Professional Documents

Culture Documents

RAMS For Harmonic Study

Uploaded by

Anandu AshokanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RAMS For Harmonic Study

Uploaded by

Anandu AshokanCopyright:

Available Formats

RISK ASSESSMENT METHOD STATEMENT

Method Statement and Risk Assessment for the

Harmonic Measurement Study Procedure

The Al Karama School, Phase 2

Abu Dhabi, UAE

Project No. M1492

Document Ref No: M1492-MCL-MCL-MSS-093

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 1 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

Project name Al Karama School, Phase 2 Project No M1492

M1492-MCL-MCL-

Main Contractor McLaren Construction LLC Document No

MSS-093

Title/Task Harmonic Measurement Study Procedure Revision No 00

Document

Date of issue 24/10/2020 Anu Baby

Prepared By

Proposed start date 24/102020 Duration of task 1 week

Contents

Section A Register of Revisions

Section B Scope of Works to be undertaken

Section C Location of the Project

Section D Location of the Works to be Undertaken with the Project

Section E Site Access/Egress and Access to the Work Zone

Section F Emergency Contacts Details and Procedures

Section G McLaren Site Specific HSE Safety Induction

Section H Welfare facilities

Section I Personal Protective Equipment

Section J Plant/Equipment and tools to be Used

Section K Materials To be used

Section L Temporary Works

Section M Inspection and Test Regime

Section N Communication/Toolbox Talks/Training Requirements

Section O Works Permits

Section P Environmental and Waste Management

Section Q Programme for the Works

Section R Housekeeping and Storage

Section S Working at Height

Section T Occupational Health

Section U Sequence of Works/Activities

Appendices

Appendix A Site Logistic Plans and Other Design Information Relative to the Works

Appendix B Crisis/Emergency Plan

Appendix C COSHH Assessments and Material Data Sheets

Appendix D Risk Assessments

Appendix E Technical Information

Appendix F Inspection and Test Plans

Appendix G Third Party competency/certifications

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 2 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

Section A - Register of Revisions

Rev. No Date Reason for Amendment Amended By Signature Has this amendment been

(Name) briefed to the operatives

involved and have the

operatives signed the register?

This method statement has been prepared in conjunction with the following documents.

1. UAE Federal Law No. 8, chapter V, Article 91 of 1980.

2. United Arab Emirate Ministerial Order 337/2, Medical care to Workers

3. UAE Fire & Life Safety Code of Practice 2018.

4. UAE Ministerial Order No. 32 of 1982.

5. Federal Environmental Authority Law No.24/1999 and its supplements.

6. Federal Law No. (20) of 1991 Concerning the Civil Aviation Law.

7. Ministerial Resolution 688 of 2013, Regarding Fixing of Working Hours During Summer

8. OSHAD Code of Practice, HSE Regulations, Technical Guidelines, Mechanisms

9. ISO 45001:2018, ISO 14001:2015 ISO 9001:2015

10. McLaren’s Integrated Management System Policy Statement

11. McLaren Management Procedures (MMP) and Function Procedures

12. McLaren’s site specific SHEQ Plan

Section B- Scope of Works to be undertaken:

The work Describes Harmonic Measurement Study Procedure at Al Karama School, Phase 2, Abudhabi

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 3 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

The following Critical Hazards have been identified during the preparation of the scope of works, please refer to

the Risk Assessments within Appendix D.

1. Falling from height.

2. Manual Handling.

3. Slip Trips and Falls.

4. Falling objects

5. Use of power tools

Section C- Location of the Project

Location of the Project;

The Project premise is located at Al Rowdah, W14-01, Abudhabi as marked below.

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 4 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

Existing Services

As per current information, there is existing irrigation network passing outside the construction work

area.

Underground electrical cables for existing lighting poles within the plot have been removed prior to

commencing works at the area. A full survey has been undertaken to confirm this including an

underground service scan and trial trenches hand excavated in various locations around the project to

locate any services running into, or close to the plot.

A permit to dig must be obtained from McLaren prior to any excavations commencing.

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 5 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

Section D- Location of the Works to be Undertaken within the Project

Section E- Site Access/Egress and Access to the Work Zone

Section F- Emergency Contacts Details and Procedures:

The following staff from McLaren and will be on site during the execution of the works and will be responsible

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 6 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

for managing the works;

Name Position Company Contact Details

Paul Carlin (Visiting) Operations Director McLaren 056 105 4691

Jamie Selway (Visiting) QHSE Manager McLaren 052 173 6235

Luke Watson Project Manager McLaren 052 1022402

Abdul Mutallib Senior HSE Officer McLaren 055 400 0602

Vignesh Prabakar Site Engineer McLaren 058 621 6731

Nesakumar P MEP Engineer McLaren 050 850 7968

Vishnu Mohan Project Manager Genfocus 056 546 5865

Anu Baby Project Engineer Genfocus 056 546 5807

Prabir Kumar HSE Officer Genfocus 054 793 7312

Mohmmed Jasim Mechanical Engineer Genfocus 056-526 8312

Parthipan Design Engineer(Elect) Genfocus 056-546 5812

Clitus Fire Warden /First Aider Genfocus 052 701 4049

In case of an Emergency/fire Alarm, all operatives, Staff and Visitors are required to report to the Assembly

Point, which is indicated on the site logistics drawing, as indicated by the symbol below. A roll call will be taken,

and registers checked to ensure that everyone is accounted for. No one will be allowed to leave the assembly

point until the Emergency Response Controller confirms that it is safe to do so.

