Professional Documents

Culture Documents

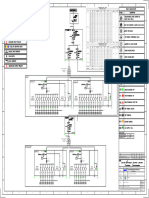

ROQ-546 GTP 7670kVA

Uploaded by

Sumit Tyagi0 ratings0% found this document useful (0 votes)

8 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views3 pagesROQ-546 GTP 7670kVA

Uploaded by

Sumit TyagiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

HAMMOND POWER SOLUTIONS PRIVATE LIMITED

MANUFACTURER'S GUARANTEED TECHNICAL PARTICULARS OF TRANSFORMER

7670kVA , V.RATIO : 11000 / 2 X 800 V,OFTC: 10 % to 15 %

REF: ROQ-546-R1 16-08-2023

Sr No Particulars Unit Offered Details

1.01. General Specifications

1 Service & Application Continuous, Solar Duty Transformer

2 Type Oil filled, Conventional Transformer

3 Location Outdoor

4 Transformer complies to IS 2026 , IS 335

5 Type of Cooling ONAN

6 Type of Oil Mineral Oil

1.02. Rating

1 Rated kVA kVA 7670

2 Rated Voltage of H.V.( Volts )/Current(Amps) Volts & Amp 11000 / 402.56 A

3 Rated voltage of L.V.(Volts)/Current(Amps) Volts & Amp 800 / 2767.67 A OF EACH LV

4 Frequency Hz 50

5 Max. Ambient Temperature °C 50

6 Yearly Weighted Average Ambient Temperature °C 32

7 Max. Temperature rise in oil by thermometer above °C 50 over Max. Ambient of 50

ambient Temperature

8 Max.Temperature rise above ambient temperature °C 55 over Max. Ambient of 50

of winding by resistance method

1.03. Winding Connection Details

1 Winding Material Electrolytic grade Copper

2 Connections

a. H.V. Winding Delta

b. L.V. Winding Star

c. Neutral brought out from tank No

2 Tapings

a. Voltage range + 10% to 15 %

b. No. of positions 10 Steps ( 11 Positions )

c. Step Voltage V 275.0

3 Vector Symbol Dy11y11

1.04. Losses and Performance

*1 Reference Temperature °C 75

2 Total losses at 100% load at rated frequency W 84370 Watts ( Max )

a) Noload losses at rated voltage W 7670 Watts ( Max )

b) Load losses at Normal Tap. W 76700 Watts ( Max )

3 Percentage Impedance at Normal tap % 8 % ( +Ve Tol. )

PREPARED BY : SRJ CHECKED BY : MSH APPROVED BY : RM

Page 1 of 3

4 No Load Current Approx % 1.0% of Full load current

5 Regulation at full load at u.p.f % 1.31

6 Efficiency u.p.f. 0.8 p.f.

a. 100% Full Load % 98.91 / 98.722 %

b. 75% Full Load % 99.12 / 98.97 %

c. 50% Full Load % 99.3 / 99.18 %

6 Maximum efficiency % 99.37

7 Load at which Max.efficiency occurs kVA kVA 2425

1.05. Constructional details

1 Terminal Arrangement

a. HV Cable Box

b. LV Cable Box

2 Type of Construction Core

3 Insulation between laminations Carlite

4 Type of joint between core limb and yoke Mitred

5 Type of Winding

a.HV Winding Disc

b.LV Winding Spiral

1.06. Insulation of conductors

a.HV Winding turn Insulation Triple paper covered

b.LV Winding turn Insulation Double paper covered

c.Between HV and LV Winding Oil duct + PC Board cylinder + Oil duct

d.Between LV Winding and core Oil duct + PC Board cylinder

1.07. Test Voltages

1 Impulse (1.2 / 50 micro second wave)

withstand voltage

a. H.V Winding kVp 75

b. L.V Winding kVp 40

c. HV Neutral kVp -

d. LV Neutral kVp 40

2 One minute power Frequency

withstand voltage

a. H.V Winding kVrms 28

b. L.V Winding kVrms 10

c. HV Neutral kVrms -

1.08. Details of Tank and Material

1 Minimum Thickness of side plates mm 5

2 Minimum Thickness of bottom plates mm 6

3 Minimum Thickness of cover plates mm 6

4 Minimum Thickness of radiator (pipes or sheets) mm 1.0 mm

1.09. Weight and Dimensions (Approx.)

1 Net untanking weight Kg 7815

(Core and windings with clamps )

