Professional Documents

Culture Documents

WPS & PQR

Uploaded by

Muhammad AwaisCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS & PQR

Uploaded by

Muhammad AwaisCopyright:

Available Formats

Assignment I

Submitted by:

Muhammad Awais

17-MME-S2-316

Submitted to:

Dr. Kamran

Subject:

Welding and Joining Processes

Department of Metallurgy & Materials Engineering

University of the Punjab

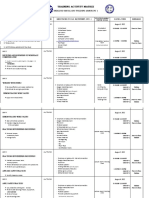

WPS

WPS no.

Welding Procedure Specification Rev: 00

WPS for Martensitic steel

Applicable Code: ASME SEC IX Welding process: MIG

Joint Type

Joint Signal bavel groove

Backing NO .

(Yes/No)

Backing type N/A

Single bevel Branch: 70 0-750± 2.50

Position

Position 3G/All position

Weld progression NILL

Base Metal

Grade ASTM ASTM C645 Thickness 10mm

Base metal Qualified P.No.: 8 or Equivalent, ASTM A312 Gr.304 or Equivalent

Filler Material

Electrode Consumable electrode Spec. No. (SFA) SFA - 5.19

Electrode Flux (Class) NA AWS No. (Class) ERA70S6

Flux Trade Name NA F.No./ A.No. 6/1

Consumable Insert NA Size of Filler Metals 10mm

Welding Parameters

PREHEAT(QW-406) POST WELD HEAT TREATMENT(QW-407)

Preheat Temperature Ambient Heating Rate N/A

(Min.)

Min Inter-pass 250 degree Celsius Holding Temperature Range N/A

Temperature

Preheat Maintenance Holding Time Range N/A

NO Cooling Rate N/A

(Yes/No)

Percentage and composition

GAS (QW-408):

Gas(es) Composition Flow Rate

Shielding Argon and carbon dioxide 90% +10% 10 – 14LPS

Trailing N/A N/A N/A

Backing N/A N/A N/A

PURGING up to hot NILL

pass

Electrical Parameters

Current AC or DC: DC Polarity: DCEN Ampere Range: 160-220 A Voltage Range: 20-40 Volts

Tungsten Electrode Size and Type NILL

Mode of Metal transfer for MIG SPRAY ARC

Electrode/Wire feed speed range N/A

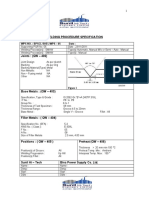

PQR

WPS no.

Procedure qualification Record Rev: 00

WPS for Martensitic steel

Applicable Code: ASME SEC IX Welding process: MIG

Joint Type

Joint Signal bavel groove

Backing (Yes/No) NO .

Backing type N/A

Single bevel Branch: 70 0-750± 2.50

Position

Position 3G/All position

Weld progression NILL

Base Metal

Grade ASTM ASTM C645 Thickness 10mm

Base metal Qualified P.No.: 8 or Equivalent, ASTM A312 Gr.304 or Equivalent

Filler Material

Electrode Consumable electrode Spec. No. (SFA) SFA - 5.19

Electrode Flux (Class) NA AWS No. (Class) ERA70S6

Flux Trade Name NA F.No./ A.No. 6/1

Consumable Insert NA Size of Filler Metals 10mm

Welding Parameters

PREHEAT(QW-406) POST WELD HEAT TREATMENT(QW-407)

Preheat Temperature (Min.) Ambient Heating Rate N/A

Min Inter-pass Temperature 250 degree Celsius Holding Temperature Range N/A

Preheat Maintenance Holding Time Range N/A

NO Cooling Rate N/A

(Yes/No)

Percentage and composition

GAS (QW-408):

Gas(es) Composition Flow Rate

Shielding Argon and carbon dioxide 90% +10% 10 – 14LPS

Trailing N/A N/A N/A

Backing N/A N/A N/A

PURGING up to hot pass NILL

Electrical Parameters

Current AC or DC: DC Polarity: DCEN Ampere Range: 160-220 A Voltage Range: 20-40 Volts

Tungsten Electrode Size and Type NILL

Mode of Metal transfer for MIG SPRAY ARC

Electrode/Wire feed speed range N/A

TEST RESULTS

VISUAL TEST RESULTS

TENSILE TESTS

Failure

Type and

Results Location

Specimen Yield Yield Tensile Tensile

No. Width Thickness Area Load Strength Load Strength

GUIDED BEND TESTS

Type and Figure Number Results

WELDER’S NAME: ID or SS No.

