Professional Documents

Culture Documents

MSP300 0078 Conica 23

MSP300 0078 Conica 23

Uploaded by

aktivrudarpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSP300 0078 Conica 23

MSP300 0078 Conica 23

Uploaded by

aktivrudarpCopyright:

Available Formats

one-half degree (0.5° or one-eighth inch in one foot) will adversely affect V-Belt life.

Improper sheave

alignment produces uneven wear of one side of the V-Belt, causing the V-Belt to roll over in the sheave

groove and throws all the load on one side of the V-Belt, stretching or breaking the cords on the side.

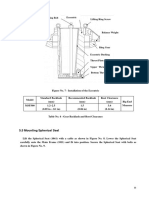

6.2.2 Installation and Take-up Allowances

After calculating a center distance from a standard pitch length, make provisions for adjusting the

center distance as in Figure No. 12 (with installation allowance). This will allow for installation of the V-Belts

without injury, for V-Belt tensioning and for maintenance of proper tension throughout the life of the

V-Belts. Refer to Table No. 5 and Table No. 6 for values.

調 整 距 Allowance

Take-Up 離

中 心 距

Center Distance

安 裝 間 隙 Allowance

Installation

Figure No. 12 - V-Belt Installation and Take-Up Allowances

Placing V-Belts on Sheaves---Shorten the center distance of the drives until the V-Belts can be put on

the sheaves without forcing. Forcing the V-Belts can cause internal injury to the V-Belts.

V-Belt Selection---For maximum service, replace V-Belt drives with a complete new matched set of

V-Belts.

NEVER employ a used V-Belt as a replacement for a V-Belt in a set. Used V-Belts, normally, are worn

in cross-section and are stretched. A new V-Belt so applied with used V-Belts will ride higher in the groove,

travel faster and operate at a much higher tension than the used V-Belts, and the cord center may be

ruptured allowing the new V-Belt to elongate. Shortly after this occurs, the new V-Belt will cease to accept

its full share of the load, leaving part of its load to the old V-Belts to accept. Thus, the new V-Belt is ruined.

V-Belts from different manufactures should not be mixed, for the same reasons.

15

You might also like

- Conveyor Belt Commissioning ProcedureDocument7 pagesConveyor Belt Commissioning Procedurevvijaybhan100% (6)

- 303 - 1 Power Transmission Equipment Course PreviewDocument19 pages303 - 1 Power Transmission Equipment Course PreviewAnonymous q9eCZHMuS0% (2)

- DODGE V Belt IOM PDFDocument8 pagesDODGE V Belt IOM PDFSupervisorNo ratings yet

- Design of Transmission Systems Subject Code: 342Document49 pagesDesign of Transmission Systems Subject Code: 342Muthuvel MNo ratings yet

- BeltsDocument2 pagesBeltsmech118No ratings yet

- V Belt DriveDocument18 pagesV Belt DriveFahad AliNo ratings yet

- Vee Belt DrivesDocument3 pagesVee Belt DrivesWaqas WakeelNo ratings yet

- ConveyorDocument14 pagesConveyorchenkok_90No ratings yet

- Training of Conveyor BeltDocument4 pagesTraining of Conveyor BeltAk AbdulwahabNo ratings yet

- MN4002 - 0222 (W)Document8 pagesMN4002 - 0222 (W)Mochamad CholiqNo ratings yet

- Sistema de ContrapesoDocument120 pagesSistema de ContrapesoVentas IzajesNo ratings yet

- Belt Installation, Tracking, and Maintenance GuideDocument11 pagesBelt Installation, Tracking, and Maintenance Guideznim04No ratings yet

- Belt Conveyor Idler: Installation InstructionsDocument8 pagesBelt Conveyor Idler: Installation InstructionsJairo Andrés FANo ratings yet

- OM 002 Belt Conveyor Idler Instruct 6E74091AB9993Document9 pagesOM 002 Belt Conveyor Idler Instruct 6E74091AB9993gopi_ggg20016099No ratings yet

- Belt ConveyorDocument3 pagesBelt ConveyorGuru Raja Ragavendran NagarajanNo ratings yet

- V Belts and Rope DriveDocument11 pagesV Belts and Rope DrivekamaleshNo ratings yet

- V - Belt BandoDocument12 pagesV - Belt BandoEko Wibowo100% (1)

- DVSM DVSR Sump Pump Manual 20210816Document12 pagesDVSM DVSR Sump Pump Manual 20210816dynapro.sharingNo ratings yet

- Belt Tension RequiredDocument2 pagesBelt Tension RequiredJinto A J100% (3)

