Professional Documents

Culture Documents

RAMS For Installation of Fire Alarm System and PAVA System

Uploaded by

Anandu AshokanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RAMS For Installation of Fire Alarm System and PAVA System

Uploaded by

Anandu AshokanCopyright:

Available Formats

RISK ASSESSMENT METHOD STATEMENT

Method Statement and Risk Assessment for the

Installation of Fire Alarm System & PAVA System

The Al Karama School, Phase 2

Abu Dhabi, UAE

Project No. M1492

Document Ref No: M1492-MCL-MCL-MSS-028

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 1 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

Project name Al Karama School, Phase 2 Project No M1492

M1492-MCL-MCL-

Main Contractor McLaren Construction LLC Document No

MSS-028

Installation of Fire Alarm System & PAVA

Title/Task Revision No 00

System

Document

Date of issue 10/06/2020 Anu Baby

Prepared By

Proposed start date 30/06/2020 Duration of task 6 Months

Contents

Section A Register of Revisions

Section B Scope of Works to be undertaken

Section C Location of the Project

Section D Location of the Works to be Undertaken with the Project

Section E Site Access/Egress and Access to the Work Zone

Section F Emergency Contacts Details and Procedures

Section G McLaren Site Specific HSE Safety Induction

Section H Welfare facilities

Section I Personal Protective Equipment

Section J Plant/Equipment and tools to be Used

Section K Materials To be used

Section L Temporary Works

Section M Inspection and Test Regime

Section N Communication/Toolbox Talks/Training Requirements

Section O Works Permits

Section P Environmental and Waste Management

Section Q Programme for the Works

Section R Housekeeping and Storage

Section S Working at Height

Section T Occupational Health

Section U Sequence of Works/Activities

Appendices

Appendix A Site Logistic Plans and Other Design Information Relative to the Works

Appendix B Crisis/Emergency Plan

Appendix C COSHH Assessments and Material Data Sheets

Appendix D Risk Assessments

Appendix E Technical Information

Appendix F Inspection and Test Plans

Appendix G Third Party competency/certifications

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 2 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

Section A - Register of Revisions

Rev. No Date Reason for Amendment Amended By Signature Has this amendment been

(Name) briefed to the operatives

involved and have the

operatives signed the register?

This method statement has been prepared in conjunction with the following documents.

1. UAE Federal Law No. 8, chapter V, Article 91 of 1980.

2. United Arab Emirate Ministerial Order 337/2, Medical care to Workers

3. UAE Fire & Life Safety Code of Practice 2018.

4. UAE Ministerial Order No. 32 of 1982.

5. Federal Environmental Authority Law No.24/1999 and its supplements.

6. Federal Law No. (20) of 1991 Concerning the Civil Aviation Law.

7. Ministerial Resolution 688 of 2013, Regarding Fixing of Working Hours During Summer

8. Dubai Municipality Code of Construction Safety Practice, 2007-2011 edition

9. Dubai Municipality Technical Guidelines

10. Local order No. 61 of 1991on Environment Protection Regulation in the Emirates of Dubai.

11. Articles (3,4,5,7) Local Law No. 21/2005 (Waste Management)

12. Local Order No. 11 of 2003 concerning Public Health & community Safety in the Emirate of Dubai

13. OSHAD Code of Practice, HSE Regulations, Technical Guidelines, Mechanisms

14. ISO 45001:2018, ISO 14001:2015 ISO 9001:2015

15. McLaren’s Integrated Management System Policy Statement

16. McLaren Management Procedures (MMP) and Function Procedures

17. McLaren’s site specific SHEQ Plan

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 3 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

Section B- Scope of Works to be undertaken:

The work Describes Installation of Fire Alarm system and PAVA System at Al Karama School, Phase 2,

Abudhabi

The following Critical Hazards have been identified during the preparation of the scope of works, please refer to

the Risk Assessments within Appendix D.

1. Falling from height.

2. Manual Handling.

3. Slip Trips and Falls.

4. Falling objects

5. Use of power tools

Section C- Location of the Project

Location of the Project;

The Project premise is located at Al Rowdah, W14-01, Abu Dhabi as marked below.

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 4 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

Existing Services

As per current information, there is existing irrigation network passing outside the construction work

area.

Underground electrical cables for existing lighting poles within the plot have been removed prior to

commencing works at the area. A full survey has been undertaken to confirm this including an

underground service scan and trial trenches hand excavated in various locations around the project to

locate any services running into, or close to the plot.

A permit to dig must be obtained from McLaren prior to any excavations commencing.

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 5 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

Section D- Location of the Works to be Undertaken within the Project

Section E- Site Access/Egress and Access to the Work Zone

Section F- Emergency Contacts Details and Procedures:

The following staff from McLaren and will be on site during the execution of the works and will be responsible

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 6 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

for managing the works;

Name Position Company Contact Details

Paul Carlin (Visiting) Operations Director McLaren 056 105 4691

Jamie Selway (Visiting) QHSE Manager McLaren 052 173 6235

Kavith Rathi Sr Site Engineer McLaren 055 190 6842

Abdul Mutallib Senior HSE Officer McLaren 055 400 0602

Vignesh Prabakar Site Engineer McLaren 058 621 6731

Nesakumar P MEP Engineer McLaren 050 850 7968

Vishnu Mohan Project Manager Genfocus 056 546 5865

Anu Baby Project Engineer Genfocus 056 546 5807

Prabir Kumar HSE Officer Genfocus 054 793 7312

Mohmmed Jasim Mechanical Engineer Genfocus 056-526 8312

Parthipan Design Engineer(Elect) Genfocus 056-546 5812

Clitus Fire Warden /First Aider Genfocus 052 701 4049

In case of an Emergency/fire Alarm, all operatives, Staff and Visitors are required to report to the Assembly

Point, which is indicated on the site logistics drawing, as indicated by the symbol below. A roll call will be taken,

and registers checked to ensure that everyone is accounted for. No one will be allowed to leave the assembly

point until the Emergency Response Controller confirms that it is safe to do so.

