Professional Documents

Culture Documents

DOD MST INS 001 Rev.0

Uploaded by

BharathiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DOD MST INS 001 Rev.0

Uploaded by

BharathiCopyright:

Available Formats

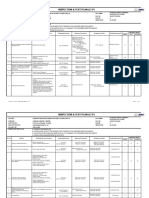

PROJECT : RASGAS ONSHORE EXPANSION PROJECT, PHASE 2 (RGX2)

COMPANY : RASGAS COMPANY LIMITED

CONTRACTOR : CTJV (JV of Chiyoda – Technip)

SUBCONTRACTOR : Dodsal Engineering and Construction Pte Ltd

JOB NUMBER : RG6-CS-004

METHOD STATEMENT

FOR

INSTRUMENTATION JUNCTION BOX,

FIELD MOUNTING PANELS, RACKS,

CONTROL OPERATING STATION

INSTALLATION AND TESTING

DOCUMENT NUMBER : DOD-MST-INS-001

REVISION NUMBER : 0

Rev. Issue Reviewed Approved

Reason for Issue Prepared Dodsal

No Date Dodsal Dodsal

Contractor’s Comments

incorporated and Issued for

Approval. Avaneesh Bikas

B 22.04.07

MST number Changed as per

Ravi shivdasan

Chaudhary Sinha

CTJV, From DOD-MST-EI-019

Contractor’s Comments

incorporated and Issued for Avaneesh

C 18.07.07 Nitin.N.Baviskar A .Sinha

Approval. Chaudhary

Company’s Comments

Pankaj Shukla Avaneesh Antonio

0 16.09.07 incorporated Issued for

Chaudhary Marchese

Construction.

Document No. DOD-MST-INS-001. Rev. 0

MST for Instrumentation Junction box, field mounting panels, racks,

control and operating station installation and Testing Page 1 of 8

REVISION CONTROL SHEET

Sr. Rev. Issue Issue Description

No. No. No. Date

Contractor’s Comments incorporated and Issued

for Approval.

1 B 0 22. 04 .07 MST number Changed as per CTJV, From DOD-

MST-EI-019

Contractor’s Comments incorporated and Issued

2 C 0 18. 07 .07 for Approval.

Company’s Comments incorporated and issued

3 0 0 16. 09 .07 for Construction.

Document No. DOD-MST-INS-001. Rev. 0

MST for Instrumentation Junction box, field mounting panels, racks,

control and operating station installation and Testing Page 2 of 8

INDEX

1.0 PURPOSE

2.0 SCOPE

3.0 REFERENCES

4.0 DEFINITIONS

5.0 RESPONSIBILITIES

6.0 PROCEDURE

7.0 DOCUMENTATION

Document No. DOD-MST-INS-001. Rev. 0

MST for Instrumentation Junction box, field mounting panels, racks,

control and operating station installation and Testing Page 3 of 8

1.0 PURPOSE:

The purpose of this Method Statement is to accomplish the Installation and testing

requirements of instrumentation junction box, field mounted panels, racks, control

operating station in accordance with applicable Project Specifications, Codes and

Standards.

2.0 SCOPE:

This scope covers installation and testing of instrumentation junction box, field

mounted panels, racks, control operating stations which are covered within the

subcontractor’s scope of work for RasGas Onshore Expansion Project, Phase-2.

3.0 REFERENCES

3.1 Codes & Standards

3.2 Contractor’s Documents:-

RG6-S-00-1370-029 : Instrument –Site Calibration and Testing

of Instruments.

RG6-S-00-1370-002 : Project Specifications General

Requirements for Instrumentation.

RG6-S-00-1370-011 : Instrumentation – Wiring for

instruments and Computers.

RG6-S-00-1370-026 : Instrumentation – Installation of

Field Mounted Instruments.

RG6-S-00-1370-081 : Instrumentation – Fiber Optic

Cables

RG6-S-00-1378-001 : Instrument Installation Drawings

Design Procedure.

RG6-D-00-1370-009 : Instrument Standard Drawings

RG6-S-00-1378-001-01 : General Notes / Symbols / Legend

for Instrumentation.

