Professional Documents

Culture Documents

Cytec Solutions 2013 19

Cytec Solutions 2013 19

Uploaded by

aktivrudarpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cytec Solutions 2013 19

Cytec Solutions 2013 19

Uploaded by

aktivrudarpCopyright:

Available Formats

Solvent Extraction, Mineral Processing and Alumina Processing

AERO®7260 HFP: Novel, Safe and Sustainable Alternative to Traditional Hazardous Modifiers

– NaSH, Nokes, Na2S, and Cyanide

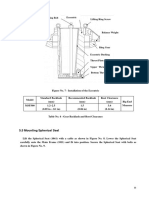

Figures 4A and B show Cu, Mo, and Fe recoveries and of 55 kg/T NaSH was required. The addition of 0.25 kg/T of

grades for lab data using AERO®7260 HFP on another North AERO 7260 HFP plus 11 kg/T of NaSH significantly enhanced

American mine Cu-Mo cleaner concentrate. In terms of both Cu and Fe depression and Mo selectivity. This suggests

Cu depression, this concentrate required about 11 kg/T of that AERO 7260 HFP is highly effective in the depression of

NaSH; however the Fe depression was not efficient at this both Cu and Fe and enables mine operations to significantly

dosage. For efficient Cu and Fe depression, a higher dosage reduce NaSH consumption, in this case by over 80%.

99.2 99 98.8

a) 100

92 NaSH 55 kg/T

90

NaSH 11 kg/T

80 NaSH 11 kg/T + 0.25 kg /T 7260

70 68.4

60

Recovery (%)

50 47.2

40 36.9 36.9

33

30

20

10

0

Cu Mo Fe

Mo Concentrate

50.7

49.2

B) 50

45.4

40

30

Grade (%)

20

FIGURE 4:

10 2nd Cleaner Circuit

4.2 Lab data of Cu, Mo and Fe

3.2 2.4 a) recovery and

0.2 0.2 0.2

0 b) grade

Cu Mo Fe

Mo Concentrate

Clearly, the benefits of adding AERO 7260 HFP are observed by the improved metallurgical performance and substantially

reduced dosage of NaSH.

19

IN PROCESS SEPARATION

You might also like

- Melbourne Basin Guide PDFDocument92 pagesMelbourne Basin Guide PDFBrad Weir100% (2)

- Chem 26.1 ProbSet1 1stSemAY1920Document3 pagesChem 26.1 ProbSet1 1stSemAY1920LoeyNo ratings yet

- Cytec Solutions 2013 18Document1 pageCytec Solutions 2013 18aktivrudarpNo ratings yet

- Cytec Solutions 2013 17Document1 pageCytec Solutions 2013 17aktivrudarpNo ratings yet

- Synthesis of Boroxine and Dioxaborole Covalent Organic Frameworks Via Transesterification and Metathesis of Pinacol BoronatesDocument7 pagesSynthesis of Boroxine and Dioxaborole Covalent Organic Frameworks Via Transesterification and Metathesis of Pinacol BoronatesSHREYANo ratings yet

- Accepted Manuscript: Materials LettersDocument8 pagesAccepted Manuscript: Materials LettersSeptian Eka TruenoNo ratings yet

- Cytec Solutions 2013 28Document1 pageCytec Solutions 2013 28aktivrudarpNo ratings yet

- Catalytic Synthesis of Methanol From CO/H,: Journ.4L of C 4talysisDocument23 pagesCatalytic Synthesis of Methanol From CO/H,: Journ.4L of C 4talysisulsakNo ratings yet

- CH He: Figure 1. Experimental SetupDocument8 pagesCH He: Figure 1. Experimental Setupapi-3728640No ratings yet

- RhLa2O3 Catalysts For Hydrogen Production Using Simultaneous CO2Document1 pageRhLa2O3 Catalysts For Hydrogen Production Using Simultaneous CO2Davood IranshahiNo ratings yet

- Strategies For Managing Contaminant Metals in The FCC Unit Kuo BASF Galveston FCCU 2017Document41 pagesStrategies For Managing Contaminant Metals in The FCC Unit Kuo BASF Galveston FCCU 2017Atharva OfficeNo ratings yet

- 8061-Article Text-39021-1-10-20230530Document7 pages8061-Article Text-39021-1-10-20230530Pietro FigueiredoNo ratings yet

