Professional Documents

Culture Documents

Wood Flooring

Uploaded by

Harsh Agarwal0 ratings0% found this document useful (0 votes)

10 views1 pageOriginal Title

WOOD FLOORING

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views1 pageWood Flooring

Uploaded by

Harsh AgarwalCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

WOODEN

FLOORING INSTALLATION PROCESS- GLUE DOWN METHOD-

Wooden flooring can be installed utilizing the glue down

Wood can be manufactured with a variety method. This is an especially popular method for solid

WHAT IS WOOD FLOORING? of different installation systems. parquet flooring installations on concrete sub floors.

Wood flooring is any product manufactured from

SOLID

timber that is designed for use as flooring, either HARDWOOD

structural or aesthetic. Wood is a common

FLOOR TONGUE

choice as a flooring material and can come in CONECTION &

ENGINEERING

various styles, colours, cuts, and species. HARDWOOD SYSTEM GROOVE

Bamboo flooring is often considered a form of

wood flooring, although it is made from a grass

LAMIANTED CLICK OR

(bamboo) rather than a timber. FLOORING GLUE

WOOD

TYPES OF WOODEN FLOORING LOCK DOWN

SYSTEM METHOD

• SOLID HARDWOOD FLOORING-

Solid hardwood floors are made

of planks milled from a single

TONGUE & GROOVE METHOD-

piece of timber.

• One side and one end of the plank have a FLOOR CONNECTION SYSTEM-

• ENGINEERED WOOD FLOORING-

groove the other side and end have a There are a wide range of connection

Engineer wood flooring consists

tongue. systems as most of them are mill-specific

of two or more layers of wood

• The tongue and groove fit roughly together manufacturing techniques. The general

adhered together to form a

thus joining or aligning the planks and are principle is to how grooves all for sides of the

plank.

not visible.. plank with a separate, unconnected, piece

• All-timber-wood

• Veneer floors. that is inserted into the grooves of two

• Acrylic planks to join them. The piece used for the

• LAMINATE FLOORING- Laminate connection can be made from wood rubber

Flooring is a photographic image or plastic.

of real hardwood topped with a

wear layer. Below is fibreboard Floor Sanding-provides a method for

that is composed of wood pulp smoothing an installed floor, compensating

for unevenness of the subfloor. Additionally,

and resin. sanding is used to renew the appearance of

older floors. Sanding using successively finer

grades of sandpaper is required to ensure

even stain penetration when stains are used,

MANUFACTURING PROCESS- as well as to eliminate visible scratches from

1. Solid wood flooring is milled coarser sandpaper grades used initially.

from a single piece of timber

that is kiln or air dried before

Floor Scrapping-Prior to the 20th

sawing. century, hardwood floors were refinished

2. The timber is cut to the desired CLICK OR LOCK SYSTEM by scraping. This process revealed

dimensions and either packed Click (or lock) flooring is very undamaged wood but left many shallow

gouges in the floor. Scraping may be

unfinished for a site-finished similar to traditional tongue performed using such tools as chisels,

installation or finished at the and groove wood flooring but planes, and cabinet scrapers. Modern

ROTARY PEEL methods duplicate this using proprietary

factory. has the additional feature of machinery.

3. The moisture content at time of an interlocking profile around

manufacturing is carefully SLICED PEEL its edge which enables the

controlled to ensure the boards to be clicked, snapped

product does not warp during or locked together.

DRY SOLID-SAWN

transport and storage.

GROUP MEMBERS-

1. HARSH AGARWAL

2. TAMANNA KEWLANI

3. UJJWAL SRIVASTAVA

4. SHUBHAM RAJAK

You might also like

- Veneer & Plywood ManufactureDocument50 pagesVeneer & Plywood Manufactureyeng botzNo ratings yet

- Builing Construction: Birla Institute of TechnologyDocument16 pagesBuiling Construction: Birla Institute of TechnologyNitesh KumarNo ratings yet

- Wooden Flooring: A Presentation by - Bapi BiswasDocument17 pagesWooden Flooring: A Presentation by - Bapi BiswasPriya RamyaNo ratings yet

- Floor N Wall CoveringsDocument66 pagesFloor N Wall CoveringsMUGHIL P - A100% (1)

- Engineered Hardwood Vs Solid HardwoodDocument6 pagesEngineered Hardwood Vs Solid HardwoodDragona FlooringNo ratings yet

- Hwno.4 - Bsa1c - Saylon - Efraine AndreaDocument19 pagesHwno.4 - Bsa1c - Saylon - Efraine Andreaefraineandrea.saylonNo ratings yet

