Professional Documents

Culture Documents

TSJ Transportation Frame General Notes

Uploaded by

Bhuvan GanesanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TSJ Transportation Frame General Notes

Uploaded by

Bhuvan GanesanCopyright:

Available Formats

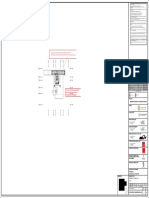

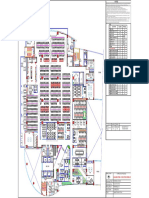

CLIENT NO: TPFMC NO: DRAWING TITLE: GENERAL NOTES FOR STRUCTURAL FABRICATION

NAP-XXX-XX-XXXX-XXXXXX-XX 078553C002-000-DW-XXXX-0001 TSJ TRANSPORTATION FRAME TITLE SHEET GENERAL NOTE 1. ALL STEELWORK INCLUDING WORKMANSHIP AND MATERIALS SHALL BE IN ACCORDANCE WITH PROJECT FABRICATION SPEC. SPC10149094

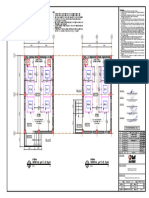

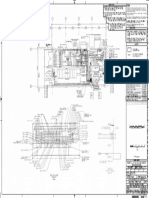

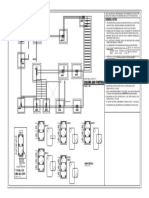

NAP-XXX-XX-XXXX-XXXXXX-XX 078553C002-000-DW-XXXX-0002 GENERAL ARRANGEMENT OF 10'' PRODUCTION TSJ ASSEMBLY 2. ALL STRUCTURAL WELDING AND NDE (INCLUDING VISUAL INSPECTION) SHALL BE IN ACCORDANCE WITH PROJECT FABRICATION SPEC. SPC10149094

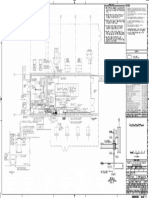

NAP-XXX-XX-XXXX-XXXXXX-XX 078553C002-000-DW-XXXX-0003 GENERAL ARRANGEMENT OF 6" GAS LIFT ASSEMBLY 3. ALL PIPELINE WELDING SHALL BE IN ACCORDANCE WITH PROJECT FABRICATION SPEC. SPC10149094

NAP-XXX-XX-XXXX-XXXXXX-XX 078553C002-000-DW-XXXX-0004 TSJ TRANSPORTATION FRAME DETAIL DRAWING 4. ALL PADEYES TO BE LOAD TESTED IN ACCORDANCE WITH PROJECT FABRICATION SPEC. SPC10149094

NAP-XXX-XX-XXXX-XXXXXX-XX 078553C002-000-DW-XXXX-0005 TSJ TRANSPORTATION FRAME ITEM DETAIL DRAWING 5. FABRICATION TOLERANCES TO BE IN ACCORDANCE WITH PROJECT FABRICATION SPEC. SPC10149094

6. PAINTING TO BE IN ACCORDANCE WITH PROJECT FABRICATION SPEC. SPC10149094

7. ALL WELDS TO BE FULL PENETRATION U.N.O.

8. WELD TESTING TO BE AS PER NDE SPEC AWS D1.1.

9. REMOVE ALL BURRS, SHARP EDGES, AND WELD SPATTER.

10. ALL LIFTING POINTS TO BE VISIBLY MARKED USING PAINT WITH THE S.W.L., THE MATERIAL GRADE,

AND THE HEAT NUMBER TO BE INDICATED ON THE AS-BUILT DRAWINGS AND / OR PROJECT DOCUMENTATION.

11. ALL PADEYES TO BE LINE BORED. DO NOT PAINT PADEYE HOLES.

12. ALL QUANTITIES SHOWN IN BILL OF MATERIAL ARE FOR ONE (1) TRANSPORTATION FRAME ASSEMBLY U.N.O.

13. ANY FLAT PATTERNS SHOWN ARE FOR REFERENCE ONLY, FABRICATOR TO DETERMINE FIT-UP ALLOWANCES AND WELD PREPS.

14. DIMENSIONAL TOLERANCES:

14.1 UNLESS OTHERWISE NOTED ON TPUSA APPROVED DESIGN DRAWINGS, TOLERANCE OF FABRICATED STRUCTURES SHALL

BE WITHIN THESE DIMENSIONAL LIMITS:

+/- 1/16" 0" to 6'-0"

+/- 1/8" >6'-0" to 20'-0"

+/- 1/4" >20'-0"

14.2 ANGULAR TOLERANCE SHALL BE 0.5 DEGREES WITH THE ANGULAR MEASUREMENT SHOWN IN THE DRAWINGS.

14.3 TOLERANCES SHALL NOT BE CUMULATIVE SUCH THAT OVERALL DIMENSIONS AS WELL AS ANY SUB DIVISIONS ARE

REQUIRED TO FALL WITHIN THESE TOLERANCES.