2 Volume of insulating oil L 3848

3 Tank and fittings Kg 7110

4 Total Weight of Transformer Kg 18025

1.10. Parts to be detached for transport Conservator, Bushing & Radiators

1.11. Painting

1 Surface preparation By Grit or sand Blasting

2 Paint type Epoxy

3 Shade 631

4 Thickness for Tank Microns 80 microns

5 Thickness for Radiators Microns 80 microns

1.12. Current transformer

1 HV side Phase / Neutral current transformer -

a. Ratio -

b. Class / Burden -

2 HV side Phase / Neutral current transformer -

a. Ratio -

b. Class / Burden -

2 HV side Phase / Neutral current transformer -

a. Ratio -

b. Class / Burden -

1.13. Tests

As per standard all the Routine tests shall

1 Routine Tests

be carried out at our works

PREPARED BY : SRJ CHECKED BY : MSH APPROVED BY : RM

Page 2 of 3

1.14. Standard Fittings and Accessories

S.No. Description Qty. (Number)

1 Rating and terminal marking plate One

2 OFTC One

RTCC & AVR N.A.

3 Earthing Terminals Two

4 Lifting Lugs (minimum) Four

5 Bi-directional Flat Rollers Four

6 Pressure relief Valve One

7 Oil filling hole with cap One

8 Oil level indicator One

9 Air release device One

10 Drain cum filter valve with blanking plate One

11 Filter valve with blanking plate One

12 Thermometer Pocket Three

13 OTI with A & T contacts One

14 WTI with A & T contacts One

15 MOG with LOLA One

16 Marshalling Box One

17 Conservator with drain plug and Silicagel breather One

1.15. Special features

1 Max. Flux Density in Core @ 100% voltage - 1.7 T

2 Max. Current Density in Winding @ Normal Tap - 3 A/mm²

3 Siite Altitude < 1000 Mtrs

1.16. Notes

QA/MKT/03A/08

PREPARED BY : SRJ CHECKED BY : MSH APPROVED BY : RM

Page 3 of 3

You might also like

- IDMTL Operating Time CalculationDocument10 pagesIDMTL Operating Time Calculationnaveendevi13No ratings yet

- SQL Queries Interview Questions and Answers - Query ExamplesDocument25 pagesSQL Queries Interview Questions and Answers - Query Examplesiveraj67% (9)

- Employee Safety Training Matrix Template ExcelDocument79 pagesEmployee Safety Training Matrix Template Excelشاز إياسNo ratings yet

- Transformer Specification - GTP (25MVA)Document1 pageTransformer Specification - GTP (25MVA)SathishNo ratings yet

- Technical Specificationof IDT Solar ProjectDocument12 pagesTechnical Specificationof IDT Solar ProjectJitendra Pathak100% (1)

- GTP - 28 MVA Transformer (JN 23421) PDFDocument7 pagesGTP - 28 MVA Transformer (JN 23421) PDFPratim DuttaNo ratings yet

- 1600 Kva GTPDocument3 pages1600 Kva GTPBADRI VENKATESHNo ratings yet

- Solar IDT SpecificationsDocument3 pagesSolar IDT SpecificationsVamsi PavuluriNo ratings yet

- GTP 63 Mva - R0 FinalDocument10 pagesGTP 63 Mva - R0 FinalmidhunvarNo ratings yet

- Newnes Circuit Calculations Pocket Book: with Computer ProgramsFrom EverandNewnes Circuit Calculations Pocket Book: with Computer ProgramsNo ratings yet

- Ccie DC Full Scale Labs PDFDocument185 pagesCcie DC Full Scale Labs PDFnaveedrana100% (2)

- Lrs Resistencia Liquid StarterDocument45 pagesLrs Resistencia Liquid StarterQ Llanos HenryNo ratings yet

- 1.a Power TransformerDocument28 pages1.a Power TransformerAnkur SinhaNo ratings yet

- Technical Data Electrical (Rev-0)Document186 pagesTechnical Data Electrical (Rev-0)kattukoluNo ratings yet

- R0 - Seci-Sccl - 90mw-Dwg-Ele-002 - MCR - Building Lighting Layout - As Built - 15.03.2022Document1 pageR0 - Seci-Sccl - 90mw-Dwg-Ele-002 - MCR - Building Lighting Layout - As Built - 15.03.2022Sumit TyagiNo ratings yet

- The Life of DadajiDocument87 pagesThe Life of DadajiMike Magee100% (1)

- PC-1 FORM Revised 2005 Government of Pakistan Planning Commission Pc-1 Form (Social SECTORS)Document18 pagesPC-1 FORM Revised 2005 Government of Pakistan Planning Commission Pc-1 Form (Social SECTORS)Muhammad IlyasNo ratings yet

- Technical Datasheet PDFDocument3 pagesTechnical Datasheet PDFAman SharmaNo ratings yet

