Professional Documents

Culture Documents

Fire Monitor Data Sheet - 3-3

Uploaded by

Bagus PrambudiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fire Monitor Data Sheet - 3-3

Uploaded by

Bagus PrambudiCopyright:

Available Formats

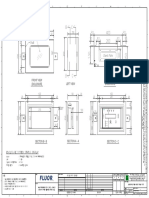

SHEET 3 OF3

DOCUMENT NO:

FOAM SYSTEM DATA SHEET

2022A775OO-ANG-MS-BDS-007

FIRE MONITOR REFERENCE DRAWING NO.

REV

1 GENERAL INFORMATION 1

2 Location : SP Tanjung Una Unit Tag No : FM-01

3 Manufacturer : (Note 1) Quantity : 1 ea

4 Model : (Note 1) Serial No. :

5 Placement : Outdoor

6 TECHNICAL DATA

7 Available Data Location : Onshore Offshore Other

8 Atmosphere : Tropical Salt Laden Other

9 o

Ambient Temp. (Max/Min) : 93.38 / 74.12 F

10 Humidity (Max/Min) : : 84 / 74 %

11

Fixed manual operated monitor with suction hose

12 Fire Monitor Feature Type :

and eductor

Rotation

13 : 360 deg

(Horizontal Movement)

14 Vertical Movement : +90/-45 deg (Note 1)

15 Inlet Connection : 6" ANSI 150# RF, graphite gasket ASME B16.5 Nozzle

Required Flowrate of Foam

16 : 500 gpm @ 100 psig (Note 1)

Solution

Design Flowrate of Foam

17 : (Note 1)

Solution

Monitor body

18 Outlet : 2-1/2 in (minimum) NST (Male)

19 Dimension : (Note 1) mm

Vertical lock

20 Weight : (Note 1) lbs

21 Working pressure : 100 psig

22 Max operating pressure : 220 psig

23 Position Lockable : Yes

Stainless Steel 304, brass, marine bronze or internally

24 Material (base & yoke) :

and externally epoxy coated

25 Color : Fire/Safety Red RAL 3000 Lever

26 Accessories : SS Tagging Plates

27 Nozzle Feature Nozzle type : Constant flow discharge nozzle with variable jet/ fog/

28 spray adjustment

Water Inlet Horizontal lock

Required Flowrate of Foam

29 : 500 gpm @ 100 psig (Note 1)

Solution

Design Flowrate of Foam

30 : (Note 1)

Solution

31 Max pattern spray angle : 90 deg cone (Note 1) Illustration of Fire Monitor

32 Material : Brass

33 Inlet Connection : 2-1/2" (minimum) NST (Female) (Note 1)

34 Discharge Range : 180 ft (54.8 m) @ 300 (max. horizontal throw)

35 100 ft (30.5 m) @ 600 (max. vertical throw) (Note 1)

36 Foam Eductor - Furnished with reinforced clear PVC pickup hose to prevent kinking

37 - Hose material shall be suitable for AFFF

38 - Check ball valve prevents back-flow into foam concentrate

39 - Detachable metering device for cleaning

40 Applicable Standard ASME B1.20.3, Ed. 2013 "Dry Seal Pipe Threads"

41 BS-336, Ed. 2010 "Specification for fire hose couplings and ancillary equipment"

42 NFPA 11, Ed. 2016 "Standard for Low-, Medium-, and High-Expansion Foam"

43 NFPA 14, Ed. 2019 "Standard for the Installation of Standpipe and Hose Systems"

44 NFPA 24, Ed. 2019 "Standard for the Installation of Private Fire Service Mains and Their Appurtenances"

45 NOTES

46 1. VENDOR to advise per manufacture standard

47 2. Instruction for use to be included.

48 3. Instruction

VENDOR to forsupply

use to fixed

be included.

foam monitor performance curve

49

50

51

PERTAMINA EP CEPU

You might also like

- Turkey Power Plant Pipe ListsDocument3 pagesTurkey Power Plant Pipe ListsJaroslav KurucNo ratings yet

- Project Name: Standpipe & Hose System of Norban Comtex LTD Area Reference: Most UnfavourableDocument4 pagesProject Name: Standpipe & Hose System of Norban Comtex LTD Area Reference: Most UnfavourablerashalNo ratings yet

- Water Injection Pump Assessment ReportDocument20 pagesWater Injection Pump Assessment ReportJonas ArifinNo ratings yet