14.4 THESE TOLERANCES AND ANY TOLERANCE EXPLICITLY STATED IN THE DESIGN DRAWINGS SHALL NOT BE CONSTRUED SO

AS TO OVER RIDE THE MECHANICAL OPERATION AND/OR ARTICULATION OF THE EQUIPMENT.

14.5 TOLERANCES OF WELDMENTS SHALL BE IN ACCORDANCE WITH AWS D1.1.

15. USE THESE D-RINGS FOR THE TIE-DOWNS TO KEEP THE TSJ IN PLACE.

ISOMETRIC VIEW

SHELL POWERNAP

TSJ TRANSPORTATION FRAME

TITLE SHEET AND GENERAL NOTES

DRAWN CHECKED ENGINEER SCALE CLIENT APPROVAL TF DRAWING NUMBER REV

This document and all information herein is confidential, and may not be used, reproduced or distributed CONFIDENTIALITY MAR AS NOTED 078553C002-000-DW-XXXX-0001

without prior authorization of Technip USA, Inc. Technip USA, Inc. disclaims any and all liabilities for any CATEGORY: A 10-MAR-2020 MAR ISSUED FOR REVIEW RPA/MWI MDG DATE DATE DATE SHEET DRAWING NUMBER

changes or modifications to this document which are made by any non-Technip party. CONFIDENTIAL REV DATE BY DESCRIPTION CHKD ENG APRVD DRAWING SIZE: ARCH D (24" x 36") 10-MAR-2020 1 OF 1 NAP-XXX-XX-XXXX-XXXXXX-XX A

Last Saved: 3/10/2020 17:29:57 By: smohamadkasimarif File Name: C:\Vault\SURF\CAD\Powernap\TSJ Transportation frame\Drawings\TRANSPORTATION FRAME GENERAL NOTES.idw TECHNIP USA, INC. TBPE FIRM REG. NO. F-3030

You might also like

- HVAC Drawings 612Document14 pagesHVAC Drawings 612MohamedHany100% (1)

- Chevrolet 1967 Camaro Factory Assembly ManualDocument20 pagesChevrolet 1967 Camaro Factory Assembly ManualJillian100% (48)

- (S01-S12) CDocument12 pages(S01-S12) CMa'arif Nuzul AddibNo ratings yet

- Treehouse, Waiheke Island: Structural Steelwork NotesDocument12 pagesTreehouse, Waiheke Island: Structural Steelwork NotesKesavan DhuraiNo ratings yet

- Standard Tech SpecDocument3 pagesStandard Tech SpecBhuvan GanesanNo ratings yet

- Pilot Learn English Now Eng0343Document18 pagesPilot Learn English Now Eng0343pedro.muneerNo ratings yet

- Perry's Maternal Child Nursing in CanadaDocument1,620 pagesPerry's Maternal Child Nursing in Canadagilbertwilliams1234No ratings yet

- Digital Systems Design and PrototypingDocument633 pagesDigital Systems Design and PrototypingAshish Shrivastava50% (2)

- Radio Stations: Installation, Design and PracticeFrom EverandRadio Stations: Installation, Design and PracticeRating: 5 out of 5 stars5/5 (2)

- Sure Track SystemDocument2 pagesSure Track SystemIcal AgamNo ratings yet

- J0535-S001 - General Notes PDFDocument1 pageJ0535-S001 - General Notes PDFSaiful IslamNo ratings yet

- Surat Metro General Arrangment DrawingsDocument5 pagesSurat Metro General Arrangment Drawingsdebapriyo50% (2)

- Estimation of Measurement Uncertainty Printout 2016-2Document94 pagesEstimation of Measurement Uncertainty Printout 2016-2GustavoCaicutoNo ratings yet