- 400 KVA WAPDA Pad Mounted TF Technical SubmittalDocument10 pages400 KVA WAPDA Pad Mounted TF Technical SubmittalCh Saif UllahJuraaNo ratings yet

- Transformer Design (Electrical) WO. No. Guaranteed Technical Particulars Bharat Bijlee Ltd. Transformer DivisionDocument3 pagesTransformer Design (Electrical) WO. No. Guaranteed Technical Particulars Bharat Bijlee Ltd. Transformer Divisionswarupkumarnayak100% (1)

- Applied Statistics in Business and Economics 5th Edition Doane Solutions ManualDocument26 pagesApplied Statistics in Business and Economics 5th Edition Doane Solutions ManualSharonMartinezfdzp100% (44)

- Scope of Works - Exclusions - (Dalmia - Bokaro)Document3 pagesScope of Works - Exclusions - (Dalmia - Bokaro)Sumit TyagiNo ratings yet

- Tech Eq-50Document2 pagesTech Eq-50Mauricio Oropeza CabreraNo ratings yet

- 1 TransformerDocument3 pages1 TransformerSyed Noman AhmedNo ratings yet

- 301 - Acutesun Private Limited, Surat, 800 KVA, 11-0.433 KV Transformer With OLTC As Per IS - 1180 Level-I, 17-02-2023Document5 pages301 - Acutesun Private Limited, Surat, 800 KVA, 11-0.433 KV Transformer With OLTC As Per IS - 1180 Level-I, 17-02-2023Jay DholaNo ratings yet

- Spek TrafoDocument1 pageSpek Trafoedi triyantoNo ratings yet

- 1600KVA GTP & DrawingsDocument8 pages1600KVA GTP & DrawingsDarshit VyasNo ratings yet

- 500KVA Technical Data Sheet INSO 1608 R1Document4 pages500KVA Technical Data Sheet INSO 1608 R1saravananNo ratings yet

- 1967 - Sahaj Solar LTD, Ahmedabad, 4000 KVA, 11-0.800 KV ID OCTC Transformer As Per Is - 1180, 22-03-2024Document8 pages1967 - Sahaj Solar LTD, Ahmedabad, 4000 KVA, 11-0.800 KV ID OCTC Transformer As Per Is - 1180, 22-03-2024kanu bhaiNo ratings yet

- Voltech Manufacturing Company LTD.: Guaranteed Technical ParticularsDocument1 pageVoltech Manufacturing Company LTD.: Guaranteed Technical ParticularsRadhaNo ratings yet

- Call Off Contract No 47 2020Document23 pagesCall Off Contract No 47 2020talalNo ratings yet

- 630 Kva Emmvee GTPDocument3 pages630 Kva Emmvee GTPGurudas SwainNo ratings yet

- Oman Electricity Transmission Co Tender PDFDocument7 pagesOman Electricity Transmission Co Tender PDFHossam AlzubairyNo ratings yet

- GTP of 2mva TransformerDocument10 pagesGTP of 2mva TransformerDarshit VyasNo ratings yet

- Transformer & Cable SpecsDocument297 pagesTransformer & Cable SpecsAulinoNo ratings yet

- Transformer - GTP - IDT FormatDocument16 pagesTransformer - GTP - IDT FormatgohilnarendraNo ratings yet

- Section-7.4 TransformerDocument51 pagesSection-7.4 TransformerBRB CABLENo ratings yet

- Technical Specification: EctionDocument22 pagesTechnical Specification: EctionmlutfimaNo ratings yet

- Data Sheet 630kva 33kv Cu F 90 Ip23Document2 pagesData Sheet 630kva 33kv Cu F 90 Ip23Anshuman PandeyNo ratings yet

- TECHNICAL DATA M326-d13-Rev1 - (2000-33-0.4)Document3 pagesTECHNICAL DATA M326-d13-Rev1 - (2000-33-0.4)Karim RahmaniNo ratings yet

- Duly Filled Technical Datasheet Od 63 KVA Inverter Duty Step Up Tef PDFDocument1 pageDuly Filled Technical Datasheet Od 63 KVA Inverter Duty Step Up Tef PDFkamaleshsNo ratings yet

- Transformer DatasheetDocument4 pagesTransformer DatasheetVasudevan KunjithapathamNo ratings yet

- 630 Kva GTPDocument2 pages630 Kva GTPgovind yadavNo ratings yet

- TTS Maxima 500kVA YNyn6 20kV-0.4kV IEC 60076Document1 pageTTS Maxima 500kVA YNyn6 20kV-0.4kV IEC 60076SetiawanBudiNo ratings yet

