Professional Documents

Culture Documents

Cytec Solutions 2013 47

Cytec Solutions 2013 47

Uploaded by

aktivrudarpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cytec Solutions 2013 47

Cytec Solutions 2013 47

Uploaded by

aktivrudarpCopyright:

Available Formats

Solvent Extraction, Mineral Processing and Alumina Processing

Scale Controlling Chemical Additives for Phosphoric Acid Production Plants

54.0

53.5

53.0

Current Load (Amps)

52.5

52.0

51.5

51.0

50.5

50.0

0 200 400 600 800 1000

Cycle Time (hours)

55

50

45

Flow Rate (m3/hr)

40

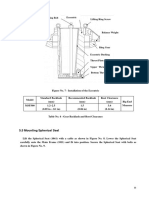

35 FIGURE 7:

30 Data for current load on

recirculating pump and feed

25 acid flow rate for extended

20 evaluation of PHOSFLOW®

0 200 400 600 800 1000

Cycle Time (hours)

The data for the process parameters show a successful their average cycle time from historical data of 486 hours so

extension of the cycle time without as significant degradation a mid-cycle wash was effectively eliminated.

in heat transfer coefficient, feed acid flow rate, or increase

in pump current load. In the case of valve position, it can When the heat exchanger was opened and inspected, it

be observed that the line was not cleaned out sufficiently was observed that only 66 tubes were plugged compared

from the start and that it had already developed a blockage. to a historical average of 150 tubes for a 3 week cycle.

Nevertheless, the antiscalant allowed for production level Additionally, the cleanout time using a high pressure

flow rates for a significant period of time before the line was water lance took approximately 2.5 hours compared with

washed. No additional line cleanouts were necessary during a historical average of 15. The operators observed that

the remainder of the trial which lasted an additional 700 the scale was very soft and easy to remove from the heat

hours past the first cleanout. This is significantly more than exchanger tube walls.

3. Conclusion

The plant trial results demonstrate that Cytec Industries Figures 8 and 9 summarize the results of the three trials and

PHOSFLOW® antiscalant technology provided a significant new process option available by applying the antiscalant. The

benefit in terms of controlling scale buildup within process trials were considered a success and are leading to further

pipelines and heat exchangers of a phosphoric acid plant. evaluations of the technology at this customer’s plant and

others to help establish the robustness of the technology.

47

IN PROCESS SEPARATION

You might also like

- Marine Trans Owners Manual 1016313 RevH 0116 CDDocument200 pagesMarine Trans Owners Manual 1016313 RevH 0116 CDMarco Aurelio BarbosaNo ratings yet

- 1218 Instrument Testing & Calibration Procedure NTGFDPDocument50 pages1218 Instrument Testing & Calibration Procedure NTGFDPTaha Hasan100% (1)

- Learner's Material: ScienceDocument27 pagesLearner's Material: ScienceCarlz BrianNo ratings yet

- Astm B 328Document4 pagesAstm B 328martin andolini100% (1)

- Analysis of Fan BladeDocument80 pagesAnalysis of Fan BladeShripad PachputeNo ratings yet

- Terry M 2008 Stalking The Wild Lop Hop HoraDocument23 pagesTerry M 2008 Stalking The Wild Lop Hop HorasudamornNo ratings yet

- Auto Reform Ad orDocument17 pagesAuto Reform Ad orAlan Flores RamirezNo ratings yet

- Computer-Aided Design of Fluid Mixing Equipment: A Guide and Tool for Practicing EngineersFrom EverandComputer-Aided Design of Fluid Mixing Equipment: A Guide and Tool for Practicing EngineersRating: 5 out of 5 stars5/5 (1)

- Flotation Circuit Simulation in ModernizationsDocument8 pagesFlotation Circuit Simulation in ModernizationsmecarrascogNo ratings yet

- Cytec Solutions 2013 46Document1 pageCytec Solutions 2013 46aktivrudarpNo ratings yet

- Cytec Solutions 2013 45Document1 pageCytec Solutions 2013 45aktivrudarpNo ratings yet

