Professional Documents

Culture Documents

MSP300 0078 Conica 4

Uploaded by

aktivrudarpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSP300 0078 Conica 4

Uploaded by

aktivrudarpCopyright:

Available Formats

13.4 ECCENTRIC PARTS LIST (3000)…………………………………….…...

…50

13.5 MAIN SHAFT ASSEMBLY PARTS LIST (4000)……………………..…..…52

13.6 COUNTERSHAFT ASSEMBLY PARTS LIST (5000)……………….…...…54

13.7 LUBRICATION PARTS LIST (6000)……………………………….……......56

13.8 HYDRAULICS PARTS LIST (8000)………………………………………….59

14 PARTS ORDER FORM……………………………………………….…………61

LIST OF TABLES

Table No.1 Closed Circuit Operation Capacities……………………………………………….…...2

Table No.2 Approximate Component Lifting Heights………………………………………….…...5

Table No.3 Weight of Major Sub-Assemblies…………………………………………………….….5

Table No.4 Gear Backlash and Root Clearance…………………………………………………....10

Table No.5 Center Distance Allowances for Narrow V-Belt Installation and Take-Up……….…15

Table No.6 Center Distance Allowances for Classical V-Belt Installation and Take-Up…….…..15

Table No.7 Motor Horsepower, Pump Deliveries and Capacities……………………………..…..18

LIST OF FIGURES

Figure No.1 Plan View of Base Plates…………………………………………………………….…..4

Figure No.2 Cross Section of Base Plate……………………………………………………....……..4

Figure No.3 Hoisting Dimensional Requirements and Clearances………………………..…..……5

Figure No.4 Proper and Improper Ore Feeding……………………………………………….….…6

Figure No.5 Removing the Thrust Plate Assembly…………………………………………….……7

Figure No.6 Mounting Countershaft and Housing Assembly………………………………….…...8

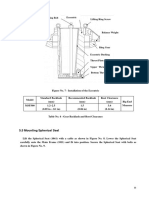

Figure No.7 Installation of the Eccentric…………………………………………………..….……10

Figure No.8 Lifting the Spherical Seat……………………………………………………….……..11

Figure No.9 Securing the Spherical Seat…………….……………………….………………..……11

Figure No.10 Installation of Main Shaft……………………...……………………………….……12

Figure No.11 Mounting the Top Frame……………………………………………………….…….13

Figure No.12 V-Belt Installation and Take-Up Allowances………………………………….…….14

Figure No.13 Measuring the V-Belt Tension………………………………………………….…….16

Figure No.14 Lubrication Schematic………………………………………………...………….…..17

Figure No.15 Adding Lubrication Oil and Checking Oil Level for Countershaft

Bearings …………………………………………………………………………………………..…..18

Figure No.16 Adjust the Discharge Setting……………………………………………………..…..20

Figure No.17 Confirming Countershaft Rotation……………………………………………….…21

Figure No.18 Replacing the Concave……………………………………………………...………. 31

Figure No.19 Replacing the Mantle………………………………………………………………....33

Figure No.20 Check Depth of Seat Liner Oil Groove…………….………..………….............…...35

Figure No. 21 Removing the Seat Liner…………………………………………..…..............…….35

Figure No. 22 Removing the Eccentric Bushing………..………………………………………..…37

Figure No. 23 Removing the Frame Bushing……..………………………………………...………39

Figure No.24 Exploded Drawing of Whole Machine………………………………….….……..…42

Figure No.25 Exploded Drawing of Lower Section Parts…………………….…………….……...43

Figure No.26 Exploded Drawing of Upper Section Parts……………..…………………………...45

iv

You might also like

- 2019 Husqvarna TE 250i - TE300i Service Repair Manual PDFDocument363 pages2019 Husqvarna TE 250i - TE300i Service Repair Manual PDFDiego Garagem P7No ratings yet

- DFMA StaplerDocument58 pagesDFMA StaplerAndrew Edward100% (2)

- ZF Marine Transmission Repair ManualDocument112 pagesZF Marine Transmission Repair ManualDavid Chalker82% (11)

