Professional Documents

Culture Documents

2342-AA00-ML-243 - 0 - Study Report (On-Line Corrosion Monitoring Study)

Uploaded by

yusuf.yuzuakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2342-AA00-ML-243 - 0 - Study Report (On-Line Corrosion Monitoring Study)

Uploaded by

yusuf.yuzuakCopyright:

Available Formats

Project N° Unit Document Code Serial N° Rev.

Page

2342 AA00 ML 243 0 1/13

KARBALA REFINERY FEED PROJECT

SCOP – IRAQ (Contract n° 2171)

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

Study Report

On-Line Corrosion Monitoring Study

which it is specifically furnished or outside the extent of the agreed upon right of use.

0 15/09/2010 ISSUE FOR FEED M.E. RENELLA F. CIFA’ C. PASCALI / O. LOIACONO

REV. DATE STATUS WRITTEN BY CHECKED BY APPROV./AUTHOR. BY

(name & visa) (name & visa) (name & visa)

DOCUMENT REVISIONS

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2342 AA00 ML 243 0 2/13

KARBALA REFINERY FEED PROJECT

SCOP – IRAQ (Contract n° 2171)

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

1 SCOPE 3

2 ONLINE CORROSION MONITORING PHILOSOPHY 4

2.1 Corrosion coupons monitoring 4

2.2 Electrical resistance probes 5

2.3 Probes selection 5

3 MONITORING SUMMARY TABLE AND LOCATIONS 6

4 COUPON PREPARATION 10

5 PROCEDURE FOR FIELD HANDLING OF COUPONS BEFORE AND AFTER

EXPOSURE 11

5.1 Laboratory analysis 11

5.2 Typical Corrosion Coupon Report 12

6 REFENCE DOCUMENTS AND LIST OF ATTACHMENTS: 13

6.1 Reference Documents 13

6.2 List of attachments 13

which it is specifically furnished or outside the extent of the agreed upon right of use.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2342 AA00 ML 243 0 3/13

KARBALA REFINERY FEED PROJECT

SCOP – IRAQ (Contract n° 2171)

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

1 SCOPE

The Corrosion monitoring study presents the recommendations for the online corrosion monitoring

for KARBALA REFINERY FEED PROJECT.

It includes description of the applied techniques and corrosion monitoring locations.

Results of this study to be implemented in the design in the EPC phase.

which it is specifically furnished or outside the extent of the agreed upon right of use.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2342 AA00 ML 243 0 4/13

KARBALA REFINERY FEED PROJECT

SCOP – IRAQ (Contract n° 2171)

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

2 ONLINE CORROSION MONITORING PHILOSOPHY

On-line monitoring refers to a special group of measurement techniques which are suitable for use

while the facility is in operation.

Contractor shall developed a comprehensive corrosion control program which includes several

techniques since no single technique is capable of providing all the information necessary to

assess completely all the ongoing degradation mechanisms.

Below is presented an overview of the online corrosion measurement techniques selected for the

KARBALA REFINERY FEED PROJECT.

2.1 Corrosion coupons monitoring

Coupons are the oldest and simplest device used in the monitoring of corrosion. Coupons are

small pieces of metal, usually of a rectangular or circular shape, which are inserted in the process

stream and removed after a period of time for study.

The most common and basic use of coupons is to determine average corrosion rate over the

period of exposure. This is accomplished by weighing the coupon before and after exposure

(coupons must first be cleaned following exposure to remove corrosion products and any other

deposits) and determining the weight loss. The average corrosion rate can easily be calculated

from the weight loss, the initial surface area of the coupon and the time exposed. It is advisable to

leave a coupon exposed for at least 30 days to obtain valid corrosion rate information.

There are two reasons for this recommended practice. First, a clean coupon generally corrodes

much faster than one which has reached equilibrium with its environment. This will cause a higher

corrosion rate to be reported in a short test than is actually being experienced on the pipe or

vessel.

Second, there is an unavoidable potential for error as a result of the cleaning operation. Coupon

cleaning procedures are designed to remove all of the deposits without disturbing the remaining

uncorroded metal of the coupon. A small amount of the underlying metal is often removed with the

deposits, however, and if the actual metal loss from corrosion is small (as would be the case in a

short test) the effect of metal removed during cleaning would create a significant error. Care must

be taken to correct for this effect. It should be recognized that a coupon can only provide corrosion

rate data based on the total weight loss divided by the total time of exposure.

One of the most important roles of coupons is to provide information about the type of corrosion.

Unlike electrical resistance probes, which only detect the amount of metal removed, coupons can

be examined for evidence of pitting and other localized forms of attack that may arise in the

which it is specifically furnished or outside the extent of the agreed upon right of use.

monitoring location.

Coupons indicate the attack of the environment only at the point of exposure; for this reason the

coupon (as the electrical resistance probe) are installed at representative locations as close as

possible to critical points where corrosion measurements is considered relevant for the plant

service life (e.g. such as vessel or pipe walls, tube sheets, trays, etc.).

