Professional Documents

Culture Documents

Solutions 4 F14

Uploaded by

nageshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solutions 4 F14

Uploaded by

nageshCopyright:

Available Formats

1. A steam power plant operates on a simple ideal Rankine cycle between the specified pressure limits.

The

thermal efficiency of the cycle, the mass flow rate of the steam, and the temperature rise of the cooling water

are to be determined.

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.

Analysis (a) From the steam tables (Tables A-4, A-5, and A-6),

h1 = h f @ 10 kPa = 191.81 kJ/kg

v 1 = v f @ 10 kPa = 0.00101 m 3 /kg

w p ,in = v 1 (P2 − P1 )

3

( ) ⎛ 1 kJ

= 0.00101 m 3 /kg (7,000 − 10 kPa )⎜

⎜ 1 kPa ⋅ m 3

⎞

⎟

⎟

7 MPa

⎝ ⎠ qin

= 7.06 kJ/kg 2

10 kPa

h2 = h1 + w p ,in = 191.81 + 7.06 = 198.87 kJ/kg 1 4

qout

P3 = 7 MPa ⎫ h3 = 3411.4 kJ/kg s

⎬

T3 = 500°C ⎭ s 3 = 6.8000 kJ/kg ⋅ K

P4 = 10 kPa ⎫ s 4 − s f 6.8000 − 0.6492

⎬ x4 = = = 0.8201

s 4 = s3 ⎭ s fg 7.4996

h4 = h f + x 4 h fg = 191.81 + (0.8201)(2392.1) = 2153.6 kJ/kg

Thus,

q in = h3 − h2 = 3411.4 − 198.87 = 3212.5 kJ/kg

q out = h4 − h1 = 2153.6 − 191.81 = 1961.8 kJ/kg

wnet = q in − q out = 3212.5 − 1961.8 = 1250.7 kJ/kg

and

wnet 1250.7 kJ/kg

η th = = = 38.9%

q in 3212.5 kJ/kg

W&net 45,000 kJ/s

(b) m& = = = 36.0 kg/s

wnet 1250.7 kJ/kg

(c) The rate of heat rejection to the cooling water and its temperature rise are

Q& = m& q = (35.98 kg/s )(1961.8 kJ/kg ) = 70,586 kJ/s

out out

Q& out 70,586 kJ/s

ΔTcooling water = = = 8.4°C

(m& c) cooling water (2000 kg/s )(4.18 kJ/kg ⋅ °C)

2. A steam power plant that operates on the ideal reheat Rankine cycle is considered. The turbine work output and

the thermal efficiency of the cycle are to be determined.

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.

Analysis From the steam tables (Tables A-4, A-5, and A-6),

h1 = h f @ 20 kPa = 251.42 kJ/kg

T

v 1 = v f @ 20 kPa = 0.001017 m 3 /kg

w p ,in = v 1 (P2 − P1 )

3 5

( ) ⎛ 1 kJ ⎞

= 0.001017 m 3 /kg (6000 − 20 kPa )⎜ ⎟

⎜ 1 kPa ⋅ m 3 ⎟

6 MPa

= 6.08 kJ/kg ⎝ ⎠ 4

h2 = h1 + w p ,in = 251.42 + 6.08 = 257.50 kJ/kg 2

P3 = 6 MPa ⎫ h3 = 3178.3 kJ/kg 20 kPa

⎬

T3 = 400°C ⎭ s 3 = 6.5432 kJ/kg ⋅ K 1 6

s

P4 = 2 MPa ⎫

⎬ h4 = 2901.0 kJ/kg

s 4 = s3 ⎭

P5 = 2 MPa ⎫ h5 = 3248.4 kJ/kg

⎬

T5 = 400°C ⎭ s 5 = 7.1292 kJ/kg ⋅ K

s 6 − s f 7.1292 − 0.8320

P6 = 20 kPa ⎫ x 6 = = = 0.8900

⎬ s fg 7.0752

s 6 = s5 ⎭

h6 = h f + x 6 h fg = 251.42 + (0.8900 )(2357.5) = 2349.7 kJ/kg

The turbine work output and the thermal efficiency are determined from

wT,out = (h3 − h4 ) + (h5 − h6 ) = 3178.3 − 2901.0 + 3248.4 − 2349.7 = 1176 kJ/kg

and

q in = (h3 − h2 ) + (h5 − h4 ) = 3178.3 − 257.50 + 3248.4 − 2901.0 = 3268 kJ/kg

wnet = wT ,out − w p ,in = 1176 − 6.08 = 1170 kJ/kg

Thus,

wnet 1170 kJ/kg

η th = = = 0.358 = 35.8%

q in 3268 kJ/kg

3. A steam power plant that operates on an ideal reheat Rankine cycle between the specified pressure limits is

considered. The pressure at which reheating takes place, the total rate of heat input in the boiler, and the thermal

efficiency of the cycle are to be determined.