TESTS CONDUCTED BY: LAB TEST No.

We the undersigned certify that the statements in this record are correct and that the test welds were

prepared, welded, and tested in accordance with the requirements of AWS D18.3.

MANUFACTURER OR CONTRACTOR

DATE BY

Please Print Signature

You might also like

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- Inspection Requirements ASME VIII DIV 1 1673549276Document39 pagesInspection Requirements ASME VIII DIV 1 1673549276Mat Pustjens100% (1)

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- Blade2008 11Document108 pagesBlade2008 11fabioboogNo ratings yet

- Piping WpsDocument37 pagesPiping WpsZulfokar FahdawiNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (2)

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Metals Bill for CMA-CGM Headquarters ConstructionDocument4 pagesMetals Bill for CMA-CGM Headquarters ConstructionsobhiNo ratings yet

- WPS 6G CS Pipe CorrectDocument4 pagesWPS 6G CS Pipe CorrectAla ReguiiNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Welding Procedure Specification for Vertical Storage TanksDocument6 pagesWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghNo ratings yet

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- Preliminary WPS for 12.7mm SMAW WeldingDocument3 pagesPreliminary WPS for 12.7mm SMAW WeldingAnonymous 4e7GNjzGW100% (1)

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Training Matrix Smaw NC IDocument10 pagesTraining Matrix Smaw NC IEdward LyleNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- Welding Standards for Corrosion-Resistant Piping MaterialsDocument10 pagesWelding Standards for Corrosion-Resistant Piping MaterialsRaj AryanNo ratings yet

- ARL-AL-WPS-001 welding procedureDocument2 pagesARL-AL-WPS-001 welding procedurerajuajiNo ratings yet

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Wood Bending: by Trey Howard, Cal Fore, Bobby Connor, Ling QiuDocument78 pagesWood Bending: by Trey Howard, Cal Fore, Bobby Connor, Ling QiuPuneeth Raj100% (1)

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 pagesWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- WC9Document5 pagesWC9Suresh KrishnanNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Tips Wps FormatDocument5 pagesTips Wps FormatWaqas WaqasNo ratings yet

- WPS for Manual SMAW Welding of 316L Stainless Steel Butt JointsDocument3 pagesWPS for Manual SMAW Welding of 316L Stainless Steel Butt JointsAmjad PathanNo ratings yet

- Final WPS - ItdcDocument2 pagesFinal WPS - ItdcsarancivilrajNo ratings yet

- WCBDocument5 pagesWCBSuresh KrishnanNo ratings yet

- WPS NMB 001Document6 pagesWPS NMB 001mohamed nasserNo ratings yet

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Welding Procedure Specification (AutoRecovered)Document2 pagesWelding Procedure Specification (AutoRecovered)virnmontalesNo ratings yet

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- Pre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectDocument2 pagesPre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectBagandi ManurungNo ratings yet

- QC E7018 CJP B-L1a OverheadDocument1 pageQC E7018 CJP B-L1a Overheadwmajordan13No ratings yet

- SPL - PQR-WPS-SWPS SmawDocument7 pagesSPL - PQR-WPS-SWPS Smawgopuvinu4uNo ratings yet

- T - Thermanit 25 - 09 CuT - de - en - 5Document1 pageT - Thermanit 25 - 09 CuT - de - en - 5NAVANEETH NAVANINo ratings yet

- Aic Asf PQR 0121Document2 pagesAic Asf PQR 0121AHMED MEDANYNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYNo ratings yet

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- REP-WPS-02Document2 pagesREP-WPS-02shaniraj BirajdarNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 01 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 01 DateAmjad PathanNo ratings yet

- Preliminary - Welding Procedure Specification (WPS)Document1 pagePreliminary - Welding Procedure Specification (WPS)Rudi DaNo ratings yet

- Balajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Document2 pagesBalajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Eswara Rao BodduNo ratings yet

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 pagesNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNo ratings yet

- Verspec WPS WPQDocument6 pagesVerspec WPS WPQgtsi.draftsmanNo ratings yet

- PQR Procedure Qualification RecordDocument3 pagesPQR Procedure Qualification RecordRejoy babyNo ratings yet

- 2G & 5GDocument2 pages2G & 5GRahul MoottolikandyNo ratings yet

- Aic Asf PQR 0122Document2 pagesAic Asf PQR 0122AHMED MEDANYNo ratings yet

- Quinco Steel Inc.: Welding Procedure Specification (WPS)Document1 pageQuinco Steel Inc.: Welding Procedure Specification (WPS)wmajordan13No ratings yet