- Hwno.8 - Bsa1c - Saylon - Efraine AndreaDocument83 pagesHwno.8 - Bsa1c - Saylon - Efraine Andreaefraineandrea.saylonNo ratings yet

- Wooden Flooring - 2 - PDFDocument58 pagesWooden Flooring - 2 - PDFSuman Kumari100% (1)

- Solid Wood Flooring vs. Engineered Wood FlooringDocument7 pagesSolid Wood Flooring vs. Engineered Wood Flooringabeer khalidNo ratings yet

- FinishesDocument4 pagesFinishesFaye SerranoNo ratings yet

- Manufactured TimberDocument4 pagesManufactured TimberbadtheanimatorNo ratings yet

- Bay15 16 PDFDocument23 pagesBay15 16 PDFBob CalebNo ratings yet

- Isd.l1.sem3.sub 1.lakshya Patel PDFDocument20 pagesIsd.l1.sem3.sub 1.lakshya Patel PDFlakshya patelNo ratings yet

- Micro Cement 2017Document6 pagesMicro Cement 2017Arrow BuildersNo ratings yet

- PLYWOODDocument3 pagesPLYWOODBob CalebNo ratings yet

- Floor Finishes: Wood: Made By-Ritisha Gupta Sayli NamjoshiDocument21 pagesFloor Finishes: Wood: Made By-Ritisha Gupta Sayli Namjoshipopy gangNo ratings yet

- BUDocument7 pagesBUhunterkiller662No ratings yet

- Flooring FinalDocument30 pagesFlooring FinalRahul PrasadNo ratings yet

- Wood Composite SeminarDocument25 pagesWood Composite SeminarsriNo ratings yet

- 127 Module 5 ADocument10 pages127 Module 5 Ayeng botzNo ratings yet

- Interior DesignDocument13 pagesInterior DesignFrenz ValdezNo ratings yet

- Arain SpecificationsDocument27 pagesArain Specificationsluismgnzls14No ratings yet

- Bergeim Bamboo FloorsDocument17 pagesBergeim Bamboo FloorsBright ZhouNo ratings yet

- Engineered Wood Flooring VsDocument3 pagesEngineered Wood Flooring VsMathew Joel MathewNo ratings yet

- Floors: Builiding ComponentDocument17 pagesFloors: Builiding ComponentNandita ChellaramaniNo ratings yet

- Floor Finishes: - Lalit Nagle - Certificate 1 YearDocument25 pagesFloor Finishes: - Lalit Nagle - Certificate 1 YearLalit NagleNo ratings yet

- FloorfinishDocument11 pagesFloorfinishYogirajsinh GohilNo ratings yet

- WOOD PRODUCTS (Compatibility Mode)Document29 pagesWOOD PRODUCTS (Compatibility Mode)BackupFilesNo ratings yet

- Hwno.4 Bsa-1a AlcantaraDocument23 pagesHwno.4 Bsa-1a AlcantaraAngel Mine AlcantaraNo ratings yet

- Wood FlooringDocument5 pagesWood FlooringtzvingNo ratings yet

- The Backing: The Inner Core: The Design/photographic Applique Layer: The Wear/protective LayerDocument12 pagesThe Backing: The Inner Core: The Design/photographic Applique Layer: The Wear/protective LayersatishNo ratings yet

- Material Case StudyDocument9 pagesMaterial Case StudySharvani MedaNo ratings yet

- FlooringDocument28 pagesFlooringRahul Prasad50% (2)

- Partition and PanelingDocument29 pagesPartition and PanelingNaveen SharmaNo ratings yet

- Soft Coverings: Carpet Linoleum Vinyl Wood Flooring Ceramic Tile Stone TerrazzoDocument44 pagesSoft Coverings: Carpet Linoleum Vinyl Wood Flooring Ceramic Tile Stone TerrazzoNoushaath Banu Akbar BashaNo ratings yet

- Panelling RakDocument30 pagesPanelling Raksameen rizviNo ratings yet

- BMC Assignment S5 (HARDBOARD&GLULAM)Document19 pagesBMC Assignment S5 (HARDBOARD&GLULAM)Ebin JoyNo ratings yet

- Lecture 7 Flooring and RoofingDocument25 pagesLecture 7 Flooring and RoofingYash PrajapatiNo ratings yet

- Finishes: ObjectivesDocument13 pagesFinishes: ObjectivesAliea NasreenNo ratings yet

- Finishes 2Document17 pagesFinishes 2Aliea NasreenNo ratings yet

- Floor Finishes: Kibe Sarah Warima Kimani Job Kogi Kimani Victoria Wangechi Kimondo Joyce WangechiDocument20 pagesFloor Finishes: Kibe Sarah Warima Kimani Job Kogi Kimani Victoria Wangechi Kimondo Joyce WangechiPankaj AgrawalNo ratings yet