- Tool Box Talk - VBelt MaintenanceDocument3 pagesTool Box Talk - VBelt MaintenancelarumaxNo ratings yet

- Single Point Lesson - V-Belt Maintenance 101Document4 pagesSingle Point Lesson - V-Belt Maintenance 101Pablo ScottNo ratings yet

- 1 Mounting V-Belt Drive (Motor Pulley, Fly Wheel, V-Belts and Guard)Document20 pages1 Mounting V-Belt Drive (Motor Pulley, Fly Wheel, V-Belts and Guard)andreaNo ratings yet

- Belt Conveyor Idler: Read These Instructions Carefully Before Starting InstallationDocument8 pagesBelt Conveyor Idler: Read These Instructions Carefully Before Starting InstallationKenji LacambraNo ratings yet

- Belt Routing GuideDocument87 pagesBelt Routing GuideBYRONGOSNo ratings yet

- V-Belt DrivesDocument12 pagesV-Belt DrivesSufiyan MohammedNo ratings yet

- V-Belt and Timing Belt Installation and Maintenance: SERVICE EXPRESS 1-800-829-6612Document11 pagesV-Belt and Timing Belt Installation and Maintenance: SERVICE EXPRESS 1-800-829-6612yeop03100% (1)

- Davit ManualDocument10 pagesDavit ManualUDAYAN PRIYAROOPNo ratings yet

- Belt Selection ConsiderationsDocument31 pagesBelt Selection Considerationsdivyaraghavaraju100% (1)

- 8' MPV User's Manual For Side Port PDFDocument20 pages8' MPV User's Manual For Side Port PDFdavibrenoNo ratings yet

- Trouble Shooting On Conveyor BeltingsDocument17 pagesTrouble Shooting On Conveyor BeltingsVimal Bhansali100% (1)

- Navod Na PouzitieDocument32 pagesNavod Na Pouzitieali222beliNo ratings yet

- V-Guided Conveyor Belts A Much Better Option For Keeping Conveyor Belts Centered Than Crowned Rollers - Machine DesignDocument4 pagesV-Guided Conveyor Belts A Much Better Option For Keeping Conveyor Belts Centered Than Crowned Rollers - Machine DesignRavindra MahadeokarNo ratings yet

- V BeltDocument10 pagesV Beltsukamto100% (1)

- W7751 Smart VAV InstallationDocument12 pagesW7751 Smart VAV InstallationAnwar LatiffNo ratings yet

- Belt DriveDocument34 pagesBelt DriveGaurav Kumar GuptaNo ratings yet

- Troubleshooting ConveyorDocument7 pagesTroubleshooting Conveyorsapu11jagat5855No ratings yet

- Willard Says : Winch InstallationDocument5 pagesWillard Says : Winch InstallationAntonio RibeiroNo ratings yet

- V-Belt Drives 0905Document3 pagesV-Belt Drives 0905FV AllanNo ratings yet

- Construction Installation and Maintenance of Power Transmission V Belt DrivesDocument55 pagesConstruction Installation and Maintenance of Power Transmission V Belt DrivesRamiz KurbegovicNo ratings yet

- Weigh Shark 2 MANUAL August 2021Document92 pagesWeigh Shark 2 MANUAL August 2021Nate SwaneyNo ratings yet

- FIXIE Inc Beltdrive Manual - pdffIXIE Inc Beltdrive ManualDocument8 pagesFIXIE Inc Beltdrive Manual - pdffIXIE Inc Beltdrive Manualnangkarak8201No ratings yet

- Pt. Magdatama - Wabo Modular JointDocument8 pagesPt. Magdatama - Wabo Modular JointMangisi Haryanto ParapatNo ratings yet

- V BeltsDocument14 pagesV BeltsLaka 98No ratings yet

- Basics of Belt DrivesDocument12 pagesBasics of Belt DrivesSrinivasan Ravi100% (1)

- Chain Installation: Safety PrecautionsDocument16 pagesChain Installation: Safety PrecautionsAlejandro RodriguezNo ratings yet

- DODGE SAF-XT & SAFS Pillow Blocks: Instruction ManualDocument4 pagesDODGE SAF-XT & SAFS Pillow Blocks: Instruction ManualALFONSO FERNANDEZ MULETNo ratings yet

- Conveyor Belt Maintenance & Trouble Shooting ManualDocument48 pagesConveyor Belt Maintenance & Trouble Shooting ManualMichael D. Torres100% (1)

- Annex 3-V BeltDocument3 pagesAnnex 3-V BeltProject SinhaNo ratings yet

- V-Belt Drives: Elemen Mesin IiDocument22 pagesV-Belt Drives: Elemen Mesin IiCarlo VossenNo ratings yet