- Uipl FPS Boq T1Document11 pagesUipl FPS Boq T1Sashikumar NarayanakurupNo ratings yet

- Fire Fighting UtmDocument27 pagesFire Fighting UtmNajwa Syafiqa100% (1)

- CO2 Calculation for Kima Aswan Diesel RoomDocument9 pagesCO2 Calculation for Kima Aswan Diesel RoomMahmoud MegahedNo ratings yet

- Laporan Hyrant and Springkle System R3Document44 pagesLaporan Hyrant and Springkle System R3Wacoman RazanNo ratings yet

- PT. WIJAYA KARYA ENGINEERING DOCUMENTDocument2 pagesPT. WIJAYA KARYA ENGINEERING DOCUMENTLucious LightNo ratings yet

- Pipelist For Ntv7Document78 pagesPipelist For Ntv7CaoQuocNo ratings yet

- KR2XX Truck-Mounted Fire Pumps PR ENDocument24 pagesKR2XX Truck-Mounted Fire Pumps PR ENfater esmandarNo ratings yet

- Penawaran Pekerjaan DED 4 Unit Tanki Rev.0Document3 pagesPenawaran Pekerjaan DED 4 Unit Tanki Rev.0m khaeronNo ratings yet

- A307 Ius FV DS 1311Document2 pagesA307 Ius FV DS 1311Ravi KumarNo ratings yet

- Spec 17037-P4-P-0a1g-Sz-00006 - 5 PDFDocument50 pagesSpec 17037-P4-P-0a1g-Sz-00006 - 5 PDFiman sihotangNo ratings yet

- HSVC Ol1/ Zone 2 Hydro Test Organization Chart: PhoneDocument4 pagesHSVC Ol1/ Zone 2 Hydro Test Organization Chart: PhoneTuấn PhạmNo ratings yet

- Civil Engineering Drawings and DocumentsDocument12 pagesCivil Engineering Drawings and DocumentsMuhammad ZaidNo ratings yet

- Saudi Aramco instrument specificationDocument1 pageSaudi Aramco instrument specificationgayu87No ratings yet

- Technical SpecificationDocument12 pagesTechnical SpecificationYousuf KamalNo ratings yet

- Form 8 PDFDocument96 pagesForm 8 PDFDavid Nugroho100% (1)

- 001 Manual Data Sheet PipaDocument3 pages001 Manual Data Sheet Pipawahyu hutamaNo ratings yet

- Sheet 01 of 03 D03 1327804 A3 059-PD-B-044127 N/A 4JSG000001P6437Document3 pagesSheet 01 of 03 D03 1327804 A3 059-PD-B-044127 N/A 4JSG000001P6437abdulkidwai2009No ratings yet

- Specification for weakly corrosive hydrocarbon piping systemDocument1 pageSpecification for weakly corrosive hydrocarbon piping systemhalim_ka100% (1)

- Ipmg B SF DSH 1005 03Document5 pagesIpmg B SF DSH 1005 03sgh1355No ratings yet

- Install Hydraulic Ram Pump VillageDocument5 pagesInstall Hydraulic Ram Pump VillageChandra Shekhar ChaurasiyaNo ratings yet

- On-Off Valve DatasheetDocument80 pagesOn-Off Valve Datasheetssmith2007No ratings yet

- A Tse Spe 000 30000 0Document28 pagesA Tse Spe 000 30000 0ZaidiNo ratings yet

- IG-100 CalculationDocument6 pagesIG-100 CalculationNA PauleNo ratings yet

- Installing FHC PDFDocument4 pagesInstalling FHC PDFZaw Moe KhineNo ratings yet

- Estimasi Biaya Jasa Pekerjaan ElectricalDocument19 pagesEstimasi Biaya Jasa Pekerjaan ElectricalHarry Priyulanda RukkaNo ratings yet

- Daftar Harga Fire Hydrant AppronDocument2 pagesDaftar Harga Fire Hydrant AppronWeri IsvebriantiNo ratings yet

- Proposal Teknis Project GITC Duri Pulo - Fire PumpDocument25 pagesProposal Teknis Project GITC Duri Pulo - Fire PumpSyncroFlo IndonesiaNo ratings yet

- Operating Conditions Liquid: Client: ServiceDocument1 pageOperating Conditions Liquid: Client: ServiceAde IskandarNo ratings yet

- Plate Sheet Cutting PlansDocument1 pagePlate Sheet Cutting PlansAlbet MulyonoNo ratings yet

