Professional Documents

Culture Documents

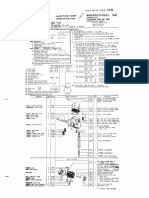

4 Modeldcgfc 629 16ag: Piige No: 6 Oo-?I Injection Fump Speclflcatlon

Uploaded by

dieselmotorsbogotasasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4 Modeldcgfc 629 16ag: Piige No: 6 Oo-?I Injection Fump Speclflcatlon

Uploaded by

dieselmotorsbogotasasCopyright:

Available Formats

.-- -...

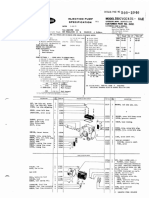

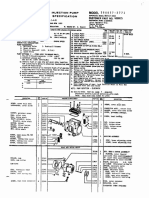

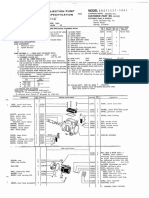

CATALOG, 4

PiiGE NO:6 oo- ?I

INJECTION FUMP

1166

MODELDCGFC

629~16AG

SUPERSEDES MODEL

SPEClFlCATlON

CUSTOMER PART NO. W5496

EDITION NO. 11 DATED 9-24-71 CUSTOMER’S NAME IL ADDRESS:

A!lis Chs1mer.z Mfg. Co.

Warvcy iorks

ENGINE D-5 506 - TLl6D FULL LOAD RPM 2200

Harvey, Il!ixis

APPLICATION “SUGAR BABE” GOV. REGULATION7-10 % ISSUED BY: F. C. Wisnieskl

NOTE: ALL SPEEDS ARE IN ENGINE RPM UNLESS 01’ HERWISE NOTED

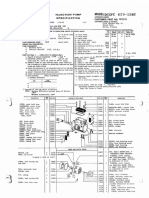

TEST STAND

1. INJECTION LINES ?,,” I.D. BY 20’ LONG 8. CHECK POINT

2. TEST OIL TECIPERATURE 110-115i F 9. CHECK POINT

3. NOZZLE OPENING PRESSURE 2500 PSI 12SDi.2 NOZZLES. I IO. CHECK POINT

4. USE ROOSA MASTER CALIBRATING OIL 11. SET TORQUE SCREW

PUMP OPERATING SPEED HALF ENGINE SPEED 12. CHECK POINT-PART LOAD

ENGINE FUEL CONSUMPTION 13. HIGH IDLE (WOT)

PUMP ACCESSORIES 14. GOVERNOR CUT-OFF (‘/z HI-IDLE DEL.)

1. Delivery Valvt! 15. LOW IDLE

2. Electric Shut-Off (24V. E.T.S.O.) 12V. COIL 16. TRANSFER PUMP PRESSURE (WOT)

17. TRANSFER PUMP PRESSURE (WOi)

:: 18. MINIMUM CRANKING SPEED DELIVERY

PUMP SETTINGS (7 _.

ITEMS APPLY TO SERVICE ONLY)

1. ROLLER TO RDLLER DIMENSION 1.9640 z.0005 *

2. GOVERNOR LINKAGE GAP ,125” TO .169 19. NAME PLATE icItilT SIDE VIEWING E.P.

‘(USE GAGE NO. 189141 20. TIMED RIGliT SIDE VIEWING E.P.

~3. OPERATE PUMP AT 1000 RPM WOT (WIDE OPEN THROTTLE) 21. TIMED TO C.W (For begfnning of Injection)

FOR 10 MINUTES TO BRING TO OPERATING TEMPERATURE AND 22. GOVERNOR CONTROL COVER TO BE STAMPED24 VOLTS.

CLEAR AIR FROM SYSTEM. 23. NUMBER ONE CYLINDER IFROM END PLATE) -_ -

4. CHECK FOR MININuM 18” HG TRANSFER PUMP LIFT AT 400 RPM. 24. SPECIAL NOTES:

IF EQUIPPED IITH THE BY PASS SYSTEM. PINCH BY PASS HOSE. a. Torque all faste:ners per XL-713 or S.B.iO6

5. ADJUST TRANSFER PUMP PRESSURE (WOT) b. rmP to be tested with fitting NO. 15830 installed

r6. CHECK FOR MINIMUM CRANKING SPEEDDELIVERY (SEE STEPIS) t. Electric Shut-Off to be tested and adjusted per XL-274 or

S. B. IOBR

7. AUTO ADVANCE SPEED RESPONSIVE

d. Throttle Shaft Assembly to be installed on Right Side vlevlng

a. ADVANCE MOVEMENT End Plate

a. Drive Shaft Key a10274 to be shipped separately.

b.

c. 25. SEALlNG WIRES: PART NO. 10408 4 REQUIRED .