Anyway, conditions of flow, temperature, concentration, etc., may change considerably only a few

inches away from any given location, with resulting differences in corrosion rates. Coupons

suspended in the center of a pipeline or vessel may corrode at different rates than coupons

suspended near the wall of the vessel or pipe, for example. Since corrosive conditions can change

significantly from one location to another, coupon data is best used for relative comparisons

(changes in the rate or characteristics of corrosion over time at a single point) and to obtain an

approximate corrosion rate at a particular point in the system rather than to precisely calculate the

corrosion rate.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2342 AA00 ML 243 0 5/13

KARBALA REFINERY FEED PROJECT

SCOP – IRAQ (Contract n° 2171)

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

2.2 Electrical resistance probes

Electrical Resistance probes and instruments are basically "automatic coupons" and share many

characteristics with coupons, as discussed above, when it comes to advantages and limitations.

Electrical resistance systems work by measuring the electrical resistance of a thin metal probe. As

corrosion causes metal to be removed from the probe, its resistance increases. The major

advantage of the electrical resistance method compared to coupons is that measurements can be

obtained on a far more frequent basis and require much less effort to make. With automated

systems, continuous readings are in fact made and sophisticated data analysis techniques are

now available which permit the detection of significant changes in corrosion rate in just a few

hours.

2.3 Probes selection

In the electric resistance probe wire loop and tube loop elements do have a tendency to be

electrically shorted by a bridge of iron sulphide corrosion product. This is especially prevalent in

low-velocity streams over an extended period. The effect of such bridging is to reduce the

measured metal loss of the probe, creating a misleadingly low corrosion rate. Cylindrical probes

demonstrate more resistance to iron-sulphide bridging due to their construction and lower inherent

which it is specifically furnished or outside the extent of the agreed upon right of use.

resistance per unit length, thus minimizing the effect of the shunt resistance.

In KARBALA REFINERY FEED PROJECT substantial FexSy deposition are expected to be

problems in main of the prevented probes and therefore particular attention should be paid on

probe design and selection.

Cylindrical probes are recommended over other types because they are less sensitive to sulphide

scale bridging; in particular, for electric resistance probe, Rohorback Cosasco Microcorr ® type or

equivalent is recommended.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2342 AA00 ML 243 0 6/13

KARBALA REFINERY FEED PROJECT

SCOP – IRAQ (Contract n° 2171)

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

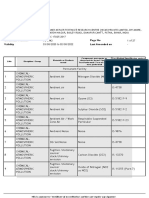

3 MONITORING SUMMARY TABLE AND LOCATIONS

A corrosion monitoring system is developed to measure the general corrosion development and

the efficacy and efficiency of the corrosion inhibitors and water washing (if any).

The summary table presents the recommended monitoring locations and the corrosion monitoring

type (coupons and/or probes).

- CC : Corrosion Coupon

- CM: Corrosion Probe (Electric Resistance)

Corrosion Monitoring type, number and locations shall be finalized during Detailed Engineering

Phase.

Unit Location* Type and

Progressive Number

01-T-001 downstream after

CC1

chemical injection

01-E-003 downstream CM1

01-E-003 downstream CC2

01-EA-004 downstream CM2

01-EA-004 downstream CC3

01 Crude and Vacuum

01-V-005 downstream CM3

Distillation Unit

01-V-005 downstream CC4

01-T-051 downstream after

CC5

chemical injection

01-PK-051 downstream CC6

01-V-051 downstream CC7

01-V-051 downstream CM4

*Reference to 2342-AA01-MSD-0011-001_0 pages from 1 to 7

Unit Location* Type and

Progressive Number

02-EA-002 downstream CC1

which it is specifically furnished or outside the extent of the agreed upon right of use.

02-EA-002 downstream CM1

02-V-003 downstream CC2

02-T-001 downstream after

02 Naphtha Hydrotreating Unit CC3

injection

02-EA-003 downstream CM2

02-EA-003 downstream CC4

02-V-005 downstream CC5

*Reference to 954085-115-msd-rev-01 marked up pages from 1 to 3 (see attachments)

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2342 AA00 ML 243 0 7/13

KARBALA REFINERY FEED PROJECT

SCOP – IRAQ (Contract n° 2171)

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

Unit Location* Type and

Progressive Number

05-EA-001 downstream CC1

05-EA-001 downstream CM1

05-V-003 downstream CC2

05-V-004 downstream CM2

05 Kerosene 05-T-001 downstream after

CC3

Hydrodesulfurization Unit injection

05-EA-002 downstream CC4

05-EA-002 downstream CM3

05-V-005 downstream CC5

05-V-005 downstream CM4

*Reference to 03317-05-MMD_Rev_B marked up pages from 1 to 4 (see attachments)

Unit Location* Type and

Progressive Number

06-EA-001 downstream CC1

06-EA-001 downstream CM1

06-V-004 downstream CC2

06-T-002 downstream after

CC3

06 Diesel injection

Hydrodesulfurization Unit 06-EA-002 downstream CC4

06-EA-002 downstream CM2

06-V-007downstream CC5

06-V-007downstream CM3

06-E-007 downstream CM4

*Reference to 03317-06-MMD_Rev_B marked up pages from 1 to 5 (see attachments)

Unit Location* Type and

Progressive Number

07-E-008 downstream CC1

07-EA-003 downstream CC2

which it is specifically furnished or outside the extent of the agreed upon right of use.