- Worth ReadingDocument4 pagesWorth ReadingPassmore DubeNo ratings yet

- Advanced Approach For Residue FCC - Residue FCC AdditivesDocument7 pagesAdvanced Approach For Residue FCC - Residue FCC Additivessaleh4060No ratings yet

- Nonkululeko Mabandla SugarbagasseDocument12 pagesNonkululeko Mabandla Sugarbagasselukhanyilemabandla99No ratings yet

- Bulatovic 2010Document15 pagesBulatovic 2010Aktiv RudarNo ratings yet

- The Inhibition of Gypsum and Barite Nucleation in Nacl Brines at Temperatures From 25 To 90°CDocument7 pagesThe Inhibition of Gypsum and Barite Nucleation in Nacl Brines at Temperatures From 25 To 90°CMo OsNo ratings yet

- Article Technical Paper Minimizing F GD CostDocument9 pagesArticle Technical Paper Minimizing F GD CostdsoNo ratings yet

- Removal of Polycyclic Aromatic Hydrocarbons (Pahs) From Offshore Produced Water Using Advanced Oxidation Processes (Aops)Document2 pagesRemoval of Polycyclic Aromatic Hydrocarbons (Pahs) From Offshore Produced Water Using Advanced Oxidation Processes (Aops)Kelly RamosNo ratings yet

- Effect of Barium Oxide On The Formation and Hydraulic Activity of Calcium Phosphoaluminate SolidDocument14 pagesEffect of Barium Oxide On The Formation and Hydraulic Activity of Calcium Phosphoaluminate SolidRaúl Marcelo VelozNo ratings yet

- S-Ocp CMC - XRDDocument1 pageS-Ocp CMC - XRD리에사 난다 메르타마니No ratings yet

- Activacion de Esfalerita en La Presencia de Iones PlomoDocument19 pagesActivacion de Esfalerita en La Presencia de Iones PlomoJunior Anderson Tinoco FaleroNo ratings yet

- Nazari and GhadiriDocument11 pagesNazari and GhadiriYassine GouzzaliNo ratings yet

- Effect of Sulphate in Flotation of Sulphide MineralsDocument15 pagesEffect of Sulphate in Flotation of Sulphide MineralsMarita Sinche GonzalezNo ratings yet

- Results and Discussions 4.1 Effect of Activated Carbon Dosage On Laundry Wastewater 4.1.1 Biological Oxygen DemandDocument9 pagesResults and Discussions 4.1 Effect of Activated Carbon Dosage On Laundry Wastewater 4.1.1 Biological Oxygen DemandCriselda CarinoNo ratings yet

- R.M. Input Quantity Guideline Per Batch - For R1 Reactor CPPF 001 CPPF 001 OCM CPPF 002 CPPF 003 CPPF 004 CPPF 004 T CPPF 005 CPPF 006Document3 pagesR.M. Input Quantity Guideline Per Batch - For R1 Reactor CPPF 001 CPPF 001 OCM CPPF 002 CPPF 003 CPPF 004 CPPF 004 T CPPF 005 CPPF 006Venkat RamananNo ratings yet

- Absorption of Carbon Dioxide by A Suspension of Activated Carbon in Aqueous Amine SolutionsDocument14 pagesAbsorption of Carbon Dioxide by A Suspension of Activated Carbon in Aqueous Amine SolutionsOsama AhmedNo ratings yet

- 74 JMES 215 2011 FassiDocument12 pages74 JMES 215 2011 FassiMootolik VorbaretNo ratings yet

- Achieve Success in Gasoline Hydrotreating - Article Hp-EnglishDocument14 pagesAchieve Success in Gasoline Hydrotreating - Article Hp-EnglishAle SanzNo ratings yet

- The Cativa'' Process For The Manufacture Plant of Acetic AcidDocument12 pagesThe Cativa'' Process For The Manufacture Plant of Acetic AcidPragadeeshNo ratings yet

- Application Biomass Pyrolysis 990 Micro GC 5994 5581en AgilentDocument3 pagesApplication Biomass Pyrolysis 990 Micro GC 5994 5581en AgilentEdinilson Ramos Camelo RamosNo ratings yet

- Solvent Extraction: Please Submit Question 4 For MarkingDocument3 pagesSolvent Extraction: Please Submit Question 4 For MarkingThembi Matebula100% (1)