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.

Analysis (a) From the steam tables (Tables A-4, A-5, and A-6),

h1 = hsat @ 10 kPa = 191.81 kJ/kg T

v 1 = v sat @ 10 kPa = 0.00101 m 3 /kg 3 5

w p ,in = v 1 (P2 − P1 ) 15

( 3

) ⎛ 1 kJ

= 0.00101 m /kg (15,000 − 10 kPa )⎜

⎜ 1 kPa ⋅ m 3

⎞

⎟

⎟

4

= 15.14 kJ/kg ⎝ ⎠

2

h2 = h1 + w p ,in = 191.81 + 15.14 = 206.95 kJ/kg

10 kPa

P3 = 15 MPa ⎫ h3 = 3310.8 kJ/kg 1 6

⎬ s

T3 = 500°C ⎭ s 3 = 6.3480 kJ/kg ⋅ K

P6 = 10 kPa ⎫ h6 = h f + x 6 h fg = 191.81 + (0.90 )(2392.1) = 2344.7 kJ/kg

⎬

s6 = s5 ⎭ s 6 = s f + x 6 s fg = 0.6492 + (0.90 )(7.4996 ) = 7.3988 kJ/kg ⋅ K

T5 = 500°C ⎫ P5 = 2150 kPa (the reheat pressure)

⎬

s5 = s6 ⎭ h5 = 3466.61 kJ/kg

P4 = 2.15 MPa ⎫

⎬ h4 = 2817.2 kJ/kg

s 4 = s3 ⎭

(b) The rate of heat supply is

Q& in = m& [(h3 − h2 ) + (h5 − h4 )]

= (12 kg/s )(3310.8 − 206.95 + 3466.61 − 2817.2)kJ/kg

= 45,039 kW

(c) The thermal efficiency is determined from

Q& = m& (h − h ) = (12 kJ/s )(2344.7 − 191.81)kJ/kg = 25,835 kJ/s

out 6 1

Thus,

Q& out 25,834 kJ/s

η th = 1 − = 1− = 42.6%

Q& 45,039 kJ/s

in

4. A steam power plant operates on an ideal regenerative Rankine cycle with two open feedwater heaters. The net

power output of the power plant and the thermal efficiency of the cycle are to be determined.

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.