- A Project Reports On SMOKE DETECTORDocument27 pagesA Project Reports On SMOKE DETECTORd3rfrefrfNo ratings yet

- Technical Offer Rev.05 Tank 24x11.5 PDFDocument4 pagesTechnical Offer Rev.05 Tank 24x11.5 PDFMohamedGhanemNo ratings yet

- BMID Hydrant Test FormDocument2 pagesBMID Hydrant Test FormSheikh Faiz RockerNo ratings yet

- Fire Protection System Design ProposalDocument4 pagesFire Protection System Design ProposalNikola TeslaNo ratings yet

- IG 55 CalculationDocument11 pagesIG 55 CalculationNoridhamNo ratings yet

- t6.5 Construction Plan - Rev.aDocument86 pagest6.5 Construction Plan - Rev.aazliza msogNo ratings yet

- Vortex Inhibitor VortibreakDocument1 pageVortex Inhibitor VortibreakNabil RamehNo ratings yet

- Fire Fighting System - Spec - Rev0Document14 pagesFire Fighting System - Spec - Rev0Ramesh-NairNo ratings yet

- MTDF-PP-300-SPE-1019-R2 - Specification For Field Piping Fabrication, Installation, Cleaning, Flushing and TestingDocument16 pagesMTDF-PP-300-SPE-1019-R2 - Specification For Field Piping Fabrication, Installation, Cleaning, Flushing and Testingmengelito almonteNo ratings yet

- MS For SprinklerDocument78 pagesMS For Sprinklerkarthy ganesanNo ratings yet

- HydraulicDocument8 pagesHydraulicOsama OmayerNo ratings yet

- Fire (V 2.0)Document9 pagesFire (V 2.0)Ferdinand AquinoNo ratings yet

- Foam Calculation Sample From ForumDocument2 pagesFoam Calculation Sample From Forumika524No ratings yet

- Vendor Data Book For Helideck Fixed Foam System (ABS Approved)Document53 pagesVendor Data Book For Helideck Fixed Foam System (ABS Approved)VAN VIET NGONo ratings yet

- AssessmentDocument31 pagesAssessmentAgustinus WaluyoNo ratings yet

- OKI PULP & PAPER MILL PROJECT SUMMARY WEEKLYDocument4 pagesOKI PULP & PAPER MILL PROJECT SUMMARY WEEKLYKusnadi AnginNo ratings yet

- Teknikal Proposal Tangki Sambu T-32 LengkapDocument17 pagesTeknikal Proposal Tangki Sambu T-32 Lengkapveva santiNo ratings yet

- FM Global Property Loss Prevention Data Sheets: List of FiguresDocument10 pagesFM Global Property Loss Prevention Data Sheets: List of FiguresCarlos Oliva LagosNo ratings yet

- PLTM Tangka Schedule Rev.01Document1 pagePLTM Tangka Schedule Rev.01Rizki KresnaNo ratings yet

- Design and hydraulic calculation of foam systemDocument26 pagesDesign and hydraulic calculation of foam systembecpavanNo ratings yet

- Atbq1714 Measurement I: Piling WorksDocument24 pagesAtbq1714 Measurement I: Piling WorksJIE YI CHENNo ratings yet

- README Registered ImplementationDocument2 pagesREADME Registered Implementationjignesh chauhanNo ratings yet

- Calculation Tank - 1500 KL SolarDocument2 pagesCalculation Tank - 1500 KL SolarAnonymous 6S9tcbhNo ratings yet

- Fire Alarm Testing & Commissioning ReportsDocument5 pagesFire Alarm Testing & Commissioning ReportsAssem ElhajjNo ratings yet

- ITP - Fire Hydrant InstallationDocument9 pagesITP - Fire Hydrant InstallationGultom Juliana LiliesNo ratings yet

- Hqs-Hse-003 Rev00Document67 pagesHqs-Hse-003 Rev00vikrant911No ratings yet

- BBS-10-W8-DS-006 - C - Glycol Charcoal Filter DS PDFDocument1 pageBBS-10-W8-DS-006 - C - Glycol Charcoal Filter DS PDFAdianto RahmanNo ratings yet

- Datasheet For Level TransmitterDocument11 pagesDatasheet For Level TransmitterEliyanto E BudiartoNo ratings yet

- HIRA For CSMS - Javaland - Rev.1Document19 pagesHIRA For CSMS - Javaland - Rev.1Bagus PrambudiNo ratings yet