Assembly Point

Please refer to the attached Crisis/Emergency Plan, (Appendix B) which is to be implemented where the need

arises.

The Qualified First Aiders for the Project are listed below, and the first Aid Boxes will be available within the

First Aid Room and in the Main Office Reception.

McLaren: (details of First Aiders) Subcontractor (Details of First Aiders)

Shebin Arun 056 746 5229 Prabir Kumar 054 7937312

Authority/Company Contact Telephone No.

Abdul Mutallib

Police 055 400 0602 999 Cletus 052 7014049

Please see Ambulance 998 below the

Emergency Fire (Civil Defence) 997 contact details:

SKMC Hospital 02 819 0000

McLaren Site Emergency No. 056 898 7960

Section G- McLaren Site Specific HSE Safety Induction:

All those working on or visiting the Al Karama School, Phase 2 Extension project will be required to undergo a

McLaren site specific HSE induction before being allowed on site. The induction will be held within the project

premises and carried out by McLaren’s HSE Representative or a Construction team member, the induction

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 7 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

includes details of the site Emergency Procedures.

On completion of the HSE induction, those involved in this activity will be briefed on the contents of the RAMS

by their respective Site Engineer or Supervisor. They will then be required a sign a RAMS Briefing Register

(SAF019 UAE) confirming that they have been briefed and that they fully understand the RAMS and what is

expected from them during the execution of the works.

Any operative who will be operating any plant or equipment will be required to produce a copy of their Dubai/

Abu Dhabi Municipality/ENAS/EIAC approved competency certificate/card and proof of health to enable

McLaren to issue them with the Plant Operators Authorisation (SAF023 UAE).

Section H- Welfare facilities:

Drinking Water-

Clean drinking water stations will be provided on site (Water coolers will be brought to site until permanent

water stations are installed) and all operatives are to ensure they take on enough fluids throughout the day and

comply with the Summer Working Plan.

Rest areas and toilet-

Rest areas and toilets are provided on site and located as per the Al Karamah School, Phase 2 Extension Project

logistics layout plan.

Section I- Personal Protective Equipment (PPE)

The Following Personal Protective Equipment must be worn/be available during the execution of the works

activities

Type of PPE Required Yes No

Safety Helmet X

Safety Footwear X

Eye protection X

Gloves X

Hi- viz Vests X

Overalls (for operatives only) X

Ear protection X

Face Respirator X

Body Harness X

Respiratory masks X

Others (other specific requirements) X

Please ensure that any specific precautions for PPE as identified within MSDS/COSHH assessment or any

specific requirements by supplier/manufacturer are to be complied and adhered to.

Section J- Plant and Equipment to be Used

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 8 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

It is anticipated that the following Plant and Equipment will be used during the execution of the works; other

items will also be identified on the schedule below;

1. Hand tools with Multimeter

2. Drill Machine and Grinder

3. Testing Kit

*Note: All relevant competency certificates to be submitted to HSE Manager/Eng./Advisor prior to start of any

activity.

Type of Plant/Equipment to be Used Yes No Type of Plant/Equipment to be Used Yes No

Lifting X Cradle X

Mechanical hoist X Skid Steer Loader X

Mobile elevating working platform X Hand tools X

Ladder X Electrical tools X

Hoist X CAT & Gen Set X

Test Equipment X Ventilation/Extraction Equip X

Task Lighting X Pump X

Scaffolding X Lifting slings/chains X

Mobile scaffolds X Tele Handler X

Podium Scaffold X Others: Mobile Crane X

Section K- Materials To be used.

The following Materials will be utilised during the execution of the works, the Material Data sheets being

provided, which will allow the relevant COSHH assessments to be carried out; (See Appendix C)

Item Material Description MSDS Attached? COSHH Assessment

Attached?

1Section L- Temporary Works

2The following Temporary Works have been identified as required for this activity:

3

4

No Temporary works included in this RAMS

*Note: All temporary Works require a design completed by a competent person and must be

approved by McLaren’s Temporary Works Coordinator (TWC)

**Note: All Temporary Works require a Temporary Works Permit to Load/ Strike

Section M- Inspection and Test Regime

<< Detail how the work will be appropriately inspected and / or tested for workmanship, safety and

environmental compliance and by whom (detail their responsibilities). What competence is needed for

inspectors? What records need to be kept?

Refer to any relevant inspection and test plans and / or inspection checklists that need to be used.

Ensure inspectors are aware of the acceptance criteria before the inspections take place. >>

Section N- Communication/Toolbox Talks/Training Requirements:

Before starting any activity, a Point of Work Risk Assessment will be carried out by the Site Engineer/ Supervisor

to ensure all risk and controls have been identified, this will be followed by a task briefing carried out in the

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 9 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

language of the team. All members of the team must sign the briefing sheet to confirm that they have

understood the task requirements.

During the Preparation of this RAMS the following training for the staff and operatives has been identified;

Item Description of Training Has the Training been If not, when will be

completed? (Yes/No) completed (Date)

1 Work at Height Yes

2 Using Abrasive wheel Yes

3 Manual Handling Yes

4 Scaffolding inspection and scaffolding erection Yes

5 Working with Power Tools Yes

*Note: All relevant certificates will be submitted prior to works commencing or during induction. Where the

training has not been carried out, it must do so prior to the works/activities commencing.