- WPS Vessel 1Document4 pagesWPS Vessel 1Naqqash SajidNo ratings yet

- Senior Welding Inspection, Steels - WIS 10: Question Paper (MSR-SWI-2)Document6 pagesSenior Welding Inspection, Steels - WIS 10: Question Paper (MSR-SWI-2)Chandra MohanNo ratings yet

- Utp Eb 1001Document1 pageUtp Eb 1001VIRPOPNo ratings yet

- PP & Ce-Unit 2 (Notes) - Part ADocument51 pagesPP & Ce-Unit 2 (Notes) - Part ASYLVIA ANITANo ratings yet

- Conveyor Idler Rollers - Waminco - Industrial Rubber & Polymer Products - Perth WADocument1 pageConveyor Idler Rollers - Waminco - Industrial Rubber & Polymer Products - Perth WACarlos Ediver Arias RestrepoNo ratings yet

- Equipment / Machinery Checklist: BlankDocument3 pagesEquipment / Machinery Checklist: Blankyared admassuNo ratings yet

- Dip Brazing: Parts To Be Dip Brazed AreDocument10 pagesDip Brazing: Parts To Be Dip Brazed AreRavin SinghNo ratings yet

- Best Speakers EVARDocument4 pagesBest Speakers EVARAccording To HondaNo ratings yet

- Welding Safety and ProceduresDocument6 pagesWelding Safety and ProceduresKim PinedaNo ratings yet

- Senior High School: First Semester S.Y. 2020-2021Document9 pagesSenior High School: First Semester S.Y. 2020-2021sheilame nudaloNo ratings yet

- CastingDocument3 pagesCastingEkwonna Ebuka SebastineNo ratings yet

- DIN 431-2000 - Iso228-1 Pipe Nuts Thread As in ISO 228-1Document3 pagesDIN 431-2000 - Iso228-1 Pipe Nuts Thread As in ISO 228-1Wai San ChanNo ratings yet

- Final Report (Akash)Document36 pagesFinal Report (Akash)Akash TaradaleNo ratings yet

- Corner ReflectorDocument37 pagesCorner ReflectorSoham DasguptaNo ratings yet

- MEP - MS ElectricalDocument43 pagesMEP - MS ElectricalsyedtalhamehmoodNo ratings yet

- Danieli Fata Hunter Aluminium Casting, Foil Rolling, Coil Coating and Tension Leveling TechnologyDocument27 pagesDanieli Fata Hunter Aluminium Casting, Foil Rolling, Coil Coating and Tension Leveling Technologysmc07No ratings yet

- MONEY'S FUNCTIONS AND CHARACTERISTICS DEFINEDDocument4 pagesMONEY'S FUNCTIONS AND CHARACTERISTICS DEFINEDrosalyn mauricioNo ratings yet

- PWPS Vahali 26 - 136 PD - FWDocument1 pagePWPS Vahali 26 - 136 PD - FWVasiljka Đordan JelacaNo ratings yet

- High Quality Presented by MYODO: M Y O D ODocument4 pagesHigh Quality Presented by MYODO: M Y O D OSinjithNo ratings yet

- WL Two-Circuit & WLM Long-Life Two-Circuit Limit SwitchDocument40 pagesWL Two-Circuit & WLM Long-Life Two-Circuit Limit SwitchMuhamad PriyatnaNo ratings yet

- Steel Grades and StandardsDocument22 pagesSteel Grades and Standardsmorning starNo ratings yet

- Wrap-On Fin Height HardwareDocument8 pagesWrap-On Fin Height HardwareMiguel Martinez GuerreroNo ratings yet

- Factors and challenges affecting exports of the Indian brassware industryDocument7 pagesFactors and challenges affecting exports of the Indian brassware industrySmriti TripathiNo ratings yet

- UNIT OF COMPETENCE: - Perform Bench Work MODULE TITLE: Performing Bench Work LO1: Lay-Out and Mark Dimensions/ Features On Work PieceDocument63 pagesUNIT OF COMPETENCE: - Perform Bench Work MODULE TITLE: Performing Bench Work LO1: Lay-Out and Mark Dimensions/ Features On Work Pieceahmed jemal100% (1)

- AMT Fixture&Spart Parts 2022Document14 pagesAMT Fixture&Spart Parts 2022doniNo ratings yet