Professional Documents

Culture Documents

Cytec Solutions 2013 7

Uploaded by

aktivrudarpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cytec Solutions 2013 7

Uploaded by

aktivrudarpCopyright:

Available Formats

Solvent Extraction, Mineral Processing and Alumina Processing

Crud Processing Improvements Using ACORGA® CB 1000 Crud Busting Reagent

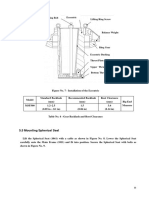

Operations that practice clay treatment of recovered organic aqueous remaining with the organic. As shown in Figure 5,

typically only utilize 0.1 – 0.3 wt% clay due to plugging an excess of 2% clay is required to restore the organic IFT

concerns. This is rarely sufficient to remove all surfactants (of this specific plant organic) to its maximum value.

from the organic, and the clay is often deactivated by

39

Recovery Organic Clay Treatment Curve

37

Interfacial Tension Time (dynes/cm)

35

33

31

29

FIGURE 5:

27 Clay Treatment vs.

0 1 2 3 4 5 6 Interfacial Tension

Clay Concentration (wt%)

The use of ACORGA CB 1000 efficiently separates the organic to be treated with the appropriate clay dosage

organic from the solids/aqueous emulsion, enabling the without deactivation of the clay.

Benefits of Higher Organic Quality

Pilot plant testing was completed to compare organic typical mechanical crud processing means. This work was

recovered by crud buster to organic recovered by completed using a 2E + 1S configuration at 6 lpm feed flow

and results are shown in Table 1.

Table 1. Pilot Plant Comparison

CB™ Processed Organic Typical Processed Organic

IFT (dynes/cm) 33.5.9 29.2

Extract PDT – Org Cont. (seconds) 51 229

Extract PDT – Aq Cont. (seconds) 63 66

Strip PDT – Org Cont. (seconds) 50 191

Dispersion Band – Org Cont. (% of org depth) 0% 61.2%

Organic Entertainment 34% decrease –

Aqueous Entertainment 18% decrease –

Cu:Fe Transfer Ration 1032 645

07

IN PROCESS SEPARATION

You might also like

- Jacobi Tis Aquasorb Raw WaterDocument15 pagesJacobi Tis Aquasorb Raw WaterFarouk Omar100% (1)

- STP SizingDocument4 pagesSTP SizingAlexandrine Roxanne Agcaoili100% (1)

- Granular Activated Carbon and Powdered Activated CarbonDocument6 pagesGranular Activated Carbon and Powdered Activated CarbonAnjali Kothe100% (1)

- 8ch0 02 Rms 20230817Document38 pages8ch0 02 Rms 20230817Baanu Thushyanthan100% (1)

- Raw Meal Grinding Aids: Improving BurnabilityDocument3 pagesRaw Meal Grinding Aids: Improving BurnabilityfaheemqcNo ratings yet

- ActivateSludgeVS Membrane Reactor SLIDEDocument36 pagesActivateSludgeVS Membrane Reactor SLIDEsebascian100% (1)

- Design FMR HighDensityDocument2 pagesDesign FMR HighDensityPandiaraj MkNo ratings yet

- Us 40Document2 pagesUs 40pedro taquichiriNo ratings yet

- Flat Plate Membrane Bioreactor (MBR) System TrainingDocument56 pagesFlat Plate Membrane Bioreactor (MBR) System TrainingmarvilouNo ratings yet

- 1.03 MLD Sbr-Process DesignDocument4 pages1.03 MLD Sbr-Process DesignHemant KaleNo ratings yet

- 2SBR REACTOR - 550CMD-MAHA POLICE - XLSXDocument5 pages2SBR REACTOR - 550CMD-MAHA POLICE - XLSXHemant KaleNo ratings yet

- Cytec Solutions 2013 6Document1 pageCytec Solutions 2013 6aktivrudarpNo ratings yet

- Nghiên C U UmbrDocument5 pagesNghiên C U UmbrDUY TONGNo ratings yet

- 1 s2.0 S1876610213012198 MainDocument9 pages1 s2.0 S1876610213012198 Mainhajar isworoNo ratings yet