Section O- Works Permits

The following works permits will be required during the execution of the Works;

Item Description of the Work Permit Permit Issued By Tick only applicable

1 Permit to Enter Confined Space McLaren

2 Permit for Lifting Operations. McLaren

3 Permit to Dig McLaren

4 Permit to work Hot cutting or Welding McLaren

5 Permit to Work in Ceiling Void McLaren

6 Permit for Roof Access McLaren

7 Permit to Work with Ladders, steps/scaffold McLaren

8 Permit to Work at Height McLaren

9 Permit to Work – Electrical above 110V McLaren

10 Permit to Work with COSHH Items McLaren

11 Permit to Work at External Face of The Building McLaren

12 Permit for Removal of Existing Fall Protections McLaren

13 Permit for Pressure Testing McLaren

14 Other Permit

Any other permits if required to be added

Section P- Environmental and Waste Management:

Labelled skips will be provided by McLaren, all waste must be segregated into the correct waste streams and

placed in the skips provided. It is important that waste is reduced, reused or recycled wherever possible.

Toolbox Talks will be regularly briefed to the workforce to ensure this is understood.

1 General Waste

2. Concrete Waste

3. Wooden Waste

4. Food Waste

5. Hazardous Waste

6. Paper / Cardboard Waste

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 10 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

Due to the nature of the works and the current site conditions, water shall be sprayed onto dirt/sand roads so

as to minimize dust pollution.

Where any plant is used, drip trays shall be placed underneath to catch any spilled oils or fuels. Oils and fuels

will be managed in accordance with the MSDS and the site Waste Management Plan.

All hazardous liquids must store in suitable, labelled containers with secondary containment to prevent ground

and water contamination.

Emergency spills kits must be available where any hazardous material is used.

Section Q- Programme for the Works.

6 Months

Section R- Housekeeping and Storage:

Housekeeping will be carried out as and when required and storage of materials will be located as per the

approved site logistics plan.

Combustible materials will be carefully managed and monitored in order to reduce the risk of fire.

Section S- Working at Height

During the preparation of the RAMS, the following activities for working at height have been identified and have

been addressed within the risk assessments within Appendix D. (to be filled if applicable to your works)

Item Activity Risk Assessment Reference

1 Working at Height Attached

2 Working at Mobile Tower/Podium Ladder Attached`

Section T- Occupational Health

During the preparation of the RAMS, the following Occupational Health issues have been reviewed and

addressed within this Method Statement.

Item Description Preventative Measures, (see also within the Risk Assessments)

1 Safety Critical Roles Anyone identified as safety critical (i.e. operators, riggers,

scaffolders, banksmen etc.) must have a medical check-up before

starting work

2 Bad Back/sprain due to A manual handing assessment will be carried out for all activities and

improper Manual handling all Operatives will receive Manual Handling training

3 Hand/Arm Vibration Exposure Action Values (EAVs) will be calculated for all vibration

activities. Where required, job rotation will be put in place and

recorded

4 Construction dust Roads shall be watered to minimise dust and housekeeping to be

carried out regularly.

RPE shall be provided for those at risk from hazardous dust

5 Noise Noise values will be monitored. Where required, job rotation will be

put in place and recorded. Where it is not possible to control noise,

PPE will be provided

6 Sun & Heat Sun creams will be provided for those that require it.

Drinking water and electrolyte additives will be provided.

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 11 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

Clothing shall cover legs and arms, gloves will be worn.

Summer Working Plans

7 Skin PPE shall provide as required by MSDS

Section U- Sequence of Works/Activities for Fire Fighting Pipe Installation

RAMS to be briefed to all the operatives involved in the work

STARRT card to be prepared by assessing the area of work prior starting the work.

Supervisor to ensure all operatives have received a McLaren site basic induction

Supervisor to ensure all operatives have adequate PPE for the job including Full body harness.

Supervisor to ensure all operators having Competent certificate.

Supervisor to ensure that the site is clean and ready to start the work

Supervisor to ensure adequate tools are provided and should be visibly clean and tidy. Advise Site manager if

more tools are needed.

Supervisor to ensure that all hygienic PPE has been issued & being worn correctly.

Supervisor to ensure that proper barricade and warning signs are provided before starting any activity.

Supervisor to ensure proper working platforms such as ladders are being used and make sure that having

ladder permit on work

Transportation to site will be as per site requirement. Timing to be agreed with McLaren

Ensuring that unloading of materials is undertaken in designated area.

When offloading the materials precaution to be taken to avoid damages.

Installation Procedure

All materials received at site shall be inspected and ensured that the materials are as per approved material submittal. Any

discrepancies, damages etc. shall be notified and reported for further action. Material found not suitable for the project

shall be removed from site immediately.

All the Fire Alarm System Outstations, Modules & Control Panels etc. shall be stored in an air conditioned place.

25 mm PVC conducting for concealed installation. For surface installation, FP200 cable will be clipped on the soffit on

the slab in false ceiling and non-false ceiling areas.

The containment system for Fire Alarm system is being used wherever required and also near the Fire Alarm control

panels.

Correct type of back boxes for all the outstations should be installed as per approved shop drawings / material submittals.

The mounting heights for the Junction boxes should be verified with approved shop drawings.

Containment System should be offered for QC verification prior to cabling works.

All the related documents like latest approved shop drawings and schematic etc. should be available with installation

team.

Site Installation Method Statement

The required amount of cable should be transferred from Stores to Site access point by pick-up and to the particular floor

with wheelbarrow as required to the work place.

The correct size and type of cable should be identified and cut to the required length.

All the cables should be clipped in surface or installed in concealed PVC conduit or G.I. Tray only.

Proper identifications to be provided for loop in / loop out of Fire Alarm cables.

The earth cables to all the outstations to be properly terminated with earth sleeve in the appropriate terminal in order to

avoid any earth fault in the loop.

