Professional Documents

Culture Documents

Cytec Solutions 2013 46

Cytec Solutions 2013 46

Uploaded by

aktivrudarpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cytec Solutions 2013 46

Cytec Solutions 2013 46

Uploaded by

aktivrudarpCopyright:

Available Formats

Scale Controlling Chemical Additives for Phosphoric Acid Production Plants

With the exception of the valve position parameter, all the control cycle indicating a reduced scaling rate. Thus

other data points indicated that the antiscalant effectively a higher rate of production was realized in the antiscalant

controlled the scale buildup in the feed acid line and heat treated cycle.

exchanger, especially compared to the control cycle. It can

When the heat exchanger was opened and inspected, it was

be observed that the flow rate, heat transfer coefficient

observed that only 18 tubes were plugged compared to a

and current load were all maintained to a greater degree

historical average of 150. Additionally, the cleanout using

than in the control cycle. With respect to the feed acid line,

a high pressure water lance took approximately one hour

it did require a washout as the data indicated a blockage

compared with a historical average of 15 hours.

occurred however it should be noted that the slope of the

curve before jumping to 100% open and after the washout The data and visual inspection results showed great promise

(where it returned to baseline) was very low in contrast to for extending the cycle length of the heat exchanger, thus it

the control cycle. Additionally, the increase in valve position was decided to continue the evaluation with a trial aimed at

was not accompanied by a large drop off in flow rate as in doubling the cycle time.

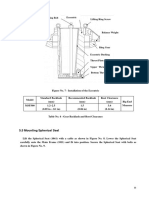

2.2. Results from Extended 6 Week Trial of PHOSFLOW® Antiscalant

As with the 3 week trial, the antiscalant was dosed into the 50 ppm (vol/vol) for the duration of the trial and monitored

outlet side of the feed line pump carrying 28% P2O5 acid regularly. Figures 6 and 7 show the data from the process

from a storage tank to a heat exchanger designed to increase parameters of interest for the antiscalant treated cycle.

the acid concentration to 54% P2O5. The dose was set at

650

Heat Transfer Coefficient (W/m2 K)

600

550

500

450

400

350

300

250

200

0 200 400 600 800 1000

Cycle Time (hours)

100

Valve Position (% Open)

80

60

FIGURE 6:

40

Data for heat transfer coefficient

and valve position for extended

20 evaluation of PHOSFLOW®

0 200 400 600 800 1000

Cycle Time (hours)

46

You might also like

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Controlled Variable Manipulated Variable Controlle R Type /scheme Gproms Model/Process NameDocument5 pagesControlled Variable Manipulated Variable Controlle R Type /scheme Gproms Model/Process NameJoseph OrjiNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Saruri Schussler VithoulkasDocument200 pagesSaruri Schussler Vithoulkasmihaipopescu075% (4)

- Emerson-Valve Sizing Calculations (Traditional Method)Document21 pagesEmerson-Valve Sizing Calculations (Traditional Method)iqtorresNo ratings yet

- Control Valve Characteristics - International Site For Spirax SarcoDocument19 pagesControl Valve Characteristics - International Site For Spirax SarcoRujisak MuangsongNo ratings yet

- Control Valve Characteristics - International Site For Spirax Sarco PDFDocument15 pagesControl Valve Characteristics - International Site For Spirax Sarco PDFLoganathan KrishnanNo ratings yet

- Improve Control: Level LoopsDocument8 pagesImprove Control: Level LoopsCraigUnderwoodNo ratings yet

- PFR Lab ReportDocument16 pagesPFR Lab Reportcog0812No ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- ESAS Compilation of ObjectivesDocument22 pagesESAS Compilation of ObjectivesRODVER BALIBALOS100% (1)

- Synthesis of Acetophenone DerivativesDocument6 pagesSynthesis of Acetophenone DerivativesAwad SaidNo ratings yet

- Computer-Aided Design of Fluid Mixing Equipment: A Guide and Tool for Practicing EngineersFrom EverandComputer-Aided Design of Fluid Mixing Equipment: A Guide and Tool for Practicing EngineersRating: 5 out of 5 stars5/5 (1)

- Water Treatment Plant Performance Evaluations and OperationsFrom EverandWater Treatment Plant Performance Evaluations and OperationsNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Lab Report - RotameterDocument7 pagesLab Report - RotameterYvonne Aklotsoe50% (2)

- Development and Application of Classical Capillary Number Curve TheoryFrom EverandDevelopment and Application of Classical Capillary Number Curve TheoryNo ratings yet

- Calculating Evaporation Swimming PoolsDocument3 pagesCalculating Evaporation Swimming PoolsSyed Munawar AliNo ratings yet