- Mitigation of Heat Exchanger Fouling PDFDocument5 pagesMitigation of Heat Exchanger Fouling PDFraymund angelo Memije100% (1)

- Study: New Logic ResearchDocument4 pagesStudy: New Logic ResearchSathishkumarNo ratings yet

- Design and Scaleup of Mixer Settlers For The DAPEX Solvent Extraction ProcessDocument76 pagesDesign and Scaleup of Mixer Settlers For The DAPEX Solvent Extraction Processdavidgaro12No ratings yet

- Mod IV FCCDocument35 pagesMod IV FCCdonald55555No ratings yet

- Vane Pump Article WearDocument7 pagesVane Pump Article WearDirk DreesNo ratings yet

- An Integrated Study of Poor Intake Conditions and Its Effect On A Pumping Station PerformanceDocument11 pagesAn Integrated Study of Poor Intake Conditions and Its Effect On A Pumping Station Performancedalia elgazzarNo ratings yet

- Does Your Flowline System Put Your Facility Under StressDocument13 pagesDoes Your Flowline System Put Your Facility Under StressasozhyanNo ratings yet

- Offshore Flow AssuranceDocument2 pagesOffshore Flow AssurancealiNo ratings yet

- Degassing Station DataDocument8 pagesDegassing Station DataBlack & WhiteNo ratings yet

- Control Loop Performance: Part 2: Open-Loop Response Testing Improves ProcessDocument5 pagesControl Loop Performance: Part 2: Open-Loop Response Testing Improves ProcessbariNo ratings yet

- Fachaufsatz 2014 02-gbDocument6 pagesFachaufsatz 2014 02-gbGoutham KSNo ratings yet

- Ind. Eng. Chem. Res. 2008 - 47 - 850-866Document17 pagesInd. Eng. Chem. Res. 2008 - 47 - 850-866Lindsey BondNo ratings yet

- Modeling The Complex Chemical Reactions and Mass T PDFDocument6 pagesModeling The Complex Chemical Reactions and Mass T PDFMateus GalvãoNo ratings yet

- HSEQ SESI QSOP 208 Ballout Chemical StimulationDocument6 pagesHSEQ SESI QSOP 208 Ballout Chemical StimulationDoni KurniawanNo ratings yet

- Control Loop Performance: Part 2: Open-Loop Response Testing Improves ProcessDocument5 pagesControl Loop Performance: Part 2: Open-Loop Response Testing Improves ProcessbariNo ratings yet

- Design of An Experimental System For Wear Assessment of Slurry PumpsDocument7 pagesDesign of An Experimental System For Wear Assessment of Slurry Pumps최승원No ratings yet

- Lab 4 (Production of Acetic Anhydride)Document10 pagesLab 4 (Production of Acetic Anhydride)afnan_lion94No ratings yet

- Selecting Valves For Pressure Swing AdsorptionDocument4 pagesSelecting Valves For Pressure Swing Adsorptionmarco8garciaNo ratings yet

- Business and Process ImprovmenttDocument15 pagesBusiness and Process ImprovmenttHamed MasaodNo ratings yet

- Lab 4 SimulationDocument8 pagesLab 4 SimulationaziziNo ratings yet

- 00 - Dri Operations Update To Damam Delegation - Aak - 04102010Document27 pages00 - Dri Operations Update To Damam Delegation - Aak - 04102010SalmanEjazNo ratings yet

- Simulador Qrod v3 para Bombeo MecanicoDocument3 pagesSimulador Qrod v3 para Bombeo MecanicobeymarNo ratings yet

- Torres 2013Document6 pagesTorres 2013Machine DesignNo ratings yet

- Barometric Column Filtration V/s Filtrate Pump Filtration Comparison: Case StudyDocument8 pagesBarometric Column Filtration V/s Filtrate Pump Filtration Comparison: Case StudyEusebio Castillo MejiaNo ratings yet

- Ponce Elec4 Ulo3Document6 pagesPonce Elec4 Ulo3Miguel Jesse Rex PonceNo ratings yet

- Afobroilereemreport2012draftappc PDFDocument978 pagesAfobroilereemreport2012draftappc PDFbajrangNo ratings yet