The junction boxes and back boxes to the outstations such as smoke detectors, manual call points and modules should be

installed as per the approved shop drawings.

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 12 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

Installation of system outstation should be offered for QC Verification.

Adequate additional cable lengths to be provided during cabling for the detectors, which are coming in False ceiling.

All the cables to be terminated in the outstations with proper screw driver and as per the identifications provided in the

cables. No joints are allowed in between two outstations.

All the Fire Alarm control Panels such as Main Control Panels, Mimic Panels, Repeater Panels should be installed as per

approved shop drawing.

Installation shall be offered for QC verification.

All Smoke Detectors to have cover on it after installation and before handing over of the area, in order to avoid any

physical damages / accumulation of dust within the Smoke Detectors.

All cables to be properly identified in Fire Alarm control panel before termination.

Installation of Beam sensors to be as per the approved shop drawings / Manufacturer’s recommendations.

Installation of Duct detectors to be as shown in the approved shop drawings.

Work Inspection Request shall be raised for Consultant’s inspection and sign o

The devices/peripherals (Smoke detectors, heat detectors, break glass, duct detectors, beam detectors, control and

monitoring modules) are connected in Class A circuit with the Control panels.

The speakers & speaker with strobes are connected in Class A circuit with the Control panels.

2 Core 1.5mm2 FP 200 cable to be used for cabling the Initiating Device Circuits (IDC) to the panel, additional 2c x

2.5mm2 FP200 cable is required for the smoke detector with sounder base for the activation of the sounders units.

2 core 1.5mm2 FP 200 cable to be used for cabling the Speakers with the panel, additional 2c x 2.5mm2 FP200 cable is

required from the FACP for the speaker with strobe for the activation of the strobe unit allied in vertical walls the run of

conduit will be kept straight.

Comply with NFPA 72 for installation of fire-alarm equipment.

Smoke- or Heat-Detector Spacing

Comply with NFPA 72, “Smoke-Sensing Fire Detectors” & “Heat-Sensing Fire Detectors”.

Smooth ceiling spacing shall not exceed 30 feet (9 m).

Fire-Alarm Control Unit: Surface mounted, with tops of cabinets not more than 72 inches (1830 mm) above the finished

floor.

Annunciator: Install with top of panel not more than 72 inches (1830 mm) above the finished floor.

Wiring & Connections Requirements

Verify that hardware and devices are NRTL listed for use with re-alarm system before making connections. Make

addressable connections with a supervised interface device to the following devices and systems. Install the interface

device less than 3 feet (1 m) from the device controller. Make an addressable confirmation connection when such

feedback is available at the device or system being controlled.

Alarm-initiating connection to smoke-control system (smoke management) at fire-fighter smoke-control system panel.

Alarm-initiating connection to stairwell and elevator-shaft pressurization systems.

Smoke dampers in air ducts of designated air-conditioning duct systems.

Alarm-initiating connection to elevator recall system and components.

Alarm-initiating connection to activate emergency lighting control.

Alarm-initiating connection to activate emergency shutoffs for gas and fuel supplies.

Supervisory connections at valve supervisory switches.

Supervisory connections at low-air-pressure switch of each dry-pipe sprinkler system.

Supervisory connections at elevator shunt trip breaker.

Supervisory connections at fire-pump power failure including a dead-phase or phase reversal condition.

Supervisory connections at fire-pump engine control panel.

Fault Finding in Fire Alarm System

Battery Charger Faults

Battery Charger Faults that can arise during the operational lifetime of a panel. You may observe one of the

following Faults;

Charger 2% out of range

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 13 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

Battery Charger Supply incorrect to correctly measure the output voltage you will need to follow the steps below.

To prevent damage to the system, disconnect the batteries & power down the system, disconnect the power & harnesses

from the Power Supply.

Connect the Multi-meter to the battery leads (with batteries disconnected), power up & measure the voltage.

Calculate the difference between the measured voltage & 27.6v. NOTE: After 90 seconds, the voltage will drop to <24v.

If this happens, power down & start again.

Positive/Negative Earth Ground Faults

Fire Panels have the ability to detect positive or negative Earth Ground Faults. An Earth Ground Fault occurs when an electrical

circuit is shorted to ground

Inspection and Field Testing

All inspection and testing for re alarm system shall be carried out in accordance with specifications. Work shall be carried out

by the experienced site team under the guidance of engineer and shall further be checked and approved by quality engineer.

Check the materials are approved.

Check for any damage or defects, name plate details

Check all devices installed as per the specifications & Drawing.

Visual Inspection: Conduct visual inspection prior to testing.

Inspection shall be based on completed and approved drawings and system documentation as per NFPA.

Comply with “Visual Inspection Frequencies” Table in the “Inspection” Section of the “Inspection, Testing and

Maintenance” Chapter in NFPA 72; retain the “Initial/Reacceptance” column and list only the installed components.

FA System Testing

Comply with “Test Methods” Table in the “Testing” Section of the “Inspection, Testing and Maintenance” Chapter in NFPA 72.

Test audible appliances for the public operating mode according to manufacturer’s written instructions.

Perform the test using a portable sound-level meter complying with Type 2 requirements in ANSI S1.4.

Test audible appliances for the private operating mode according to manufacturer’s written instructions.

Test visible appliances for the public operating mode according to manufacturer’s written instructions.

Factory-authorized service representative shall prepare the “Fire Alarm System Record of Completion” in the

“Documentation” Section of the “Fundamentals of Fire Alarm Systems” Chapter in NFPA 72 and the

“Inspection and Testing Form” in the “Records” Section of the “Inspection, Testing and Maintenance”

Chapter in NFPA 72.

Re-acceptance Testing: Perform re-acceptance testing to verify the proper operation of added or replaced devices and

appliances. Test all the field loop devices with the control panel.