- Efficacy of Relaxation Backflushing ChemDocument9 pagesEfficacy of Relaxation Backflushing ChemGraziella NavacciNo ratings yet

- Sajjad RM PresentationDocument8 pagesSajjad RM PresentationSajjad AhmadNo ratings yet

- Lead Pollution Removal From Water Via Clinoptilolite Fixed Bed ColumnDocument3 pagesLead Pollution Removal From Water Via Clinoptilolite Fixed Bed ColumnfonsynickNo ratings yet

- Stabilization of Expansive Soil by Shallow and Deep Mixing MethodDocument6 pagesStabilization of Expansive Soil by Shallow and Deep Mixing MethodLalit ThakurNo ratings yet

- Life Cycle Assessment of A Bioreactor and An Engineered Landfill For Municipal Solid Waste TreatmentDocument23 pagesLife Cycle Assessment of A Bioreactor and An Engineered Landfill For Municipal Solid Waste TreatmentWeff JingNo ratings yet

- PosterDocument1 pagePosterAntonioMonteolivaGarcíaNo ratings yet

- MBR Towards Micropollutant RejectionDocument88 pagesMBR Towards Micropollutant RejectionShankara NarayananNo ratings yet

- Balance de Cromo en Procesamiento de Cuero PDFDocument18 pagesBalance de Cromo en Procesamiento de Cuero PDFismael ttaccaNo ratings yet

- Chrome Balance IN Leather ProcessingDocument18 pagesChrome Balance IN Leather ProcessingLuis Paz Soldán GNo ratings yet

- Stabilization of Black Cotton Soil by Using Bio-Enzymes For Pavement ConstructionDocument8 pagesStabilization of Black Cotton Soil by Using Bio-Enzymes For Pavement ConstructionRahul KumarNo ratings yet

- Stabilization of Black Cotton Soil by Using Bio-Enzymes For Pavement ConstructionDocument8 pagesStabilization of Black Cotton Soil by Using Bio-Enzymes For Pavement Constructionoil digNo ratings yet

- Adsorptive Removal of Methylene Blue Onto ZnCl2 AcDocument12 pagesAdsorptive Removal of Methylene Blue Onto ZnCl2 AcHazel Rene Gallegos MorenoNo ratings yet

- Experimental Comparison Between MBBR and Activated Sludge System For The Treatment of Municipal WastewaterDocument8 pagesExperimental Comparison Between MBBR and Activated Sludge System For The Treatment of Municipal WastewaterAssad MahmoudNo ratings yet

- Methodology For Carbon Measurement in Burned Peat: Lailan Syaufina Faculty of Forestry Ipb 2010Document24 pagesMethodology For Carbon Measurement in Burned Peat: Lailan Syaufina Faculty of Forestry Ipb 2010Nasrul IchsanNo ratings yet

- 12549-003 Andes Iron - Rheomet Draft Results Memo-Sep 11 2013Document10 pages12549-003 Andes Iron - Rheomet Draft Results Memo-Sep 11 2013RolfNo ratings yet

- Gas Flooding System ComparisonDocument2 pagesGas Flooding System ComparisontribhuNo ratings yet

- Clay Treatment in Solvet ExtractionDocument12 pagesClay Treatment in Solvet ExtractionAbrahan BVNo ratings yet

- Oxidation Case StudiesDocument71 pagesOxidation Case StudiesYassine SabekNo ratings yet

- New MBBR Carriers For High Loading ApplicationsDocument21 pagesNew MBBR Carriers For High Loading Applicationszizitro-1No ratings yet

- AMTA - 2014 - Paper - Kim-Hak - LG Chem LOW PRESSURE APPLICATIONS OF THIN FILM NANOCOMPOSITE (TFN) MEMBRANESDocument8 pagesAMTA - 2014 - Paper - Kim-Hak - LG Chem LOW PRESSURE APPLICATIONS OF THIN FILM NANOCOMPOSITE (TFN) MEMBRANESYoo BoyyooNo ratings yet

- Article Li PUR Foam 2012Document2 pagesArticle Li PUR Foam 2012vytoNo ratings yet