(REFERENCE DRAWING XL545 OR SERVICE BULLETIN 134R)

d. / High Idle Scrrw to Lever

* Av?r.=ge of rhe tvo pairs of Rollers

NOTE: !;2;;zum difference between pairs of Rollers

ici tv .004” I

_- ___ --._ _- __ ____-- ---

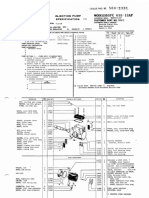

zz

x0. A

‘ RT

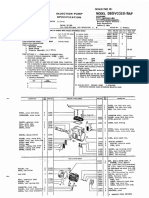

F NO. HO”SwKi

LDRlYEOno”P ---Ez

-

--

1 f

I

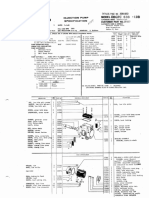

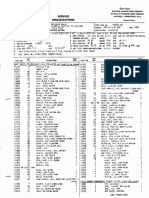

SCREW, cover hold down 12202; .-

LOCKWASHER, cover screw

CASKET, governor cover 1 comcn ASSY.~.feturll line

SW., pilot tube 3 WASHER, cover hold down .uev

SUt, drive shaft 1 CWFB, go”erlmor control

STOP, throttle

SMrr ASSY., drive

SW, drive : SCREW, head locking

1

1

KEY, drive shaft 1 102741

BUTTON, thrust 1 1204C 1

i: 1467! 1

SPRING. thrust 1

I!

WASHER, torq. screw hole I10464

SCREW. torq. .cr* bolt pl : 112259

SCReV, name plate 2 110401 1 wus1ffi WSemLY

PLATE, name 1 I10394 B’JSHING, thrattlc rbft

CA6KEI, timing llna co”er 2 110574 : TUBE,pilot

SCBEY, tiring lfnc covar b I10584

awl!&, timing line 2 1 0567 1 WASNER, cam 1oceting screw

NUT, drive shaft 1 1 0529 1 SEAL. head louti~ Lcteu

1 SCRIU, bard loutin~

LOCKWASHER, drive shaft 1

1 SCREW, cam locating

1 .-- ._. = _ ---

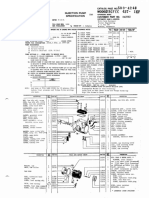

“LID a HDTOYORo”P

1 HYD. HEAC 6 Rl?l’oI? ASSY. l

,* INDENTED ITEHS INCLUDED *

11056 2 PLUNGER, rotor (basic)

ROLL% cam 11141

use 11057 thrul1060 (Standard)

SHOE, :a, roller 15833

or1 1062 thrw11065 (OverSiac:l

SPRING, leaf 15724

as indicated on rotor

SCRW, leaf spring adj. 15869

16044 2 PLUNGER, rotor (basic)

CAM R INC 10375

use16045 thru16048 (Standard1 ’

or 16067 thru16070 (O~ersizc:~

SEAL. hydraulic head 1 11304

as indicated on rotor

2 RETAINER, rotor

I 53’-5 1 BINC, rotor retainer

1 SCREW, delivery valve ret.

1 STOP, deliver:r valve

SCREW, leaf spring adJ. 1 I .5619

.16441 1 SPRING, delivsry valve

SCREW, fuel line connector 6 I 11346 c 13829

11437

1 VALVE, delivery

or13830 (Oversize)

WIRE, “ant

S.B. 143g

aa rewired

11438 : SCREW, hydraulic head ~1~6

11439 1 WIKE,ventrire ret

12216 1 SC~EY,hydraulic head Plus

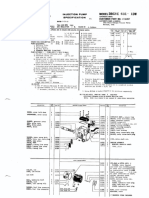

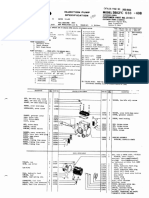

D@tC6~6KiT---- --

PLUC ASSY., end plate adj.