Check the detectors with the artificial test smoke spray. Use forms developed for initial tests and inspections.

Field tests shall be witnessed by authorities having jurisdiction.

Manufacturer’s Field Service

Engage a factory-authorized service representative to inspect, test, and adjust components, assemblies, and equipment

installations, including connections.

Perform tests and inspections. After testing & commissioning provide training demonstration to facility management

team.

Conduct Cause effect inspection as per programmed cause & effect matrix. Test all the connected devices responds as per

the matrix.

Identify system components, wiring, cabling, and terminals. Comply with requirements for identification specified in

specifications.

Install framed instructions in a location visible from fire-alarm control unit.

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 14 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

APPENDIX A

Site Logistics Plan

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 15 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 16 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

A

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 17 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

PPENDIX B

Al Karamah School, Phase 2

Abu Dhabi, UAE

CRISIS PLAN

Upon an incident, being discovered the first member of McLaren’s staff or the site operative

1.

discovering the incident shall inform the Project Manager and HSE department by Project

Emergency no- 056 898 7960

Both the Safety Officer and the first Aider are to attend the scene with their mobile. The project

2.

Manager or site receptionist waits in office ready to telephone relevant emergency services.

Both the Safety Officer and the first Aider are to assess the situation and put in place the relevant

3.

systems to end/deal with the emergency.

Both the Safety Officer and the first Aider are to ensure all trades are gathered at the assembly

4.

point and liaise with supervisor to account for all operatives - no person should leave site.

Either the Safety Officer or the first Aider phones the project Manager or site receptionist and

5.

informs him/her of which emergency services are required.

6. The Project Manager calls all relevant McLaren staff.

Both the Safety Officer and the first Aider waits for the emergency services at scene.

7.

Once emergency services arrive, The Project Manager will telephone the relevant authorities, i.e.

8.

the HSE/Client’s Safety Advisor/McLaren’s Operations & QHSE Manager.

Both the Safety Officer and the first Aider keep trades informed of the situation and releases

9.

trades to return to work or leave site only when emergency services or The Project Manager

instruct that it is safe to do so, and all names of witnesses are recorded.

The Project Manager or Construction Manager are to arrange for photographs of the scene to be

10.

taken, and if necessary the area to be cordoned.

A full investigation of the Incident is to be carried out, with a written report being submitted the

11.

SHEQ Director, as soon as practicably possible after the incident, including all witness statements,

photos of the scene, induction and method statement records, recommendation to prevent a re-

occurrence and what action has been taken since the incident taking place.

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 18 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

APPENDIX C

COSHH ASSESSMENTS AND MSDS

(Attach if any)

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 19 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

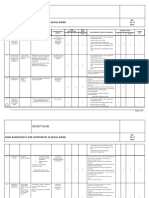

APPENDIX- D

RISK ASSESSMENT

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 20 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

APPENDIX-E

TECHNICAL INFORMATION

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 21 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

APPENDIX-F

INSPECTION AND TEST PLANS

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 22 of 23 RISK ASSESSMENT METHOD STATEMENT

RISK ASSESSMENT METHOD STATEMENT

APPENDIX-G

THIRD PARTY COMPETENCY/CERTIFICATES

Title: Installation of Fire Alarm System & PAVA System Ref. No: M1492-MCL-MCL-MSS-028

Project: Al Karamah School, Phase 2 Rev. No: 00

Prepared By: Anu Baby Approved By: Vishnu Mohan Rev. Date: 00

SAF-098 (UAE) 03/20 Rev I 23 of 23 RISK ASSESSMENT METHOD STATEMENT

You might also like

- RAMS For Installation of Installation of Sanitary Fixture & MixersDocument23 pagesRAMS For Installation of Installation of Sanitary Fixture & MixersAnandu AshokanNo ratings yet

- RAMS For Modification of Phase 1 Existing Water TankDocument22 pagesRAMS For Modification of Phase 1 Existing Water TankAnandu AshokanNo ratings yet

- RAMS For Installation of Fire Fighting SystemDocument24 pagesRAMS For Installation of Fire Fighting SystemAnandu AshokanNo ratings yet

- RAMS For Installation & Testing of BMSDocument23 pagesRAMS For Installation & Testing of BMSAnandu AshokanNo ratings yet

- RAMS For Installation of Fire Alarm System and PAVA SystemDocument23 pagesRAMS For Installation of Fire Alarm System and PAVA SystemAnandu Ashokan100% (1)

- RAMS For Testing & Commissioning of HVACDocument42 pagesRAMS For Testing & Commissioning of HVACAnandu AshokanNo ratings yet

- RAMS For Commissioning of LCP and IlluminationDocument23 pagesRAMS For Commissioning of LCP and IlluminationAnandu AshokanNo ratings yet

- MS For Installation of SMDB, DB PanelsDocument20 pagesMS For Installation of SMDB, DB PanelsAnandu AshokanNo ratings yet

- Installation of Light Fitting.Document68 pagesInstallation of Light Fitting.Anandu AshokanNo ratings yet

- MS For Installation of FF Pipes FittingsDocument23 pagesMS For Installation of FF Pipes FittingsAnandu Ashokan100% (1)

- MS For Installation of Electrical Wiring & Cable PullingDocument20 pagesMS For Installation of Electrical Wiring & Cable PullingAnandu Ashokan100% (1)

- RAMS For Installation and Testing of Access Control SystemDocument22 pagesRAMS For Installation and Testing of Access Control SystemAnandu AshokanNo ratings yet

- MS For Installation of Grills, Diffuser & LouversDocument21 pagesMS For Installation of Grills, Diffuser & LouversAnandu AshokanNo ratings yet