3.3 Subcontractor’s Documents

DOD-QMS-M001 : Quality Assurance System Manual

DOD-QA/QC-PQP-M130 : Project Quality Plan

DOD-HSE-RG-HSEP-H001 : Health, Safety, Environment Plan

DOD-QCP-QC-001 : Material Control & Storage

DOD-QCP-QC-002 : Material Receiving Inspection

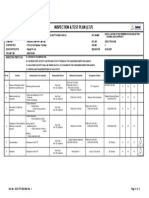

DOD-QCP-INS-001 : QCP for Instrumentation junction box,

field mounting Instrument panels, racks,

control operating station Installation and

testing.

DOD-ITP-INS-001 : ITP for Instrumentation junction box, field

mounting Instrument panels, racks,

control operating station Installation and

testing

Document No. DOD-MST-INS-001. Rev. 0

MST for Instrumentation Junction box, field mounting panels, racks,

control and operating station installation and Testing Page 4 of 8

4 DEFINITIONS

Company : RasGas Company Limited

Contractor : CTJV (Chiyoda – Technip Joint Venture)

Subcontractor : Dodsal Engineering and Construction

Pte Limited.

Supplier : Sub-Contractor to Dodsal Engg. and

Construction Pte Limited.

5 RESPONSIBILITIES

5.1 CHIEF CONSTRUCTION MANAGER: - shall be responsible for the

implementation of this Method Statement and shall pass on instructions down

the line to ensure the required HSE and Quality standards, practices and

procedures are maintained at each stage of the Work.

5.2 E&I MANAGER / DEPUTY E&I MANAGER:- Shall be responsible for the

implementation of this Method Statement and ensure the required HSE and

Quality standard, Practices and procedures are maintained for installation of

junction box, field mounting instrument panels, racks, control operating station

installation and testing.

5.3 SENIOR INSTRUMENT ENGINEER: - shall be responsible for the implementation

of this Method Statement and correct working techniques and shall ensure that the

instrumentation works are carried out as per approved IFC drawings, Project

Specifications & Standards. He shall be responsible for overall site supervision

and work execution with strict adherence to this method statement and required

HSE & Quality standards, practices and procedures at site. He shall arrange for

necessary inspection & documentation.

5.4 INST SITE- ENGINEER / SUPERINTENDENT: - Shall be responsible for the

execution of instrumentation works as per approved IFC drawings, Project

Specification & Standard. He shall be responsible for supervision of execution

works with strict adherence to this method statement and required HSE & Quality

practices and procedures at site. He shall be responsible to raise RFI for the works

to be inspected and attend punch- points as required.

5.5 INSTRUMENT FOREMAN: - Shall be responsible for the execution of the

instrumentation work as per approved IFC Drawings, Specifications & Standards,

and method statement and responsible for required HSE and Quality standards,

practice and procedures at site.

5.6 INSTRUMENT QA/QC.ENGINEER / INSPECTOR: - The Instrument QC

Engineer/Inspector shall be responsible to forward the RFI (Request for

Inspection) Form No: DOD-RGX-F056 to CTJV after carrying out internal

inspection of the work. He will perform daily pre-inspection for instrument

installation works and confirm readiness for the inspection of the instrumentation

works, compilation and retention of reports and records as per QCP’S and ITP’S

requirements as well as the loop release. He will also be responsible for issuing

non -Conformance Reports (NCR) and punch list for the discrepancies of the work.

All & associated works will be

Inspected upon receipt at site and checked for any damage during transit and

shall be verified against manufacturer’s relevant test certificates & inspection

reports duly signed.OSDR (Overage, Short, Damage Report) to be prepared as

applicable, shall be duly signed by concerned personnel/ Deptt. / Client

Document No. DOD-MST-INS-001. Rev. 0

MST for Instrumentation Junction box, field mounting panels, racks,

control and operating station installation and Testing Page 5 of 8

representative and to be immediately submitted to the client with all the

documentation & procedural requirements.