- Zte BSC Hardware PresentationDocument53 pagesZte BSC Hardware PresentationNgoy Saro100% (2)

- Abs Propulsion Shafting Alignment PDFDocument37 pagesAbs Propulsion Shafting Alignment PDFCalandrasReyCalandrasreyNo ratings yet

- Chapt 12Document28 pagesChapt 12DevilZaaNo ratings yet

- Declaration: ENGINEERING CORPORATION LIMITED During The Period From 21 May To 21 July inDocument8 pagesDeclaration: ENGINEERING CORPORATION LIMITED During The Period From 21 May To 21 July inANKESHNo ratings yet

- List of Figure Figure No. Description Page NoDocument6 pagesList of Figure Figure No. Description Page NoRaKesh P SuKhwalNo ratings yet

- Low-Cost Expendable UAV Final Report: Department of Aerospace and Ocean EngineeringDocument92 pagesLow-Cost Expendable UAV Final Report: Department of Aerospace and Ocean EngineeringMunem BushraNo ratings yet

- CAT Delta 30, 90 X-Ray - Service ManualDocument171 pagesCAT Delta 30, 90 X-Ray - Service ManualLuis Fernando Garcia SNo ratings yet

- 1089 Kg/year Cephalosporin Antibiotic Production Plant From Corn Steep LiquorDocument136 pages1089 Kg/year Cephalosporin Antibiotic Production Plant From Corn Steep LiquorPinak ChowdhuryNo ratings yet

- Industrial FinalpaperDocument125 pagesIndustrial FinalpaperrainmetzieeNo ratings yet

- E Illustrated Parts C-Arm C-Arm IPM ContentsDocument73 pagesE Illustrated Parts C-Arm C-Arm IPM ContentsNirav Barot67% (3)

- 3 Table of ContentsDocument6 pages3 Table of ContentsRyan ReyesNo ratings yet

- Reparaturanleitung U Ersatzteilliste ZF25 Bis ZF45-1 PDFDocument85 pagesReparaturanleitung U Ersatzteilliste ZF25 Bis ZF45-1 PDFGustavo BelgranoNo ratings yet

- RailwayDocument1 pageRailwayRounak PramanikNo ratings yet

- zt350t Euro V 2022Document115 pageszt350t Euro V 2022Kunji ManiNo ratings yet

- BobCAD-CAM Version 21 Manual - English - LCDocument551 pagesBobCAD-CAM Version 21 Manual - English - LCs_barrios100% (1)

- Table of Content: Project Work 2018-2019Document4 pagesTable of Content: Project Work 2018-2019ChowdariNo ratings yet

- HarDocument47 pagesHarnagaraju tangellaNo ratings yet

- Reparaturanleitung U Ersatzteilliste ZF25 Bis ZF45-1Document85 pagesReparaturanleitung U Ersatzteilliste ZF25 Bis ZF45-1Claudio CastioniNo ratings yet

- Taller - MOTOR ZONTES350Document56 pagesTaller - MOTOR ZONTES350Emiliano Arocha CorsoNo ratings yet

- GE Portascan Portable Bladder Scanner - Service ManualDocument18 pagesGE Portascan Portable Bladder Scanner - Service ManualRuslan SergeevNo ratings yet

- Heat Exchange Institute, Inc.: Standards ForDocument5 pagesHeat Exchange Institute, Inc.: Standards ForDepid Prasetyo UNo ratings yet

- Mongoose PT Mud Cleaner: Installation, Operation, and Maintenance Manual ForDocument118 pagesMongoose PT Mud Cleaner: Installation, Operation, and Maintenance Manual ForMartin CollingsNo ratings yet

- FE3R16N Operation Maintenance ManualDocument112 pagesFE3R16N Operation Maintenance ManualCristian Javier Sierra100% (1)

- Msp300#0078-ConicaDocument69 pagesMsp300#0078-ConicaMartín Lescano ParedesNo ratings yet

- Reparaturanleitung U Ersatzteilliste ZF63A Bis ZF85ADocument112 pagesReparaturanleitung U Ersatzteilliste ZF63A Bis ZF85APaul De Caluwe0% (2)