- DTR 1000 KvaDocument7 pagesDTR 1000 KvaAbhinav TewariNo ratings yet

- Specification of 33-.63 KV 1.67MVA TransformerDocument8 pagesSpecification of 33-.63 KV 1.67MVA TransformerM Abu SayedNo ratings yet

- Technical Submittal 1000kVA PAECDocument9 pagesTechnical Submittal 1000kVA PAECGhilman HabibNo ratings yet

- Qa0874 2023Document7 pagesQa0874 2023Jaks JaksNo ratings yet

- Technical Specifications: A. General CharacteristicsDocument3 pagesTechnical Specifications: A. General CharacteristicsHendri AskoroNo ratings yet

- 8.490428 A4-L 1.0 enDocument129 pages8.490428 A4-L 1.0 enDuc Nguyen VanNo ratings yet

- 630 KVA Transformer GTP 19-09-2022Document7 pages630 KVA Transformer GTP 19-09-2022SANJIB KUMAR CHHATRIANo ratings yet

- 250kVA - KEDocument1 page250kVA - KEabdullah khanNo ratings yet

- 630 Kva GTP - L-1Document2 pages630 Kva GTP - L-1govind yadavNo ratings yet

- Supply of Cast Resin Transformers 11/0.433 KV, 1000 kVA - 2 NosDocument13 pagesSupply of Cast Resin Transformers 11/0.433 KV, 1000 kVA - 2 NosDarwish MammiNo ratings yet

- DS14051985Document1 pageDS14051985appuNo ratings yet

- Tech Spec 8mvaDocument40 pagesTech Spec 8mvachekurivishnu7No ratings yet

- Nesco Odisha Technical Specification of 8 MVA Power TransformerDocument52 pagesNesco Odisha Technical Specification of 8 MVA Power TransformerMPCZ ASSETMAPPINGNo ratings yet

- UNINDO 100kva PDFDocument2 pagesUNINDO 100kva PDFanjargoklithNo ratings yet

- Pak Elektron Limited Technical Data Sheet of Transformer: SpecificationDocument1 pagePak Elektron Limited Technical Data Sheet of Transformer: SpecificationbilalNo ratings yet

- Technical Data Sheet - 250kva TransformersDocument2 pagesTechnical Data Sheet - 250kva TransformerspavanNo ratings yet

- Technical Specifications: A. General CharacteristicsDocument2 pagesTechnical Specifications: A. General CharacteristicsanjargoklithNo ratings yet

- 4000kVA Technical Submittal IEC76Document7 pages4000kVA Technical Submittal IEC76Bilal KhalidNo ratings yet

- Example 3500 - 1600kVA Oil TX-Liquid Distribution Transformer SpecificationDocument24 pagesExample 3500 - 1600kVA Oil TX-Liquid Distribution Transformer SpecificationSlick72No ratings yet

- Tech Spec 1750kvaDocument6 pagesTech Spec 1750kvatinguloverNo ratings yet

- Technical Spec Travo 630 KVADocument2 pagesTechnical Spec Travo 630 KVAArdi NalNo ratings yet

- STD GSP 1600kva Indoor PDFDocument2 pagesSTD GSP 1600kva Indoor PDFArifSamsulNo ratings yet

- Specification For 1000 KV TransformerDocument1 pageSpecification For 1000 KV TransformerSandeep SoniNo ratings yet

- TDS 630kVA 20kV 400V 50Hz Dyn5 - 1 Cu-CuDocument2 pagesTDS 630kVA 20kV 400V 50Hz Dyn5 - 1 Cu-CuFardi KalumataNo ratings yet

- Comments On Pour Card ChecklistDocument1 pageComments On Pour Card ChecklistSumit TyagiNo ratings yet

- Comments On FQP - CE ME 26.05.23 (Latest)Document17 pagesComments On FQP - CE ME 26.05.23 (Latest)Sumit TyagiNo ratings yet

- Techno-Commercial EPC Proposal - Shri Tirupati Steel Cast LTD - 25 MWP - R2!27!11-2023Document24 pagesTechno-Commercial EPC Proposal - Shri Tirupati Steel Cast LTD - 25 MWP - R2!27!11-2023Sumit TyagiNo ratings yet

- Investigating The Effect of Orientation and Tilt Angle On Bifacial PV Modules On Vertical EastDocument5 pagesInvestigating The Effect of Orientation and Tilt Angle On Bifacial PV Modules On Vertical EastSumit TyagiNo ratings yet

- Overall Ac SLD - SattaurDocument1 pageOverall Ac SLD - SattaurSumit TyagiNo ratings yet