Assembly Point

Please refer to the attached Crisis/Emergency Plan, (Appendix B) which is to be implemented where the need

arises.

The Qualified First Aiders for the Project are listed below, and the first Aid Boxes will be available within the

First Aid Room and in the Main Office Reception.

McLaren: (details of First Aiders) Subcontractor (Details of First Aiders)

Shebin Arun 056 746 5229 Prabir Kumar 054 7937312

Authority/Company Contact Telephone No.

Abdul Mutallib

Police 055 400 0602 999 Cletus 052 7014049

Please see Ambulance 998 below the

Emergency Fire (Civil Defence) 997 contact details:

SKMC Hospital 02 819 0000

McLaren Site Emergency No. 056 898 7960

Section G- McLaren Site Specific HSE Safety Induction:

All those working on or visiting the Al Karama School, Phase 2 Extension project will be required to undergo a

McLaren site specific HSE induction before being allowed on site. The induction will be held within the project

premises and carried out by McLaren’s HSE Representative or a Construction team member, the induction

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 7 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

includes details of the site Emergency Procedures.

On completion of the HSE induction, those involved in this activity will be briefed on the contents of the RAMS

by their respective Site Engineer or Supervisor. They will then be required a sign a RAMS Briefing Register

(SAF019 UAE) confirming that they have been briefed and that they fully understand the RAMS and what is

expected from them during the execution of the works.

Any operative who will be operating any plant or equipment will be required to produce a copy of their Dubai/

Abu Dhabi Municipality/ENAS/EIAC approved competency certificate/card and proof of health to enable

McLaren to issue them with the Plant Operators Authorisation (SAF023 UAE).

Section H- Welfare facilities:

Drinking Water-

Clean drinking water stations will be provided on site (Water coolers will be brought to site until permanent

water stations are installed) and all operatives are to ensure they take on enough fluids throughout the day and

comply with the Summer Working Plan.

Rest areas and toilet-

Rest areas and toilets are provided on site and located as per the Al Karamah School, Phase 2 Extension Project

logistics layout plan.

Section I- Personal Protective Equipment (PPE)

The Following Personal Protective Equipment must be worn/be available during the execution of the works

activities

Type of PPE Required Yes No

Safety Helmet X

Safety Footwear X

Eye protection X

Gloves X

Hi- viz Vests X

Overalls (for operatives only) X

Ear protection X

Face Respirator X

Body Harness X

Respiratory masks X

Face Mask for Covid 19 X

Please ensure that any specific precautions for PPE as identified within MSDS/COSHH assessment or any

specific requirements by supplier/manufacturer are to be complied and adhered to.

Section J- Plant and Equipment to be Used

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 8 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

It is anticipated that the following Plant and Equipment will be used during the execution of the works; other

items will also be identified on the schedule below;

1 Insulated Hand tools with Multimeter

2 Harmonic analysers

*Note: All relevant competency certificates to be submitted to HSE Manager/Eng./Advisor prior to start of any

activity.

Type of Plant/Equipment to be Used Yes No Type of Plant/Equipment to be Used Yes No

Lifting X Cradle X

Mechanical hoist X Skid Steer Loader X

Mobile elevating working platform X Hand tools X

Ladder X Electrical tools X

Hoist X CAT & Gen Set X

Test Equipment X Ventilation/Extraction Equip X

Task Lighting X Pump X

Scaffolding X Lifting slings/chains X

Mobile scaffolds X Tele Handler X

Podium Scaffold X Others: Mobile Crane X

Section K- Materials To be used.

The following Materials will be utilised during the execution of the works, the Material Data sheets being

provided, which will allow the relevant COSHH assessments to be carried out; (See Appendix C)

Item Material Description MSDS Attached? COSHH Assessment

Attached?

1Section

N/AL- Temporary Works N/A N/A

2The following Temporary Works have been identified as required for this activity:

3

4

No Temporary works included in this RAMS

*Note: All temporary Works require a design completed by a competent person and must be

approved by McLaren’s Temporary Works Coordinator (TWC)

**Note: All Temporary Works require a Temporary Works Permit to Load/ Strike

Section M- Inspection and Test Regime

<< Detail how the work will be appropriately inspected and / or tested for workmanship, safety and

environmental compliance and by whom (detail their responsibilities). What competence is needed for

inspectors? What records need to be kept?

Refer to any relevant inspection and test plans and / or inspection checklists that need to be used.