- Repair Manual ZF 45-1 Workshop MaunalDocument85 pagesRepair Manual ZF 45-1 Workshop MaunalBertrand Legendre100% (1)

- ISODC, IIT Kharagpur Team, May 2008Document269 pagesISODC, IIT Kharagpur Team, May 2008Prabhakar Tiwari100% (1)

- 2012 XK - X150 PDFDocument126 pages2012 XK - X150 PDFJonas LuciusNo ratings yet

- Chapter 1: Introduction: Coating Inspector Program Level 2 List of FiguresDocument9 pagesChapter 1: Introduction: Coating Inspector Program Level 2 List of FiguresHope Samantha AbaoNo ratings yet

- Celitron Operacion InglesDocument85 pagesCelitron Operacion InglesLeonel Losada CardozoNo ratings yet

- Interstage 300B Parallel Monoblock V 3.08Document98 pagesInterstage 300B Parallel Monoblock V 3.08andree wNo ratings yet

- Operation and Installation Manual Small Volume ProverDocument72 pagesOperation and Installation Manual Small Volume Proverdrejas100% (2)

- Operation & Maintenance Manual: Zhejiang Noblelift Equipment Joint Stock Co.,LtdDocument77 pagesOperation & Maintenance Manual: Zhejiang Noblelift Equipment Joint Stock Co.,LtdМикола Попович100% (1)

- Sba 330Document76 pagesSba 330Trung Kính NguyễnNo ratings yet

- Vasantdada Sugar Institute: MANJARI (B), 412 307 Tal. Haveli, Dist. PuneDocument12 pagesVasantdada Sugar Institute: MANJARI (B), 412 307 Tal. Haveli, Dist. PuneDhansingh KokareNo ratings yet

- EN17353458 - Gamage O.D. - Machine - Design - II - Year2019 - Submission - 26th PDFDocument99 pagesEN17353458 - Gamage O.D. - Machine - Design - II - Year2019 - Submission - 26th PDFOshada GamageNo ratings yet

- CoetDocument4 pagesCoetShidhin TomNo ratings yet

- Line Balancing Considering Ergonomics PDFDocument67 pagesLine Balancing Considering Ergonomics PDFNitin PradhanNo ratings yet

- Levas Connecting Rod Flywheel CamshaftDocument2 pagesLevas Connecting Rod Flywheel CamshaftJesus FonsecaNo ratings yet

- List of FiguresDocument2 pagesList of Figuressourabhj999No ratings yet

- Geely CK Sparepart CatalogDocument221 pagesGeely CK Sparepart CatalogJorge Soto Batalla100% (1)

- 24c64 DatasheetDocument26 pages24c64 DatasheetNom AkNo ratings yet

- LIST of FIGURES ExampleDocument2 pagesLIST of FIGURES ExampleMuhammadNurArifinNo ratings yet

- Structural DynamicsDocument79 pagesStructural DynamicsJunnaz BalacuitNo ratings yet

- Service Manual: Publ - No.: 3HNT 02330-1 en Rev.03Document192 pagesService Manual: Publ - No.: 3HNT 02330-1 en Rev.03John BenjaminNo ratings yet

- Componente 5500 PDFDocument604 pagesComponente 5500 PDFDenisa NeagoeNo ratings yet

- Introduction To Piezoelectric Transducers Carter Kensley 2022Document72 pagesIntroduction To Piezoelectric Transducers Carter Kensley 2022svfNo ratings yet

- Optimization of Formula Car Double Wishbone Suspension System PDFDocument70 pagesOptimization of Formula Car Double Wishbone Suspension System PDFznamNo ratings yet

- GAV Gesipa ManualDocument167 pagesGAV Gesipa Manual'Lampa'No ratings yet

- Jurassic Park: Service and Operation Manual Service and Operation ManualDocument66 pagesJurassic Park: Service and Operation Manual Service and Operation ManualpangymylyNo ratings yet

- NSCR EPRMP Vol 1 PDFDocument233 pagesNSCR EPRMP Vol 1 PDFPeter Paul BucsitNo ratings yet