SLEEVE, end plate

12406 SEAL, end plate rleeve

15225 EL FMENT, filter

15627 SE AL, element

ROLLPIN, end plate lot. 11525 11507 RI NG,slceve reel

SPRING, trans. pump blade 15699 15701 SP RING, tcylating

BUDE, transfer pump 18137 11508 PI STON, regulating

17056 SE AL, regulatiag piston

LINER, transfer pump 16753

16222

15877 PL ATE, end

SEAL, transfer pump 11329 13521 WASHER, end plate screw

PLATE. thrust 15875 11532 SC ilEW, end plate

PLUG, end plate pipe 15821 -Q 1 - 1 11582 Lo CKWASHER, end plate screw

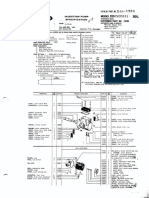

SPRIKC, governor control 1 11994 12210 1 RE TAINER. spring

11966 1 SP RING, idling

ARM, governcr 1 14482 11969 1 Gli IDE, idling spring

SHAFT, go”. arm pivot 1 12214 146So 1 AR H ASSY., ,Wtartng Valve

SEAL, pivot shaft 2 11588 13556 1 WASHER, guide stud

NUT. pivot shaft redo 2 12260 122oe 1 STUD,

‘ guide

11610 1 SH IM, metering valve

11563 1 VA LVE, metering

1 14483 11604 1 SP RING, metering valve

19717 I TAINER ASSY., go”. might

6 11658~

19541 1 RET. ASSY..~OV. wt.(baslc)

19527 1 RETAINER, So”. weight

WASHER, go”. thrust Sleeve 1 11620 19536 1 HUB ASSY., SO”. veight

RING, go”. cage retaining 1 ,583s 1751: 1 RING, flexible ret.

= B

I-----+ 15026 Bz ASSY l ,tbrott1e-

13003 :fNC.throttle Ieva

13010 MINER ,thrott lc lever rprl~

1 12174 12999 SWE!J,cbrottle spring

*OY idle rdj. SCTCY

low idle adj. 1 12972

throttle shaft 1 12221

kIF.~shafe retaining 12253

SEAL. throttle shaft : 12040 12971 SC REV, high idle adj.

VASHER, throttle shaft seal 2 14408 12171 NV T, high idle l dj.

15024 SXIWI ASSY., throttle

S!WT,shut-off 1 12235 HO

‘ O‘ K AS&BLY., ~0”. Linkage

11901

1236C SCRW, gov. link. book adj

12362 WASHEd, go”. link. hook ad’

119oc HOOK, governor linkage !

123% LINK ASSY., ~0”. link adj.

11919 SF RI%, governor linkage

E

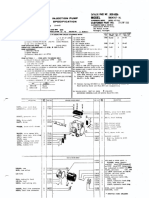

ELECTRIC SH~-OFF GROW (E.T.S.O.)

LOCRSLT, terminal contact 2 14760

WASHER,tenninal contact 1 18501

WIRE ASs’Y. ,tem.grounding 1 18491

1 12049 1.84 93 LOCKUASHER,cover (ICI

LOCKk‘ASHER,teminaI contact

18501 1.25 19 Nur, terminal contact

KASHER, terminal contact

WASHER.terminal insulating ; 12500 _

Install Grounding Wire

on RIGHT side Vieving

End Plate per XL-683. :I25 13

A&l ASS’Y., shut-down coil 1 I2474

SPRING, shut-down arm 1 12481

FRA.% ASS’Y., solenoid 1 16353

= := =

I

FOR SERVICE USE ONLY FOR EEGIh‘EERING USE ONLY

CHG. NO. EDITIOF

APPLICABLE SERVICE ASSEMBLIES -DATE

C.askct !.it :: 14369 9-27-64 9221 8

Pi:<,r r_..!;< rk,:>l.%<.. .‘~l I) 15378 2-10-69 10304 9

SOLEKOID AND ARM ASSNBLY 18695 4-I- 70 10818 10

c i>vi-r and scicnoic assrmbly If 18523 9-2L-71 11360 11

You might also like

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- 3'6 63'7 l'IL%F: Model DBGFCDocument2 pages3'6 63'7 l'IL%F: Model DBGFCMiguel RojasNo ratings yet

- 0 - 10 3 0 DBGFC 6 37 - I::.Batalog Pa&E Nqi 5 0 - Customer Part No. 11339772Document2 pages0 - 10 3 0 DBGFC 6 37 - I::.Batalog Pa&E Nqi 5 0 - Customer Part No. 11339772Miguel RojasNo ratings yet