5.7 SAFETY OFFICER shall ensure that all the Equipment, Tools and Tackles are

certified in accordance with the site HSE Requirement. All manpower, directly or

indirectly involved in this activity shall be informed of the hazards and risk factor.

All regular Safety Equipments (PPE) shall be used like helmet, goggles, work

gloves, safety harness etc.

6 PROCEDURE

6.1 Safety

6.1.1 All equipment and accessories shall be verified for adequate capacity according to

HSE requirements. Refer JSA No.: DOD-MST-INS-001

6.1.2 All personnel involved in Instrumentation panel/ junction box etc. installation shall

be informed of job hazards and will adopt preventive measures while undertaking

subject instrumentation works.

6.1.3 All personnel must use their Safety Equipments and Personnel Protective

Equipments (PPE).

6.1.4 Tool Box meeting shall be held daily, prior to start of the work

6.2 MATERIALS

Materials shall be supplied by M/s CTJV based on the M/s RasGas Standard,

and Project purchase documents & approved manufacturer’s specification.

All materials purchased by Dodsal will be approved before usage by

CTJV QC vía “MAR” Material Approval Request form no: - DOD-RGX-F037

6.3 Equipments & Tools / Tackles

Welding machine

Drilling machine

Cable Cutter

Pliers, Screw driver set

Hammer - Steel / Plastic Lead Hammer

Hand tools kit.

6.4 ERECTION PROCEDURES

The Dodsal Document control Department shall ensure that all approved

construction drawings, approved procedure and other necessary documents have

been issued to the personnel in-charge of the work.

Ensure that all Instrumentation junction boxes, field mounting panels, racks control

& operating station installation shall be carried out as per approved IFC drawing

and shall confirm to the applicable requirements of RasGas Instrumentation

Standards & specifications.

Document No. DOD-MST-INS-001. Rev. 0

MST for Instrumentation Junction box, field mounting panels, racks,

control and operating station installation and Testing Page 6 of 8

All location of JB’s, Field panels, racks, control, operating station Installation shall

be verified as per approved IFC Instrumentation layout drawings before

installation.

6.5 INSTALLATION OF JUNCTION BOX, FIELD MOUNTING PANELS, RACKS,

CONTROL & OPERATING STATION.

6.5.1 The installation of junction box, field mounting panels, racks will be made as per

approved IFC Drawing and with necessary HOT / COLD permits and “new work

start card”.

6.5.2 Supports will be fabricated as per approved Instrumentation Layout, Standard

Drawings, and Project Specification.

6.5.3 Field mounted Instrument panels, racks and junction boxes will be secured

through external bolts as per approved installation specifications.

6.5.4 All junction box, field mounting panels, racks will be recorded on Form No.

DOD-RGX-F379 in accordance with ITP & QCP project specification.

6.5.5 Cables will be fixed and terminated in field mounted panels and Junction boxes

with glands suitable for explosion proof / safe zone as per project specifications &

standards.

6.5.6 Cable gland will be installed with necessary adaptors and /or reducers as per

requirement.

6.5.7 Necessary tags will be installed as per specifications.

6.6 FINAL INSPECTION

6.6.1 Visual inspection will be conducted.

6.6.2 Gaskets will be inspected.

6.6.3 JB Fixing bolts will be tightened properly.

6.6.4 Junction box cover bolts to be tightened properly.

6.6.5 Tags will be checked and recorded.

6.7 JOB SAFETY ANALYSIS (JSA)

6.7.1 Job Safety Analysis (JSA), as per attachment. JSA NO: DOD-MST-INS-001

Document No. DOD-MST-INS-001. Rev. 0

MST for Instrumentation Junction box, field mounting panels, racks,

control and operating station installation and Testing Page 7 of 8

7 DOCUMENTATION

7.1 Application for New work start : DOD-RGX-F350

7.2 Material Approval Request : DOD-RGX-F037

7.3 Material Receipt Inspection Report : DOD-RGX-F051

7.4 Installation of Instrument field mounted panels : DOD-RGX-F379

Junction Box .