Ensure inspectors are aware of the acceptance criteria before the inspections take place. >>

Section N- Communication/Toolbox Talks/Training Requirements:

Before starting any activity, a Point of Work Risk Assessment will be carried out by the Site Engineer/ Supervisor

to ensure all risk and controls have been identified, this will be followed by a task briefing carried out in the

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 9 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

language of the team. All members of the team must sign the briefing sheet to confirm that they have

understood the task requirements.

During the Preparation of this RAMS the following training for the staff and operatives has been identified;

Item Description of Training Has the Training been If not, when will be

completed? (Yes/No) completed (Date)

1 Work at Height Yes

2 Electrical Safety Yes

*Note: All relevant certificates will be submitted prior to works commencing or during induction. Where the

training has not been carried out, it must do so prior to the works/activities commencing.

Section O- Works Permits

The following works permits will be required during the execution of the Works;

Item Description of the Work Permit Permit Issued By Tick only applicable

1 Permit to Enter Confined Space McLaren

2 Permit for Lifting Operations. McLaren

3 Permit to Dig McLaren

4 Permit to work Hot cutting or Welding McLaren

5 Permit to Work in Ceiling Void McLaren

6 Permit for Roof Access McLaren

7 Permit to Work with Ladders, steps/scaffold McLaren

8 Permit to Work at Height McLaren

9 Permit to Work – Electrical above 110V McLaren

10 Permit to Work with COSHH Items McLaren

11 Permit to Work at External Face of The Building McLaren

12 Permit for Removal of Existing Fall Protections McLaren

13 Permit for Pressure Testing McLaren

14 LOTO Permit McLaren

Any other permits if required to be added

Section P- Environmental and Waste Management:

Labelled skips will be provided by McLaren, all waste must be segregated into the correct waste streams and

placed in the skips provided. It is important that waste is reduced, reused or recycled wherever possible.

Toolbox Talks will be regularly briefed to the workforce to ensure this is understood.

1 General Waste

2. Concrete Waste

3. Wooden Waste

4. Food Waste

5. Hazardous Waste

6. Paper / Cardboard Waste

Due to the nature of the works and the current site conditions, water shall be sprayed onto dirt/sand roads so

as to minimize dust pollution.

Where any plant is used, drip trays shall be placed underneath to catch any spilled oils or fuels. Oils and fuels

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 10 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

will be managed in accordance with the MSDS and the site Waste Management Plan.

All hazardous liquids must store in suitable, labelled containers with secondary containment to prevent ground

and water contamination.

Emergency spills kits must be available where any hazardous material is used.

Section Q- Programme for the Works.

6 Months

Section R- Housekeeping and Storage:

Housekeeping will be carried out as and when required and storage of materials will be located as per the

approved site logistics plan.

Combustible materials will be carefully managed and monitored in order to reduce the risk of fire.

Section S- Working at Height

During the preparation of the RAMS, the following activities for working at height have been identified and have

been addressed within the risk assessments within Appendix D. (to be filled if applicable to your works)

Item Activity Risk Assessment Reference

1 Working at Height Attached

2 Working at Mobile Tower/Podium Ladder Attached`

Section T- Occupational Health

During the preparation of the RAMS, the following Occupational Health issues have been reviewed and

addressed within this Method Statement.

Item Description Preventative Measures, (see also within the Risk Assessments)

1 Safety Critical Roles Anyone identified as safety critical (i.e. operators, riggers,

scaffolders, banksmen etc.) must have a medical check-up before

starting work

2 Bad Back/sprain due to A manual handing assessment will be carried out for all activities and

improper Manual handling all Operatives will receive Manual Handling training

3 Hand/Arm Vibration Exposure Action Values (EAVs) will be calculated for all vibration

activities. Where required, job rotation will be put in place and

recorded

4 Construction dust Roads shall be watered to minimise dust and housekeeping to be

carried out regularly.

RPE shall be provided for those at risk from hazardous dust

5 Noise Noise values will be monitored. Where required, job rotation will be

put in place and recorded. Where it is not possible to control noise,

PPE will be provided

6 Sun & Heat Sun creams will be provided for those that require it.

Drinking water and electrolyte additives will be provided.

Clothing shall cover legs and arms, gloves will be worn.

Summer Working Plans

7 Skin PPE shall provide as required by MSDS

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 11 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

Section U- Sequence of Works/Activities for Harmonic Measurement Study Procedure

RAMS to be briefed to all the operatives involved in the work

STARRT card to be prepared by assessing the area of work prior starting the work.

Supervisor to ensure all operatives have received a McLaren site basic induction

Supervisor to ensure all operatives have adequate PPE for the job including Full body harness.

Supervisor to ensure all operators having Competent certificate.

Supervisor to ensure that the site is clean and ready to start the work

Supervisor to ensure adequate tools are provided and should be visibly clean and tidy. Advise Site manager if

more tools are needed.

Supervisor to ensure that all hygienic PPE has been issued & being worn correctly.

Supervisor to ensure that proper barricade and warning signs are provided before starting any activity.

Supervisor to ensure proper working platforms such as ladders are being used and make sure that having

ladder permit on work

Safety Precautions:

Make sure operatives involved must have covid test every 7 days with Covid negative report.