- DBGFC 429-22 AF ., .: HMS ModelDocument2 pagesDBGFC 429-22 AF ., .: HMS ModelDIESEL MOTORSNo ratings yet

- ,5 (-J - $438 DBGFC 631-44AJ: I Customer Part No., Y51 q955Document2 pages,5 (-J - $438 DBGFC 631-44AJ: I Customer Part No., Y51 q955dieselmotorsbogotasasNo ratings yet

- Modeldbgfcc 431": - Catalog'Page NO: 580 - 3 51 6Document2 pagesModeldbgfcc 431": - Catalog'Page NO: 580 - 3 51 6johnny sabinNo ratings yet

- Injection Pump Model Diesel Systems Specification Nay514958Document2 pagesInjection Pump Model Diesel Systems Specification Nay514958dieselmotorsbogotasasNo ratings yet

- Model: Catalog Page No: 50 0 - DBGFC63741AJ Customer Part NoDocument2 pagesModel: Catalog Page No: 50 0 - DBGFC63741AJ Customer Part NodieselmotorsbogotasasNo ratings yet

- DBGVC231 7BMDocument3 pagesDBGVC231 7BMMiguel RojasNo ratings yet

- DCGFC 629-Z Ap: Model "Document2 pagesDCGFC 629-Z Ap: Model "dieselmotorsbogotasasNo ratings yet

- Modeldbg'Vcc% 31-: Injection Pump SpecificationDocument2 pagesModeldbg'Vcc% 31-: Injection Pump SpecificationdieselmotorsbogotasasNo ratings yet

- Iiza 1AJ: Modeldbgfcc635Document2 pagesIiza 1AJ: Modeldbgfcc635dieselmotorsbogotasasNo ratings yet

- 3 J 4 DBGFCC631-2AE: Customer Part No. 79885Document2 pages3 J 4 DBGFCC631-2AE: Customer Part No. 79885Miguel RojasNo ratings yet

- Modeldbgfc 6i37-49a J: Injection Pump Specification Customer Part No. 4515115Document2 pagesModeldbgfc 6i37-49a J: Injection Pump Specification Customer Part No. 4515115dieselmotorsbogotasasNo ratings yet

- Model: - OBGFC637 - ISA.1Document2 pagesModel: - OBGFC637 - ISA.1dieselmotorsbogotasasNo ratings yet

- MODELDCGFC 629-15&G: Customer Part No. 4025676Document2 pagesMODELDCGFC 629-15&G: Customer Part No. 4025676dieselmotorsbogotasasNo ratings yet

- Modeldbgfc 635-: Catalog Pagit NoDocument2 pagesModeldbgfc 635-: Catalog Pagit NoMiguel RojasNo ratings yet

- 51 F3 Modeldbgfcc431-3Latl: - . C!Talog Page'NoDocument2 pages51 F3 Modeldbgfcc431-3Latl: - . C!Talog Page'Nojohnny sabinNo ratings yet

- 1 JJ Model: C"A?Al - Og No: Eititfcc93T Part No. A 35776Document2 pages1 JJ Model: C"A?Al - Og No: Eititfcc93T Part No. A 35776johnny sabinNo ratings yet

- DBGFC 431-?'dif$: ModelDocument2 pagesDBGFC 431-?'dif$: Modeljohnny sabinNo ratings yet

- Modeldbgvc 63i-1DW: Injection Pump SpecificationDocument2 pagesModeldbgvc 63i-1DW: Injection Pump Specificationjohnny sabinNo ratings yet

- Diesel Systems De0637-2771: 1njecflon Speclflcatlon Sucersedls Customer Part No. Too6625Document3 pagesDiesel Systems De0637-2771: 1njecflon Speclflcatlon Sucersedls Customer Part No. Too6625Mario Fernando Blanco LópezNo ratings yet

- Model Ibgf 633 - Im: Injection Pump Speci - Fication Supersedes Model Custop Ier Part 9 C"Stomer'SDocument2 pagesModel Ibgf 633 - Im: Injection Pump Speci - Fication Supersedes Model Custop Ier Part 9 C"Stomer'Sjohnny sabinNo ratings yet

- Catalog Page No 6 00 - 631 - Customer Part No. 4028125Document2 pagesCatalog Page No 6 00 - 631 - Customer Part No. 4028125Eduardo David Castillo QuijandriaNo ratings yet