- Paper 2Document28 pagesPaper 2Vaughan HawkNo ratings yet

- ADP I ContentsDocument3 pagesADP I Contentsparamaguru vNo ratings yet

- zt310t Euro IVDocument109 pageszt310t Euro IVEmiliano Arocha CorsoNo ratings yet

- l3 Phono Stage v2Document110 pagesl3 Phono Stage v2redlab100% (1)

- Variable Speed Pumping: A Guide to Successful ApplicationsFrom EverandVariable Speed Pumping: A Guide to Successful ApplicationsRating: 3 out of 5 stars3/5 (2)

- Incompressible Flow Turbomachines: Design, Selection, Applications, and TheoryFrom EverandIncompressible Flow Turbomachines: Design, Selection, Applications, and TheoryNo ratings yet

- Microprocessor Programming and Applications for Scientists and EngineersFrom EverandMicroprocessor Programming and Applications for Scientists and EngineersNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-50Document1 page612431362-200928-MSP300-0078-CONICA-50aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-61Document1 page612431362-200928-MSP300-0078-CONICA-61aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-67Document1 page612431362-200928-MSP300-0078-CONICA-67aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-49Document1 page612431362-200928-MSP300-0078-CONICA-49aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-65Document1 page612431362-200928-MSP300-0078-CONICA-65aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-52Document1 page612431362-200928-MSP300-0078-CONICA-52aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-36Document1 page612431362-200928-MSP300-0078-CONICA-36aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-39Document1 page612431362-200928-MSP300-0078-CONICA-39aktivrudarpNo ratings yet

- MSP300 0078 Conica 23Document1 pageMSP300 0078 Conica 23aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-45Document1 page612431362-200928-MSP300-0078-CONICA-45aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-40Document1 page612431362-200928-MSP300-0078-CONICA-40aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-43Document1 page612431362-200928-MSP300-0078-CONICA-43aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-48Document1 page612431362-200928-MSP300-0078-CONICA-48aktivrudarpNo ratings yet

- MSP300 0078 Conica 3Document1 pageMSP300 0078 Conica 3aktivrudarpNo ratings yet

- MSP300 0078 Conica 2Document1 pageMSP300 0078 Conica 2aktivrudarpNo ratings yet

- MSP300 0078 Conica 21Document1 pageMSP300 0078 Conica 21aktivrudarpNo ratings yet

- MSP300 0078 Conica 19Document1 pageMSP300 0078 Conica 19aktivrudarpNo ratings yet

- MSP300 0078 Conica 5Document1 pageMSP300 0078 Conica 5aktivrudarpNo ratings yet

- Cytec Solutions 2013 46Document1 pageCytec Solutions 2013 46aktivrudarpNo ratings yet

- Cytec Solutions 2013 42Document1 pageCytec Solutions 2013 42aktivrudarpNo ratings yet

- Cytec Solutions 2013 39Document1 pageCytec Solutions 2013 39aktivrudarpNo ratings yet

- Cytec Solutions 2013 45Document1 pageCytec Solutions 2013 45aktivrudarpNo ratings yet

- Cytec Solutions 2013 50Document1 pageCytec Solutions 2013 50aktivrudarpNo ratings yet

- Cytec Solutions 2013 31Document1 pageCytec Solutions 2013 31aktivrudarpNo ratings yet

- Cytec Solutions 2013 34Document1 pageCytec Solutions 2013 34aktivrudarpNo ratings yet

- Cytec Solutions 2013 35Document1 pageCytec Solutions 2013 35aktivrudarpNo ratings yet

- Cytec Solutions 2013 23Document1 pageCytec Solutions 2013 23aktivrudarpNo ratings yet

- Cytec Solutions 2013 18Document1 pageCytec Solutions 2013 18aktivrudarpNo ratings yet

- Cytec Solutions 2013 6Document1 pageCytec Solutions 2013 6aktivrudarpNo ratings yet

- Cytec Solutions 2013 7Document1 pageCytec Solutions 2013 7aktivrudarpNo ratings yet