7.5 Overage, Short, Damage Report : DOD-RGX-F049

Document No. DOD-MST-INS-001. Rev. 0

MST for Instrumentation Junction box, field mounting panels, racks,

control and operating station installation and Testing Page 8 of 8

You might also like

- DOD-MST-INS-003 Insta. & Testing of Inst. Cables-Rev-0Document11 pagesDOD-MST-INS-003 Insta. & Testing of Inst. Cables-Rev-0BharathiNo ratings yet

- DOD-MST-INS-002, MST For Installation of Field Instruments.-Rev-1Document15 pagesDOD-MST-INS-002, MST For Installation of Field Instruments.-Rev-1BharathiNo ratings yet

- DOD-MST-INS-004, MST For Insta. of Tubes, Pipes & Pressure Testing.-Rev.0Document11 pagesDOD-MST-INS-004, MST For Insta. of Tubes, Pipes & Pressure Testing.-Rev.0BharathiNo ratings yet

- DOD QCP INS 001.rev.1Document7 pagesDOD QCP INS 001.rev.1BharathiNo ratings yet

- DOD-MST-INS-008 Installation and Testing of Fiber Optic Cable - Rev.0Document14 pagesDOD-MST-INS-008 Installation and Testing of Fiber Optic Cable - Rev.0BharathiNo ratings yet

- DOD-QCP-INS-002, Rev-0Document7 pagesDOD-QCP-INS-002, Rev-0BharathiNo ratings yet

- Mov DBDocument22 pagesMov DBASHISH GORDENo ratings yet

- Saj-Po-Cgc-Mst-Hv-0001-01 Mos For Installation of Metallic Ducts Gi+Black SteelDocument73 pagesSaj-Po-Cgc-Mst-Hv-0001-01 Mos For Installation of Metallic Ducts Gi+Black SteelMonish T MonuNo ratings yet

- Technical Specification For Motor Operated ValvesDocument6 pagesTechnical Specification For Motor Operated ValvesĐặng Trung AnhNo ratings yet

- Mitp For Surveying Setting Out ApprovedDocument4 pagesMitp For Surveying Setting Out ApprovedMogu MohanNo ratings yet

- OM Manual For Wiring and AccDocument54 pagesOM Manual For Wiring and Accmukilanarul12No ratings yet

- Process Pipe Support Structure Design CalnDocument39 pagesProcess Pipe Support Structure Design CalnSanjayNo ratings yet

- 1TB01006 006C22 Ste MTS Ci 0027Document35 pages1TB01006 006C22 Ste MTS Ci 0027asifnazir.gill08No ratings yet

- Toaz - Info Abu Dhabi National Oil Company Adnoc CCTV System Testing and Commissioning T PRDocument9 pagesToaz - Info Abu Dhabi National Oil Company Adnoc CCTV System Testing and Commissioning T PRNitin JadhavNo ratings yet

- JAW - 00-K - 11a - 040 - PP - 176 - Commissioning ITP-LV DISTRIBUTION BOARD (MCC) 00BJA10 & 00BJB10 - Rev.0Document13 pagesJAW - 00-K - 11a - 040 - PP - 176 - Commissioning ITP-LV DISTRIBUTION BOARD (MCC) 00BJA10 & 00BJB10 - Rev.0MedrouaNo ratings yet

- MITP For Excavation and Backfilling ApprovedDocument7 pagesMITP For Excavation and Backfilling ApprovedMogu MohanNo ratings yet

- Instrumentation: Method Statement ForDocument8 pagesInstrumentation: Method Statement ForWalid MarhabaNo ratings yet

- RDJ ITP 06 I 05 - Inspection and Test Plan For Fiber Optic Cabling and Termination - EN Rev00Document3 pagesRDJ ITP 06 I 05 - Inspection and Test Plan For Fiber Optic Cabling and Termination - EN Rev00محمد رمضانNo ratings yet

- Stsedac QC SRP Uf 01 ReviewedDocument6 pagesStsedac QC SRP Uf 01 Reviewedmohd as shahiddin jafriNo ratings yet

- MITP For Roofing Works ApprovedDocument7 pagesMITP For Roofing Works ApprovedMogu MohanNo ratings yet