- Carbonate Acidizing AHDocument79 pagesCarbonate Acidizing AHMarrry Florencia100% (1)

- Lab Report CSTR 40LDocument26 pagesLab Report CSTR 40LAnonymous NyvKBW33% (3)

- Distillation Column Control Design Using Steady StateDocument18 pagesDistillation Column Control Design Using Steady Stateb95504048No ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Plug Flow ReactorDocument15 pagesPlug Flow ReactorSeiji Kyousei91% (11)

- Cytec Solutions 2013 47Document1 pageCytec Solutions 2013 47aktivrudarpNo ratings yet

- Cytec Solutions 2013 44Document1 pageCytec Solutions 2013 44aktivrudarpNo ratings yet

- Lab Report CSTR 40LDocument26 pagesLab Report CSTR 40LHazieqahNo ratings yet

- Case Studies, Optimizations and Trials For PSDDocument5 pagesCase Studies, Optimizations and Trials For PSDIbrahim Nick DibalNo ratings yet

- Fig 306F PICV Hattersley IOM 0221Document8 pagesFig 306F PICV Hattersley IOM 0221OYAESPETAHNo ratings yet

- CHEN3003 IndividualDocument12 pagesCHEN3003 IndividualsadanakarunarathneNo ratings yet

- Uitm Lab Report Plug Flow ReactorDocument15 pagesUitm Lab Report Plug Flow ReactorNabilah SyaheeraNo ratings yet

- Rotameter DoneDocument10 pagesRotameter DoneAnele HadebeNo ratings yet

- Lab1 MemoDocument2 pagesLab1 MemoLiuJamesNo ratings yet

- Control Valves: Fluid Jet Energy Criterion ForDocument4 pagesControl Valves: Fluid Jet Energy Criterion ForjosethompsonNo ratings yet

- Lab 4 Production of Acetic AnhydrideDocument9 pagesLab 4 Production of Acetic AnhydrideFirdaus MohamadNo ratings yet

- Internship Report Pakistan Oilfields LimitedDocument22 pagesInternship Report Pakistan Oilfields LimitedArif SamoNo ratings yet

- Lab Manual Experiment 5 Scale Up of BioreactorsDocument12 pagesLab Manual Experiment 5 Scale Up of BioreactorsNUR QURRATUAININo ratings yet

- Accu 12 V 100AH SpecDocument2 pagesAccu 12 V 100AH SpecBagus Tri NuscahyoNo ratings yet

- ControlValveCharacteristics HTMLDocument14 pagesControlValveCharacteristics HTMLempanadaNo ratings yet

- Kinpactor APC-1-514KDocument10 pagesKinpactor APC-1-514Kdannymay95No ratings yet

- Lab 4 SimulationDocument8 pagesLab 4 SimulationaziziNo ratings yet

- Lab Report 4Document24 pagesLab Report 4aidoo3045No ratings yet

- Hydraulic Bench ExperimentDocument6 pagesHydraulic Bench ExperimentMuhammad Abdullah Zafar GhauriNo ratings yet

- Talisman Energy Capillary Pressure Saturation Permeability and NMR Malay Basin Example PDFDocument60 pagesTalisman Energy Capillary Pressure Saturation Permeability and NMR Malay Basin Example PDFRiccardo SNo ratings yet

- Val Matic Pump Control Ball Valve For Energy SavingsDocument9 pagesVal Matic Pump Control Ball Valve For Energy SavingsLuis DanielNo ratings yet

- Solid Liquid Filtration Unit M6: Learning ObjectivesDocument4 pagesSolid Liquid Filtration Unit M6: Learning ObjectivesMayank VashishthaNo ratings yet

- Flowbenches SuperFlowDocument8 pagesFlowbenches SuperFlowM.H.KNo ratings yet

- Lecture 6 Vapor and Combined Power Cycles 10Document61 pagesLecture 6 Vapor and Combined Power Cycles 10Aahjssb HznsmsbNo ratings yet

- Calculation of Ventilation Requirements For Indoor Pools Based On Moisture EvaporationDocument12 pagesCalculation of Ventilation Requirements For Indoor Pools Based On Moisture Evaporationibrahim68No ratings yet

- Experiment 4 Centrifugal PumpDocument9 pagesExperiment 4 Centrifugal PumpSaranya Devi RagupathyNo ratings yet

- 959 TP Severe Service Power Applications Handbook Low ResDocument52 pages959 TP Severe Service Power Applications Handbook Low Respneuma110No ratings yet

- Muzahid Latif, Centrifugal PumpDocument8 pagesMuzahid Latif, Centrifugal PumpMuzahid KhatryNo ratings yet