- Home Work Day 1 - 24 Augus 2021Document12 pagesHome Work Day 1 - 24 Augus 2021Bagus PrambudiNo ratings yet

- Fire Department Dixon Valve FreeportDocument1 pageFire Department Dixon Valve FreeportBagus PrambudiNo ratings yet

- Racking InergasDocument13 pagesRacking InergasBagus PrambudiNo ratings yet

- Detail Cal. & Boq Inergas Ig - 541 - Project Juno - 140 LDocument41 pagesDetail Cal. & Boq Inergas Ig - 541 - Project Juno - 140 LBagus PrambudiNo ratings yet

- CALCULATION TOOL Rev1Document17 pagesCALCULATION TOOL Rev1Bagus PrambudiNo ratings yet

- JKT02-MTP-FLS-050 Material Approval For HDPE Pipe Sprinkler Line Rev 02 - ReplyDocument19 pagesJKT02-MTP-FLS-050 Material Approval For HDPE Pipe Sprinkler Line Rev 02 - ReplyBagus PrambudiNo ratings yet

- N2 Generator CalculationDocument9 pagesN2 Generator CalculationBagus PrambudiNo ratings yet

- Approval Document ASSET DOC LOC 5506285Document48 pagesApproval Document ASSET DOC LOC 5506285Pamela Joyce MaddumaNo ratings yet

- Enclosure SSDDocument1 pageEnclosure SSDBagus PrambudiNo ratings yet

- Hilti PROFIS Engineering 3.0.80 ReportDocument10 pagesHilti PROFIS Engineering 3.0.80 ReportCloud XNo ratings yet

- Box Fire Extinguisher-PtjDocument1 pageBox Fire Extinguisher-PtjBagus PrambudiNo ratings yet

- Anchor BoltDocument8 pagesAnchor Boltazwan50% (2)

- Calculation Report Status For Support Pipe & Cable LDocument4 pagesCalculation Report Status For Support Pipe & Cable LBagus PrambudiNo ratings yet

- JCI Nitrogen Dry-Preaction Project Form - 202006 (FILL)Document2 pagesJCI Nitrogen Dry-Preaction Project Form - 202006 (FILL)Bagus PrambudiNo ratings yet

- PRE-ACTION VALVE CONTROL COMPONENTSDocument1 pagePRE-ACTION VALVE CONTROL COMPONENTSBagus PrambudiNo ratings yet

- Open Storage Water Sprinkler Calculation - ExampleDocument4 pagesOpen Storage Water Sprinkler Calculation - ExampleBagus PrambudiNo ratings yet

- Fire Monitor Data Sheet - 2-2Document1 pageFire Monitor Data Sheet - 2-2Bagus PrambudiNo ratings yet

- Kidde AEGIS 2 0 Conventional Fire Alarm-Suppression Control Unit K-84-200Document6 pagesKidde AEGIS 2 0 Conventional Fire Alarm-Suppression Control Unit K-84-200Bagus PrambudiNo ratings yet

- Sprinkler System Schematic (MCV)Document1 pageSprinkler System Schematic (MCV)Bagus PrambudiNo ratings yet

- Fire Monitor Data Sheet - 1-1Document1 pageFire Monitor Data Sheet - 1-1Bagus PrambudiNo ratings yet

- FIRE ALARM BILL OF QUANTITY MT. AKRADocument4 pagesFIRE ALARM BILL OF QUANTITY MT. AKRABagus PrambudiNo ratings yet

- Perhitungan Detail Fire Alarm Akra 50 - Rev 1Document17 pagesPerhitungan Detail Fire Alarm Akra 50 - Rev 1Bagus PrambudiNo ratings yet

- Time Schedule - PfizerDocument2 pagesTime Schedule - PfizerBagus Prambudi100% (2)

- BOQ Kapal Patroli Cepat Ukuran 60 Meter PT. RBPN (Jakarta)Document13 pagesBOQ Kapal Patroli Cepat Ukuran 60 Meter PT. RBPN (Jakarta)Bagus PrambudiNo ratings yet

- Foam Concentrate MSDSDocument4 pagesFoam Concentrate MSDScoolsummer1112143No ratings yet

- Boq Fire Alarm Mt. Akra 50 - Rev 2Document18 pagesBoq Fire Alarm Mt. Akra 50 - Rev 2Bagus PrambudiNo ratings yet