- Processes 09 01538 v2Document14 pagesProcesses 09 01538 v2camilo.gonzalez.pozoNo ratings yet

- For UloDocument14 pagesFor UloMiguel Jesse Rex PonceNo ratings yet

- 104SE-Combining New and Old Technologies - Inlet Diffuser and Random Packing Dramatically Improve Reactor PerformanceDocument10 pages104SE-Combining New and Old Technologies - Inlet Diffuser and Random Packing Dramatically Improve Reactor PerformanceSHINo ratings yet

- Manual Controle de Qualidade PDFDocument7 pagesManual Controle de Qualidade PDFRogerio Nunes MarinhoNo ratings yet

- 1986 - Chilvers - Measuring Vacuum Pump PerformanceDocument5 pages1986 - Chilvers - Measuring Vacuum Pump PerformanceNARAYANA RAO PUPPALANo ratings yet

- AcumulatorDocument6 pagesAcumulatormaiconNo ratings yet

- Modern Total Well Management PDFDocument14 pagesModern Total Well Management PDFXXXXNo ratings yet

- PSG PumpPerformanceDocument6 pagesPSG PumpPerformanceLuis Meza ArevaloNo ratings yet

- Optimo Control Valvula ControlDocument6 pagesOptimo Control Valvula ControlJOSE MARTIN MORA RIVEROSNo ratings yet

- Primavac System - 2Document36 pagesPrimavac System - 2UmairNo ratings yet

- Calibration of Peristaltic Pumps - Lab 1Document12 pagesCalibration of Peristaltic Pumps - Lab 1mmccomas08100% (2)

- Development of Emission Factors From API 622 - 624 Test Data - Buzz Harris - Bronson PateDocument23 pagesDevelopment of Emission Factors From API 622 - 624 Test Data - Buzz Harris - Bronson PateratnakarpatilNo ratings yet

- Hydraulic BenchDocument18 pagesHydraulic Benchchesca marasigan100% (1)

- Sciencedirect: The Use of Advanced Process Controls in A Phosphoric Acid ReactorDocument7 pagesSciencedirect: The Use of Advanced Process Controls in A Phosphoric Acid ReactorJavier Alejandro RodriguezNo ratings yet

- Cooling System ArticleDocument16 pagesCooling System ArticleRiski Nalendra SukmaNo ratings yet

- Algeria in Amenas Project: Rotating Equipment Job PlanDocument2 pagesAlgeria in Amenas Project: Rotating Equipment Job PlanKama Bena BenarousNo ratings yet

- Technical Basis For Scaling of Air Sparger Systems For Mixing in Non Newtonian SlurriesDocument149 pagesTechnical Basis For Scaling of Air Sparger Systems For Mixing in Non Newtonian SlurriesIlker CetinNo ratings yet

- Lab 4 Production of Acetic AnhydrideDocument9 pagesLab 4 Production of Acetic AnhydrideFirdaus MohamadNo ratings yet

- Fakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakaDocument17 pagesFakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakasyukzzNo ratings yet

- Introduction To Tunnel and Metro Ventilation (2022)Document40 pagesIntroduction To Tunnel and Metro Ventilation (2022)ayaliyaenterprisesNo ratings yet

- Uitm Lab Report Plug Flow ReactorDocument15 pagesUitm Lab Report Plug Flow ReactorNabilah SyaheeraNo ratings yet

- Batstone (2006) Industrial Applications of The IWA Anaerobic Digestion Model No. 1 (ADM1)Document8 pagesBatstone (2006) Industrial Applications of The IWA Anaerobic Digestion Model No. 1 (ADM1)Juan Jose SossaNo ratings yet

- SPE 29259 An Innovative Model For Drilling Fluid HydraulicsDocument17 pagesSPE 29259 An Innovative Model For Drilling Fluid HydraulicsmucoNo ratings yet

- Flownex Profile PDFDocument4 pagesFlownex Profile PDFSrashmiNo ratings yet

- 06 Erling Steinnes FramoDocument28 pages06 Erling Steinnes FramoMyoung ChoiNo ratings yet