Make safety barrier warning signs around the area

Review the entire manual before use of the Analyzer and its accessories.

Avoid working alone.

Do not operate the Analyser around explosive gas or vapor.

Use only insulated current probes, test leads and adapters as

supplied with the Analyser, or indicated as suitable for the

Fluke 434/435 Analyzer.

Before use, inspect the Analyser, voltage probes, test leads and accessories for mechanical damage

and replace when damaged. Look for cracks or missing plastic. Pay special attention to the insulation

surrounding the connectors.

Remove all probes, test leads and accessories that are not in use.

Always connect the Battery Charger / Power Adapter first to the AC outlet before connecting it to the

Analyser.

Use the ground input only to ground the Analyser and do not apply any voltage.

Do not apply input voltages above the rating of the instrument.

Do not apply voltages in excess of the marked ratings of the voltage probes or current clamps.

Take special care during fitting and removal of the flexible current probe: de-energize the installation

under test or wear suitable protective clothing.

Do not use exposed metal BNC or banana plug connectors.

Do not insert metal objects into connectors.

Use only the power supply, Model BC430 (Battery Charger / Power Adapter).

Equipment Connection & Measurement ACTIVITIES:

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 12 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

The following are the checks/setting to be carried out on Equipment: -

Phase voltages. Should be close to the nominal value. Voltage waveforms must be a sine

wave that is smooth and free from distortion. Use Scope Waveform to check the

waveform shape. Use Dips & Swells to record sudden voltage changes. Use Transients

mode to capture voltage anomalies.

Phase currents. Use Volts/Amps/Hertz and Dips & Swells to check current/voltage

relations. Use Inrush Current to record sudden current increases like motor inrush.

Crest Factor. A CF of 1.8 or higher means high waveform distortion. Use Scope

Waveform to see waveform distortion. Use Harmonics mode to identify harmonics and

THD (Total Harmonic Distortion).

Harmonics. Use Harmonics mode to check for voltage and current harmonics and THD

per phase. Use Trend to record harmonics over time.

Flicker. Use Flicker to check short- and long-term voltage flicker and related data per

phase. Use Trend to record these values over time.

Dips & Swells. Use Dips & Swells to record sudden voltage changes as short as half a

cycle.

Frequency. Should be close to nominal value. Frequency is normally very stable. Select

Volts/Amps/Hertz to display frequency. The course of frequency over time is recorded in

the Trend screens.

Unbalance. Each phase voltage should not differ more than 1 % from the average of the

three. Current unbalance should not exceed 10 %. Use Scope Phasor or Unbalance mode

to investigate unbalances.

Mains Signaling. Can be used to analyser the level of remote control signals that often are

present on power distribution systems.

Logger. Allows you to store multiple readings with high resolution in a long memory.

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 13 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

First put the current clamps around the conductors of phase A (L1), B (L2), C (L3), and N(neutral). The

clamps are marked with an arrow indicating the correct signal polarity. Next make the voltage connections: start

with Ground and then in succession N, A (L1),B (L2), and C (L3). For correct measuring results, always connect the

Ground input.

Always double-check the connections. Make sure that current clamps are secured and

Completely closed around the conductors.

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 14 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

Before making any measurements, set the Analyser up for the line voltage, frequency,

and wiring configuration of the power system you want to measure.

Scope Waveform and Phasor display are useful to check if voltage leads and current

clamps are connected correctly. In the vector diagram the phase voltages and currents A

(L1), B (L2), and C (L3) should appear in sequence when observing them in clockwise

direction as shown in the example in Figure.

4. Submission of Reports:

The measurement results shall be downloaded from the equipment and

summarised Reports in soft copy will be submitted upon completion.

5. PLANT, TOOLS, EQUIPMENT ARRANGEMENTS

Fluke 435 II Series with all accessories.

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 15 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

6. Appendices

6.1) Attachment -1

-: Equipment Photos

ATTACHMENT -1

Equipment photos and calibration certificates

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 16 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 17 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

APPENDIX A

Site Logistics Plan

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 18 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

A

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 19 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

PPENDIX B

Al Karamah School, Phase 2

Abu Dhabi, UAE

CRISIS PLAN

Upon an incident, being discovered the first member of McLaren’s staff or the site operative

1.

discovering the incident shall inform the Project Manager and HSE department by Project

Emergency no- 056 898 7960

Both the Safety Officer and the first Aider are to attend the scene with their mobile. The project

2.

Manager or site receptionist waits in office ready to telephone relevant emergency services.

Both the Safety Officer and the first Aider are to assess the situation and put in place the relevant

3.

systems to end/deal with the emergency.

Both the Safety Officer and the first Aider are to ensure all trades are gathered at the assembly

4.

point and liaise with supervisor to account for all operatives - no person should leave site.

Either the Safety Officer or the first Aider phones the project Manager or site receptionist and

5.

informs him/her of which emergency services are required.

6. The Project Manager calls all relevant McLaren staff.

Both the Safety Officer and the first Aider waits for the emergency services at scene.

7.