Analysis

7

Turbine 7

Boiler

8 6 10 MPa

10 5 0.6 MPa 8

6 4

9 y 1-y

3 0.2 MPa

2 9

fwh II fwh I Condenser

1-y-z

5 kPa

4 2 10

1 1

5 3

P III P II PI s

(a) From the steam tables (Tables A-4, A-5, and A-6),

h1 = h f @ 5 kPa = 137.75 kJ/kg

v 1 = v f @ 5 kPa = 0.001005 m 3 /kg

( ) ⎛ 1 kJ

w pI ,in = v 1 (P2 − P1 ) = 0.001005 m 3 /kg (200 − 5 kPa )⎜

⎜ 1 kPa ⋅ m 3

⎞

⎟ = 0.20 kJ/kg

⎟

h =h +w = 137.75 + 0.20 = 137.95 kJ/kg ⎝ ⎠

2 1 pI ,in

P3 = 0.2 MPa ⎫ h3 = h f @ 0.2 MPa = 504.71 kJ/kg

⎬

⎭ v 3 = v f @ 0.2 MPa = 0.001061 m /kg

3

sat.liquid

( ) ⎛ 1 kJ

w pII ,in = v 3 (P4 − P3 ) = 0.001061 m 3 /kg (600 − 200 kPa )⎜

⎜ 1 kPa ⋅ m 3

⎞

⎟

⎟

= 0.42 kJ/kg ⎝ ⎠

h4 = h3 + w pII ,in = 504.71 + 0.42 = 505.13 kJ/kg

P5 = 0.6 MPa ⎫ h5 = h f @ 0.6 MPa = 670.38 kJ/kg

⎬

⎭ v 5 = v f @ 0.6 MPa = 0.001101 m /kg

3

sat.liquid

( ) ⎛ 1 kJ

w pIII ,in = v 5 (P6 − P5 ) = 0.001101 m 3 /kg (10,000 − 600 kPa )⎜

⎜ 1 kPa ⋅ m 3

⎞

⎟

⎟

= 10.35 kJ/kg ⎝ ⎠

h6 = h5 + w pIII ,in = 670.38 + 10.35 = 680.73 kJ/kg

P7 = 10 MPa ⎫ h7 = 3625.8 kJ/kg

⎬

T7 = 600°C ⎭ s 7 = 6.9045 kJ/kg ⋅ K

P8 = 0.6 MPa ⎫

⎬ h8 = 2821.8 kJ/kg

s8 = s 7 ⎭

s9 − s f 6.9045 − 1.5302

P9 = 0.2 MPa ⎫ x 9 = = = 0.9602

⎬ s fg 5.5968

s9 = s7 ⎭

h9 = h f + x 9 h fg = 504.71 + (0.9602 )(2201.6 ) = 2618.7 kJ/kg

5. An ideal regenerative Rankine cycle with a closed feedwater heater is considered. The work produced by the

turbine, the work consumed by the pumps, and the heat added in the boiler are to be determined.

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.

Analysis From the steam tables (Tables A-4, A-5, and A-6),

h1 = h f @ 20 kPa = 251.42 kJ/kg

v 1 = v f @ 20 kPa = 0.001017 m 3 /kg 4

Turbine

wp,in = v 1 ( P2 − P1 )

⎛ 1 kJ ⎞

= (0.001017 m 3 /kg )(3000 − 20)kPa ⎜ ⎟ 5

⎝ 1 kPa ⋅ m 3 ⎠

= 3.03 kJ/kg Boiler 6

h2 = h1 + wp,in = 251.42 + 3.03 = 254.45 kJ/kg

P4 = 3000 kPa ⎫ h4 = 3116.1 kJ/kg Condenser

⎬ 7 8

T4 = 350°C ⎭ s 4 = 6.7450 kJ/kg ⋅ K

Closed

P5 = 1000 kPa ⎫ fwh

1

⎬ h5 = 2851.9 kJ/kg Pump

s5 = s 4 ⎭ 3 2

s6 − s f 6.7450 − 0.8320

P6 = 20 kPa ⎫ x 6 = = = 0.8357

⎬ s 7.0752

s6 = s 4 fg

⎭ h = h + x h = 251.42 + (0.8357)(2357.5) = 2221.7 kJ/kg

6 f 6 fg

For an ideal closed feedwater heater, the feedwater is

heated to the exit temperature of the extracted steam, which

ideally leaves the heater as a saturated liquid at the T

extraction pressure.

P7 = 1000 kPa ⎫ h7 = 762.51 kJ/kg 4

⎬

x7 = 0 ⎭ T7 = 179.9°C 3 MPa

h8 = h7 = 762.51 kJ/kg qin

P3 = 3000 kPa 3 1 MPa y

⎫

⎬ h = 763.53 kJ/kg 2 5

T3 = T7 = 209.9°C ⎭ 3 7

8 20 kPa 1-y

An energy balance on the heat exchanger gives the

fraction of steam extracted from the turbine ( = m& 5 / m& 4 ) 1 qout 6

for closed feedwater heater: s

∑ m& i hi = ∑ m& e he

m& 5 h5 + m& 2 h2 = m& 3 h3 + m& 7 h7

yh5 + 1h2 = 1h3 + yh7

Rearranging,

h3 − h2 763.53 − 254.45

y= = = 0.2437

h5 − h7 2851.9 − 762.51

Then,

wT,out = h4 − h5 + (1 − y )(h5 − h6 ) = 3116.1 − 2851.9 + (1 − 0.2437)(2851.9 − 2221.7) = 740.9 kJ/kg

wP,in = 3.03 kJ/kg

q in = h4 − h3 = 3116.1 − 763.53 = 2353 kJ/kg

Also, wnet = wT,out − wP,in = 740.9 − 3.03 = 737.8 kJ/kg

wnet 737.8

η th = = = 0.3136

q in 2353

You might also like

- Regenerative Rankine CycleDocument14 pagesRegenerative Rankine CycleSamson GabrielNo ratings yet