- Construction Materials and Testing Reviewer (Mass Moveent, Earthquake, Geologic Map and StructureDocument3 pagesConstruction Materials and Testing Reviewer (Mass Moveent, Earthquake, Geologic Map and StructureKeisser lois CaballesNo ratings yet

- Berry Floor Accessories FolderDocument12 pagesBerry Floor Accessories Folderistomina2No ratings yet

- BT6 - FinishesDocument36 pagesBT6 - FinishesHatdugNo ratings yet

- Laminated Flooring - HDF Laminated Wooden Flooring ManufacturerDocument3 pagesLaminated Flooring - HDF Laminated Wooden Flooring ManufacturerJames WoodNo ratings yet

- Wallpaper and VeneerDocument6 pagesWallpaper and VeneerYogirajsinh GohilNo ratings yet

- Woodenflooring 161023174827Document24 pagesWoodenflooring 161023174827Swapnil DahaleNo ratings yet

- Building Materials2Document51 pagesBuilding Materials2jeo TinioNo ratings yet

- Engineered Wood: - Presented by IshitaDocument10 pagesEngineered Wood: - Presented by IshitaI love taehyungoppaNo ratings yet

- BT5 ReviewerDocument9 pagesBT5 ReviewerilovebojojoNo ratings yet

- CB PlywoodDocument18 pagesCB PlywoodLionel TebonNo ratings yet

- 873 - 52 - 473 - Module 1 Wood SubstitutesDocument18 pages873 - 52 - 473 - Module 1 Wood SubstitutesAlexNo ratings yet

- Material Case Study: Building Services Iv-Game Centre DesignDocument45 pagesMaterial Case Study: Building Services Iv-Game Centre DesignSharvani MedaNo ratings yet

- Materials in Interior Design and Application - 3Document10 pagesMaterials in Interior Design and Application - 3Dulara Upekshani SenevirathnaNo ratings yet

- FlooringDocument36 pagesFlooringYeng LugtuNo ratings yet

- Lecture 4 : FlooringDocument85 pagesLecture 4 : FlooringMaryam HeshamNo ratings yet

- Flortex BroucherDocument12 pagesFlortex BroucherAnjum Begum ShaikNo ratings yet

- Floor FinishesDocument20 pagesFloor FinishesFidha SulfiNo ratings yet

- Timber m2Document47 pagesTimber m2Ankur SharmaNo ratings yet

- Successful Timber Floors: A Guide to Real Timber FlooringFrom EverandSuccessful Timber Floors: A Guide to Real Timber FlooringRating: 3 out of 5 stars3/5 (2)

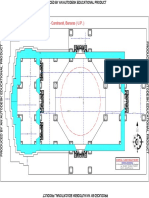

- Shree Digamber Jain Mandir - Candravati, Banaras (U.P.) : Sompura Sahdevbhai PurohitDocument1 pageShree Digamber Jain Mandir - Candravati, Banaras (U.P.) : Sompura Sahdevbhai PurohitHarsh AgarwalNo ratings yet

- Shree Digamber Jain Mandir - Candravati, Banaras (U.P.) : Sompura Sahdevbhai PurohitDocument1 pageShree Digamber Jain Mandir - Candravati, Banaras (U.P.) : Sompura Sahdevbhai PurohitHarsh AgarwalNo ratings yet

- Shree Digamber Jain Mandir - Candravati, Banaras (U.P.) : Sompura Sahdevbhai PurohitDocument1 pageShree Digamber Jain Mandir - Candravati, Banaras (U.P.) : Sompura Sahdevbhai PurohitHarsh AgarwalNo ratings yet

- Shree Digamber Jain Mandir - Candravati, Banaras (U.P.) : Sompura Sahdevbhai PurohitDocument1 pageShree Digamber Jain Mandir - Candravati, Banaras (U.P.) : Sompura Sahdevbhai PurohitHarsh AgarwalNo ratings yet

- Ayodhya LogoDocument2 pagesAyodhya LogoHarsh AgarwalNo ratings yet

- Ez Lucknow Ujjwal Srvastava s1Document19 pagesEz Lucknow Ujjwal Srvastava s1Harsh AgarwalNo ratings yet

- Onewayslab Numerical - AdhyaDocument10 pagesOnewayslab Numerical - AdhyaHarsh AgarwalNo ratings yet