- Horcajada, Serre, Mckinlay, & Morris, 2011 Shugalei, Garabadgiu, Ilyushin, & Sudarikov, 2012Document10 pagesHorcajada, Serre, Mckinlay, & Morris, 2011 Shugalei, Garabadgiu, Ilyushin, & Sudarikov, 2012Luis EduardoNo ratings yet

- Can 2007Document14 pagesCan 2007Stive BrackNo ratings yet

- Cytec Solutions 2013 20Document1 pageCytec Solutions 2013 20aktivrudarpNo ratings yet

- ภาพถ่ายหน้าจอ 2565-01-22 เวลา 12.51.00Document5 pagesภาพถ่ายหน้าจอ 2565-01-22 เวลา 12.51.00Wig 008No ratings yet

- Rapid and Catalyst‐Free α‐Halogenation of Ketones using N‐Halosuccinamides in DMSODocument9 pagesRapid and Catalyst‐Free α‐Halogenation of Ketones using N‐Halosuccinamides in DMSOthegreatgbrothersNo ratings yet

- Note On The Titration of Iodide by The Andrews MethodDocument4 pagesNote On The Titration of Iodide by The Andrews MethodChilaNo ratings yet

- Process Notes: Final ProjectDocument8 pagesProcess Notes: Final ProjectCluisantony Jayco DizeNo ratings yet

- Added: 9.78 ML of Ethyl Acetate in 1 Liter Water Added: 4G of Naoh in 1000Ml or 1 Liter WaterDocument8 pagesAdded: 9.78 ML of Ethyl Acetate in 1 Liter Water Added: 4G of Naoh in 1000Ml or 1 Liter WaterABHAY PARASHARNo ratings yet

- Seminar Assignments - Assignment 2 Questions + Answers Seminar Assignments - Assignment 2 Questions + AnswersDocument6 pagesSeminar Assignments - Assignment 2 Questions + Answers Seminar Assignments - Assignment 2 Questions + AnswersHenry KimNo ratings yet

- Impact of Fuel Ash On Clinker Quality: Tom LowesDocument3 pagesImpact of Fuel Ash On Clinker Quality: Tom LowesJohn GiannakopoulosNo ratings yet

- Lukhanyile Mabandla Activated Charcoal ..Document13 pagesLukhanyile Mabandla Activated Charcoal ..lukhanyilemabandla99No ratings yet

- Catalisis FFC DivididoDocument56 pagesCatalisis FFC DivididoGómez Aguilar Angelica BelenNo ratings yet

- Absorption ProcessDocument24 pagesAbsorption ProcessM TNo ratings yet

- Supplementary Materials (Applied Catalysis B: Environmental)Document33 pagesSupplementary Materials (Applied Catalysis B: Environmental)anhchangcodon88No ratings yet

- Cytec Solutions 2013 26Document1 pageCytec Solutions 2013 26aktivrudarpNo ratings yet

- HHV Dan LHVDocument5 pagesHHV Dan LHVGunturMudaAliAkbarNo ratings yet

- 19 (1985) 219-223 Elsevier Science Publishers V., Amsterdam - Printed in The Netherlands 219Document5 pages19 (1985) 219-223 Elsevier Science Publishers V., Amsterdam - Printed in The Netherlands 219Syukri ZainuddinNo ratings yet

- Tutorial 2 18 April 2023Document14 pagesTutorial 2 18 April 2023Tshwarelo LebohoNo ratings yet

- The Product Yield of Pyrolysis of Biomass and A Kinetic Study of Gasification of Biomass CharDocument27 pagesThe Product Yield of Pyrolysis of Biomass and A Kinetic Study of Gasification of Biomass CharNovita maraNo ratings yet

- Separation : (HGMS)Document7 pagesSeparation : (HGMS)tranbinhxuanNo ratings yet

- Report Vol 2Document147 pagesReport Vol 2Inam ur RehmanNo ratings yet

- Book 1Document208 pagesBook 1MARTIN SUGIARTOMANURUNGNo ratings yet

- Supplementary Materials: Electroreduction of CO Into Ethanol Over An Active Catalyst: Copper Supported On TitaniaDocument8 pagesSupplementary Materials: Electroreduction of CO Into Ethanol Over An Active Catalyst: Copper Supported On Titaniamithun sahooNo ratings yet