- Modeldeigfc: Catalog PAGE NO: 50@ 5Document2 pagesModeldeigfc: Catalog PAGE NO: 50@ 5johnny sabinNo ratings yet

- Specification: 2.speed Advance 3 DDocument2 pagesSpecification: 2.speed Advance 3 Djohnny sabinNo ratings yet

- DBGFC 633 - 4DB: ModelDocument2 pagesDBGFC 633 - 4DB: Modeljohnny sabinNo ratings yet

- DBGV (X429 - 3cli: ModelDocument2 pagesDBGV (X429 - 3cli: ModelMiguel RojasNo ratings yet

- Injection Pump Speclflcatlon: Test Stand 1. All Speeds RPYDocument2 pagesInjection Pump Speclflcatlon: Test Stand 1. All Speeds RPYMiguel RojasNo ratings yet

- Model: Pump Injection SpecificationDocument2 pagesModel: Pump Injection SpecificationdieselmotorsbogotasasNo ratings yet

- DBGVC 433-1DW: ModelDocument2 pagesDBGVC 433-1DW: ModelMiguel RojasNo ratings yet

- Model% Ifc637-38Aj Customer Part No. 451494 &on ..-: Diesel SystemsDocument2 pagesModel% Ifc637-38Aj Customer Part No. 451494 &on ..-: Diesel SystemsMiguel RojasNo ratings yet

- Livery: LL?PL GroupDocument2 pagesLivery: LL?PL Groupjohnny sabinNo ratings yet

- 5 TJ - 1 Odeldbg'Vcc43I-2Dv: Catalog NODocument2 pages5 TJ - 1 Odeldbg'Vcc43I-2Dv: Catalog NOdieselmotorsbogotasasNo ratings yet

- Model Bbkvct63L - Lit P: Catalog NoDocument2 pagesModel Bbkvct63L - Lit P: Catalog NodieselmotorsbogotasasNo ratings yet

- DBGVC 437 - 8af": Customer Part No. JD403F-206 Z LDocument2 pagesDBGVC 437 - 8af": Customer Part No. JD403F-206 Z LMiguel RojasNo ratings yet

- DBGVC2314NZ: ModelDocument2 pagesDBGVC2314NZ: ModelMiguel RojasNo ratings yet

- ,Lfd'Lalag'Pkge:Ljfj 500 - 35 L5: - . ZZ!ZZ - Mm. Per Max. Y&R. Trans. PumpDocument2 pages,Lfd'Lalag'Pkge:Ljfj 500 - 35 L5: - . ZZ!ZZ - Mm. Per Max. Y&R. Trans. Pumpjohnny sabinNo ratings yet

- Catalog Page No: Injection Pump Model Df3Gfccwl-27Aj Specification Customer Part Hl0. 3577'4Document2 pagesCatalog Page No: Injection Pump Model Df3Gfccwl-27Aj Specification Customer Part Hl0. 3577'4johnny sabinNo ratings yet

- 6 HP Evinrude ManualDocument9 pages6 HP Evinrude Manualcainanashton0% (1)

- Modeldbglrc: 0257 Customer Part No. ZD/29F-231Document2 pagesModeldbglrc: 0257 Customer Part No. ZD/29F-231Miguel RojasNo ratings yet

- Injection Pump Specipicaticbn: No. Customer'SDocument2 pagesInjection Pump Specipicaticbn: No. Customer'SdieselmotorsbogotasasNo ratings yet

- Modeldbgfc 3'3.3 - LDB SupersmlsmodelDocument2 pagesModeldbgfc 3'3.3 - LDB Supersmlsmodeljohnny sabinNo ratings yet

- Dm4627Md2865: Edmonno Customer Part No. Ar 66395Document3 pagesDm4627Md2865: Edmonno Customer Part No. Ar 66395Robert Alexander FrankNo ratings yet

- D B 0 4 2 Diesel Systems: 9 - 0494 AT16518T TractorDocument2 pagesD B 0 4 2 Diesel Systems: 9 - 0494 AT16518T TractorDave MilnerNo ratings yet

- Modeil Dbgvcc631-2Dli: Catilog Page No: 500-905Document2 pagesModeil Dbgvcc631-2Dli: Catilog Page No: 500-905dieselmotorsbogotasasNo ratings yet

- 46 Modeldbgfcc: DatedDocument2 pages46 Modeldbgfcc: DatedMiguel RojasNo ratings yet