Once emergency services arrive, The Project Manager will telephone the relevant authorities, i.e.

8.

the HSE/Client’s Safety Advisor/McLaren’s Operations & QHSE Manager.

Both the Safety Officer and the first Aider keep trades informed of the situation and releases

9.

trades to return to work or leave site only when emergency services or The Project Manager

instruct that it is safe to do so, and all names of witnesses are recorded.

The Project Manager or Construction Manager are to arrange for photographs of the scene to be

10.

taken, and if necessary, the area to be cordoned.

A full investigation of the Incident is to be carried out, with a written report being submitted the

11.

SHEQ Director, as soon as practicably possible after the incident, including all witness statements,

photos of the scene, induction and method statement records, recommendation to prevent a re-

occurrence and what action has been taken since the incident taking place.

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 20 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

APPENDIX C

COSHH ASSESSMENTS AND MSDS

(Attach if any)

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 21 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

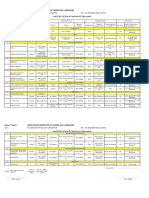

APPENDIX- D

RISK ASSESSMENT

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 22 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

APPENDIX-E

TECHNICAL INFORMATION

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 23 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

APPENDIX-F

INSPECTION AND TEST PLANS

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 24 of 25 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

APPENDIX-G

THIRD PARTY COMPETENCY/CERTIFICATES

Title: Harmonic Measurement Study Procedure Ref. No: M1492-MCL-MCL-MSS-093

Project: Al Karama School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 25 of 25 RISK ASSESSMENT METHOD STATEMENT

You might also like

- Python3 Tutorial PDFDocument26 pagesPython3 Tutorial PDFferronatto11100% (1)

- Manpower Record ListDocument3 pagesManpower Record ListMohamad Hidayat Zainul Masri100% (1)

- Testing Commissioning of HVAC SystemDocument53 pagesTesting Commissioning of HVAC SystemAnandu Ashokan100% (4)

- Risk Assessment Form - TV StudioDocument2 pagesRisk Assessment Form - TV StudioMark Rainsford100% (1)

- Installation and Testing Commissioning of PumpsDocument60 pagesInstallation and Testing Commissioning of PumpsAnandu Ashokan100% (1)

- Ara-Dc-Ms-Ele-0030 Sat of LV Cables (Gen)Document15 pagesAra-Dc-Ms-Ele-0030 Sat of LV Cables (Gen)Anandu AshokanNo ratings yet

- Ara-Dc-Ms-Ele-0030 Sat of LV Cables (Gen)Document15 pagesAra-Dc-Ms-Ele-0030 Sat of LV Cables (Gen)Anandu AshokanNo ratings yet

- Master Log - LOGDocument15 pagesMaster Log - LOGAnandu AshokanNo ratings yet

- Construction Quality ReportsDocument36 pagesConstruction Quality ReportsKamran AkhtarNo ratings yet

- Shutdown ReportDocument7 pagesShutdown ReportmasudalamNo ratings yet

- Installation of Toilet Exhaust FansDocument51 pagesInstallation of Toilet Exhaust FansAnandu AshokanNo ratings yet

- Bonding and GroundingDocument183 pagesBonding and Groundingbanjan0230No ratings yet

- Dismantling of Temporary ServicesDocument22 pagesDismantling of Temporary ServicesAnandu AshokanNo ratings yet

- Security Analytics For Dummies Securonix Special Edition PDFDocument53 pagesSecurity Analytics For Dummies Securonix Special Edition PDFAgteNo ratings yet

- Testing & Commissioning of Fire Fighting SystemDocument25 pagesTesting & Commissioning of Fire Fighting SystemAnandu Ashokan100% (1)

- m1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelDocument53 pagesm1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelAnandu AshokanNo ratings yet

- m1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelDocument53 pagesm1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelAnandu AshokanNo ratings yet

- m1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelDocument53 pagesm1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelAnandu AshokanNo ratings yet

- RAMS For Pressure TestingDocument21 pagesRAMS For Pressure TestingAnandu AshokanNo ratings yet

- A Practical Study For New Design of Essential OilsDocument17 pagesA Practical Study For New Design of Essential OilsEmmanuel PlazaNo ratings yet

- Methos of Statement For Startup WorkDocument6 pagesMethos of Statement For Startup WorkMahesh MirajkarNo ratings yet

- M1439 GHD MCL MSS 030 Rev 01 Wiring Accessories BDocument72 pagesM1439 GHD MCL MSS 030 Rev 01 Wiring Accessories BAnandu AshokanNo ratings yet

- Risk Assessment for Fire Alarm IntegrationDocument49 pagesRisk Assessment for Fire Alarm IntegrationAnandu AshokanNo ratings yet

- M1439-GHD-MCL-MSS-056 Lockout and Tag Out For Islolation ActivityDocument24 pagesM1439-GHD-MCL-MSS-056 Lockout and Tag Out For Islolation ActivityAnandu AshokanNo ratings yet

- SAT of Final Small Power & Lighting Circuits (GEN)Document13 pagesSAT of Final Small Power & Lighting Circuits (GEN)Anandu AshokanNo ratings yet