- Gas Power Cycles ChapterDocument11 pagesGas Power Cycles ChapterLayla JhNo ratings yet

- Assumptions 1 Steady Operating Conditions Exist. 2 Kinetic and Potential Energy Changes Are Negligible. Analysis (A) From The Steam Tables (Tables A-4, A-5, and A-6)Document1 pageAssumptions 1 Steady Operating Conditions Exist. 2 Kinetic and Potential Energy Changes Are Negligible. Analysis (A) From The Steam Tables (Tables A-4, A-5, and A-6)Juan Andres Barragan ZabalaNo ratings yet

- Sheet SolutionsDocument11 pagesSheet SolutionsMahmoud adelNo ratings yet

- Thermodynamics 2 Quiz #3 - T01: Name: ID #: Problem:: 1 Mark 1 MarkDocument2 pagesThermodynamics 2 Quiz #3 - T01: Name: ID #: Problem:: 1 Mark 1 MarkPratulya KolheNo ratings yet

- CalculationsDocument2 pagesCalculationsLeoNo ratings yet

- ch13 PDFDocument6 pagesch13 PDFAkash ThummarNo ratings yet

- Thermo HWDocument6 pagesThermo HWMuhammad Fawwad ObaidaNo ratings yet

- Sheet (1&2) ThermoDocument17 pagesSheet (1&2) ThermoAhmed A. TaimaNo ratings yet

- Tutorial 6sol2 PDFDocument4 pagesTutorial 6sol2 PDFSohayb GattousNo ratings yet

- Thermo 5th Chap10 P046Document23 pagesThermo 5th Chap10 P046IENCSNo ratings yet

- c08 - Pending 8.36Document262 pagesc08 - Pending 8.36SeungMin LeeNo ratings yet

- Vapour Power Cycles Mixed Pressure TurbinesDocument53 pagesVapour Power Cycles Mixed Pressure Turbinesaditya yadavNo ratings yet

- Chapter 10 Vapor and Combined Power CyclesDocument29 pagesChapter 10 Vapor and Combined Power Cyclesnamsun100% (1)

- Ch11 SolutionsDocument3 pagesCh11 SolutionsJhuzel ColisNo ratings yet

- Sample Calculation-BDocument14 pagesSample Calculation-BEdrielleNo ratings yet

- Steam Power Board Problems PDFDocument6 pagesSteam Power Board Problems PDFKim Niño FelisminoNo ratings yet

- Answers: 0.2467 1421.06kJ/kg 9.09kJ/kg 46%Document16 pagesAnswers: 0.2467 1421.06kJ/kg 9.09kJ/kg 46%Marianne DevillenaNo ratings yet

- At 2.5 Mpa 2803.1 6.2575 at 50 Kpa 340.49 1.0910 2305.4 6.2575 0.000103 Sol'N: 280.31Kj /KG Solving For H: + 6.2575 1.0910+X (6.5029)Document22 pagesAt 2.5 Mpa 2803.1 6.2575 at 50 Kpa 340.49 1.0910 2305.4 6.2575 0.000103 Sol'N: 280.31Kj /KG Solving For H: + 6.2575 1.0910+X (6.5029)Ariel GamboaNo ratings yet

- Problems On Regenerative CycleDocument6 pagesProblems On Regenerative CycleMurvin VillarosaNo ratings yet

- Thermo 5th Chap10 P001Document29 pagesThermo 5th Chap10 P001Rodrigo Andre Zuniga JuarezNo ratings yet

- Exercicio TermoDocument1 pageExercicio Termomcpe2793No ratings yet

- Design Option 3Document9 pagesDesign Option 3무제untitledNo ratings yet

- 2nd Law Analysis For A Control VolumeDocument13 pages2nd Law Analysis For A Control VolumeSergey ShkapovNo ratings yet

- Refrigeration Quiz Effects of Temperature and Pressure ChangesDocument4 pagesRefrigeration Quiz Effects of Temperature and Pressure ChangesMartiNo ratings yet

- Problems On Reheat CycleDocument8 pagesProblems On Reheat CycleMurvin VillarosaNo ratings yet

- Sample Problems: Rankine CycleDocument12 pagesSample Problems: Rankine CycleReiVanNo ratings yet

- Ejercicio para CompararDocument4 pagesEjercicio para CompararCamila SarabiaNo ratings yet

- Steam Turbinedocx PDF FreeDocument13 pagesSteam Turbinedocx PDF Freeben richNo ratings yet