- Crochet Pattern "Doll-Chamomile": TanaticrochetDocument9 pagesCrochet Pattern "Doll-Chamomile": TanaticrochetElene Lomidze100% (1)

- Seam 325 Prelim Exam ReviewerDocument6 pagesSeam 325 Prelim Exam ReviewerKyle Steven CaymeNo ratings yet

- Distribution - SS Rev.7A AP-2023.07.06Document12 pagesDistribution - SS Rev.7A AP-2023.07.06sundareee96No ratings yet

- DSS - Layout.Without - TX AP-2023.07.06Document1 pageDSS - Layout.Without - TX AP-2023.07.06sundareee96No ratings yet

- 715752-Ne-Jubbah Exch 2215000015Document1 page715752-Ne-Jubbah Exch 2215000015aelsheikh834No ratings yet

- D-EUGP1-TPT-G-000-GEN-FWG-001-R00 With Comments 18 10 2021Document1 pageD-EUGP1-TPT-G-000-GEN-FWG-001-R00 With Comments 18 10 2021debapriyoNo ratings yet

- J1078-S001-General NotesDocument1 pageJ1078-S001-General Notesroy jackNo ratings yet

- J0673-S001 - General NotesDocument1 pageJ0673-S001 - General NotesEmon RayNo ratings yet

- J-S001-General NotesDocument1 pageJ-S001-General Notesroy jackNo ratings yet

- Gis 2315000007 Civil 1Document1 pageGis 2315000007 Civil 1aelsheikh834No ratings yet

- MH232 Type-Iil: OS BALAD: 401-00-000 P-Msan: Msen E108Document1 pageMH232 Type-Iil: OS BALAD: 401-00-000 P-Msan: Msen E108Mohamed BadrNo ratings yet

- J0647-S001 - General NotesDocument1 pageJ0647-S001 - General NotesEmon Ray100% (1)

- General Notes and Specification: 3-LegendDocument1 pageGeneral Notes and Specification: 3-LegendReadian FedelinNo ratings yet

- Page 16Document1 pagePage 16barcoma.mylene.nNo ratings yet

- AB-036395 - Fiber Module Installation - SAUDI ARAMCODocument1 pageAB-036395 - Fiber Module Installation - SAUDI ARAMCOAkhil GeorgeNo ratings yet

- Saudi Arabian Oil Company: DA-727899 005 P 0A3 K07 RestrictedDocument1 pageSaudi Arabian Oil Company: DA-727899 005 P 0A3 K07 RestrictedWaqarNo ratings yet

- General Specification For ConstructionDocument1 pageGeneral Specification For ConstructionabigailNo ratings yet

- Jn1252-S001-General NotesDocument1 pageJn1252-S001-General Notesroy jackNo ratings yet

- General Notes: Notes For Electrical: Notes For Etisalat & Eitc (Du) : NOTES FOR ETISALAT & EITC (Du) : (Continuation)Document1 pageGeneral Notes: Notes For Electrical: Notes For Etisalat & Eitc (Du) : NOTES FOR ETISALAT & EITC (Du) : (Continuation)togireeshNo ratings yet

- 7 Septic VaultDocument1 page7 Septic VaultB R PAUL FORTINNo ratings yet

- FL DS 1023Document1 pageFL DS 1023basemapNo ratings yet

- 006 STRCT1Document1 page006 STRCT1kingjam dimacaling2019No ratings yet

- Short BridgeDocument306 pagesShort BridgeChowdhury PriodeepNo ratings yet

- Plumbing1 ModelDocument1 pagePlumbing1 ModelMarvin VinaraoNo ratings yet

- Plumbing1 ModelDocument1 pagePlumbing1 ModelMarvin VinaraoNo ratings yet

- FF To Roof: Storey MarkingDocument1 pageFF To Roof: Storey MarkingHong Jin YaoNo ratings yet

- J1273-S001-General NotesDocument1 pageJ1273-S001-General Notesroy jackNo ratings yet

- 1 Footing Plan PDFDocument1 page1 Footing Plan PDF114 Gopal jagtapNo ratings yet

- Metro Proj - 12 MTR Span-1Document3 pagesMetro Proj - 12 MTR Span-1kukadiya127_48673372No ratings yet

- Saudi Arabian Oil Company: DA-727739 005 P 0A3 K06 RestrictedDocument1 pageSaudi Arabian Oil Company: DA-727739 005 P 0A3 K06 RestrictedWaqarNo ratings yet