- ETIHAD SOUTHSIDE CATERING ELECTRICAL TESTINGDocument81 pagesETIHAD SOUTHSIDE CATERING ELECTRICAL TESTINGAnandu AshokanNo ratings yet

- GANTTDocument14 pagesGANTTManisha ThakurNo ratings yet

- Arc Flash Awareness: An IntroductionDocument83 pagesArc Flash Awareness: An IntroductionAnonymous q2iHVf100% (1)

- Record No.: Equip. No. Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoDocument2 pagesRecord No.: Equip. No. Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoDinesh Pitchaivel100% (1)

- Master Document Register for Majnoon ME&I ProjectDocument15 pagesMaster Document Register for Majnoon ME&I ProjectAbdullah Abdullah100% (1)

- Installation of Underground Electrical-ELV DuctDocument41 pagesInstallation of Underground Electrical-ELV DuctAnandu AshokanNo ratings yet

- RAMS For Installation of Fire Fighting SystemDocument24 pagesRAMS For Installation of Fire Fighting SystemAnandu AshokanNo ratings yet

- Rock Mass Classification SystemsDocument33 pagesRock Mass Classification Systemsmortaza7094No ratings yet

- RAMS For Installation and Testing of Access Control SystemDocument22 pagesRAMS For Installation and Testing of Access Control SystemAnandu AshokanNo ratings yet

- Etihad Southside Catering Facility Lockout Tagout Method StatementDocument24 pagesEtihad Southside Catering Facility Lockout Tagout Method StatementAnandu AshokanNo ratings yet

- Testing Commissioning Fire Fighting SystemsDocument47 pagesTesting Commissioning Fire Fighting SystemsAnandu AshokanNo ratings yet

- Testing Commissioning Fire Fighting SystemsDocument47 pagesTesting Commissioning Fire Fighting SystemsAnandu AshokanNo ratings yet

- KP-00+++-CQ712-B7360-Electrical Works (Switchyard Lightning Arrester Installation)Document3 pagesKP-00+++-CQ712-B7360-Electrical Works (Switchyard Lightning Arrester Installation)Utku Can KılıçNo ratings yet

- m1439 GHD MCL Mss 053 Modification For LV PanelDocument84 pagesm1439 GHD MCL Mss 053 Modification For LV PanelAnandu AshokanNo ratings yet

- m1439 GHD MCL Mss 053 Modification For LV PanelDocument84 pagesm1439 GHD MCL Mss 053 Modification For LV PanelAnandu AshokanNo ratings yet

- Earthing and Bonding Method StatementDocument4 pagesEarthing and Bonding Method StatementMusthafa Shaik100% (1)

- Saudi Aramco Oil Company: SECTION 01720 Record DocumentsDocument4 pagesSaudi Aramco Oil Company: SECTION 01720 Record DocumentsPhilip YapNo ratings yet

- Ooredoo: Method Statement For Fiber Optic Cable WorkDocument5 pagesOoredoo: Method Statement For Fiber Optic Cable WorkYousaf RichuNo ratings yet

- M1439-GHD-MCL-MSS-032 Rev. 01 Installation of TransformerDocument63 pagesM1439-GHD-MCL-MSS-032 Rev. 01 Installation of TransformerAnandu AshokanNo ratings yet

- Water Filtration System - Method StatementDocument7 pagesWater Filtration System - Method Statementsunil_v575% (4)

- SAT of Earthing & Lightning Protection System (GEN)Document15 pagesSAT of Earthing & Lightning Protection System (GEN)Anandu AshokanNo ratings yet

- m1439-Ghd-mcl-mss-005 Existing Dry Type Transformer ReconditioningDocument27 pagesm1439-Ghd-mcl-mss-005 Existing Dry Type Transformer ReconditioningAnandu AshokanNo ratings yet

- 13.11.2023 SKD - DEC - QAC - ITP - 054 - ITP - of Cable Installation and TerminationDocument20 pages13.11.2023 SKD - DEC - QAC - ITP - 054 - ITP - of Cable Installation and Terminationsokhib.salimov1992No ratings yet

- RRU and BBU Configurations 02-08-2012Document20 pagesRRU and BBU Configurations 02-08-2012Mohammed UD100% (2)

- MSS Approvals Required for HVAC InstallationDocument102 pagesMSS Approvals Required for HVAC InstallationAnandu AshokanNo ratings yet

- O&M Commission & Testing GuidelinesDocument2 pagesO&M Commission & Testing GuidelinesRami Mikati100% (1)

- DCPRO Submittal Response Sheet ReviewDocument1 pageDCPRO Submittal Response Sheet ReviewAnandu AshokanNo ratings yet

- BMS Installation & Testing Risk Assessment for Al Karama SchoolDocument23 pagesBMS Installation & Testing Risk Assessment for Al Karama SchoolAnandu AshokanNo ratings yet

- SOP16 Testing of Fire Alarm SystemDocument1 pageSOP16 Testing of Fire Alarm Systemanil kumarNo ratings yet