- Chum Saf-Xt ManualDocument8 pagesChum Saf-Xt Manualingrojas_No ratings yet

- V Belt TrainingDocument14 pagesV Belt TrainingsantoshNo ratings yet

- Operation & Maintenance Manual Belt Drive Troubleshooting: CRSH-OM-0003ENG (OCT-2014) B - 3 Model CT-Series Jaw CrushersDocument4 pagesOperation & Maintenance Manual Belt Drive Troubleshooting: CRSH-OM-0003ENG (OCT-2014) B - 3 Model CT-Series Jaw CrushersjlfyNo ratings yet

- Wire Rope-Steel TechnicalDocument37 pagesWire Rope-Steel TechnicalAndreea LucaNo ratings yet

- Basics of Belt DriveDocument11 pagesBasics of Belt DriveAnonymous ETBwIduGi50% (2)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Understanding Your Boats Systems and Choices.From EverandUnderstanding Your Boats Systems and Choices.Rating: 3 out of 5 stars3/5 (1)

- MSP300 0078 Conica 67Document1 pageMSP300 0078 Conica 67aktivrudarpNo ratings yet

- MSP300 0078 Conica 61Document1 pageMSP300 0078 Conica 61aktivrudarpNo ratings yet

- MSP300 0078 Conica 65Document1 pageMSP300 0078 Conica 65aktivrudarpNo ratings yet

- MSP300 0078 Conica 52Document1 pageMSP300 0078 Conica 52aktivrudarpNo ratings yet

- MSP300 0078 Conica 36Document1 pageMSP300 0078 Conica 36aktivrudarpNo ratings yet

- MSP300 0078 Conica 40Document1 pageMSP300 0078 Conica 40aktivrudarpNo ratings yet

- MSP300 0078 Conica 43Document1 pageMSP300 0078 Conica 43aktivrudarpNo ratings yet

- MSP300 0078 Conica 3Document1 pageMSP300 0078 Conica 3aktivrudarpNo ratings yet

- MSP300 0078 Conica 39Document1 pageMSP300 0078 Conica 39aktivrudarpNo ratings yet

- MSP300 0078 Conica 49Document1 pageMSP300 0078 Conica 49aktivrudarpNo ratings yet

- MSP300 0078 Conica 48Document1 pageMSP300 0078 Conica 48aktivrudarpNo ratings yet

- MSP300 0078 Conica 50Document1 pageMSP300 0078 Conica 50aktivrudarpNo ratings yet

- Cytec Solutions 2013 39Document1 pageCytec Solutions 2013 39aktivrudarpNo ratings yet

- MSP300 0078 Conica 4Document1 pageMSP300 0078 Conica 4aktivrudarpNo ratings yet

- MSP300 0078 Conica 45Document1 pageMSP300 0078 Conica 45aktivrudarpNo ratings yet

- MSP300 0078 Conica 21Document1 pageMSP300 0078 Conica 21aktivrudarpNo ratings yet

- MSP300 0078 Conica 19Document1 pageMSP300 0078 Conica 19aktivrudarpNo ratings yet

- MSP300 0078 Conica 5Document1 pageMSP300 0078 Conica 5aktivrudarpNo ratings yet

- MSP300 0078 Conica 2Document1 pageMSP300 0078 Conica 2aktivrudarpNo ratings yet

- Cytec Solutions 2013 50Document1 pageCytec Solutions 2013 50aktivrudarpNo ratings yet

- Cytec Solutions 2013 45Document1 pageCytec Solutions 2013 45aktivrudarpNo ratings yet

- Cytec Solutions 2013 46Document1 pageCytec Solutions 2013 46aktivrudarpNo ratings yet

- Cytec Solutions 2013 34Document1 pageCytec Solutions 2013 34aktivrudarpNo ratings yet

- Cytec Solutions 2013 42Document1 pageCytec Solutions 2013 42aktivrudarpNo ratings yet

- Cytec Solutions 2013 23Document1 pageCytec Solutions 2013 23aktivrudarpNo ratings yet

- Cytec Solutions 2013 7Document1 pageCytec Solutions 2013 7aktivrudarpNo ratings yet

- Cytec Solutions 2013 35Document1 pageCytec Solutions 2013 35aktivrudarpNo ratings yet

- Cytec Solutions 2013 6Document1 pageCytec Solutions 2013 6aktivrudarpNo ratings yet

- Cytec Solutions 2013 31Document1 pageCytec Solutions 2013 31aktivrudarpNo ratings yet

- Cytec Solutions 2013 18Document1 pageCytec Solutions 2013 18aktivrudarpNo ratings yet