- PV Array Layout - Packing Plant Canteen BuildingDocument1 pagePV Array Layout - Packing Plant Canteen BuildingSumit TyagiNo ratings yet

- PV Module GTP - BokaroDocument1 pagePV Module GTP - BokaroSumit TyagiNo ratings yet

- R00 - Generation Report - Dalmiacement - JCW Bokaro - MPDocument7 pagesR00 - Generation Report - Dalmiacement - JCW Bokaro - MPSumit TyagiNo ratings yet

- Proposed Array Layout - Kia Motor - ApDocument1 pageProposed Array Layout - Kia Motor - ApSumit TyagiNo ratings yet

- 48 N-S MWP SOLAR PlANT - Project - VC0-ReportDocument8 pages48 N-S MWP SOLAR PlANT - Project - VC0-ReportSumit TyagiNo ratings yet

- R0 - Seci-Sccl-Kgm37-Dwg-Civ-001-Mms Foundation Marking Layout - As Built - 14.03.2022-Plot-1Document1 pageR0 - Seci-Sccl-Kgm37-Dwg-Civ-001-Mms Foundation Marking Layout - As Built - 14.03.2022-Plot-1Sumit TyagiNo ratings yet

- 605 N TYPE 55MWp SOLAR PlANT - Project - VC0-ReportDocument9 pages605 N TYPE 55MWp SOLAR PlANT - Project - VC0-ReportSumit TyagiNo ratings yet

- Temp Derating TI en 15Document8 pagesTemp Derating TI en 15Sumit TyagiNo ratings yet

- DissertationDocument134 pagesDissertationAbbas AbbasiNo ratings yet

- Geologic Report Arches NationalDocument9 pagesGeologic Report Arches NationalJacob AndersonNo ratings yet

- PHP - Google Maps - How To Get GPS Coordinates For AddressDocument4 pagesPHP - Google Maps - How To Get GPS Coordinates For AddressAureliano DuarteNo ratings yet

- 15 Steps of Analysing A PoemDocument17 pages15 Steps of Analysing A PoemAthanasioNo ratings yet

- NN IP Guidebook To Alternative CreditDocument140 pagesNN IP Guidebook To Alternative CreditBernardNo ratings yet

- Ol7 SecurityDocument84 pagesOl7 Securityneaman_ahmedNo ratings yet

- Councillor Danny Thorpe: Leader, Royal Borough of GreenwichDocument2 pagesCouncillor Danny Thorpe: Leader, Royal Borough of GreenwichDr-Syed Ali TarekNo ratings yet

- Noli and El FiliDocument2 pagesNoli and El FiliGeramei Vallarta TejadaNo ratings yet

- Grade 10 SAU 1, Term 4Document5 pagesGrade 10 SAU 1, Term 4Aizat SarsenovaNo ratings yet

- Analogy - 10 Page - 01 PDFDocument10 pagesAnalogy - 10 Page - 01 PDFrifathasan13No ratings yet

- Assignment 3: Course Title: ECO101Document4 pagesAssignment 3: Course Title: ECO101Rashik AhmedNo ratings yet

- Biodiversity ReportDocument52 pagesBiodiversity ReportAdrian HudsonNo ratings yet

- Reynald Hernandez: ExperienceDocument2 pagesReynald Hernandez: ExperienceRey HernandezNo ratings yet

- User Manual: Series 7Document44 pagesUser Manual: Series 7Roniel ManjaresNo ratings yet

- 1.1.DeFacto Academy enDocument7 pages1.1.DeFacto Academy enYahya AçafNo ratings yet

- Jess's Heart Is Racing at 100 Miles Per Hour.Document3 pagesJess's Heart Is Racing at 100 Miles Per Hour.vexagon wallowNo ratings yet

- The Human Body: Winston S. Abena, RMT, MD, DPASMAPDocument51 pagesThe Human Body: Winston S. Abena, RMT, MD, DPASMAPMinelli ArgonzaNo ratings yet

- Pps Overview BrochureDocument15 pagesPps Overview BrochureizzybjNo ratings yet

- Msds 2342Document5 pagesMsds 2342Gabo TellezNo ratings yet

- The Dedicated - A Biography of NiveditaDocument384 pagesThe Dedicated - A Biography of NiveditaEstudante da Vedanta100% (2)

- QP English Viii 201920Document14 pagesQP English Viii 201920Srijan ChaudharyNo ratings yet

- IPS e El 110Document105 pagesIPS e El 110alinaghibNo ratings yet

- Garmin GNC 250xl Gps 150xlDocument2 pagesGarmin GNC 250xl Gps 150xltordo22No ratings yet

- MGW Health CheckDocument2 pagesMGW Health Checkkaramdo0% (1)