- c03 Ar f25-79 Sat ReportDocument18 pagesc03 Ar f25-79 Sat ReportSenthilkumaran VenkatasamyNo ratings yet

- Pressure TestingDocument45 pagesPressure TestingAnandu AshokanNo ratings yet

- Harmonic Measurement Risk AssessmentDocument41 pagesHarmonic Measurement Risk AssessmentAnandu AshokanNo ratings yet

- Toolbox4Planning - Activities and Logical Sequence For Electrical and Instrumentation EngineeringDocument1 pageToolbox4Planning - Activities and Logical Sequence For Electrical and Instrumentation EngineeringMuslimNo ratings yet

- KP-00+++-CY712-BKM7109 Method Statment For Lightning Protection System Installation WorksDocument16 pagesKP-00+++-CY712-BKM7109 Method Statment For Lightning Protection System Installation WorksUtku Can KılıçNo ratings yet

- Quality Assurance of PV CellsDocument5 pagesQuality Assurance of PV CellssasikumarNo ratings yet

- SAT of MV Cables (GEN)Document18 pagesSAT of MV Cables (GEN)Anandu AshokanNo ratings yet

- Activity Schedule of ESSDocument17 pagesActivity Schedule of ESSkumar100% (1)

- Method of Statement HDDDocument12 pagesMethod of Statement HDDSyed FaizNo ratings yet

- Traffic Management PlanDocument10 pagesTraffic Management PlanJake CortezNo ratings yet

- Installation of Sanitary Fixtures MixersDocument44 pagesInstallation of Sanitary Fixtures MixersAnandu AshokanNo ratings yet

- IP - Ingress Protection RatingsDocument1 pageIP - Ingress Protection Ratingsanon_904868564No ratings yet

- An Overview On Arc Flash StudyDocument7 pagesAn Overview On Arc Flash StudySoni Bibi100% (1)

- Material and Equipment Standard: IPS-M-EL-136Document14 pagesMaterial and Equipment Standard: IPS-M-EL-136Fatholla SalehiNo ratings yet

- (Project Title) : Earned Value Analysis ReportDocument3 pages(Project Title) : Earned Value Analysis ReportSadia Rahman100% (1)

- QAP For Overall Mechanical ActivitiesDocument2 pagesQAP For Overall Mechanical ActivitiesMaheshwar polepallyNo ratings yet

- Business Process Management (BPM)Document14 pagesBusiness Process Management (BPM)zmrman0% (1)

- Tool Box Talk 2-07 Excavation Egress - OSHADocument3 pagesTool Box Talk 2-07 Excavation Egress - OSHAloveanbu24No ratings yet

- Method Statement for Installation of Switchgear & IsolatorDocument14 pagesMethod Statement for Installation of Switchgear & IsolatorProjects INTSNo ratings yet

- Testing Commissioning of Electrical InstallationDocument39 pagesTesting Commissioning of Electrical InstallationAnandu AshokanNo ratings yet

- Design of A Chemical Plant PDFDocument2 pagesDesign of A Chemical Plant PDFAdarsh SvNo ratings yet

- Project Cost Monitoring Process SheetDocument1 pageProject Cost Monitoring Process Sheetabhimehta90No ratings yet

- Pulp and Paper IndustryDocument6 pagesPulp and Paper IndustrySaad AhmedNo ratings yet

- Commissioning and Start-UpDocument1 pageCommissioning and Start-UpLuciano GaglianoNo ratings yet

- E-003B Rev C2-MIPS Distribution BoardDocument2 pagesE-003B Rev C2-MIPS Distribution BoardMusab ShabbirNo ratings yet

- Jacking Procedurefor Construction of Tanks NEWDocument9 pagesJacking Procedurefor Construction of Tanks NEWVikram RangasamyNo ratings yet

- Cat Ladder Details2Document185 pagesCat Ladder Details2Shoaib KhanNo ratings yet

- Lighting REV 0Document24 pagesLighting REV 0كرم عمروNo ratings yet

- Lux Reading Test QCDD FormDocument2 pagesLux Reading Test QCDD FormMohamed AbdelnabyNo ratings yet

- Irf - 618 1H2Document13 pagesIrf - 618 1H2atif_aman123No ratings yet

- Export - Duty CalculationDocument2 pagesExport - Duty CalculationSunil MateNo ratings yet

- Systrome Sd-154 Dual Band Adsl Modem Operation Manual: Presentation To CAAZ Fixed Network O&MDocument21 pagesSystrome Sd-154 Dual Band Adsl Modem Operation Manual: Presentation To CAAZ Fixed Network O&MAragawNo ratings yet

- BGR-PPD-208-EL-FQP-0553, REV0 - 28.01.2015 - Action 5Document4 pagesBGR-PPD-208-EL-FQP-0553, REV0 - 28.01.2015 - Action 5Santoshkumar GuptaNo ratings yet

- Method Statement FOR Testing and Commissioning: Grounding SystemDocument3 pagesMethod Statement FOR Testing and Commissioning: Grounding SystemNon Etabas Gadnatam100% (1)