- D Eugp1 TPT G 000 Gen FWG 001 R01Document1 pageD Eugp1 TPT G 000 Gen FWG 001 R01debapriyoNo ratings yet

- Storm Drainage System - General NotesDocument1 pageStorm Drainage System - General NotessathishNo ratings yet

- 1250 GPM DieselDocument1 page1250 GPM DieselProyectos e Ingeniería - Inprofuego, C.A.No ratings yet

- STR 05Document1 pageSTR 05Karrena ArabiaNo ratings yet

- 4457 Bwo U Ka 00000 SK 029 Ver A Spreader Bar SupportDocument3 pages4457 Bwo U Ka 00000 SK 029 Ver A Spreader Bar SupportisaacNo ratings yet

- Capture D'écran . 2020-01-30 À 1.22.21 PMDocument1 pageCapture D'écran . 2020-01-30 À 1.22.21 PMHaikel Ben SalahNo ratings yet

- View - 01 (3d) 1: PO Box 500103 Dubai, U.A.E. Tel: +971 4 391 5640 Fax: +971 4 391 6799Document1 pageView - 01 (3d) 1: PO Box 500103 Dubai, U.A.E. Tel: +971 4 391 5640 Fax: +971 4 391 6799Neil SoansNo ratings yet

- ,åtgfjt: Kuwait EngíneeríngDocument26 pages,åtgfjt: Kuwait Engíneeríngvignesh558855No ratings yet

- Issued For Construction: ZAIT Engineering Solutions Pty LTDDocument1 pageIssued For Construction: ZAIT Engineering Solutions Pty LTDAhmedBoutlyNo ratings yet

- Arch Plans v2 (Approved)Document12 pagesArch Plans v2 (Approved)rabbetmrNo ratings yet

- General Construction Notes: FC Engineering ServicesDocument1 pageGeneral Construction Notes: FC Engineering ServicesMac KYNo ratings yet

- General Notes: Plumbing Notes and Abbrevations Plan and SectionDocument1 pageGeneral Notes: Plumbing Notes and Abbrevations Plan and SectionKlausmene AveriaNo ratings yet

- General Notes: General Notes: NOTES FOR STORM WATER: (Continuation) Notes For Sewer LinesDocument1 pageGeneral Notes: General Notes: NOTES FOR STORM WATER: (Continuation) Notes For Sewer LinestogireeshNo ratings yet

- Design Criteria: GeneralDocument1 pageDesign Criteria: GeneralRolly Marc G. SoteloNo ratings yet

- Quiruben M. Mera Engr. Landrito R. Pilao: S-1 Highline Builders CompanyDocument1 pageQuiruben M. Mera Engr. Landrito R. Pilao: S-1 Highline Builders CompanyHighline BuildersNo ratings yet

- Insulated Panel Installation GuideDocument11 pagesInsulated Panel Installation Guidemichael turcotteNo ratings yet

- Salebuild: Team Architects (I) Pvt. LTDDocument1 pageSalebuild: Team Architects (I) Pvt. LTDNavdeep GopamwarNo ratings yet

- APT001-D-DWG-ME-003 - Drawing Water Coalescer Tank (T-106A-B) - 0 - IFBDocument2 pagesAPT001-D-DWG-ME-003 - Drawing Water Coalescer Tank (T-106A-B) - 0 - IFBRoy RahadianNo ratings yet

- Townhouse Development 100 - 104 Anderson Road, Sunbury City of Hume FOR WBD GroupDocument4 pagesTownhouse Development 100 - 104 Anderson Road, Sunbury City of Hume FOR WBD GroupArash GhaedizadehNo ratings yet

- General Notes:-: Tirupati Smart City Corporation LimitedDocument1 pageGeneral Notes:-: Tirupati Smart City Corporation LimitedAecom IndiaNo ratings yet

- 3616A, B ModelDocument1 page3616A, B ModelVarun MalhotraNo ratings yet

- I - General NotesDocument1 pageI - General NotesReadian FedelinNo ratings yet

- General Notes: Legends: Abbreviations:: Reference DrawingsDocument1 pageGeneral Notes: Legends: Abbreviations:: Reference DrawingsmuthuvelaaNo ratings yet

- 715706-Gis-2315000028-Civil BaqaDocument1 page715706-Gis-2315000028-Civil Baqaaelsheikh834No ratings yet