- Power Plant Design Plan ADocument21 pagesPower Plant Design Plan Akim deygabiNo ratings yet

- Orca Share Media1519993790396 PDFDocument10 pagesOrca Share Media1519993790396 PDFSecret SecretNo ratings yet

- Thermodynamics An Engineering Approach 6Th Edition Cengel Solutions Manual Full Chapter PDFDocument67 pagesThermodynamics An Engineering Approach 6Th Edition Cengel Solutions Manual Full Chapter PDFphelimletitiaioxb0100% (6)

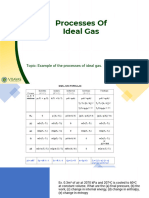

- Ideal Gas Processes ExampleDocument14 pagesIdeal Gas Processes ExampleMary Joy AlmerenoNo ratings yet

- Problems on Regenerative Cycle Steam TurbineDocument6 pagesProblems on Regenerative Cycle Steam TurbineMurvin VillarosaNo ratings yet

- Applied Thermodynamics Exam 2018 Wirh SolutionsDocument9 pagesApplied Thermodynamics Exam 2018 Wirh SolutionsFarouk BassaNo ratings yet

- Assumptions 1 Steady Operating Conditions Exist. 2 Kinetic and Potential Energy Changes Are Negligible. Analysis From The Steam Tables (Tables A-4, A-5, and A-6)Document1 pageAssumptions 1 Steady Operating Conditions Exist. 2 Kinetic and Potential Energy Changes Are Negligible. Analysis From The Steam Tables (Tables A-4, A-5, and A-6)Sai BalaNo ratings yet

- Extra Sol11Document8 pagesExtra Sol11Ahmed NasrNo ratings yet

- Solutions To Extra Problems in Chapter 11: November 29, 2000 J. MurthyDocument8 pagesSolutions To Extra Problems in Chapter 11: November 29, 2000 J. Murthycobalt boronNo ratings yet

- Ideal Rankine CycleDocument20 pagesIdeal Rankine CycleJasmin TulosaNo ratings yet

- Finalized and Edited Group 5Document12 pagesFinalized and Edited Group 5Ralph EvidenteNo ratings yet

- Combined gas-steam power cycle analysisDocument16 pagesCombined gas-steam power cycle analysisRSS RSSNo ratings yet

- Cartajena REVISEDDocument11 pagesCartajena REVISEDJerome Russel PublìcòNo ratings yet

- Uygulama 1-2 & Ornek SorularDocument16 pagesUygulama 1-2 & Ornek SorularMuhittin SimsekNo ratings yet

- Problem Sheet No. 1 Submitted By: Mukhamad Zaman Chatkha Chemical Engineering Thermodynamics-II (CHE-332)Document6 pagesProblem Sheet No. 1 Submitted By: Mukhamad Zaman Chatkha Chemical Engineering Thermodynamics-II (CHE-332)Izza AfaqNo ratings yet

- Solutions 3 F14Document2 pagesSolutions 3 F14Leul AchawNo ratings yet

- Problem Set No 1pdfpdf PDF FreeDocument87 pagesProblem Set No 1pdfpdf PDF FreeMaria Perez100% (1)

- X X H H S S: F FG F FGDocument2 pagesX X H H S S: F FG F FGSeila MolinaNo ratings yet

- Formulas and Processes in Fluid DynamicsDocument8 pagesFormulas and Processes in Fluid DynamicsFenrir RozenNo ratings yet

- Process Design Process Flow Diagram (Ideal Rankine Cylce)Document4 pagesProcess Design Process Flow Diagram (Ideal Rankine Cylce)Haziq AzliNo ratings yet

- UntitledDocument3 pagesUntitledAntonio AdorzaNo ratings yet

- Fluid Mechanics Cengel (Solutions Manual) Chap12-001Document34 pagesFluid Mechanics Cengel (Solutions Manual) Chap12-001NURUL SYUHADA BT ISMAIL HAJAR50% (2)

- 1st Nungay MergedDocument20 pages1st Nungay MergedGino NungayNo ratings yet

- Thermo1 AssignentDocument6 pagesThermo1 AssignentmasmashitahNo ratings yet

- Steam Power Board ProblemsDocument6 pagesSteam Power Board ProblemsCaguioa Mark Anthony G.100% (4)