- BBGBR: ModelDocument2 pagesBBGBR: ModeldieselmotorsbogotasasNo ratings yet

- Specification Customer Fart No. AR35081R: Injection Pump Bdel CZ'CDocument2 pagesSpecification Customer Fart No. AR35081R: Injection Pump Bdel CZ'Cjohnny sabinNo ratings yet

- Saudi Arabian Oil Company Valve Data Sheet General DataDocument2 pagesSaudi Arabian Oil Company Valve Data Sheet General Datasalihmohammed533No ratings yet

- DBGVCC429 4alDocument2 pagesDBGVCC429 4alOFFICE DANACNo ratings yet

- DBGFC 633 - 5DB: ModelDocument2 pagesDBGFC 633 - 5DB: Modeljohnny sabinNo ratings yet

- DBGFC 431-z DB: ModelDocument2 pagesDBGFC 431-z DB: Modeljohnny sabinNo ratings yet

- DBGVCC631-3DL: ModelDocument2 pagesDBGVCC631-3DL: ModeldieselmotorsbogotasasNo ratings yet

- 00775Document2 pages00775johnny sabinNo ratings yet

- MODEL DBGFC 637-n AF: Qtilog - Page NO GDocument2 pagesMODEL DBGFC 637-n AF: Qtilog - Page NO GMiguel RojasNo ratings yet

- Injection Pump Model I! Specification O'577: BGVC431-3AJDocument2 pagesInjection Pump Model I! Specification O'577: BGVC431-3AJjohnny sabinNo ratings yet

- Modeldbgfc 633-2Dh: Lnjectlon PLJNFP Specification / - / Customer Part No - at 22'+90 TDocument2 pagesModeldbgfc 633-2Dh: Lnjectlon PLJNFP Specification / - / Customer Part No - at 22'+90 Tjohnny sabinNo ratings yet

- Injection Pump Specification LN3Dyf1500 " - 8A ' 2 'Document2 pagesInjection Pump Specification LN3Dyf1500 " - 8A ' 2 'johnny sabinNo ratings yet

- DBGVC 631-1lAF: ModelDocument2 pagesDBGVC 631-1lAF: Modelmurillo_rodriguez8382No ratings yet

- DCGFC 629-Z Ap: Model "Document2 pagesDCGFC 629-Z Ap: Model "dieselmotorsbogotasasNo ratings yet

- Micron CoalecsingDocument1 pageMicron CoalecsingdieselmotorsbogotasasNo ratings yet

- Modeldbgfc 6i37-49a J: Injection Pump Specification Customer Part No. 4515115Document2 pagesModeldbgfc 6i37-49a J: Injection Pump Specification Customer Part No. 4515115dieselmotorsbogotasasNo ratings yet

- Injection Pump Model Diesel Systems Specification Nay514958Document2 pagesInjection Pump Model Diesel Systems Specification Nay514958dieselmotorsbogotasasNo ratings yet

- Model: Pump Injection SpecificationDocument2 pagesModel: Pump Injection SpecificationdieselmotorsbogotasasNo ratings yet

- Model: - OBGFC637 - ISA.1Document2 pagesModel: - OBGFC637 - ISA.1dieselmotorsbogotasasNo ratings yet

- Model Bbkvct63L - Lit P: Catalog NoDocument2 pagesModel Bbkvct63L - Lit P: Catalog NodieselmotorsbogotasasNo ratings yet

- 00877Document2 pages00877dieselmotorsbogotasasNo ratings yet

- 00866Document2 pages00866dieselmotorsbogotasasNo ratings yet

- ShaftDocument2 pagesShaftdieselmotorsbogotasasNo ratings yet

- DBGVCC631 2apDocument2 pagesDBGVCC631 2apdieselmotorsbogotasasNo ratings yet

- Imjectlqn PU: 1545 K.P.M. / r-1 4. Keducr SPC - Ed Co I R T C"1 8Document2 pagesImjectlqn PU: 1545 K.P.M. / r-1 4. Keducr SPC - Ed Co I R T C"1 8dieselmotorsbogotasasNo ratings yet

- Dbgvcc431-: Ca-Ialog Pagt No: S 0 - 2 3 5 3Document2 pagesDbgvcc431-: Ca-Ialog Pagt No: S 0 - 2 3 5 3dieselmotorsbogotasasNo ratings yet