07-EA-003 downstream CM1

07-V-005 downstream CC3

07-V-006 downstream CC4

07 VGO Hydrotreating Unit 07-V-006 downstream CM2

07-EA-005 downstream CC5

07-EA-005 downstream CM3

07-V-010 downstream CC6

07-V-010 downstream CM4

07-P-008 A/B downstream CM5

*Reference to 954088-115-msd-rev-00 marked up from pages 1 to 12 (see attachments)

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2342 AA00 ML 243 0 8/13

KARBALA REFINERY FEED PROJECT

SCOP – IRAQ (Contract n° 2171)

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

Unit Location* Type and

Progressive Number

main column reflux feed line CC1

main column reflux feed line CM1

08-T-201 downstream after

CC2

water injection

08-EA-201 downstream CC3

08-EA-201 downstream CM2

08-V-202 downstream CM3

08-K-301 downstream after

CM4

water injection

08 Fluid Catalytic Cracking 08-K-301 downstream after

CC4

Unit water injection

08-E-302 downstream CC5

08-E-302 downstream CM5

08-V-303 downstream CM6

08-E-303 downstream CM7

08-E-304 downstream CM8

08-E-307 downstream CM9

08-E-316 A/B downstream CC6

08-E-316 A/B downstream CM10

08-V-306 downstream CM11

*Reference to 954213-115-msd-rev-00 marked up pages from 1 to 4 (see attachments)

*Reference to 954214-115-msd-rev-00 marked up pages from 1 to 5 (see attachments)

Unit Location* Type and

Progressive Number

16 Gas Sweetening and

Rich Amine inlet line CC1

Amine Regeneration Unit

*Reference to 2342-AA16-MSD-0011-001_0 from 1 to 5 pages

which it is specifically furnished or outside the extent of the agreed upon right of use.

Unit Location* Type and

Progressive Number

17-E-101 downstream CC1

17-T-101 downstream CC2

17-P-102 A/B downstream CC3

17-V-101 upstream CC4

17 Sour Water Stripper Unit

17-E-201 downstream CC5

17-T-201 downstream CC6

17-P-202 A/B downstream CC7

17-V-201 upstream CC8

*Reference to 2342-AA17-MSD-0011-001_0 pages from 1 to 4

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2342 AA00 ML 243 0 9/13

KARBALA REFINERY FEED PROJECT

SCOP – IRAQ (Contract n° 2171)

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

Unit Location* Type and

Progressive Number

30 Raw Water Treatment Unit 30-TK-009 A/B downstream CC1

*Reference to 2342-AA30-MSD-0011-001-01_1 marked up (see attachments)

Unit Location* Type and

Progressive Number

CC1 (coupon rack)

33 Cooling Water Unit Cooling Water Return

CM1 (LPR)

*Reference to 2342-AA33-MSD-0011-001-02-01_0

Unit Location* Type and

Progressive Number

60 River Water Intake Unit 60-TK-001 A/B downstream CC1

*Reference to 2342-AA60-MSD-0011-001-02-01_0 marked up (see attachments)

Unit Location* Type and

Progressive Number

18 Sulphur Recovery Unit - CC1-CC3

Number and location: HOLD

1st train CM1

Unit Location* Type and

Progressive Number

19 Sulphur Recovery Unit - CC1-CC3

Number and location: HOLD

2nd train CM1

Unit Location* Type and

Progressive Number

which it is specifically furnished or outside the extent of the agreed upon right of use.

20 Sulphur Recovery Unit CC1-CC4

Number and location: HOLD

common parts and TGT CM1-CM2

Nevertheless it should be pointed out that corrosion monitors measure corrosion events taking

place on their probes only.

The measurements should not be considered precise or exact replica of all corrosion of the plant.

Corrosion is not a property of a material that could be measured with precision; it is a process that

can vary between one location and another on the same surface.

Is extremely important, to perform ultrasonic thickness program to supplement the monitors.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2342 AA00 ML 243 0 10/13

KARBALA REFINERY FEED PROJECT

SCOP – IRAQ (Contract n° 2171)

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

4 COUPON PREPARATION

A serial number shall be stamped or etched on each coupon.

Coupons may be prepared by grinding smooth with 120 grit paper, by tumbling with loose grit, or

blasting with abrasive blasting material. All abrasives should be free of metallic particles.

After the coupons have to be cleaned and handled by suitable means to prevent contamination of

the surface with oils, body salts, and other foreign materials. Clean, lint-free cotton gloves or

cloths, disposable plastic gloves, coated tongs, or coated tweezers should normally be used.

Under a ventilated hood, remove any residual oils with a hydrocarbon solvent such as xylene,

toluene, or 1,1,1 trichloroethane and rinse with anhydrous isopropyl alcohol. If oils are not present,

cleaning with alcohol or acetone should be sufficient.