- H S S X S S HDocument4 pagesH S S X S S HahmadskhanNo ratings yet

- Rankine Cycle Diagram: K KG KJ K KG KJ Kpa S Kpa S S XDocument16 pagesRankine Cycle Diagram: K KG KJ K KG KJ Kpa S Kpa S S Xanon_166336005No ratings yet

- Assignment No. 1 in PpeDocument3 pagesAssignment No. 1 in PpeJenny Mae PomedaNo ratings yet

- Chap7 3Document10 pagesChap7 3Kerem Taha TekinNo ratings yet

- FT - Receipt - 04 04 2022 14 08 16Document1 pageFT - Receipt - 04 04 2022 14 08 16nageshNo ratings yet

- Modified Motorcycle Info-02.04.2022Document13 pagesModified Motorcycle Info-02.04.2022nageshNo ratings yet

- This Is A System-Generated Statement. Hence, It Does Not Require Any SignatureDocument5 pagesThis Is A System-Generated Statement. Hence, It Does Not Require Any SignaturenageshNo ratings yet

- Ensc 388 - P4 - 63Document1 pageEnsc 388 - P4 - 63nageshNo ratings yet

- HW4 Solutions 2014 2Document15 pagesHW4 Solutions 2014 2Kallu Badmash100% (2)

- Acceleration of blocks on double inclined plane and frictionDocument10 pagesAcceleration of blocks on double inclined plane and frictionHemantSumanNo ratings yet

- Solving Heat Transfer Problems Using Transient Conduction AnalysisDocument103 pagesSolving Heat Transfer Problems Using Transient Conduction Analysismaria xNo ratings yet

- Rankine 1 PDFDocument76 pagesRankine 1 PDFBryan Dominic Gabriel PaduaNo ratings yet

- Physics 111 Homework Solution #5Document20 pagesPhysics 111 Homework Solution #5jhunNo ratings yet

- MG 901465 20201229 FonDocument2 pagesMG 901465 20201229 FonnageshNo ratings yet

- ENGR-1100 Introduction To Engineering AnalysisDocument16 pagesENGR-1100 Introduction To Engineering AnalysisnageshNo ratings yet

- Problem 9.2: SolutionDocument6 pagesProblem 9.2: SolutionnageshNo ratings yet

- Set3 AnswersDocument7 pagesSet3 AnswersnageshNo ratings yet

- Aluminum Channel ExtrusionsDocument4 pagesAluminum Channel ExtrusionsnageshNo ratings yet

- M.D-I Final Tutorial and AssignmentDocument16 pagesM.D-I Final Tutorial and AssignmentnageshNo ratings yet

- Homework 13Document2 pagesHomework 13nageshNo ratings yet

- ME 230 Kinematics and Dynamics Equations of MotionDocument93 pagesME 230 Kinematics and Dynamics Equations of MotiongNo ratings yet

- ENGN.2070 Assignment 20 SolutionDocument6 pagesENGN.2070 Assignment 20 SolutionnageshNo ratings yet

- Principles of DimensioningDocument7 pagesPrinciples of Dimensioningaseem_singla_1No ratings yet

- Solution Manual For Mechanics of Materials 3rd Edition by PhilpotDocument53 pagesSolution Manual For Mechanics of Materials 3rd Edition by PhilpotKrisha Ann M. Mendoza71% (7)

- EMA 202 Midterm 2 Fall 2014 SolutionsDocument9 pagesEMA 202 Midterm 2 Fall 2014 SolutionsnageshNo ratings yet

- PROBLEM 6.126: SolutionDocument4 pagesPROBLEM 6.126: SolutionDeepash JoshiNo ratings yet

- TIASA - Thermal Insulation HandbookDocument58 pagesTIASA - Thermal Insulation HandbookSirGawain99No ratings yet

- 2005 Exam3Document2 pages2005 Exam3nageshNo ratings yet

- Statics hw3Document3 pagesStatics hw3nageshNo ratings yet

- 2Document39 pages2nageshNo ratings yet

- Homework 5 SolutionsDocument10 pagesHomework 5 SolutionsBryle CoNo ratings yet

- Circles and Their AnglesDocument7 pagesCircles and Their AnglesDhawal PanchalNo ratings yet

- Thermodynamic Properties of R-134a Saturated R-134aDocument6 pagesThermodynamic Properties of R-134a Saturated R-134aGvbo rA9No ratings yet