- JAW - 00-K - 11a - 040 - PP - 144 - Commissioning ITP - MV System Essential Boards - 00BDA10 - Rev.0Document21 pagesJAW - 00-K - 11a - 040 - PP - 144 - Commissioning ITP - MV System Essential Boards - 00BDA10 - Rev.0MedrouaNo ratings yet

- C08-016-000J-TS070 - 0 Nuclear Level SwitchDocument8 pagesC08-016-000J-TS070 - 0 Nuclear Level SwitchCristian RománNo ratings yet

- 20SP-010-BA-6180-00006 - 01E - IFR - Method Statement For Inverter Installation - Code-3Document21 pages20SP-010-BA-6180-00006 - 01E - IFR - Method Statement For Inverter Installation - Code-3lintangNo ratings yet

- DQ - CRAB For Lyo LoadingDocument30 pagesDQ - CRAB For Lyo Loadingdhanu_lagwankarNo ratings yet

- 111573-DS CoverDocument1 page111573-DS CoversamirNo ratings yet

- Cat Ladder Details3Document36 pagesCat Ladder Details3Shoaib KhanNo ratings yet

- 028120-SPT-006 Control Valve and Regulator SpecificationDocument23 pages028120-SPT-006 Control Valve and Regulator SpecificationBang JaliNo ratings yet

- 033000-126-1 Shop Drawings - Floor Penetrations - Temple Third LevelDocument2 pages033000-126-1 Shop Drawings - Floor Penetrations - Temple Third LeveljosselNo ratings yet

- Abj 89 103778 Ba 6070 00024 0000 01Document16 pagesAbj 89 103778 Ba 6070 00024 0000 01Nithin GNo ratings yet

- 2722-ME-007 - Piping Design, Fabrication & InstallationDocument42 pages2722-ME-007 - Piping Design, Fabrication & InstallationEngr Muhammad AliNo ratings yet

- Inspection Test Plan For ISBL 1Document59 pagesInspection Test Plan For ISBL 1Sharat SahaNo ratings yet

- Welding Inspection Ass 1Document7 pagesWelding Inspection Ass 1mohd as shahiddin jafriNo ratings yet

- P15340 Cyd V013 I BQ 0002 - 0Document2 pagesP15340 Cyd V013 I BQ 0002 - 0meeNo ratings yet

- PWHT ProceduresDocument15 pagesPWHT Proceduresmd quasid rabbaniNo ratings yet

- Fiberglass and FosterchecklistDocument2 pagesFiberglass and FosterchecklistAlaa AliNo ratings yet

- 1TB03300 300C04 STC Wir Me 0010 - C2Document18 pages1TB03300 300C04 STC Wir Me 0010 - C2Saud KhanNo ratings yet

- O&m Manual For Landscapeing LightDocument104 pagesO&m Manual For Landscapeing Lightmukilanarul12No ratings yet

- Saj-Po-Cgc-Mst-Pl-0002-01 Installation For Above Ground Drainage and Vent Piping SystemsDocument52 pagesSaj-Po-Cgc-Mst-Pl-0002-01 Installation For Above Ground Drainage and Vent Piping SystemsMonish T MonuNo ratings yet

- Technical Submital Form - Du PontDocument1 pageTechnical Submital Form - Du PontVijayakumar KarunanidhiNo ratings yet

- CL-NG-6460-002-067 Checklist For Metrosil and Non Linear Resistor Rev01Document1 pageCL-NG-6460-002-067 Checklist For Metrosil and Non Linear Resistor Rev01محمد عادلNo ratings yet

- $W - 00-K - 11a - 040 - PP - 140 - Commissioning ITP-MV SWGR 11BBB10 - Rev.0Document13 pages$W - 00-K - 11a - 040 - PP - 140 - Commissioning ITP-MV SWGR 11BBB10 - Rev.0MedrouaNo ratings yet

- 1TB03300 300C04 STC Wir Me 0013Document12 pages1TB03300 300C04 STC Wir Me 0013Saud KhanNo ratings yet