- Final Centrifugal LabDocument11 pagesFinal Centrifugal LabShazeem HoseinNo ratings yet

- Modelling and System Identification of Gas Fuel Valves in Rowen's Model For Dry Low Emission Gas TurbineDocument5 pagesModelling and System Identification of Gas Fuel Valves in Rowen's Model For Dry Low Emission Gas TurbineDiego CarpioNo ratings yet

- Experiment 2: Level Transmitter CalibrationDocument13 pagesExperiment 2: Level Transmitter CalibrationMuhammad FawwazNo ratings yet

- Home Experiment 4: Hp145 Compact Reciprocating Pump Test SetDocument9 pagesHome Experiment 4: Hp145 Compact Reciprocating Pump Test SetPietro Ian AbdonNo ratings yet

- Home Experiment 5: Hp135 Compact Gear Pump Test SetDocument9 pagesHome Experiment 5: Hp135 Compact Gear Pump Test SetPietro Ian AbdonNo ratings yet

- Procedures: Safety Googles, Gloves and Lab Coat Were Worn When Handling These Chemicals)Document4 pagesProcedures: Safety Googles, Gloves and Lab Coat Were Worn When Handling These Chemicals)JxinLeeNo ratings yet

- Respiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManFrom EverandRespiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Recent Advances in the Science and Technology of Zeolites and Related Materials: Proceedings of the 14th International Zeolite Conference, Cape Town, South Africa, 25-30th April 2004From EverandRecent Advances in the Science and Technology of Zeolites and Related Materials: Proceedings of the 14th International Zeolite Conference, Cape Town, South Africa, 25-30th April 2004No ratings yet

- MSP300 0078 Conica 67Document1 pageMSP300 0078 Conica 67aktivrudarpNo ratings yet

- MSP300 0078 Conica 61Document1 pageMSP300 0078 Conica 61aktivrudarpNo ratings yet

- MSP300 0078 Conica 65Document1 pageMSP300 0078 Conica 65aktivrudarpNo ratings yet

- MSP300 0078 Conica 52Document1 pageMSP300 0078 Conica 52aktivrudarpNo ratings yet

- MSP300 0078 Conica 36Document1 pageMSP300 0078 Conica 36aktivrudarpNo ratings yet

- MSP300 0078 Conica 49Document1 pageMSP300 0078 Conica 49aktivrudarpNo ratings yet

- MSP300 0078 Conica 43Document1 pageMSP300 0078 Conica 43aktivrudarpNo ratings yet

- MSP300 0078 Conica 19Document1 pageMSP300 0078 Conica 19aktivrudarpNo ratings yet

- MSP300 0078 Conica 39Document1 pageMSP300 0078 Conica 39aktivrudarpNo ratings yet

- MSP300 0078 Conica 40Document1 pageMSP300 0078 Conica 40aktivrudarpNo ratings yet

- MSP300 0078 Conica 48Document1 pageMSP300 0078 Conica 48aktivrudarpNo ratings yet

- MSP300 0078 Conica 50Document1 pageMSP300 0078 Conica 50aktivrudarpNo ratings yet

- Cytec Solutions 2013 39Document1 pageCytec Solutions 2013 39aktivrudarpNo ratings yet

- MSP300 0078 Conica 3Document1 pageMSP300 0078 Conica 3aktivrudarpNo ratings yet

- MSP300 0078 Conica 45Document1 pageMSP300 0078 Conica 45aktivrudarpNo ratings yet

- MSP300 0078 Conica 21Document1 pageMSP300 0078 Conica 21aktivrudarpNo ratings yet

- MSP300 0078 Conica 23Document1 pageMSP300 0078 Conica 23aktivrudarpNo ratings yet

- MSP300 0078 Conica 4Document1 pageMSP300 0078 Conica 4aktivrudarpNo ratings yet

- MSP300 0078 Conica 5Document1 pageMSP300 0078 Conica 5aktivrudarpNo ratings yet

- MSP300 0078 Conica 2Document1 pageMSP300 0078 Conica 2aktivrudarpNo ratings yet

- Cytec Solutions 2013 50Document1 pageCytec Solutions 2013 50aktivrudarpNo ratings yet

- Cytec Solutions 2013 45Document1 pageCytec Solutions 2013 45aktivrudarpNo ratings yet

- Cytec Solutions 2013 34Document1 pageCytec Solutions 2013 34aktivrudarpNo ratings yet

- Cytec Solutions 2013 42Document1 pageCytec Solutions 2013 42aktivrudarpNo ratings yet

- Cytec Solutions 2013 23Document1 pageCytec Solutions 2013 23aktivrudarpNo ratings yet