- Testing Commissioning of LCS and IlluminationDocument36 pagesTesting Commissioning of LCS and IlluminationAnandu AshokanNo ratings yet

- MS For Installation of Drainage PipesDocument20 pagesMS For Installation of Drainage PipesAnandu Ashokan100% (1)

- MS For MEP IsolationDocument19 pagesMS For MEP IsolationAnandu Ashokan67% (3)

- Integration of Fire Alarm System, PAVA - ELV SystemDocument49 pagesIntegration of Fire Alarm System, PAVA - ELV SystemAnandu AshokanNo ratings yet

- Method Statement For Installation of Temporary ServicesDocument22 pagesMethod Statement For Installation of Temporary Servicesfaizan khanNo ratings yet

- RAMS For Installation of Installation of HVAC Duct and AccessoriesDocument23 pagesRAMS For Installation of Installation of HVAC Duct and AccessoriesAnandu AshokanNo ratings yet

- RAMS For Installation of Light FittingsDocument22 pagesRAMS For Installation of Light FittingsAnandu AshokanNo ratings yet

- 07.01 Risk Assessment For Fire Alarm SystemDocument15 pages07.01 Risk Assessment For Fire Alarm SystemShah MuzzamilNo ratings yet

- Light FittingsDocument35 pagesLight FittingsAnandu AshokanNo ratings yet

- Method Statement and Risk Assessment For Installation of Cable Ladders & Perforated TraysDocument11 pagesMethod Statement and Risk Assessment For Installation of Cable Ladders & Perforated TraysImran Khan100% (1)

- PPRDocument10 pagesPPRachusanachuNo ratings yet

- m1439-Ghd-mcl-mss-005 Existing Dry Type Transformer ReconditioningDocument27 pagesm1439-Ghd-mcl-mss-005 Existing Dry Type Transformer ReconditioningAnandu AshokanNo ratings yet

- Pressure TestingDocument45 pagesPressure TestingAnandu AshokanNo ratings yet

- Electric Risk AssessmentDocument10 pagesElectric Risk AssessmentThandabantu MagengeleleNo ratings yet

- TRA 003-010 (1) - RemovedDocument7 pagesTRA 003-010 (1) - RemovedrashidNo ratings yet

- Method of Statement For Fire AlarmDocument10 pagesMethod of Statement For Fire AlarmShah MuzzamilNo ratings yet

- Risk Assessment For Installation of Automatic Sliding DoorDocument6 pagesRisk Assessment For Installation of Automatic Sliding DoorKalid JmalNo ratings yet

- Method Statement - Fire AlarmDocument9 pagesMethod Statement - Fire AlarmiamajumalNo ratings yet

- Risk Assessment For Installation of Diesel Generator111111Document8 pagesRisk Assessment For Installation of Diesel Generator111111Baher Mohamed100% (1)

- p103 Stts Gec Asi Ms Ele 010 - Method Statement For Installation of Wiring AccessoriesDocument6 pagesp103 Stts Gec Asi Ms Ele 010 - Method Statement For Installation of Wiring AccessoriesAnandu AshokanNo ratings yet

- Safe Work Method Statement For Testing & Commissioning of DX Split UnitsDocument5 pagesSafe Work Method Statement For Testing & Commissioning of DX Split Unitsvin ssNo ratings yet

- R-A CP2H NIGHT SHIFT ACTIVITY NewDocument16 pagesR-A CP2H NIGHT SHIFT ACTIVITY Newthomson100% (1)

- MDB Testing & Commissioning Procedure - Method Statement HQDocument3 pagesMDB Testing & Commissioning Procedure - Method Statement HQHansika RajapakshaNo ratings yet

- Method Statement - Exterior Lighting Fixtures InstallationDocument7 pagesMethod Statement - Exterior Lighting Fixtures Installationisrar50% (2)

- Method of Statement For Bus Duct InstallationDocument11 pagesMethod of Statement For Bus Duct InstallationMohd MuksinNo ratings yet

- Risk Assessment - Hot Water BoilersDocument4 pagesRisk Assessment - Hot Water BoilersUgonnaNo ratings yet

- Company Instrumentation & Control Specialists, Inc Document ID No. Department/s Contractor Revision No Job Title Coring Works Effective DateDocument11 pagesCompany Instrumentation & Control Specialists, Inc Document ID No. Department/s Contractor Revision No Job Title Coring Works Effective DateJayson EscamillanNo ratings yet

- Mos Hvac Ductwork Chilled Water Pipework 1650884167Document56 pagesMos Hvac Ductwork Chilled Water Pipework 1650884167Prabesh ShresthaNo ratings yet

- Table of Contents: Method Statement FOR Lightning Protection System InstallationDocument10 pagesTable of Contents: Method Statement FOR Lightning Protection System Installationw fathyNo ratings yet

- Installation of Fire Fighting SystemDocument66 pagesInstallation of Fire Fighting SystemAnandu AshokanNo ratings yet

- Method Statement For Installation of Grill, Diffuser & LouversDocument51 pagesMethod Statement For Installation of Grill, Diffuser & LouversAnandu Ashokan100% (1)

- Risk Assessment For Excavation Works Prior To Installation of Signage Gantry at Road A3Document6 pagesRisk Assessment For Excavation Works Prior To Installation of Signage Gantry at Road A3Muideen OyedeleNo ratings yet

- JSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Document11 pagesJSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Jayson EscamillanNo ratings yet

- JET Fan InstallationDocument2 pagesJET Fan InstallationKrishna Patil100% (2)

- HIRADC Assessment-INSTALLATION OF BUSDUCTDocument6 pagesHIRADC Assessment-INSTALLATION OF BUSDUCTTengkudin LatifNo ratings yet