Dry, measure, and weigh the coupons to within ±0.1 mg. Record the mass, serial number, and

exposed dimensions. Calculate the surface area (including the edges) and record. The areas

covered by the coupon holder and shielded areas of flush-mounted coupons must be excluded.

Prior to shipment, store the individually packaged coupons in a closed container with indicating

silica gel.

which it is specifically furnished or outside the extent of the agreed upon right of use.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2342 AA00 ML 243 0 11/13

KARBALA REFINERY FEED PROJECT

SCOP – IRAQ (Contract n° 2171)

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

5 PROCEDURE FOR FIELD HANDLING OF COUPONS BEFORE AND AFTER EXPOSURE

Prior to coupon installation, record the following information: coupon serial number, installation

date, name of system, location of the coupon in the system (including fluid or vapour phase), and

orientation of the coupon and holder. (see a Typical Corrosion Coupon Report hereinafter

reported)

During installation, handle the coupon carefully to prevent contamination of the coupon surface.

When the coupon is removed, record the coupon serial number, removal date, observations of any

erosion or mechanical damage, and appearance of scale or corrosion product.

The coupon should be photographed immediately after removal, particularly if appearance of the

corrosion product or scale is important. Protect the coupon from contamination by oxidation and

handling. Place the coupon in a moisture-proof or special envelope impregnated with volatile

corrosion inhibitor and ship immediately to a laboratory for analysis. Do not coat the coupon with

grease or otherwise alter it. Gentle blotting with tissue paper or a clean soft cloth may be desirable

to remove moisture prior to shipment. Corrosion products or scale deposits should not be removed

in the field.

5.1 Laboratory analysis

Laboratory procedure for cleaning and weighing coupons after exposure should be realized in

accordance with the recommended practice NACE RP0775. The average corrosion rate, mass

loss, the deepest measured pit, the maximum pitting rate, the description of deposit before and

after cleaning(e.g., etch, pitting, erosion, etc.) and analysis of deposit should be reported in the

attached form

which it is specifically furnished or outside the extent of the agreed upon right of use.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2342 AA00 ML 243 0 12/13

KARBALA REFINERY FEED PROJECT

SCOP – IRAQ (Contract n° 2171)

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

5.2 Typical Corrosion Coupon Report

Coupon location in system

3 3

Flowrate Oil, m /d Water m /d

3

Gas m /d

2

Temperature °C Pressure kg/cm

Fluid analysis (attach if lengthy)

Gas analysis (attach if lengthy)

Sketch of system with coupon position shown:

Coupon number Material

Exposed area

Dimensions

Installation date Installation mass

Removal date Removal mass

Days in system Mass after cleaning

Average corrosion rate: mm/y Mass loss

Deepest measured pit mm Maximum pitting rate mm/y

Description of deposit before cleaning

Analysis of deposit

which it is specifically furnished or outside the extent of the agreed upon right of use.

Description of coupon after cleaning (e.g., etch, pitting, erosion, etc.)

Chemical treatment during exposure

Other remarks

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

Project N° Unit Document Code Serial N° Rev. Page

2342 AA00 ML 243 0 13/13

KARBALA REFINERY FEED PROJECT

SCOP – IRAQ (Contract n° 2171)

The present document or drawing is property of TECHNIP ITALY S.p.A. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for

6 REFENCE DOCUMENTS AND LIST OF ATTACHMENTS:

6.1 Reference Documents

- Material Selection Diagrams: 2342-AA01-MSD-0011-001_0

- Material Selection Diagrams: 2342-AA16-MSD-0011-001_0

- Material Selection Diagrams: 2342-AA17-MSD-0011-001_0

- Material Selection Diagrams: 2342-AA33-MSD-0011-001-02-01_0

6.2 List of attachments

- Material Selection Diagrams: 954085-115-msd-rev-01 marked up

- Material Selection Diagrams: 03317-05-MMD_Rev_B marked up

- Material Selection Diagrams: 03317-06-MMD_Rev_B marked up

- Material Selection Diagrams: 954088-115-msd-rev-00 marked up

- Material Selection Diagrams: 954213-115-msd-rev-00 marked up

- Material Selection Diagrams: 954214-115-msd-rev-00 marked up

- Material Selection Diagrams: 2342-AA30-MSD-0011-001-01_1 marked up

- Material Selection Diagrams: 2342-AA60-MSD-0011-001-02-01_0 marked up

which it is specifically furnished or outside the extent of the agreed upon right of use.