- Fly Ash Geopolymer Pervious Concrete: A Study of Durability Performance Under Cold-Climate ConditionsDocument7 pagesFly Ash Geopolymer Pervious Concrete: A Study of Durability Performance Under Cold-Climate ConditionsRosario CornejoNo ratings yet

- Coagulation Adsorption Ultrafiltration For Wastewater Treatment and Reuse - 2000 - DesalinationDocument8 pagesCoagulation Adsorption Ultrafiltration For Wastewater Treatment and Reuse - 2000 - DesalinationAlvaro HueteNo ratings yet

- .A Study On Concrete Mixed With Rice Husk AshDocument7 pages.A Study On Concrete Mixed With Rice Husk Ash18103045 HICET - STUDENT CIVILNo ratings yet

- Magnasoft FluidDocument7 pagesMagnasoft FluidbobbymayaaNo ratings yet

- CHPL332 Test 1 - 1-2021Document2 pagesCHPL332 Test 1 - 1-2021sinothandombili4No ratings yet

- BioRes 14-4-7869 Xue LLH Struc Changes Lignin Soda Delignif Pollution Load 15912Document17 pagesBioRes 14-4-7869 Xue LLH Struc Changes Lignin Soda Delignif Pollution Load 15912Elaine PolilloNo ratings yet

- ICPS Presentation-ParthaDocument38 pagesICPS Presentation-ParthaMohebul AhsanNo ratings yet

- Introduction To MBR O-1141Document25 pagesIntroduction To MBR O-1141Madhusudanan78No ratings yet

- Interbond 201 Temperate Eng A4 20171106Document4 pagesInterbond 201 Temperate Eng A4 20171106Purwanto ritzaNo ratings yet

- Room Temperature Prevulcanized NR Latex Compounds FOR BETTER LATEX-Based ProductsDocument8 pagesRoom Temperature Prevulcanized NR Latex Compounds FOR BETTER LATEX-Based Productsรอคนบนฟ้า ส่งใครมาให้ สักคนNo ratings yet

- Comparative Study of Conventional Concrete With Micropozz Based Geopolymer Concrete Along With GGBSDocument3 pagesComparative Study of Conventional Concrete With Micropozz Based Geopolymer Concrete Along With GGBSVivek PatvaNo ratings yet

- Effect of - Irradiation On The Properties of Rubber-Based Conductive Blend CompositesDocument10 pagesEffect of - Irradiation On The Properties of Rubber-Based Conductive Blend CompositesDr. Ahmed Abdel-HakimNo ratings yet

- BCB Cyclotene 3000 RevaDocument8 pagesBCB Cyclotene 3000 RevaaliflailasurumiNo ratings yet

- 1 s2.0 S0011916402007592 MainDocument5 pages1 s2.0 S0011916402007592 Mainmrsuriyaa63No ratings yet

- Influence of CDW Recycled Aggregate On Drying Shrinkage of MortarDocument5 pagesInfluence of CDW Recycled Aggregate On Drying Shrinkage of MortarJotica SuárezNo ratings yet

- 15.effect of Partial Replacement of Cement WithDocument11 pages15.effect of Partial Replacement of Cement WithIsrael VenkatNo ratings yet

- Clouzot 2010Document5 pagesClouzot 2010ricardo.abejonNo ratings yet

- Energy Production From Wastewater: Barış ÇALLIDocument30 pagesEnergy Production From Wastewater: Barış ÇALLIEslam ibrahimNo ratings yet

- Srchae@eng - Hokudai.ac - JP Yoshiw@eng - Hokudai.ac - JPDocument4 pagesSrchae@eng - Hokudai.ac - JP Yoshiw@eng - Hokudai.ac - JPAnonymous aYmVPmdcLjNo ratings yet

- MEJSRZinali 1Document9 pagesMEJSRZinali 1korope8705No ratings yet

- Data Sheet HFE-71DEDocument4 pagesData Sheet HFE-71DEsshaffer_9No ratings yet

- TAHIRI - Biogas - Boues STEP - PARTIE4 - 2021Document24 pagesTAHIRI - Biogas - Boues STEP - PARTIE4 - 2021ELGUERCHENo ratings yet