- QC-143 R2 Distribution Panel ChecklistDocument1 pageQC-143 R2 Distribution Panel ChecklistCamilo Jorquera100% (1)

- Ms - CCTV SystemDocument24 pagesMs - CCTV Systemarun kurlanNo ratings yet

- Pipe Nitrogen Testing in Non Confined SpaceDocument4 pagesPipe Nitrogen Testing in Non Confined SpaceKannan KamalNo ratings yet

- Safe Work Method Statement: (Installation of Wet Sprinkler System)Document10 pagesSafe Work Method Statement: (Installation of Wet Sprinkler System)balaji100% (1)

- Job Safety Analysis (JSA) - HVAC Ducting DateDocument1 pageJob Safety Analysis (JSA) - HVAC Ducting DatenabeelNo ratings yet

- Tool Box Talk 2-07 Excavation Egress - OSHADocument3 pagesTool Box Talk 2-07 Excavation Egress - OSHAloveanbu24No ratings yet

- Work Method Statement FOR HVAC DuctingCopper PipesDocument9 pagesWork Method Statement FOR HVAC DuctingCopper PipesSameer JogasNo ratings yet

- LPS-01-HTI-MST-EL-009 - Light FixturesDocument18 pagesLPS-01-HTI-MST-EL-009 - Light FixturesJomy JohnyNo ratings yet

- Method Statement For Installation of Light Fixtures and FittingsDocument6 pagesMethod Statement For Installation of Light Fixtures and Fittingsadeniyi abiolaNo ratings yet

- Testing and Commissioning of IG 100 System: Inspection Test Plan (ITP)Document3 pagesTesting and Commissioning of IG 100 System: Inspection Test Plan (ITP)Samboy DionisioNo ratings yet

- Testing & Commissioning of Fire Fighting SystemDocument25 pagesTesting & Commissioning of Fire Fighting SystemAnandu Ashokan100% (1)

- Testing Commissioning Fire Fighting SystemsDocument47 pagesTesting Commissioning Fire Fighting SystemsAnandu AshokanNo ratings yet

- Ara-Dc-Ms-Ele-0030 Sat of LV Cables (Gen)Document15 pagesAra-Dc-Ms-Ele-0030 Sat of LV Cables (Gen)Anandu AshokanNo ratings yet

- SAT of MV Cables (GEN)Document1 pageSAT of MV Cables (GEN)Anandu AshokanNo ratings yet

- SAT of Final Small Power & Lighting Circuits (GEN)Document13 pagesSAT of Final Small Power & Lighting Circuits (GEN)Anandu AshokanNo ratings yet

- SAT of MV Cables (GEN)Document18 pagesSAT of MV Cables (GEN)Anandu AshokanNo ratings yet

- SAT of Earthing & Lightning Protection System (GEN)Document15 pagesSAT of Earthing & Lightning Protection System (GEN)Anandu AshokanNo ratings yet

- Master Log - LOGDocument15 pagesMaster Log - LOGAnandu AshokanNo ratings yet

- m1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelDocument53 pagesm1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelAnandu AshokanNo ratings yet

- m1439 GHD MCL Mss 053 Modification For LV PanelDocument84 pagesm1439 GHD MCL Mss 053 Modification For LV PanelAnandu AshokanNo ratings yet

- m1439 GHD MCL Mss 053 Modification For LV PanelDocument84 pagesm1439 GHD MCL Mss 053 Modification For LV PanelAnandu AshokanNo ratings yet

- M1439-Ghd-Mcl-Mss-041stat B, Electrical Testing and CommisioningDocument81 pagesM1439-Ghd-Mcl-Mss-041stat B, Electrical Testing and CommisioningAnandu AshokanNo ratings yet

- M1439-GHD-MCL-MSS-056 Lockout and Tag Out For Islolation ActivityDocument24 pagesM1439-GHD-MCL-MSS-056 Lockout and Tag Out For Islolation ActivityAnandu AshokanNo ratings yet

- m1439 GHD MCL Mss 056 Loto Status BDocument24 pagesm1439 GHD MCL Mss 056 Loto Status BAnandu AshokanNo ratings yet

- M1439 GHD MCL MSS 030 Rev 01 Wiring Accessories BDocument72 pagesM1439 GHD MCL MSS 030 Rev 01 Wiring Accessories BAnandu AshokanNo ratings yet

- m1439-Ghd-mcl-mss-005 Existing Dry Type Transformer ReconditioningDocument27 pagesm1439-Ghd-mcl-mss-005 Existing Dry Type Transformer ReconditioningAnandu AshokanNo ratings yet

- m1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelDocument53 pagesm1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelAnandu AshokanNo ratings yet

- Installation and Testing Commissioning of PumpsDocument60 pagesInstallation and Testing Commissioning of PumpsAnandu Ashokan100% (1)

- M1439-GHD-MCL-MSS-032 Rev. 01 Installation of TransformerDocument63 pagesM1439-GHD-MCL-MSS-032 Rev. 01 Installation of TransformerAnandu AshokanNo ratings yet

- Integration of Fire Alarm System, PAVA - ELV SystemDocument49 pagesIntegration of Fire Alarm System, PAVA - ELV SystemAnandu AshokanNo ratings yet

- m1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelDocument53 pagesm1439-Ghd-mcl-mss-040 Installation of HV and LV Switch Gear PanelAnandu AshokanNo ratings yet

- Harmonic StudyDocument41 pagesHarmonic StudyAnandu AshokanNo ratings yet

- Water Filtration System - Method StatementDocument7 pagesWater Filtration System - Method Statementsunil_v575% (4)

- Testing Commissioning Fire Fighting SystemsDocument47 pagesTesting Commissioning Fire Fighting SystemsAnandu AshokanNo ratings yet