- SL No Phase Week - 1 Identify, Assign and Schedule PersonnelDocument3 pagesSL No Phase Week - 1 Identify, Assign and Schedule Personnelfairoos aliNo ratings yet

- Dream Catcher Events Financial PlanDocument10 pagesDream Catcher Events Financial PlanPrince Jeffrey FernandoNo ratings yet

- Electrical Engineer (Professional) CLASSIC TemplateDocument1 pageElectrical Engineer (Professional) CLASSIC TemplateNguyen LongNo ratings yet

- Night Work Permit.Document2 pagesNight Work Permit.Farman ShaikhNo ratings yet

- Attachment 12.5 - QA - QC Checklist - SMDBDocument6 pagesAttachment 12.5 - QA - QC Checklist - SMDBehteshamNo ratings yet

- RFQDocument4 pagesRFQPaul SigeiNo ratings yet

- Resume - Anil SinghDocument3 pagesResume - Anil SinghAnil SinghNo ratings yet

- Rerouting of Existing MEP Services in New SubstationDocument52 pagesRerouting of Existing MEP Services in New SubstationAnandu AshokanNo ratings yet

- Installation of Grill Diffuser LouversDocument51 pagesInstallation of Grill Diffuser LouversAnandu AshokanNo ratings yet

- Principles of Metal Forming TheoryDocument21 pagesPrinciples of Metal Forming TheoryAshok Kumar UppariNo ratings yet

- CV - Teguh Agung Kusuma - COC I - Chief Mate - AHTS, Survey, AWBDocument7 pagesCV - Teguh Agung Kusuma - COC I - Chief Mate - AHTS, Survey, AWBTeguh Agung KusumaNo ratings yet

- Data StructuresDocument41 pagesData StructuresSree Charan ReddyNo ratings yet

- Wire Size Chart NEC 2011Document1 pageWire Size Chart NEC 2011Gustavo TovarNo ratings yet

- Name of Work: Estimation For Proposed Construction of Tara Ramesh, Tangali, Kadur Taluk, Chikkamagalur DistrictDocument25 pagesName of Work: Estimation For Proposed Construction of Tara Ramesh, Tangali, Kadur Taluk, Chikkamagalur DistrictDEEPIKANo ratings yet

- OXIDATIONDocument36 pagesOXIDATIONMansab AliNo ratings yet

- User Manual For AzAmerica - S1005 - 20131023Document35 pagesUser Manual For AzAmerica - S1005 - 20131023Alonso IbacetaNo ratings yet

- Complete Lesson 4 Assessment Task On The Maneuver of The ShipDocument2 pagesComplete Lesson 4 Assessment Task On The Maneuver of The ShipMixed VideosNo ratings yet

- Searchq Cache JK76 QUqg RF8 JWWWDocument36 pagesSearchq Cache JK76 QUqg RF8 JWWWSajuSadasivanNo ratings yet

- Impedance, Angular Velocities & Frequencies of Oscillating CurrentsDocument32 pagesImpedance, Angular Velocities & Frequencies of Oscillating CurrentselectrosciNo ratings yet

- 2 Introduction To Quiz Wind Turbine Rotor Speed Control Strategy New CourseraDocument5 pages2 Introduction To Quiz Wind Turbine Rotor Speed Control Strategy New CourseraUsama Majeed33% (3)

- Pneumatic Can Crusher SystemDocument21 pagesPneumatic Can Crusher Systemkamleshm2No ratings yet

- 2nd Quarter Week 3 Parallel CircuitDocument12 pages2nd Quarter Week 3 Parallel CircuitjNo ratings yet

- Cse3024 Web-Mining Eth 1.1 47 Cse3024 PDFDocument12 pagesCse3024 Web-Mining Eth 1.1 47 Cse3024 PDFAyush SoodNo ratings yet

- Robin Grayson Gold Recovery Method73Document1 pageRobin Grayson Gold Recovery Method73Senthilkumar PragasamNo ratings yet

- Assignment Guiding Note 2023Document2 pagesAssignment Guiding Note 2023Nicole RodriguezNo ratings yet

- Engineering Data Sheet: Bill of MaterialDocument7 pagesEngineering Data Sheet: Bill of MaterialJairo andres Guarnizo SuarezNo ratings yet

- Waller Park Preview 2021Document7 pagesWaller Park Preview 2021Jason DelgadoNo ratings yet

- BRC PDFDocument106 pagesBRC PDFМиша ШаулаNo ratings yet

- Bil Jax 2622T - ManualDocument60 pagesBil Jax 2622T - ManualDuynamndk100% (1)

- Phan Tich Bang Cong Cu PTBCC Chapter 10 Gas Chromatography (Cuuduongthancong - Com)Document86 pagesPhan Tich Bang Cong Cu PTBCC Chapter 10 Gas Chromatography (Cuuduongthancong - Com)Phong VõNo ratings yet

- Aquini: 3 Decades of ExcellenceDocument13 pagesAquini: 3 Decades of ExcellenceAnuj AggarwalNo ratings yet