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

You might also like

- 2342-AA00-ML-258 - 0 - Machinery Design RulesDocument5 pages2342-AA00-ML-258 - 0 - Machinery Design Rulesyusuf.yuzuakNo ratings yet

- 2342-Aa00-Jsm-201 - 0 - Item Numbering and Coding ProcedureDocument16 pages2342-Aa00-Jsm-201 - 0 - Item Numbering and Coding Procedureyusuf.yuzuakNo ratings yet

- 2342-AA00-JSM-603 - 0 - Spare Parts RequirementsDocument5 pages2342-AA00-JSM-603 - 0 - Spare Parts Requirementsyusuf.yuzuakNo ratings yet

- 2342-Aa00-Jsm-205 - 0 - Information Management RequirementsDocument22 pages2342-Aa00-Jsm-205 - 0 - Information Management Requirementsyusuf.yuzuakNo ratings yet

- 2342-Aa00-Jsm-601 - 0 - Procurement Guidilines and RequirementsDocument23 pages2342-Aa00-Jsm-601 - 0 - Procurement Guidilines and Requirementsyusuf.yuzuakNo ratings yet

- 2342-Aa00-Jsm-903 - 0 - Checklist For Plant Completion Pre-Commissioning and Start-UpDocument22 pages2342-Aa00-Jsm-903 - 0 - Checklist For Plant Completion Pre-Commissioning and Start-Upyusuf.yuzuakNo ratings yet

- 2342-AA00-JSD-0000-02 - 1 - Basic Process Design Requirements and CriteriaDocument51 pages2342-AA00-JSD-0000-02 - 1 - Basic Process Design Requirements and Criteriayusuf.yuzuakNo ratings yet

- 2342-Aa00-Jsm-301 - 0 - Project Procedure For Planning Scheduling Progress Control and ReportingDocument31 pages2342-Aa00-Jsm-301 - 0 - Project Procedure For Planning Scheduling Progress Control and Reportingyusuf.yuzuakNo ratings yet

- 2342-Aa00-Pp-809 - 0 - Epc Tender Package ConstructionDocument24 pages2342-Aa00-Pp-809 - 0 - Epc Tender Package Constructionyusuf.yuzuakNo ratings yet

- 2342-AA00-JSM-904 - 0 - General Guidelines For Vendor Maintenance ManualsDocument14 pages2342-AA00-JSM-904 - 0 - General Guidelines For Vendor Maintenance Manualsyusuf.yuzuakNo ratings yet

- 2342-Aa00-Jsm-202 - 0 - Detailed Hazopsil Review Procedure For Epc PhaseDocument19 pages2342-Aa00-Jsm-202 - 0 - Detailed Hazopsil Review Procedure For Epc Phaseyusuf.yuzuakNo ratings yet

- 2342-AA00-JSM-902 - 0 - Training Requirements For EPC ContractorDocument25 pages2342-AA00-JSM-902 - 0 - Training Requirements For EPC Contractoryusuf.yuzuakNo ratings yet

- 2342-Aa00-Ml-259 - 0 - Sleepers Elevation Optimization ReportDocument5 pages2342-Aa00-Ml-259 - 0 - Sleepers Elevation Optimization Reportyusuf.yuzuakNo ratings yet

- 2342-AA00-ML-201 - 0 - Hazards Analysis (HAZAN)Document32 pages2342-AA00-ML-201 - 0 - Hazards Analysis (HAZAN)yusuf.yuzuakNo ratings yet

- 2342-Aa00-Jsm-901 - 0 - Precommissioning & Commissioning Execution PlanDocument17 pages2342-Aa00-Jsm-901 - 0 - Precommissioning & Commissioning Execution Planyusuf.yuzuakNo ratings yet

- Petrovietnam Fertilizer and Chemicals Corporation (Pvfcco) Ammonia Plant Revamp ProjectDocument10 pagesPetrovietnam Fertilizer and Chemicals Corporation (Pvfcco) Ammonia Plant Revamp ProjectNcTungNo ratings yet

- LPG Project SpecificationsDocument14 pagesLPG Project Specificationspraveenvelath100% (1)

- 2342-Aa00-Jsm-102 - 0 - Project Coordination Procedure Between Company and ContractorDocument15 pages2342-Aa00-Jsm-102 - 0 - Project Coordination Procedure Between Company and Contractoryusuf.yuzuakNo ratings yet

- 2342-Aa00-Jsm-501 - 0 - Quality Management Requirement For Epc ContractorsDocument14 pages2342-Aa00-Jsm-501 - 0 - Quality Management Requirement For Epc Contractorsyusuf.yuzuakNo ratings yet

- 2342-Aa00-Jsm-701 - 0 - Hse RequirementsDocument28 pages2342-Aa00-Jsm-701 - 0 - Hse Requirementsyusuf.yuzuakNo ratings yet

- 2342-Aa00-Jsm-900 - 0 - Operation, Maintenance and Preservation PhilosophyDocument107 pages2342-Aa00-Jsm-900 - 0 - Operation, Maintenance and Preservation Philosophyyusuf.yuzuakNo ratings yet

- Pipeline Detail Design DataDocument114 pagesPipeline Detail Design DataYusuf100% (3)

- Price List For Painting Works: 2450 0000 PS 2300 03 A Mangalore Pta Plant JBF Petrochemicals LimitedDocument24 pagesPrice List For Painting Works: 2450 0000 PS 2300 03 A Mangalore Pta Plant JBF Petrochemicals LimitedSoumitra GuptaNo ratings yet

- Welding Experiences MethodDocument31 pagesWelding Experiences MethodYusufNo ratings yet

- 2539-00-ITP-012 - 0 - ITP For Plastic Piping PDFDocument17 pages2539-00-ITP-012 - 0 - ITP For Plastic Piping PDFdang2172014100% (1)