- Hasmizam 2008Document6 pagesHasmizam 2008Ananda Vallezi PaladinoNo ratings yet

- Degradation of Polyvinyl Alcohol (Pva) by Fenton Process: KeywordsDocument4 pagesDegradation of Polyvinyl Alcohol (Pva) by Fenton Process: Keywordsbushra shahidNo ratings yet

- Introduction To Wolsong Tritium Removal Facility (WTRF)Document2 pagesIntroduction To Wolsong Tritium Removal Facility (WTRF)Anonymous 1hOgJqwZuzNo ratings yet

- Molecular CatalysisDocument9 pagesMolecular Catalysishenry martinez quiñonezNo ratings yet

- The Chemistry of Membranes Used in Fuel Cells: Degradation and StabilizationFrom EverandThe Chemistry of Membranes Used in Fuel Cells: Degradation and StabilizationShulamith SchlickNo ratings yet

- MSP300 0078 Conica 67Document1 pageMSP300 0078 Conica 67aktivrudarpNo ratings yet

- MSP300 0078 Conica 65Document1 pageMSP300 0078 Conica 65aktivrudarpNo ratings yet

- MSP300 0078 Conica 61Document1 pageMSP300 0078 Conica 61aktivrudarpNo ratings yet

- MSP300 0078 Conica 52Document1 pageMSP300 0078 Conica 52aktivrudarpNo ratings yet

- MSP300 0078 Conica 40Document1 pageMSP300 0078 Conica 40aktivrudarpNo ratings yet

- MSP300 0078 Conica 43Document1 pageMSP300 0078 Conica 43aktivrudarpNo ratings yet

- MSP300 0078 Conica 48Document1 pageMSP300 0078 Conica 48aktivrudarpNo ratings yet

- MSP300 0078 Conica 36Document1 pageMSP300 0078 Conica 36aktivrudarpNo ratings yet

- MSP300 0078 Conica 45Document1 pageMSP300 0078 Conica 45aktivrudarpNo ratings yet

- MSP300 0078 Conica 23Document1 pageMSP300 0078 Conica 23aktivrudarpNo ratings yet

- MSP300 0078 Conica 19Document1 pageMSP300 0078 Conica 19aktivrudarpNo ratings yet

- MSP300 0078 Conica 49Document1 pageMSP300 0078 Conica 49aktivrudarpNo ratings yet

- MSP300 0078 Conica 50Document1 pageMSP300 0078 Conica 50aktivrudarpNo ratings yet

- MSP300 0078 Conica 21Document1 pageMSP300 0078 Conica 21aktivrudarpNo ratings yet

- MSP300 0078 Conica 39Document1 pageMSP300 0078 Conica 39aktivrudarpNo ratings yet

- MSP300 0078 Conica 2Document1 pageMSP300 0078 Conica 2aktivrudarpNo ratings yet

- MSP300 0078 Conica 4Document1 pageMSP300 0078 Conica 4aktivrudarpNo ratings yet

- Cytec Solutions 2013 45Document1 pageCytec Solutions 2013 45aktivrudarpNo ratings yet

- MSP300 0078 Conica 3Document1 pageMSP300 0078 Conica 3aktivrudarpNo ratings yet

- MSP300 0078 Conica 5Document1 pageMSP300 0078 Conica 5aktivrudarpNo ratings yet

- Cytec Solutions 2013 23Document1 pageCytec Solutions 2013 23aktivrudarpNo ratings yet

- Cytec Solutions 2013 39Document1 pageCytec Solutions 2013 39aktivrudarpNo ratings yet

- Cytec Solutions 2013 34Document1 pageCytec Solutions 2013 34aktivrudarpNo ratings yet

- Cytec Solutions 2013 50Document1 pageCytec Solutions 2013 50aktivrudarpNo ratings yet

- Cytec Solutions 2013 46Document1 pageCytec Solutions 2013 46aktivrudarpNo ratings yet

- Cytec Solutions 2013 42Document1 pageCytec Solutions 2013 42aktivrudarpNo ratings yet

- Cytec Solutions 2013 35Document1 pageCytec Solutions 2013 35aktivrudarpNo ratings yet

- Cytec Solutions 2013 31Document1 pageCytec Solutions 2013 31aktivrudarpNo ratings yet