- Case Study 3Document49 pagesCase Study 3eze_atn_vNo ratings yet

- Treatment of Tannery Effluent by Tunisian Clay: Colloid and Surface ScienceDocument7 pagesTreatment of Tannery Effluent by Tunisian Clay: Colloid and Surface ScienceJuan Carlos ZavaletaNo ratings yet

- Bentonite Functionalised with 2-(3-(2-aminoethylthio)propylthio)ethanamine (AEPE) for the Removal of Hg(II) from Wastewaters: Synthesis, Characterisation and Hg(II) Adsorption PropertiesFrom EverandBentonite Functionalised with 2-(3-(2-aminoethylthio)propylthio)ethanamine (AEPE) for the Removal of Hg(II) from Wastewaters: Synthesis, Characterisation and Hg(II) Adsorption PropertiesNo ratings yet

- Progress in Nuclear Magnetic Resonance Spectroscopy: Volume 14From EverandProgress in Nuclear Magnetic Resonance Spectroscopy: Volume 14No ratings yet

- MSP300 0078 Conica 5Document1 pageMSP300 0078 Conica 5aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-65Document1 page612431362-200928-MSP300-0078-CONICA-65aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-61Document1 page612431362-200928-MSP300-0078-CONICA-61aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-36Document1 page612431362-200928-MSP300-0078-CONICA-36aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-67Document1 page612431362-200928-MSP300-0078-CONICA-67aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-43Document1 page612431362-200928-MSP300-0078-CONICA-43aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-52Document1 page612431362-200928-MSP300-0078-CONICA-52aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-40Document1 page612431362-200928-MSP300-0078-CONICA-40aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-49Document1 page612431362-200928-MSP300-0078-CONICA-49aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-48Document1 page612431362-200928-MSP300-0078-CONICA-48aktivrudarpNo ratings yet

- MSP300 0078 Conica 23Document1 pageMSP300 0078 Conica 23aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-39Document1 page612431362-200928-MSP300-0078-CONICA-39aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-45Document1 page612431362-200928-MSP300-0078-CONICA-45aktivrudarpNo ratings yet

- MSP300 0078 Conica 21Document1 pageMSP300 0078 Conica 21aktivrudarpNo ratings yet

- MSP300 0078 Conica 19Document1 pageMSP300 0078 Conica 19aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-50Document1 page612431362-200928-MSP300-0078-CONICA-50aktivrudarpNo ratings yet

- MSP300 0078 Conica 3Document1 pageMSP300 0078 Conica 3aktivrudarpNo ratings yet

- MSP300 0078 Conica 2Document1 pageMSP300 0078 Conica 2aktivrudarpNo ratings yet

- MSP300 0078 Conica 4Document1 pageMSP300 0078 Conica 4aktivrudarpNo ratings yet

- Cytec Solutions 2013 45Document1 pageCytec Solutions 2013 45aktivrudarpNo ratings yet

- Cytec Solutions 2013 46Document1 pageCytec Solutions 2013 46aktivrudarpNo ratings yet

- Cytec Solutions 2013 50Document1 pageCytec Solutions 2013 50aktivrudarpNo ratings yet

- Cytec Solutions 2013 42Document1 pageCytec Solutions 2013 42aktivrudarpNo ratings yet

- Cytec Solutions 2013 23Document1 pageCytec Solutions 2013 23aktivrudarpNo ratings yet

- Cytec Solutions 2013 39Document1 pageCytec Solutions 2013 39aktivrudarpNo ratings yet

- Cytec Solutions 2013 35Document1 pageCytec Solutions 2013 35aktivrudarpNo ratings yet

- Cytec Solutions 2013 18Document1 pageCytec Solutions 2013 18aktivrudarpNo ratings yet

- Cytec Solutions 2013 34Document1 pageCytec Solutions 2013 34aktivrudarpNo ratings yet

- Cytec Solutions 2013 31Document1 pageCytec Solutions 2013 31aktivrudarpNo ratings yet

- Sample PDF Chemistry 1 Challenger Book Neet Ug Jee MainDocument30 pagesSample PDF Chemistry 1 Challenger Book Neet Ug Jee MainPratyusha DasNo ratings yet