- XXXX - PTC-XXXX - E - 0 Oct 2Document49 pagesXXXX - PTC-XXXX - E - 0 Oct 2pjosesmNo ratings yet

- Method Statements of Surface Treatment and Painting For Valves Nh3 ProjectDocument5 pagesMethod Statements of Surface Treatment and Painting For Valves Nh3 ProjectDuongthithuydung0% (1)

- Werkstatt 01 SchematicsDocument9 pagesWerkstatt 01 Schematicsfelas37616No ratings yet

- Abts Uqair-B.2Document1 pageAbts Uqair-B.2Anonymous BZQOJwWIh6No ratings yet

- Sae As 33649a 2005-08Document4 pagesSae As 33649a 2005-08Andr EkmeNo ratings yet

- TabindaDocument1 pageTabindaAnonymous BZQOJwWIh6No ratings yet

- Procurement Guidelines and Requirements: 2271 AAA JSM 601 C 1/23Document23 pagesProcurement Guidelines and Requirements: 2271 AAA JSM 601 C 1/23Norgjie100% (1)

- 2023.01.15 - VDRL TEMPLATE PEP - Rev.F 15 Jan 22)Document72 pages2023.01.15 - VDRL TEMPLATE PEP - Rev.F 15 Jan 22)Andy ArdianNo ratings yet

- Small Boat Harbours Project: Inspection and Test Plan For Casting of Concrete Quay Wall BlocksDocument4 pagesSmall Boat Harbours Project: Inspection and Test Plan For Casting of Concrete Quay Wall BlockseleanorNo ratings yet

- 000 M TSP 50002 001 R0aDocument61 pages000 M TSP 50002 001 R0aJoaquim FernandesNo ratings yet

- HVAC Ducting Layout For Sub Station (S.F) For HVAC SystemDocument5 pagesHVAC Ducting Layout For Sub Station (S.F) For HVAC SystemSandip SurNo ratings yet

- MECHANICALDocument3 pagesMECHANICALAbigail SalazarNo ratings yet

- 2271 Aaa JSM 301 - B PDFDocument65 pages2271 Aaa JSM 301 - B PDFNorgjieNo ratings yet

- Diag, Schem Pp-Fire Protection 121T1290Document3 pagesDiag, Schem Pp-Fire Protection 121T1290Bounezra OussamaNo ratings yet

- 115Kv Busbar & BF Protection Panel-1 (D01/D02) : A P HA556 3-1313003.05 4400004657 EA-381637Document1 page115Kv Busbar & BF Protection Panel-1 (D01/D02) : A P HA556 3-1313003.05 4400004657 EA-381637Anonymous BZQOJwWIh6No ratings yet

- Páginas desde70180-00-CW - YDA-TRE-001Document1 pagePáginas desde70180-00-CW - YDA-TRE-001Leonel Perez RubioNo ratings yet

- 000-A-PRO-50061-001-R0 Work at Height ProcedureDocument30 pages000-A-PRO-50061-001-R0 Work at Height ProceduresantoshNo ratings yet

- 036909C 000 ATT8 01 A Coordination ProcedureDocument49 pages036909C 000 ATT8 01 A Coordination ProcedurePham Quang VinhNo ratings yet

- 214690C-000-SOW-1410-0001 - REV A - SignedDocument39 pages214690C-000-SOW-1410-0001 - REV A - SignedMohamed AskarNo ratings yet

- EP-300 Operating Manual E1Document343 pagesEP-300 Operating Manual E1leman quliyevaNo ratings yet

- Pt. Steadfast Marine: 40M Aht Vessel (Logindo Vigilant)Document6 pagesPt. Steadfast Marine: 40M Aht Vessel (Logindo Vigilant)halimNo ratings yet

- 01 - General Tracker-1Document4 pages01 - General Tracker-1MAGED ELSADIGNo ratings yet

- 2495 000 JSD 1501 01 - BDocument30 pages2495 000 JSD 1501 01 - BSinaNo ratings yet

- 2342-Aa00-Ml-261 - 0 - Underground Network Arrangement ReportDocument20 pages2342-Aa00-Ml-261 - 0 - Underground Network Arrangement Reportyusuf.yuzuakNo ratings yet

- S781-CV-DWG-00004-01-213036-B - OQ Approved - 14.03.2023Document2 pagesS781-CV-DWG-00004-01-213036-B - OQ Approved - 14.03.2023MDhana SekarNo ratings yet

- Environmental Aspects and Impacts Evaluation REV-003Document12 pagesEnvironmental Aspects and Impacts Evaluation REV-003sunthu100% (1)

- 1663-43691010-Me-Dwg-7380-00-Cu-Cl2-Bdu-Fru-Assy-1 (R1)Document1 page1663-43691010-Me-Dwg-7380-00-Cu-Cl2-Bdu-Fru-Assy-1 (R1)raacontreras21No ratings yet

- WPRK Pack Preparation PDFDocument42 pagesWPRK Pack Preparation PDFYusufNo ratings yet

