouringDocument7 pagesRisk Assessment - Foundation and Ground Works Concrete Pouringabdullah ashrafNo ratings yet

- RA - Foundation (Formwork & Reinforcement)Document8 pagesRA - Foundation (Formwork & Reinforcement)abhinav djNo ratings yet

- RA - Blinding ConcreteDocument6 pagesRA - Blinding Concreteabhinav djNo ratings yet

- UG RA 002 - Route SurveyingDocument4 pagesUG RA 002 - Route SurveyingshamshuddinNo ratings yet

- Risk Assessment For Coring WorksDocument5 pagesRisk Assessment For Coring WorksFaizan Tanveer100% (1)

- Preliminary Hazard AnalysisDocument26 pagesPreliminary Hazard AnalysisShahadat HossainNo ratings yet

- OHS-PR-09-03-F02 HIRA - 002 Marking and Layout of Site Being Surveyed Rev. 2021Document11 pagesOHS-PR-09-03-F02 HIRA - 002 Marking and Layout of Site Being Surveyed Rev. 2021MuhammadAsimMuneerNo ratings yet

- UntitledDocument8 pagesUntitledshaibaz chafekarNo ratings yet

- OHS-PR-09-03-F02 HIRA - 003 Temporary Perimeter Fencing Rev. 2021Document7 pagesOHS-PR-09-03-F02 HIRA - 003 Temporary Perimeter Fencing Rev. 2021MuhammadAsimMuneerNo ratings yet

- Ansi C29.13Document24 pagesAnsi C29.13Carla Parra MedinaNo ratings yet

- Poster Machine SafetyDocument1 pagePoster Machine SafetyAfonso BuenoNo ratings yet

- RA - Excavation, Backfilling and CompactionDocument10 pagesRA - Excavation, Backfilling and Compactionabhinav dj80% (5)

- Unit I: CODES AND REGULATIONS - : Lesson 1: The National Building Code of The PhilippinesDocument27 pagesUnit I: CODES AND REGULATIONS - : Lesson 1: The National Building Code of The PhilippinesStevenNo ratings yet

- OHS-PR-09-03-F02 HIRA - 001 Mobilization and Preparation of Site Offices Rev. 2021Document21 pagesOHS-PR-09-03-F02 HIRA - 001 Mobilization and Preparation of Site Offices Rev. 2021Jaafar LagayanNo ratings yet

- Project ReportDocument63 pagesProject ReportLuit Baro100% (2)

- Two Post LiftDocument53 pagesTwo Post LiftBasit WaniNo ratings yet

- Ocd Earthquake Drill Evaluation FormDocument1 pageOcd Earthquake Drill Evaluation FormLGU Guimbal100% (1)

- 2.8c Risk Assessment - 003 Temporary Perimeter Fencing Rev. July 2019Document6 pages2.8c Risk Assessment - 003 Temporary Perimeter Fencing Rev. July 2019Shah MuzzamilNo ratings yet

- OHS-PR-02-03-F02 HIRA-Hazard ID and Risk Assessment Form and RegisterDocument12 pagesOHS-PR-02-03-F02 HIRA-Hazard ID and Risk Assessment Form and RegisterhamzahayatNo ratings yet

- 03-F02 HIRA-Hazard ID and Risk Assessment Form and RegisterDocument8 pages03-F02 HIRA-Hazard ID and Risk Assessment Form and RegisterSn AhsanNo ratings yet

- Risk Assessment - Backfilling and CompactionDocument6 pagesRisk Assessment - Backfilling and Compactionabdullah ashrafNo ratings yet

- 06 ASH Handling System (ASH Unloading Manually)Document9 pages06 ASH Handling System (ASH Unloading Manually)Shah MuzzamilNo ratings yet

- Ra For Cable Testing #58Document16 pagesRa For Cable Testing #58shaibaz chafekarNo ratings yet

- 2.8c Risk Assessment - 001 Site Survey of Land Rev. July 2019Document7 pages2.8c Risk Assessment - 001 Site Survey of Land Rev. July 2019sadafnoor997No ratings yet

- 03-F02 HIRA-Hazard ID and Risk Assessment Form and RegisterDocument2 pages03-F02 HIRA-Hazard ID and Risk Assessment Form and RegisterWAQAS AHMEDNo ratings yet

- UntitledDocument8 pagesUntitledshaibaz chafekarNo ratings yet

- Hazard Identification and Risk Assessment and RegisterDocument19 pagesHazard Identification and Risk Assessment and Registershaibaz chafekarNo ratings yet

- Insignificant (2) Minor (3) Moderate (4) Major (5) CatastrophicDocument6 pagesInsignificant (2) Minor (3) Moderate (4) Major (5) CatastrophicmuradNo ratings yet

- Dsti. 0SMDocument1 pageDsti. 0SMStephenNo ratings yet

- 10th RA Minarul - R0Document45 pages10th RA Minarul - R0smn.ussharNo ratings yet

- T12 S50 32 01Document1 pageT12 S50 32 01smn.ussharNo ratings yet

- SMN All Activeties Work Project of Final HIRADocument34 pagesSMN All Activeties Work Project of Final HIRAsmn.ussharNo ratings yet

- 19th RA Seikh BachchuDocument6 pages19th RA Seikh Bachchusmn.ussharNo ratings yet

- 4th RA S.K. Construction (Pintu)Document2 pages4th RA S.K. Construction (Pintu)smn.ussharNo ratings yet

- MTC IMS FO 14A Monthly Safety ReportDocument7 pagesMTC IMS FO 14A Monthly Safety Reportsmn.ussharNo ratings yet