- 1007 DISQ 0 J SS 33030 Control Valve SpecificationDocument18 pages1007 DISQ 0 J SS 33030 Control Valve Specificationeng20072007No ratings yet

- Mtsi-Tdjv-Nscr-Trans - 01-21-216 Method Statement For Retouching of Paint of The Installed Steel Doors-1Document36 pagesMtsi-Tdjv-Nscr-Trans - 01-21-216 Method Statement For Retouching of Paint of The Installed Steel Doors-1AdrianNodaloNo ratings yet

- Method Statement-Piping-HadeedDocument5 pagesMethod Statement-Piping-HadeedJaseelKanhirathinkalNo ratings yet

- P1122 Arco Gen Me Man 0023 01Document137 pagesP1122 Arco Gen Me Man 0023 01safeer SulaimanNo ratings yet

- Saj-Po-Cgc-Mst-Hv-0004-00 Mos For Installation of Air Inlets Ad OutletsDocument43 pagesSaj-Po-Cgc-Mst-Hv-0004-00 Mos For Installation of Air Inlets Ad OutletsMonish T MonuNo ratings yet

- DOD-ITP-INS-008 - Cover Sheet - Rev.0Document2 pagesDOD-ITP-INS-008 - Cover Sheet - Rev.0BharathiNo ratings yet

- Nghi Son 2 BOT Thermal Power Plant Project Design Query SheetDocument3 pagesNghi Son 2 BOT Thermal Power Plant Project Design Query SheetMr NgocNo ratings yet

- Neral Specification For Technical Requirement-GTS-01Document6 pagesNeral Specification For Technical Requirement-GTS-01T ViswanathanNo ratings yet

- 1TB03300 300C04 STC Wir Me 0014Document13 pages1TB03300 300C04 STC Wir Me 0014Saud KhanNo ratings yet

- C08-016-000J-TS030 - 0 Pressure TranmitterDocument10 pagesC08-016-000J-TS030 - 0 Pressure TranmitterCristian RománNo ratings yet

- NER Commissioning Rev01Document7 pagesNER Commissioning Rev01pradeepmv159No ratings yet

- Indra: Detail Pre-Commissioning Procedure For Service Test of IA For Unit 040/041/042/043Document42 pagesIndra: Detail Pre-Commissioning Procedure For Service Test of IA For Unit 040/041/042/043AnhTuấnPhanNo ratings yet

- StsDocument6 pagesStsmohd as shahiddin jafri100% (1)

- HKN PRC Qa 0002 Rev.e DRRDocument25 pagesHKN PRC Qa 0002 Rev.e DRRjennyNo ratings yet

- ITP Water Treatment Tank ACC. Div 1Document14 pagesITP Water Treatment Tank ACC. Div 1Hani HatemNo ratings yet

- Adobe Scan 02-Jul-2022Document4 pagesAdobe Scan 02-Jul-2022Shamsher SinghNo ratings yet

- 1TB03300 300C04 STC Wir Me 0009Document14 pages1TB03300 300C04 STC Wir Me 0009Saud KhanNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Dod-Rgx-F425 - Fibre Optic Cable Pre-Installation Test ReportDocument2 pagesDod-Rgx-F425 - Fibre Optic Cable Pre-Installation Test ReportBharathiNo ratings yet

- DOD-RGX-F051 Rev 2 - Material Receipt Cum Inspection ReportDocument1 pageDOD-RGX-F051 Rev 2 - Material Receipt Cum Inspection ReportBharathiNo ratings yet

- General Notes 8A22-V09 D01 MD-502-8A22-EG-PR-PID-1011 8A22-V01 8A22-R03Document1 pageGeneral Notes 8A22-V09 D01 MD-502-8A22-EG-PR-PID-1011 8A22-V01 8A22-R03Bharathi100% (1)

- Load CalculationDocument6 pagesLoad CalculationBharathi100% (1)

- DOD-ITP - INS-008-ITP FOR Installation and Testing of Fiber Optic Cable - Rev.0Document2 pagesDOD-ITP - INS-008-ITP FOR Installation and Testing of Fiber Optic Cable - Rev.0Bharathi100% (1)