- AVEVA E3D Tutorial Equipment Modeling With Practical ExampleDocument8 pagesAVEVA E3D Tutorial Equipment Modeling With Practical ExampleRamon Alejandro Porras Hernandez100% (1)

- Citadel of Kirkuk 1Document17 pagesCitadel of Kirkuk 1ArézAzadNo ratings yet

- Catalog Man 1Document116 pagesCatalog Man 1Petrov AndreiNo ratings yet

- Schrodinger Wave EquationsDocument6 pagesSchrodinger Wave EquationsksksvtNo ratings yet

- TamasDocument180 pagesTamaslike 2No ratings yet

- Samuelson and Nordhaus ch22 PDFDocument30 pagesSamuelson and Nordhaus ch22 PDFVictor ManatadNo ratings yet

- Igc 3 Practical NeboshDocument20 pagesIgc 3 Practical NeboshAbdelkader FattoucheNo ratings yet

- Materi B.inggris SMP Kelas 9 Kurikulum 2013Document21 pagesMateri B.inggris SMP Kelas 9 Kurikulum 2013Siti DianurNo ratings yet

- Reservoir Rock PropertiesDocument148 pagesReservoir Rock Propertiesiscribdusername100% (7)

- Donali Lalich Literature ReviewDocument4 pagesDonali Lalich Literature Reviewapi-519746057No ratings yet

- Content For Essay and Paragraph Writing On Maritime HistoryDocument15 pagesContent For Essay and Paragraph Writing On Maritime HistoryRaju KumarNo ratings yet

- The Coffee Shop Easy Reading - 152542Document1 pageThe Coffee Shop Easy Reading - 152542Fc MakmurNo ratings yet

- X Glo LED Strip Lighting For Tunnelling BrochureDocument6 pagesX Glo LED Strip Lighting For Tunnelling BrochureJOSE HUAMANINo ratings yet

- 020 Basketball CourtDocument4 pages020 Basketball CourtMohamad TaufiqNo ratings yet

- A Review of Linear AlgebraDocument19 pagesA Review of Linear AlgebraOsman Abdul-MuminNo ratings yet

- Iron FistDocument2 pagesIron FistVictor PileggiNo ratings yet

- 2006 - Dong Et Al - Bulk and Dispersed Aqueous Phase Behavior of PhytantriolDocument7 pages2006 - Dong Et Al - Bulk and Dispersed Aqueous Phase Behavior of PhytantriolHe ZeeNo ratings yet

- HW 1 2018Document4 pagesHW 1 2018Huy TranNo ratings yet

- Advanced Logic Synthesis: Multiple Choice QuestionsDocument16 pagesAdvanced Logic Synthesis: Multiple Choice QuestionsmanojkumarNo ratings yet

- Safety Data Sheet 3D TRASAR® 3DT128: Section: 1. Product and Company IdentificationDocument10 pagesSafety Data Sheet 3D TRASAR® 3DT128: Section: 1. Product and Company IdentificationEscobar ValderramaNo ratings yet

- Module III Rural MarketingDocument30 pagesModule III Rural MarketingNikita YadavNo ratings yet

- Model A SOLUTIONSDocument8 pagesModel A SOLUTIONSasdfNo ratings yet

- Asutphin Client Assessment Matrix Fitt Pros Unit 8Document4 pagesAsutphin Client Assessment Matrix Fitt Pros Unit 8api-307235123No ratings yet

- 2020 Landfill Capacity Calculation Work SheetDocument4 pages2020 Landfill Capacity Calculation Work SheetLYNo ratings yet

- Our Lady of Fatima University: College of Business & AccountancyDocument17 pagesOur Lady of Fatima University: College of Business & AccountancyCLARIN GERALDNo ratings yet

- Cracked Tooth Syndrome. Part 1 Aetiology and DiagnosisDocument17 pagesCracked Tooth Syndrome. Part 1 Aetiology and Diagnosisfloressam2000No ratings yet

- 1.toyotamarklogo Standard Jan 2021 eDocument43 pages1.toyotamarklogo Standard Jan 2021 eMercadeo TosakaNo ratings yet

- Yamaha rx-v395 v395rds htr-5130 5130rdsDocument55 pagesYamaha rx-v395 v395rds htr-5130 5130rdsdomino632776No ratings yet

- OKM 54MP FlyerDocument1 pageOKM 54MP FlyerJohnsonNo ratings yet

- Tas 5731Document60 pagesTas 5731charly36No ratings yet