- Mace Ar 10 B1 02Document1 pageMace Ar 10 B1 02Syead OwaisNo ratings yet

- TSJ Transportation Frame Item Detail DrawingDocument1 pageTSJ Transportation Frame Item Detail DrawingBhuvan GanesanNo ratings yet

- TSJ Transportation Frame Detail DrawingDocument1 pageTSJ Transportation Frame Detail DrawingBhuvan GanesanNo ratings yet

- General Arrangement of 10'' Production TSJ AssemblyDocument1 pageGeneral Arrangement of 10'' Production TSJ AssemblyBhuvan GanesanNo ratings yet

- GAIL (India) Limited:: Senior Engineer (Civil) : E-2 (INR 60000-180000) Registration No.: 50787381Document4 pagesGAIL (India) Limited:: Senior Engineer (Civil) : E-2 (INR 60000-180000) Registration No.: 50787381Bhuvan GanesanNo ratings yet

- Feed Back FormDocument2 pagesFeed Back FormBhuvan GanesanNo ratings yet

- Energy and Buildings: F. AsdrubaliDocument9 pagesEnergy and Buildings: F. AsdrubaliBogdan BrieNo ratings yet

- What's in Your BackpackDocument31 pagesWhat's in Your Backpackjohn ezekiel de asisNo ratings yet

- Kafka and NiFIDocument8 pagesKafka and NiFIabhimanyu thakurNo ratings yet

- Vitamins and Minerals Lecture NotesDocument9 pagesVitamins and Minerals Lecture NotesJoymae Olivares Tamayo100% (1)

- MISSISSIPPI Chanery ClerksDocument7 pagesMISSISSIPPI Chanery Clerks2PlusNo ratings yet

- Money and BankingDocument20 pagesMoney and BankingFAH EEMNo ratings yet

- E38 Closed Circuit Current TestDocument4 pagesE38 Closed Circuit Current TestCezaryCezasNo ratings yet

- Part - I: Subjective Questions: Introduction To ChemistryDocument7 pagesPart - I: Subjective Questions: Introduction To ChemistryMohini DeviNo ratings yet

- OCI Introduction: Presented By: Rahul MiglaniDocument21 pagesOCI Introduction: Presented By: Rahul Miglanisss pppNo ratings yet

- Unit 7 Legal EthicalDocument22 pagesUnit 7 Legal Ethicalapi-462777064No ratings yet

- Strategy SolutionsDocument2 pagesStrategy SolutionsIbrahim OsmanNo ratings yet

- CS317 IR W1aDocument20 pagesCS317 IR W1aHatim Juzer KhambatwalaNo ratings yet

- DLL - July 15 - Idiomatic ExpressionsDocument2 pagesDLL - July 15 - Idiomatic ExpressionsLenlen Santos Catinoy100% (1)

- Our Proper Home Garbage Disposal GuideDocument7 pagesOur Proper Home Garbage Disposal GuideNovelNo ratings yet

- Help Utf8Document8 pagesHelp Utf8Jorge Diaz LastraNo ratings yet

- 01-PPS SMOI User Manual BodyDocument93 pages01-PPS SMOI User Manual BodyGuelahourou Joel SossieNo ratings yet

- CGC TemplateDocument19 pagesCGC TemplateVictoria Stephanie AshleyNo ratings yet

- Experiment No.1. (Monograph)Document3 pagesExperiment No.1. (Monograph)ayeza.sarwar2021No ratings yet

- MSYS-1 0 11-ChangesDocument3 pagesMSYS-1 0 11-ChangesCyril BerthelotNo ratings yet

- Lab Report Literature Review ExampleDocument5 pagesLab Report Literature Review ExampleafmzmqwdglhzexNo ratings yet

- It Didn't Snow On Saturday. It Rained On SaturdayDocument1 pageIt Didn't Snow On Saturday. It Rained On SaturdayAnna Talhammer100% (1)

- Thesis On Corporate Governance and Firm PerformanceDocument10 pagesThesis On Corporate Governance and Firm Performancegja8e2sv100% (2)

- Deadlocks: Silberschatz, Galvin and Gagne ©2013 Operating System Concepts - 9 EditionDocument43 pagesDeadlocks: Silberschatz, Galvin and Gagne ©2013 Operating System Concepts - 9 EditionmigadNo ratings yet