- PosterDocument1 pagePosterHarsh AgarwalNo ratings yet

- Detach 1Document1 pageDetach 1Harsh AgarwalNo ratings yet

- Structure ModelDocument1 pageStructure ModelHarsh AgarwalNo ratings yet

- SGRHGREDocument1 pageSGRHGREHarsh AgarwalNo ratings yet

- Stage 4 Group HousingDocument4 pagesStage 4 Group HousingHarsh AgarwalNo ratings yet

- Inexpensive 2x4 Combat Crossbow PlansDocument8 pagesInexpensive 2x4 Combat Crossbow PlansHajka MateuszNo ratings yet

- Wudpro Flyer 2020 PDFDocument7 pagesWudpro Flyer 2020 PDFPuneeth RajNo ratings yet

- LanikSky - My Little Bear Baby RattleDocument12 pagesLanikSky - My Little Bear Baby RattleJudit FrittmannéNo ratings yet

- Grade 8: Prepare Netting Materials For Net ConstructionDocument10 pagesGrade 8: Prepare Netting Materials For Net ConstructionJerald Novero100% (1)

- Cashmerino Chunky: Cosy Slipper SocksDocument3 pagesCashmerino Chunky: Cosy Slipper SocksStefania MNo ratings yet

- Singer 507Document44 pagesSinger 507fogart1067% (18)

- Kooky The Dragon: by AquariwoolDocument5 pagesKooky The Dragon: by Aquariwoolçukurova tıp100% (1)

- Q1 To Q4 Budget of Work - Grade 8 TLEDocument8 pagesQ1 To Q4 Budget of Work - Grade 8 TLEFlorinda GagasaNo ratings yet

- Toys Master - Lyubov Volkova - Planter Tiger and Cat CubDocument18 pagesToys Master - Lyubov Volkova - Planter Tiger and Cat CubPriscila Vanina CórdobaNo ratings yet

- Types of Drill BitsDocument3 pagesTypes of Drill BitsShameema FarjanNo ratings yet

- Introduction To Pile FabricsDocument8 pagesIntroduction To Pile FabricsMina Samy abd el zaher100% (1)

- Handicraft SummativeDocument4 pagesHandicraft SummativeNoican Leira Tnecniv LuapNo ratings yet

- Vimana Q1 UpdatedDocument10 pagesVimana Q1 UpdatedOrlyn DanielsNo ratings yet

- Crochet Bunny Mariana Keychain PDF Amigurumi PatternDocument7 pagesCrochet Bunny Mariana Keychain PDF Amigurumi PatternJustyna Janicka0% (1)

- Presentation On Stitch and Seam Details of Men's Formal ShirtDocument22 pagesPresentation On Stitch and Seam Details of Men's Formal ShirtAkriti Dixit100% (1)

- SelvedgeDocument16 pagesSelvedgejony_nsu022No ratings yet

- Sutton Tools L343 Engineers Black Book - 3rd Edition 235 PagesDocument3 pagesSutton Tools L343 Engineers Black Book - 3rd Edition 235 PagesPloop20000% (1)

- Nepal National Building Code: TimberDocument26 pagesNepal National Building Code: TimberPramod Raj UpdNo ratings yet

- Kasumi-Tsunagi: Hosted by Sashiko - Lab January - 2021Document11 pagesKasumi-Tsunagi: Hosted by Sashiko - Lab January - 2021Patricia Majadas0% (1)

- NMM BronzeDocument19 pagesNMM BronzeEmilioNo ratings yet

- Crochet World 2014 PDFDocument68 pagesCrochet World 2014 PDFDallina78100% (2)

- Alaska APO02 ENGDocument20 pagesAlaska APO02 ENGsounditoutNo ratings yet

- VinCrafty Lucario PatternDocument15 pagesVinCrafty Lucario Patternjose112393100% (3)

- Group 2 Comtemporary Philippine Arts From The Regions SummaryDocument5 pagesGroup 2 Comtemporary Philippine Arts From The Regions SummaryKrizahMarieCaballeroNo ratings yet

- Celtic Knot Fingerless GlovesDocument3 pagesCeltic Knot Fingerless GlovesNguyễn Thu ThuỷNo ratings yet

- Santas Favorite ToyDocument57 pagesSantas Favorite ToynoelisumNo ratings yet

- Accordion BookDocument2 pagesAccordion BookdemonrageNo ratings yet

- Parts of The Sewing MachineDocument3 pagesParts of The Sewing MachineJoules Laureta Fabros GaleraNo ratings yet

- Free Amigurumi PatternsDocument94 pagesFree Amigurumi PatternsDaniela FrancoNo ratings yet

- USA Format: Free Baby Crochet Pattern Boys Sweater and PantsDocument3 pagesUSA Format: Free Baby Crochet Pattern Boys Sweater and Pantsoum bouchra NourNo ratings yet