- Elec Schematic 2658488584 - 015Document24 pagesElec Schematic 2658488584 - 015aidaluz achahui condoriNo ratings yet

- 8997 0846 00 DrawingsDocument41 pages8997 0846 00 Drawingsedduami montoya neyraNo ratings yet

- 2023-02-14 MAR-065 Concrete Deisgn Mix Using Type 1 For Water Retaining Structures - EXAN Rev. B RRAADocument1 page2023-02-14 MAR-065 Concrete Deisgn Mix Using Type 1 For Water Retaining Structures - EXAN Rev. B RRAAjaymarNo ratings yet

- Alterations To 265 & 267 Wellington Street, Launceston: Jackson Trade CarsDocument7 pagesAlterations To 265 & 267 Wellington Street, Launceston: Jackson Trade CarsThe ExaminerNo ratings yet

- Comment Resolution Sheet (CRS) : As ListedDocument2 pagesComment Resolution Sheet (CRS) : As ListedMDhana SekarNo ratings yet

- 2271-711-JSD-1530-01 - C Telecoms Philosophy PDFDocument67 pages2271-711-JSD-1530-01 - C Telecoms Philosophy PDFSay Hong Jeffrey Tan0% (1)

- Internal Coatings For Vessels in Wet H2S Service-LCLDocument11 pagesInternal Coatings For Vessels in Wet H2S Service-LCLyusuf.yuzuakNo ratings yet

- Internal Coatings MSDocument30 pagesInternal Coatings MSyusuf.yuzuakNo ratings yet

- Coal-Tar Enamel Corrosion Coating of Submarine Pipelines-MSDocument12 pagesCoal-Tar Enamel Corrosion Coating of Submarine Pipelines-MSyusuf.yuzuakNo ratings yet

- External Coatings LCLDocument10 pagesExternal Coatings LCLyusuf.yuzuakNo ratings yet

- 19 - ReferencesDocument2 pages19 - Referencesyusuf.yuzuakNo ratings yet

- 208-04a - IDENTIFICATION AND TRACEABILITY OFDocument8 pages208-04a - IDENTIFICATION AND TRACEABILITY OFyusuf.yuzuakNo ratings yet

- 209-04a - CONTROL OF FABRICATION, CONSTRUCTION AND INSTALLATION ACTIVITIESDocument15 pages209-04a - CONTROL OF FABRICATION, CONSTRUCTION AND INSTALLATION ACTIVITIESyusuf.yuzuakNo ratings yet

- 215-04a - HANDLING, STORAGE, PACKAGING, PRESERVATION AND DELIVERYDocument8 pages215-04a - HANDLING, STORAGE, PACKAGING, PRESERVATION AND DELIVERYyusuf.yuzuakNo ratings yet

- 218-05 - TrainingDocument8 pages218-05 - Trainingyusuf.yuzuakNo ratings yet

- Internal Coatings For Vessels in Wet H2S Service-MSDocument13 pagesInternal Coatings For Vessels in Wet H2S Service-MSyusuf.yuzuakNo ratings yet

- 213-04a - CONTROL OF NON-CONFORMING PRODUCTDocument7 pages213-04a - CONTROL OF NON-CONFORMING PRODUCTyusuf.yuzuakNo ratings yet

- 16 - PumpsDocument3 pages16 - Pumpsyusuf.yuzuakNo ratings yet

- 219-04a - VENDOR OPERATING AND SERVICING DOCUMENTATION AND SPARESDocument6 pages219-04a - VENDOR OPERATING AND SERVICING DOCUMENTATION AND SPARESyusuf.yuzuakNo ratings yet

- 23 - Crushers and PulverizersDocument10 pages23 - Crushers and Pulverizersyusuf.yuzuakNo ratings yet

- 2342-Aa00-Jsm-900 - 0 - Operation, Maintenance and Preservation PhilosophyDocument107 pages2342-Aa00-Jsm-900 - 0 - Operation, Maintenance and Preservation Philosophyyusuf.yuzuakNo ratings yet

- 01 - Corporate Piping-Mechanical ProceduresDocument2 pages01 - Corporate Piping-Mechanical Proceduresyusuf.yuzuakNo ratings yet

- 26 - ReferencesDocument2 pages26 - Referencesyusuf.yuzuakNo ratings yet

- 2342-Aa00-Jsm-501 - 0 - Quality Management Requirement For Epc ContractorsDocument14 pages2342-Aa00-Jsm-501 - 0 - Quality Management Requirement For Epc Contractorsyusuf.yuzuakNo ratings yet

- 2342-Aa00-Jsm-901 - 0 - Precommissioning & Commissioning Execution PlanDocument17 pages2342-Aa00-Jsm-901 - 0 - Precommissioning & Commissioning Execution Planyusuf.yuzuakNo ratings yet

- 2342-AA00-ML-201 - 0 - Hazards Analysis (HAZAN)Document32 pages2342-AA00-ML-201 - 0 - Hazards Analysis (HAZAN)yusuf.yuzuakNo ratings yet