- Co Spring23 StudentsDocument4 pagesCo Spring23 StudentsSerge DemirdjianNo ratings yet

- G101evn01 0Document27 pagesG101evn01 0amir baroughNo ratings yet

- Quality Control of Nuclear Medicine Equipment: The Anger Scintillation Gamma CameraDocument66 pagesQuality Control of Nuclear Medicine Equipment: The Anger Scintillation Gamma CameraMarian JonahNo ratings yet

- ATV930 - Unidade de Frenagem e Resistencias de Frenagem - Nov2018Document8 pagesATV930 - Unidade de Frenagem e Resistencias de Frenagem - Nov2018Dyana GontijoNo ratings yet

- HighbayDocument3 pagesHighbayJeevaNo ratings yet

- Manual de Reparacion CD25PDocument964 pagesManual de Reparacion CD25PMauro Antihual88% (8)

- Service Manual Liftstar-2014Document46 pagesService Manual Liftstar-2014Adam SchwemleinNo ratings yet

- Space Truss PDFDocument43 pagesSpace Truss PDFChockalingam100% (2)

- Pyramidal Horn Antenna Design GuideDocument38 pagesPyramidal Horn Antenna Design GuideJocaNo ratings yet

- Ac Cassette 1Document1 pageAc Cassette 1Surya LiemNo ratings yet

- VFD Ac ReportDocument20 pagesVFD Ac ReportSameer ZareNo ratings yet

- Dynamic Design For AnchorsDocument6 pagesDynamic Design For AnchorsFlorin BodogaNo ratings yet

- Questions Bank On ElectrostaticsDocument2 pagesQuestions Bank On Electrostaticsashok PradhanNo ratings yet

- Paramagnetic Lab - Farheen & MowDocument8 pagesParamagnetic Lab - Farheen & MowFarheenNo ratings yet

- Hydrogen ResumeDocument4 pagesHydrogen ResumeBang KaiNo ratings yet

- Vd13 Vd14 Axitub Piros Winder 4 630t 4 1.10kw - UkDocument2 pagesVd13 Vd14 Axitub Piros Winder 4 630t 4 1.10kw - UkConstantin294No ratings yet

- Curiculum Vitae Iyere Faith-1Document5 pagesCuriculum Vitae Iyere Faith-1Halleluyah HalleluyahNo ratings yet

- Fume Hood Catalogue 1626520570844 PDFDocument7 pagesFume Hood Catalogue 1626520570844 PDFTgemunuNo ratings yet

- Cryogenic Rocket Engine Development at Delft Aerospace Rocket EngineeringDocument13 pagesCryogenic Rocket Engine Development at Delft Aerospace Rocket EngineeringAlexyz33No ratings yet

- Prof DontwiDocument122 pagesProf DontwiRexford AmponsahNo ratings yet

- Manufacturing Processes and Materials for Portable Cooling FanDocument13 pagesManufacturing Processes and Materials for Portable Cooling FanHarizx SaufixNo ratings yet

- World Grid, Bruce Cathie, Chemtrails, UFO's, Secret Bases New ZealandDocument44 pagesWorld Grid, Bruce Cathie, Chemtrails, UFO's, Secret Bases New Zealandsecondfield100% (15)

- Statics of Rigid BodiesDocument34 pagesStatics of Rigid BodiespesobucksNo ratings yet

- Lesson 29: Integration by Substitution (Worksheet Solutions)Document5 pagesLesson 29: Integration by Substitution (Worksheet Solutions)Matthew Leingang100% (3)

- SEL-TBD-I-DS-017 - R0 - Data Sheet For MSAI Shutdown Valve - SignDocument4 pagesSEL-TBD-I-DS-017 - R0 - Data Sheet For MSAI Shutdown Valve - SignhadiNo ratings yet

- Einstein's Genealogy.Document6 pagesEinstein's Genealogy.lennysanchezNo ratings yet

- DC Relay For Microgrid PDFDocument12 pagesDC Relay For Microgrid PDFvasiliy vasilievichNo ratings yet

- CH21-3 - Standing Waves: Important IdeasDocument4 pagesCH21-3 - Standing Waves: Important Ideasمحمد رزقNo ratings yet

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Incidents That Define Process SafetyFrom EverandIncidents That Define Process SafetyNo ratings yet

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Safety Fundamentals and Best Practices in Construction IndustryFrom EverandSafety Fundamentals and Best Practices in Construction IndustryNo ratings yet

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)