- DOD-RGX-F427 - FIBRE OPTIC CABLE Splice Termination Test ReportDocument2 pagesDOD-RGX-F427 - FIBRE OPTIC CABLE Splice Termination Test ReportBharathiNo ratings yet

- DOD-RGX-F049 Rev 0 - Over - Short - Damage ReportDocument1 pageDOD-RGX-F049 Rev 0 - Over - Short - Damage ReportBharathiNo ratings yet

- DOD-ITP-INS-008 - Cover Sheet - Rev.0Document2 pagesDOD-ITP-INS-008 - Cover Sheet - Rev.0BharathiNo ratings yet

- How To Convert Amps To Kilowatts & KW To AmpsDocument3 pagesHow To Convert Amps To Kilowatts & KW To AmpsBharathiNo ratings yet

- DOD-QCP-INS-002, Rev-0Document7 pagesDOD-QCP-INS-002, Rev-0BharathiNo ratings yet

- DOD ITP INS 001 Rev 1Document1 pageDOD ITP INS 001 Rev 1BharathiNo ratings yet

- DOD-ITP-INS-003 - Rev-2Document4 pagesDOD-ITP-INS-003 - Rev-2BharathiNo ratings yet

- DOD-ITP-INS-002 - Installation of Field Instrument Rev.1Document3 pagesDOD-ITP-INS-002 - Installation of Field Instrument Rev.1BharathiNo ratings yet

- DOD-ITP - INS-008-ITP FOR Installation and Testing of Fiber Optic Cable - Rev.0Document1 pageDOD-ITP - INS-008-ITP FOR Installation and Testing of Fiber Optic Cable - Rev.0BharathiNo ratings yet

- DOD-ITP-INS-004 - Installation and Testing of Air and Impulse Piping, Tubing.-Rev-2Document1 pageDOD-ITP-INS-004 - Installation and Testing of Air and Impulse Piping, Tubing.-Rev-2BharathiNo ratings yet

- History MapsDocument2 pagesHistory MapsBharathiNo ratings yet

- DOD ITP INS 006 Rev 1Document1 pageDOD ITP INS 006 Rev 1BharathiNo ratings yet

- CH # 15 Work SheetDocument1 pageCH # 15 Work SheetBharathiNo ratings yet

- Binder 1Document16 pagesBinder 1BharathiNo ratings yet

- Why Do We Use Vacuum Flask To Keep Hot Water or Tea For A Longer TimeDocument2 pagesWhy Do We Use Vacuum Flask To Keep Hot Water or Tea For A Longer TimeBharathiNo ratings yet

- Class 5 DecimalsDocument2 pagesClass 5 DecimalsBharathiNo ratings yet

- JACOBS Template (Repaired)Document5 pagesJACOBS Template (Repaired)BharathiNo ratings yet

- Water TherapyDocument3 pagesWater TherapyBharathiNo ratings yet

- Time and Temperature - Class 5Document2 pagesTime and Temperature - Class 5Bharathi100% (1)

- CH # 13 WorksheetDocument2 pagesCH # 13 WorksheetBharathiNo ratings yet

- 007 Mobile Crane ChecklistDocument2 pages007 Mobile Crane ChecklistJoshua ThomasNo ratings yet

- Membrane StructureDocument3 pagesMembrane StructureMa. Beatriz MonteverdeNo ratings yet

- Fire Protection Hydraulic CalculationsDocument25 pagesFire Protection Hydraulic CalculationsWillden100% (9)

- BDCC's Quality Control PlanDocument18 pagesBDCC's Quality Control PlanMohammad Taqi HamidiNo ratings yet

- BS en 14693-2017 - TC - (2020-08-27 - 08-40-38 Am)Document34 pagesBS en 14693-2017 - TC - (2020-08-27 - 08-40-38 Am)梁山伯No ratings yet

- Ridgid MS255SR Miter Saw ManualDocument36 pagesRidgid MS255SR Miter Saw ManualGordon LemmonNo ratings yet

- Wall PanelDocument27 pagesWall Panelcheska100% (1)