- 2342-Aa00-Ml-261 - 0 - Underground Network Arrangement ReportDocument20 pages2342-Aa00-Ml-261 - 0 - Underground Network Arrangement Reportyusuf.yuzuakNo ratings yet

- IONE-1B03-SP-PR-0002 PROCESS PROCESS DESCRIPTION For UNIT 03 Rev.0 Code 2 TransmittalDocument10 pagesIONE-1B03-SP-PR-0002 PROCESS PROCESS DESCRIPTION For UNIT 03 Rev.0 Code 2 Transmittalyusuf.yuzuakNo ratings yet

- 2342-Aa00-Jsm-102 - 0 - Project Coordination Procedure Between Company and ContractorDocument15 pages2342-Aa00-Jsm-102 - 0 - Project Coordination Procedure Between Company and Contractoryusuf.yuzuakNo ratings yet

- 000 A Ee 0190227 R1 - 231110 - 092118Document24 pages000 A Ee 0190227 R1 - 231110 - 092118yusuf.yuzuakNo ratings yet

- Ie 12 Lec Act IiiDocument2 pagesIe 12 Lec Act IiiLance JayomaNo ratings yet

- Science Project Presentation For Electrical ConductorsDocument18 pagesScience Project Presentation For Electrical ConductorsZuanel DiazNo ratings yet

- Lesson 10.2 The Solid StateDocument14 pagesLesson 10.2 The Solid StatefitriNo ratings yet

- Deret TribolistrikDocument3 pagesDeret TribolistrikdaryekokuNo ratings yet

- WWW NDT Ed OrgDocument2 pagesWWW NDT Ed OrgGuru SamyNo ratings yet

- GenChem AssignmentDocument12 pagesGenChem AssignmentGivenchy SanicoNo ratings yet

- Periodic Table (Sample)Document12 pagesPeriodic Table (Sample)Chick ChikNo ratings yet

- Metallography PDFDocument185 pagesMetallography PDFDante GarzaNo ratings yet

- Bruchure Metal SolutionDocument10 pagesBruchure Metal Solutionanibal rey brito lopezNo ratings yet

- Chemistry - Revision - Grade - 8 - 1st - Term Answer KeyDocument9 pagesChemistry - Revision - Grade - 8 - 1st - Term Answer KeyWaLkiEs TaLkIeSNo ratings yet

- White CementDocument5 pagesWhite CementAhmed Younis100% (1)

- Chapter 10 Lead PDFDocument12 pagesChapter 10 Lead PDFjessy eghNo ratings yet

- BAHAN KULIAH MATERIAL ELEKTROTEKNIK LandscapeDocument54 pagesBAHAN KULIAH MATERIAL ELEKTROTEKNIK LandscapeFrissa Aninditaalan08No ratings yet

- Forging PDF NotesDocument51 pagesForging PDF Notesaman prasadNo ratings yet

- Astm A193/a 193MDocument13 pagesAstm A193/a 193MCLEMENTNo ratings yet

- Greentel: Wires & CablesDocument6 pagesGreentel: Wires & CablesAfricab OblineNo ratings yet

- JAE 1991 ReviewDocument10 pagesJAE 1991 ReviewCan ERTANNo ratings yet

- Elements - Metals, Non-Metals and Semi-MetalsDocument4 pagesElements - Metals, Non-Metals and Semi-MetalsLulu Li100% (1)

- OPP - Power Cable Seminar - (August 21, 2010) - FINALDocument108 pagesOPP - Power Cable Seminar - (August 21, 2010) - FINALJheny B. Bayon100% (2)

- Standarde Cold FormedDocument2 pagesStandarde Cold FormedviviNo ratings yet

- Electrodeposited Coatings of Cadmium: Standard Specification ForDocument9 pagesElectrodeposited Coatings of Cadmium: Standard Specification ForChuponcitoViveNo ratings yet

- Limit Test of Heavy Metals - Web FormulasDocument2 pagesLimit Test of Heavy Metals - Web FormulasknbiolabsNo ratings yet

- Metal Alkoxides PDFDocument94 pagesMetal Alkoxides PDFangelofgloryNo ratings yet

- Metals MiningDocument52 pagesMetals MiningsamathagondiNo ratings yet

- VSC SSPC Visual Guide To Surface Prep PDFDocument8 pagesVSC SSPC Visual Guide To Surface Prep PDFABCNo ratings yet

- Friction: Kenneth C LudemaDocument29 pagesFriction: Kenneth C Ludemaocto widodoNo ratings yet

- NABL Scope JKTRCDocument27 pagesNABL Scope JKTRCNeelam PatelNo ratings yet

- ASTM G46 94 Examination and Evaluation of Pitting PDFDocument8 pagesASTM G46 94 Examination and Evaluation of Pitting PDFAmbar100% (1)

- Pharmaceutical Catalysis HandbookDocument108 pagesPharmaceutical Catalysis HandbookLeda PrandiNo ratings yet

- Full Download Introduction To Management Accounting 16th Edition Horngren Test BankDocument36 pagesFull Download Introduction To Management Accounting 16th Edition Horngren Test Bankjack9716pe100% (41)