- Installation of Sanitary Fixtures MixersDocument44 pagesInstallation of Sanitary Fixtures MixersAnandu AshokanNo ratings yet

- Rerouting of Existing MEP Services in New SubstationDocument52 pagesRerouting of Existing MEP Services in New SubstationAnandu AshokanNo ratings yet

- Pressure TestingDocument45 pagesPressure TestingAnandu AshokanNo ratings yet

- Testing Commissioning of HVAC SystemDocument53 pagesTesting Commissioning of HVAC SystemAnandu Ashokan100% (4)

- Installation of Underground Electrical-ELV DuctDocument41 pagesInstallation of Underground Electrical-ELV DuctAnandu AshokanNo ratings yet

- Installation of Grill Diffuser LouversDocument51 pagesInstallation of Grill Diffuser LouversAnandu AshokanNo ratings yet

- Installation of Toilet Exhaust FansDocument51 pagesInstallation of Toilet Exhaust FansAnandu AshokanNo ratings yet

- Installation of VRF System FAHU DX Package Unit With Dehumidifier DX Split UnitDocument102 pagesInstallation of VRF System FAHU DX Package Unit With Dehumidifier DX Split UnitAnandu AshokanNo ratings yet

- Kindergarten: Learn Not To BurnDocument59 pagesKindergarten: Learn Not To BurnCHRISTIAN RIVAS FIERRONo ratings yet

- 2013 Esser CatalogDocument364 pages2013 Esser CatalogArman Ul Nasar100% (2)

- 2020 Alarm MiniDocument44 pages2020 Alarm MiniLuis Alberto Serrano MesaNo ratings yet

- Fire Alarm SystemDocument18 pagesFire Alarm SystemelmerNo ratings yet

- 5 Flashscan Type and Type Code LabelsDocument24 pages5 Flashscan Type and Type Code LabelsAnonymous 8RFzObvNo ratings yet

- Dragline Fire Suppression System RecomendationsDocument5 pagesDragline Fire Suppression System RecomendationsJaya Angel100% (1)

- 9101 Conventional Combination Heat Photoelectric Smoke Detector IssueDocument2 pages9101 Conventional Combination Heat Photoelectric Smoke Detector Issuenagulanmurugan_38134No ratings yet

- Brosur Fire Alarm Horing LihDocument1 pageBrosur Fire Alarm Horing LihJuniar Putra TheflyingdeadmanNo ratings yet

- Fzm-1 Interface Module: Installation and Maintenance InstructionsDocument2 pagesFzm-1 Interface Module: Installation and Maintenance InstructionsRobel MTNo ratings yet

- Planning and Facilities: Building StorageDocument31 pagesPlanning and Facilities: Building Storagequsai migdadiNo ratings yet

- System Sensor Product BrochureDocument24 pagesSystem Sensor Product BrochureJAY ROD AWITNo ratings yet

- B787 2020Document17 pagesB787 2020Hoàng Việt Trung100% (3)

- Catalog Fire en 2020Document248 pagesCatalog Fire en 2020CiprianNo ratings yet

- Inspection Check List - Fire Alarm System Rev 01Document5 pagesInspection Check List - Fire Alarm System Rev 01Anonymous ixIhrPM2100% (1)

- Amt Airframe HB Vol 2Document62 pagesAmt Airframe HB Vol 2nourNo ratings yet

- CAT-1006 MR-2900 MR-2920 Addressable Fire Alarm Control Panels PDFDocument8 pagesCAT-1006 MR-2900 MR-2920 Addressable Fire Alarm Control Panels PDFEddi Pelaez Salinas100% (1)

- C-9102 Conventional Photoelectric Smoke Detector: FeaturesDocument2 pagesC-9102 Conventional Photoelectric Smoke Detector: Featuresfirex spNo ratings yet

- NFS2-640/E: Fire Alarm Control Panel Installation ManualDocument76 pagesNFS2-640/E: Fire Alarm Control Panel Installation ManualLeandro de FigueiredoNo ratings yet

- Smoke Alarm Maintenance ChecklistDocument2 pagesSmoke Alarm Maintenance Checklistananthu.u100% (2)

- B - Chem SLC Wiring ManualDocument60 pagesB - Chem SLC Wiring Manualyachtsman57No ratings yet

- CPP Study Guide 1 1Document566 pagesCPP Study Guide 1 1John Philip BarrientosNo ratings yet

- Gmrt2130 Iss 3Document42 pagesGmrt2130 Iss 3yadvikram7100% (1)

- Section5 - Group 6 - BFC32602 FULL REPORT - 20202021Document25 pagesSection5 - Group 6 - BFC32602 FULL REPORT - 20202021Ooi Chin KaiNo ratings yet

- SdiDocument11 pagesSdiAbdeldjalil BenyahiaNo ratings yet

- Simmons v. Jelniker, 4th Cir. (2005)Document7 pagesSimmons v. Jelniker, 4th Cir. (2005)Scribd Government DocsNo ratings yet

- ContextPlus Conventional Brochure 2019 - REV 1aDocument16 pagesContextPlus Conventional Brochure 2019 - REV 1aRasheedNo ratings yet

- Apartment Lease Contract: November 6, 2019Document55 pagesApartment Lease Contract: November 6, 2019WSYX/WTTE100% (1)

- SDX 751emDocument4 pagesSDX 751emnabil lakrafiNo ratings yet

- LS10050-007NF-E-C - ONYXWorks Configuration Tool - RevCDocument36 pagesLS10050-007NF-E-C - ONYXWorks Configuration Tool - RevCTú VũNo ratings yet

- How To Submit Kidde Brand Smoke Detector Recall ClaimDocument12 pagesHow To Submit Kidde Brand Smoke Detector Recall ClaimWTSP 10No ratings yet