- Solvent-Free Methods in NanocatalysisDocument347 pagesSolvent-Free Methods in NanocatalysisojodeimprentaNo ratings yet

- Wo3 2Document6 pagesWo3 2elvannrmnNo ratings yet

- 1.05 HAARIBOL - KLOREEN - MSDS Ver.3Document11 pages1.05 HAARIBOL - KLOREEN - MSDS Ver.3bil ishlahiNo ratings yet

- Cambridge IGCSE ™: Chemistry 0620/43Document11 pagesCambridge IGCSE ™: Chemistry 0620/43Jahangir KhanNo ratings yet

- 1 Corrosion Prevention by Protective Coatings (Munger)Document19 pages1 Corrosion Prevention by Protective Coatings (Munger)Gagan MehandirattaNo ratings yet

- Resumiendo STEWART, Acido-Base 12Document4 pagesResumiendo STEWART, Acido-Base 12GiovannaNo ratings yet

- B-DopingDocument37 pagesB-DopingMalik IrfanNo ratings yet

- Transition Metal-Catalyzed Conversion of Aldehydes To KetonesDocument20 pagesTransition Metal-Catalyzed Conversion of Aldehydes To KetonesjavasoloNo ratings yet

- Ejercicios Entrega Tema 5Document4 pagesEjercicios Entrega Tema 5Andrea Garcia EstellesNo ratings yet

- 12th ChemistryDocument36 pages12th Chemistrysri mathiNo ratings yet

- Astm E1473 22Document12 pagesAstm E1473 22Dip MNo ratings yet

- SDS-LB-52U-GBDocument20 pagesSDS-LB-52U-GBGristio PratamaNo ratings yet

- Lab Act 4Document9 pagesLab Act 4VALERIE JOY CATUDIONo ratings yet

- Gradeviiisas V II Sindhi CompressedDocument44 pagesGradeviiisas V II Sindhi Compressedmrsindhi838No ratings yet

- Isolobal AnalogyDocument3 pagesIsolobal AnalogyShantanu MawaskarNo ratings yet

- Angami Is A Folk Dance of NagalandDocument2 pagesAngami Is A Folk Dance of NagalandKiran MittalNo ratings yet

- SEMESTER TEST 1 - MEMODocument7 pagesSEMESTER TEST 1 - MEMOkyte.No ratings yet

- YEAR 7 -8 QUIZ 2021Document12 pagesYEAR 7 -8 QUIZ 2021kirtiNo ratings yet

- G.O.C & Isomerism - DPP 04 (Of Lec 07) - (Arjuna JEE 2023)Document3 pagesG.O.C & Isomerism - DPP 04 (Of Lec 07) - (Arjuna JEE 2023)jeemainsmaterial97No ratings yet

- Unit 20 - Petrochemicals & Polymers: 20A 1. Common Fossil FuelsDocument9 pagesUnit 20 - Petrochemicals & Polymers: 20A 1. Common Fossil FuelsanayNo ratings yet

- DEVITRIFICATION SCRIPTDocument10 pagesDEVITRIFICATION SCRIPTPerlievic TesoroNo ratings yet

- LAS 1-5 TransesDocument2 pagesLAS 1-5 TransesLyna FloridaNo ratings yet

- Water & Sulphur SystemDocument11 pagesWater & Sulphur Systemhoxemib349No ratings yet

- Research Paper On AdsorptionDocument6 pagesResearch Paper On Adsorptiongz98szx1100% (1)

- 1 s2.0 S0360319920345109 MainDocument16 pages1 s2.0 S0360319920345109 MainMihirduttaNo ratings yet

- Mole Concept _ DPP 05 (Extra DPP) __ Prayas JEE 2025Document3 pagesMole Concept _ DPP 05 (Extra DPP) __ Prayas JEE 2025mrmkofficial73No ratings yet

- EXP CHEM F5 - ACT 1d - Displacement of HalogenDocument3 pagesEXP CHEM F5 - ACT 1d - Displacement of HalogenRoszamzuliani SharipuddinNo ratings yet

- Large-Scale Syntheses of 2D Materials Flash Joule HeatingDocument28 pagesLarge-Scale Syntheses of 2D Materials Flash Joule HeatingkaamilNo ratings yet