- Cytec Solutions 2013 6Document1 pageCytec Solutions 2013 6aktivrudarpNo ratings yet

- New Connection Application FormDocument5 pagesNew Connection Application FormsiamitonsingNo ratings yet

- Lesson 1 - From The Perspective of PhilosophyDocument58 pagesLesson 1 - From The Perspective of PhilosophyPoeil Sergio MoldezNo ratings yet

- Physical Science Q1 Module 1Document17 pagesPhysical Science Q1 Module 1Crispulo Arquero III87% (15)

- Septic Tank Components and Design of Septic TankDocument21 pagesSeptic Tank Components and Design of Septic TankChau Suktana EnlingNo ratings yet

- Cruise Control Izusu CamionesDocument12 pagesCruise Control Izusu CamionesAnonymous KOtSfT6qNo ratings yet

- M435 Chapter 5 GeodesicsDocument8 pagesM435 Chapter 5 GeodesicsNithya SridharNo ratings yet

- The Ultimate Veritas Cluster Server VCS Interview QuestionsDocument19 pagesThe Ultimate Veritas Cluster Server VCS Interview QuestionsBharanitharan SundaramNo ratings yet

- Winn Old European ScriptDocument24 pagesWinn Old European ScriptDumitrascu Liviu100% (2)

- Cambridge IGCSE™ (9-1) : English As A Second Language 9-1 0993/11 May/June 2021Document9 pagesCambridge IGCSE™ (9-1) : English As A Second Language 9-1 0993/11 May/June 2021GhostNo ratings yet

- Complex Ions and Coordination Compounds: Practice ExamplesDocument17 pagesComplex Ions and Coordination Compounds: Practice Exampleskennethleo69No ratings yet

- Cscro VIII HR Training Center Building - Phase 1 Plans PDFDocument10 pagesCscro VIII HR Training Center Building - Phase 1 Plans PDFJohn Laurence Crucena VillaNo ratings yet

- NCPWBDocument8 pagesNCPWBfraemddNo ratings yet

- Evolving Trends in Infective Endocarditis in A Developing Country: A Consequence of Medical Progress?Document9 pagesEvolving Trends in Infective Endocarditis in A Developing Country: A Consequence of Medical Progress?Hassan Abdi JamaNo ratings yet

- Hellcat Pilot InstructionsDocument22 pagesHellcat Pilot InstructionsRefugio Hernandez ArceNo ratings yet

- Energies: Building Applications, Opportunities and Challenges of Active Shading Systems: A State-Of-The-Art ReviewDocument32 pagesEnergies: Building Applications, Opportunities and Challenges of Active Shading Systems: A State-Of-The-Art ReviewNupur BhadraNo ratings yet

- Irish LyricsDocument18 pagesIrish Lyricsmattgood0% (1)

- DnlodDocument43 pagesDnlod312887No ratings yet

- Ship ParticularsDocument1 pageShip ParticularsEbony CarterNo ratings yet

- Delatore - STM25 - Physics - Da1Document5 pagesDelatore - STM25 - Physics - Da1Mikela DelatoreNo ratings yet

- Original Article: Clinical and Histopathological Correlation of Cutaneous TuberculosisDocument6 pagesOriginal Article: Clinical and Histopathological Correlation of Cutaneous Tuberculosisderil ridwanNo ratings yet

- 2019 Torts Higuit Case DigestsDocument29 pages2019 Torts Higuit Case DigestsJan VelascoNo ratings yet

- AtpDocument40 pagesAtpSergio GasparriNo ratings yet

- BDC Preboard Feb 2011 - MasDocument10 pagesBDC Preboard Feb 2011 - Mas1hewlett100% (1)

- General Specification: Welding - MaterialsDocument14 pagesGeneral Specification: Welding - MaterialsGil-Alain EgnakouNo ratings yet

- Las Shs Gen Chem2 q4 RedoxDocument10 pagesLas Shs Gen Chem2 q4 Redoxetherskye05clydeNo ratings yet

- Auto-Injector Review/AnalysisDocument20 pagesAuto-Injector Review/AnalysisArjun RamchandranNo ratings yet

- D5F F3Document11 pagesD5F F3SuNo ratings yet

- Rotational Equilibrium and Rotational DynamicsDocument8 pagesRotational Equilibrium and Rotational DynamicsNathalie SerafinNo ratings yet