- Chemguard 3% Afff (c3b) MTR Aghs enDocument9 pagesChemguard 3% Afff (c3b) MTR Aghs enBagus PrambudiNo ratings yet

- National Fire Protection Association: Anwar EffendyDocument1 pageNational Fire Protection Association: Anwar EffendyBagus PrambudiNo ratings yet

- Cooling Tower Fundamentals PDFDocument27 pagesCooling Tower Fundamentals PDFDarshan Raghunath100% (3)

- Ideal KitchenDocument1 pageIdeal KitchenThe Illimitable ManNo ratings yet

- FC Installation SheetDocument4 pagesFC Installation SheetSamuel Lopez BenitesNo ratings yet

- PMC Pitch 2Document2 pagesPMC Pitch 2Aashish PardeshiNo ratings yet

- SEO-Optimized Title for Foundation Design DocumentDocument16 pagesSEO-Optimized Title for Foundation Design DocumentAhmed Shaban100% (1)

- As1684 Split Level c2 House BracingDocument43 pagesAs1684 Split Level c2 House BracingUday PratapNo ratings yet

- Lightning ProtectionDocument9 pagesLightning Protectioncharitha RanwalaNo ratings yet

- Retard ChamberDocument2 pagesRetard ChamberAhrian BenaNo ratings yet

- Test Report ASSET DOC LOC 66319Document22 pagesTest Report ASSET DOC LOC 66319Nyein ZawNo ratings yet

- Sample Drawing: PerspectiveDocument7 pagesSample Drawing: PerspectiveRichie Juls BacalsoNo ratings yet

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- FM Global Property Loss Prevention Data Sheets: List of FiguresDocument44 pagesFM Global Property Loss Prevention Data Sheets: List of Figureshanlove100% (2)

- Air Release Valve Val - 3Document1 pageAir Release Valve Val - 3Coordinador TecnicoNo ratings yet

- 527 538Document7 pages527 538smaajNo ratings yet

- SGP Stress Analysis ReportDocument14 pagesSGP Stress Analysis ReportDenstar Ricardo Silalahi100% (2)

- Stability Analysis of Curved Beams and ArchesDocument8 pagesStability Analysis of Curved Beams and Archeslalo198No ratings yet

- Report LampuDocument31 pagesReport LampuArip SuhariyantoNo ratings yet

- National Highways Authority of India: DIRECT SHEAR TEST (IS 2720 Part-13: 2009)Document2 pagesNational Highways Authority of India: DIRECT SHEAR TEST (IS 2720 Part-13: 2009)DeepakNo ratings yet

- Design of SpillwaysDocument29 pagesDesign of SpillwaysALvin SaLvaNo ratings yet

- Draft Development Control Plan No: 171/10/0002Document16 pagesDraft Development Control Plan No: 171/10/0002North Canberra Community Council IncNo ratings yet

- The S-Curve For Forecasting Waste Generation in Construction Projects Lu, Peng, Chen, Skitmore, ZhangDocument12 pagesThe S-Curve For Forecasting Waste Generation in Construction Projects Lu, Peng, Chen, Skitmore, ZhangisenefretNo ratings yet

- Tutorial-Bridgedesign103 0Document63 pagesTutorial-Bridgedesign103 0Nikola RajićNo ratings yet

- Fosroc Supercast SWX TDS AdditiveDocument2 pagesFosroc Supercast SWX TDS AdditivecalitheanNo ratings yet

- Convair New Tanker Operation & Maintenance Manual Nov 2010Document24 pagesConvair New Tanker Operation & Maintenance Manual Nov 2010engfaridmalk100% (1)

- Unit IG2: Risk AssessmentDocument11 pagesUnit IG2: Risk Assessmentshaukat81% (98)

- 37 Sustainable Construction and Building MaterialsDocument9 pages37 Sustainable Construction and Building Materials薇神No ratings yet

- Service BECKER DVT 3.100Document8 pagesService BECKER DVT 3.100Graphica EuroNo ratings yet

- Hearst Tower Feb 06Document0 pagesHearst Tower Feb 06denis1808scribdNo ratings yet

- Show All The Necessary Steps To Solve The Following ProblemsDocument2 pagesShow All The Necessary Steps To Solve The Following ProblemsMistireselassieNo ratings yet

- Schedule of Rates 2010 2011Document121 pagesSchedule of Rates 2010 2011Madhu IndrachapaNo ratings yet