- Cytec Solutions 2013 7Document1 pageCytec Solutions 2013 7aktivrudarpNo ratings yet

- Cytec Solutions 2013 35Document1 pageCytec Solutions 2013 35aktivrudarpNo ratings yet

- Cytec Solutions 2013 6Document1 pageCytec Solutions 2013 6aktivrudarpNo ratings yet

- Cytec Solutions 2013 31Document1 pageCytec Solutions 2013 31aktivrudarpNo ratings yet

- Cytec Solutions 2013 18Document1 pageCytec Solutions 2013 18aktivrudarpNo ratings yet

- Hsslive 7. Equilibrium SignedDocument94 pagesHsslive 7. Equilibrium Signednoel tomNo ratings yet

- Alchol, Ethor Phenol Ex-1Document12 pagesAlchol, Ethor Phenol Ex-1Subhangi MohantyNo ratings yet

- F7 Exp7Document7 pagesF7 Exp7Jody-Ann MearsNo ratings yet

- List Af All Chemical Required in Lab Name-Smrati Chaudhari (M.Pharm 2 Year, 4sem) Pharmaceutical ChemistryDocument3 pagesList Af All Chemical Required in Lab Name-Smrati Chaudhari (M.Pharm 2 Year, 4sem) Pharmaceutical Chemistryseema yadavNo ratings yet

- Methods of Soil Analysis - 1965 - Norman - AluminumDocument21 pagesMethods of Soil Analysis - 1965 - Norman - AluminumPaula BrazueloNo ratings yet

- Lab Activity 5 - PH of Familiar ProductsDocument5 pagesLab Activity 5 - PH of Familiar ProductsCharles Reginald K. HwangNo ratings yet

- HCL Testing Procedure PDFDocument22 pagesHCL Testing Procedure PDFRavi ShankarNo ratings yet

- Microbiology Basic and Clinical Principles 1st Edition Mckay Test BankDocument35 pagesMicrobiology Basic and Clinical Principles 1st Edition Mckay Test Bankduongnujl33q100% (31)

- Hydrochloric Acid Corrosion Resistant AlloysDocument2 pagesHydrochloric Acid Corrosion Resistant AlloysZlatko PartličNo ratings yet

- Description BioRePeelCl3Document3 pagesDescription BioRePeelCl3kkNo ratings yet

- ConfD Kick Start GuideDocument37 pagesConfD Kick Start Guidekamal710229No ratings yet

- Problem Set: Acid-Base EquilibriaDocument8 pagesProblem Set: Acid-Base EquilibriaPamie Penelope BayogaNo ratings yet

- Nitrogen & Fertilisers (Multiple Choice) QPDocument8 pagesNitrogen & Fertilisers (Multiple Choice) QPRizky HermawanNo ratings yet

- This Study Resource WasDocument6 pagesThis Study Resource WasBeatrice GutierrezNo ratings yet

- Fiitjee Aits Jee Main 2019 PT IDocument23 pagesFiitjee Aits Jee Main 2019 PT IPriyasu GuinNo ratings yet

- Chemistry MCQ CDocument8 pagesChemistry MCQ Cdaisuke ʕ•ᴥ•ʔNo ratings yet

- Astm F 2034Document4 pagesAstm F 2034edson alfaNo ratings yet

- Standard SolutionDocument9 pagesStandard SolutionPradeep KumarNo ratings yet

- Calcium CarbonateDocument2 pagesCalcium CarbonateSACHIN H. DHAMAPURKARNo ratings yet

- Arlan G8 Rate of Reaction Criteria B & CDocument8 pagesArlan G8 Rate of Reaction Criteria B & CHEY ERLNo ratings yet

- Preparation of Chromatography Spray ReagentsDocument12 pagesPreparation of Chromatography Spray ReagentsNina Nur AiniNo ratings yet

- GCI Topics PDFDocument4 pagesGCI Topics PDFMuhammad QaisarNo ratings yet

- Characteristics of Microorganisms Used in Industrial MicrobiologyDocument62 pagesCharacteristics of Microorganisms Used in Industrial Microbiologyjaveriazia97No ratings yet

- January 2016 (IAL) QP - Unit 3 Edexcel ChemistryDocument20 pagesJanuary 2016 (IAL) QP - Unit 3 Edexcel ChemistryXhanAfaqNo ratings yet

- Aldehydes Ketones and Carboxylic AcidsDocument37 pagesAldehydes Ketones and Carboxylic Acidsssheeladevi84100% (1)

- Acetylsalicylic Acid ManufacturingDocument19 pagesAcetylsalicylic Acid ManufacturinghomarearisugawaNo ratings yet