- T12 S50 32 03Document1 pageT12 S50 32 03smn.ussharNo ratings yet

- T12 S20 32 01Document1 pageT12 S20 32 01smn.ussharNo ratings yet

- 3rd RA Bill - Mainul Hk.Document3 pages3rd RA Bill - Mainul Hk.smn.ussharNo ratings yet

- Smn-Fy 23-24Document17 pagesSmn-Fy 23-24smn.ussharNo ratings yet

- SCMQ - 3122Document9 pagesSCMQ - 3122smn.ussharNo ratings yet

- 18th RA Seikh BachchuDocument10 pages18th RA Seikh Bachchusmn.ussharNo ratings yet

- Nirman Concrete Ledger (Usshar)Document23 pagesNirman Concrete Ledger (Usshar)smn.ussharNo ratings yet

- 6th GST Invoice Birendra DasDocument4 pages6th GST Invoice Birendra Dassmn.ussharNo ratings yet

- SMN MTC-IMS-FO-14A-Monthly-Safety-Report-Xls SMN TATADocument7 pagesSMN MTC-IMS-FO-14A-Monthly-Safety-Report-Xls SMN TATAsmn.ussharNo ratings yet

- SMN Labour Salary (Usshar) November - 23Document3 pagesSMN Labour Salary (Usshar) November - 23smn.ussharNo ratings yet

- 25-02-24 DPRDocument3 pages25-02-24 DPRsmn.ussharNo ratings yet

- 3rd RA of R.A. Enterprise of JCB & DumperDocument2 pages3rd RA of R.A. Enterprise of JCB & Dumpersmn.ussharNo ratings yet

- Quotation Normal RSP 800 Ambuja RealtyDocument2 pagesQuotation Normal RSP 800 Ambuja Realtysmn.ussharNo ratings yet

- Subal Consruction GST Invoice 7Document4 pagesSubal Consruction GST Invoice 7smn.ussharNo ratings yet

- SM Payment Reconsilation 27.11.23 - For As Per SiteDocument36 pagesSM Payment Reconsilation 27.11.23 - For As Per Sitesmn.ussharNo ratings yet

- Blue Star RA7Document4 pagesBlue Star RA7smn.ussharNo ratings yet

- 6th GST INVOICE SUPREMEDocument4 pages6th GST INVOICE SUPREMEsmn.ussharNo ratings yet

- Asbestos Regulations, 2001Document16 pagesAsbestos Regulations, 2001Mufasa_WrightNo ratings yet

- Smart Flex Effector BAL en V3.0Document109 pagesSmart Flex Effector BAL en V3.0Nguyễn HậuNo ratings yet

- Chryso MSDSDocument5 pagesChryso MSDSDileepa DissanayakeNo ratings yet

- Betriebsanl 150556 1431517-ENDocument739 pagesBetriebsanl 150556 1431517-ENcataconstantinNo ratings yet

- Design Calculations of Lightning Protection Systems - Part NineDocument11 pagesDesign Calculations of Lightning Protection Systems - Part NineHansika RajapakshaNo ratings yet

- SECOM 737: User ManualDocument133 pagesSECOM 737: User Manualdinojr2010No ratings yet

- Welding and Cutting Do's and Don'Ts Global EHS DD 004Document6 pagesWelding and Cutting Do's and Don'Ts Global EHS DD 004SYED AHMEDNo ratings yet

- PTW - SB - Module 4Document14 pagesPTW - SB - Module 4Mohd HaroonNo ratings yet

- Tool Box Talk Topic-Workplace Housekeeping & Material StackingDocument2 pagesTool Box Talk Topic-Workplace Housekeeping & Material StackingSameer PatilNo ratings yet

- Isomol 500 Exp V01Document9 pagesIsomol 500 Exp V01Marco OlivoNo ratings yet

- Zeeshan Ahmad - HSE ManagerDocument2 pagesZeeshan Ahmad - HSE Managercdeeky100% (1)

- 24215-S12-01-B, GHS SDS, English, VisiJet M2 Cast, VisiJet M3 CastDocument5 pages24215-S12-01-B, GHS SDS, English, VisiJet M2 Cast, VisiJet M3 CastVijay SaneNo ratings yet

- Tricon Safety Instrumented System (SIL3) : Ensuring Operational Continuity and Managing Operational RisksDocument4 pagesTricon Safety Instrumented System (SIL3) : Ensuring Operational Continuity and Managing Operational RisksROAMEN ENGINEERINGNo ratings yet

- Jurnal Mengenai Alat Pemotong DahanDocument10 pagesJurnal Mengenai Alat Pemotong DahanSyifa AwaliaNo ratings yet

- Feroz Ahmed: Objectives CareerDocument5 pagesFeroz Ahmed: Objectives Careerimran raza82No ratings yet

- SAG - Emergency Medical Services NC II (Amended 2013)Document5 pagesSAG - Emergency Medical Services NC II (Amended 2013)Jaypz DelNo ratings yet

- 0J9943Y12 Rev DDocument36 pages0J9943Y12 Rev DFelipe Téllez HernándezNo ratings yet

- Mechanical Engineering DepartmentDocument20 pagesMechanical Engineering DepartmentAiril AizanNo ratings yet

- ME 317 Basic Occupational, Safety and Health (BOSH) : Based On OSH Standards of DOLEDocument7 pagesME 317 Basic Occupational, Safety and Health (BOSH) : Based On OSH Standards of DOLEAaron Choco De GuzmanNo ratings yet

- Risk Management Chapter 2Document25 pagesRisk Management Chapter 2Nayle aldrinn LuceroNo ratings yet

- 90over100 Quiz 2 Risk ManagementDocument12 pages90over100 Quiz 2 Risk ManagementKenneth EsguerraNo ratings yet