- Amlock Leading Non Banking Financial Company Building Society in The UKDocument2 pagesAmlock Leading Non Banking Financial Company Building Society in The UKNguyễn Quốc MạnhNo ratings yet

- Newspaper Collection Policy & Appointment Request Form (3/19/14)Document2 pagesNewspaper Collection Policy & Appointment Request Form (3/19/14)HSLBNo ratings yet

- Aplications of Casing DrillingDocument19 pagesAplications of Casing DrillingRaul Alberto Miranda Loayza100% (1)

- HHS Letter To State Medicaid Directors On Hospice Care For Children in Medicaid and CHIPDocument3 pagesHHS Letter To State Medicaid Directors On Hospice Care For Children in Medicaid and CHIPBeverly TranNo ratings yet

- Welding Journal 1959 8Document142 pagesWelding Journal 1959 8AlexeyNo ratings yet

- Remote Sensing in Minerals ExplorationDocument35 pagesRemote Sensing in Minerals ExplorationIqra AyeshaNo ratings yet

- George StephensonDocument3 pagesGeorge StephensonGongga NapitupuluNo ratings yet

- DOP 206 - Rev 4Document12 pagesDOP 206 - Rev 4Fernando AybarNo ratings yet

- Motion To Release AccusedDocument3 pagesMotion To Release AccusedStef OcsalevNo ratings yet

- Gain, Attenuation, and DecibelsDocument10 pagesGain, Attenuation, and DecibelsValentina NietoNo ratings yet

- Aeropostale AnalysisDocument6 pagesAeropostale AnalysisHani WaniNo ratings yet

- 02 - Syllabus Property Discussion GuideDocument67 pages02 - Syllabus Property Discussion GuideGianna CantoriaNo ratings yet

- Sr. Product Design Engineer Vivek VermaDocument2 pagesSr. Product Design Engineer Vivek Vermavivek vermaNo ratings yet

- The Candlemakers' Petition: Frederic BastiatDocument4 pagesThe Candlemakers' Petition: Frederic Bastiatmonisha8bandopadhyayNo ratings yet

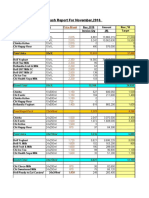

- Aba Monthly Report As at Nov (1) .'10Document78 pagesAba Monthly Report As at Nov (1) .'10Vivek RaghavNo ratings yet

- Datasheet: C P V 5 3 7 5 Compactpci Host Slot Processor BoardDocument5 pagesDatasheet: C P V 5 3 7 5 Compactpci Host Slot Processor BoardprimaryrateNo ratings yet

- Kenya Mccarty IndictmentDocument1 pageKenya Mccarty IndictmentAnthony WarrenNo ratings yet

- W1FB - Design NotebookDocument200 pagesW1FB - Design NotebookHsu100% (1)

- Health Care GuideDocument51 pagesHealth Care GuideM Zainuddin M SaputraNo ratings yet

- Sybase CatalogDocument48 pagesSybase CatalogPankaj KumarNo ratings yet

- 2019-157 PHLDocument4 pages2019-157 PHLJAGUAR GAMINGNo ratings yet

- The Digital Musician Second Edition by ADocument3 pagesThe Digital Musician Second Edition by AEddie IpenzaNo ratings yet

- Common Base Transistor Configuration (CB) : Savan MehtaDocument3 pagesCommon Base Transistor Configuration (CB) : Savan MehtaAhmad RazaNo ratings yet

- PM Project CharterDocument8 pagesPM Project CharterMuhammad AididNo ratings yet

- Iis 2 MDCDocument40 pagesIis 2 MDCAdrian Reyes GalavizNo ratings yet

- How To Sell Cyber Security To Your BoardDocument18 pagesHow To Sell Cyber Security To Your BoardLuis SosaNo ratings yet

- Ibs Vigyan January 2023Document4 pagesIbs Vigyan January 2023chinnusaisanthoshNo ratings yet

- Particulate Matter in Injectables, USP Criteria - 1Document6 pagesParticulate Matter in Injectables, USP Criteria - 1SolomonNo ratings yet