- A3-Bill of Quantities (BOQ)Document10 pagesA3-Bill of Quantities (BOQ)Wael Sayed omarNo ratings yet

- 13920a1 UnlockedDocument6 pages13920a1 UnlockedDhruv and pari showtimeNo ratings yet

- 2022 Spyderco Product GuideDocument220 pages2022 Spyderco Product Guidegordonsanwey0% (1)

- Group 4 - Lab 4Document12 pagesGroup 4 - Lab 4jia jun wanNo ratings yet

- 2022 - 03 - Voluntary Scheme in Enhancing Plumbing Works Control Stage 2 - Provisional of Site Supervision Team For Large-Scale Plumbing WorksDocument47 pages2022 - 03 - Voluntary Scheme in Enhancing Plumbing Works Control Stage 2 - Provisional of Site Supervision Team For Large-Scale Plumbing Workskumshing88cwNo ratings yet

- A Homebrewed Scrape Blade: Our Mini-Tractor's First Implement Will Work With Any Category 0 Tractor Hitch!Document2 pagesA Homebrewed Scrape Blade: Our Mini-Tractor's First Implement Will Work With Any Category 0 Tractor Hitch!WolfgangNo ratings yet

- Power For You: Quality Changes The WorldDocument4 pagesPower For You: Quality Changes The WorldLutfi DstrNo ratings yet

- ODA (P&BS) Rules 2020 PDFDocument152 pagesODA (P&BS) Rules 2020 PDFAnshuman RathNo ratings yet

- Truss TerminologyDocument3 pagesTruss Terminologymark aley solimanNo ratings yet

- Workshops - Composite, Riveting, Fabric & MaintenanceDocument6 pagesWorkshops - Composite, Riveting, Fabric & Maintenanceairbuk doeing100% (1)

- BC Rich Stealth Full RockarDocument1 pageBC Rich Stealth Full RockarPablo FerrariNo ratings yet

- CP../EFDCN.. Series Push Button Stations: Technical FeaturesDocument4 pagesCP../EFDCN.. Series Push Button Stations: Technical FeaturesYao TinchonNo ratings yet

- 51 - Test Format (Xxi) - Results of Conc - Cube Crushing Strength.Document1 page51 - Test Format (Xxi) - Results of Conc - Cube Crushing Strength.Prasanta ParidaNo ratings yet

- Schedule of Construction Equipment and VehiclesDocument2 pagesSchedule of Construction Equipment and VehiclessswahyudiNo ratings yet

- Construction Claims & Responses: Effective Writing & PresentationDocument10 pagesConstruction Claims & Responses: Effective Writing & PresentationmunisamyprabakaranNo ratings yet

- Mechanical Rotating-Supervisor Training PDFDocument19 pagesMechanical Rotating-Supervisor Training PDFWahyu IrwansyahNo ratings yet

- Daftar Harga: Push - On Fitting Untuk Pipa 25 JANUARI 2021 Rusli SaktiDocument2 pagesDaftar Harga: Push - On Fitting Untuk Pipa 25 JANUARI 2021 Rusli SaktiArif HidayatNo ratings yet

- 2016 12 Darch HouDocument153 pages2016 12 Darch HouEman J. AlnajiNo ratings yet

- Felias Bill of MaterialsDocument11 pagesFelias Bill of MaterialsRomneil D. CabelaNo ratings yet

- Finshing BOQ - RevDocument14 pagesFinshing BOQ - RevAmmar HattabNo ratings yet

- Installing A Protective Cementitious Liner System in Sanitary Sewer ManholesDocument4 pagesInstalling A Protective Cementitious Liner System in Sanitary Sewer ManholesAhmad Zubair RasulyNo ratings yet

- Proposed Sewage Treatment Plant of Domestic Waste 5CmD (Design and Build) .1Document2 pagesProposed Sewage Treatment Plant of Domestic Waste 5CmD (Design and Build) .1John Axl LajomNo ratings yet

- The Contractor' S H&S Plan-ToolsDocument16 pagesThe Contractor' S H&S Plan-ToolsnervozaurNo ratings yet