- Advanced Steam System Optimization Program PDFDocument5 pagesAdvanced Steam System Optimization Program PDFRobert MontoyaNo ratings yet

- Eaton Vickers PVH Variable Axial Piston Pump: Industrial Applications Mobile ApplicationsDocument9 pagesEaton Vickers PVH Variable Axial Piston Pump: Industrial Applications Mobile ApplicationsPedro LandazuriNo ratings yet

- Continuous Pickling Line Process Efficiency Achievements at ArvediDocument7 pagesContinuous Pickling Line Process Efficiency Achievements at Arvedijose santiago vazquezNo ratings yet

- PumpDocument15 pagesPumpmohammedNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-61Document1 page612431362-200928-MSP300-0078-CONICA-61aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-65Document1 page612431362-200928-MSP300-0078-CONICA-65aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-36Document1 page612431362-200928-MSP300-0078-CONICA-36aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-67Document1 page612431362-200928-MSP300-0078-CONICA-67aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-49Document1 page612431362-200928-MSP300-0078-CONICA-49aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-40Document1 page612431362-200928-MSP300-0078-CONICA-40aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-48Document1 page612431362-200928-MSP300-0078-CONICA-48aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-52Document1 page612431362-200928-MSP300-0078-CONICA-52aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-39Document1 page612431362-200928-MSP300-0078-CONICA-39aktivrudarpNo ratings yet

- MSP300 0078 Conica 3Document1 pageMSP300 0078 Conica 3aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-43Document1 page612431362-200928-MSP300-0078-CONICA-43aktivrudarpNo ratings yet

- MSP300 0078 Conica 19Document1 pageMSP300 0078 Conica 19aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-50Document1 page612431362-200928-MSP300-0078-CONICA-50aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-45Document1 page612431362-200928-MSP300-0078-CONICA-45aktivrudarpNo ratings yet

- MSP300 0078 Conica 21Document1 pageMSP300 0078 Conica 21aktivrudarpNo ratings yet

- MSP300 0078 Conica 23Document1 pageMSP300 0078 Conica 23aktivrudarpNo ratings yet

- MSP300 0078 Conica 5Document1 pageMSP300 0078 Conica 5aktivrudarpNo ratings yet

- MSP300 0078 Conica 4Document1 pageMSP300 0078 Conica 4aktivrudarpNo ratings yet

- MSP300 0078 Conica 2Document1 pageMSP300 0078 Conica 2aktivrudarpNo ratings yet

- Cytec Solutions 2013 39Document1 pageCytec Solutions 2013 39aktivrudarpNo ratings yet

- Cytec Solutions 2013 42Document1 pageCytec Solutions 2013 42aktivrudarpNo ratings yet

- Cytec Solutions 2013 50Document1 pageCytec Solutions 2013 50aktivrudarpNo ratings yet

- Cytec Solutions 2013 35Document1 pageCytec Solutions 2013 35aktivrudarpNo ratings yet

- Cytec Solutions 2013 31Document1 pageCytec Solutions 2013 31aktivrudarpNo ratings yet

- Cytec Solutions 2013 34Document1 pageCytec Solutions 2013 34aktivrudarpNo ratings yet

- Cytec Solutions 2013 23Document1 pageCytec Solutions 2013 23aktivrudarpNo ratings yet

- Cytec Solutions 2013 6Document1 pageCytec Solutions 2013 6aktivrudarpNo ratings yet

- Cytec Solutions 2013 18Document1 pageCytec Solutions 2013 18aktivrudarpNo ratings yet

- Physical and Chemical PropertiesDocument42 pagesPhysical and Chemical PropertiesAndrejSukoraNo ratings yet

- RRL SteelDocument3 pagesRRL SteelSamantha ManimtimNo ratings yet

- Com Tran Ther Roto - 2012Document44 pagesCom Tran Ther Roto - 2012Mohsen SaidiNo ratings yet

- Introduction To Plastic: Plastic Is A Material Consisting of Any of A Wide Range ofDocument22 pagesIntroduction To Plastic: Plastic Is A Material Consisting of Any of A Wide Range ofRavi kumar YeluruNo ratings yet

- PECVD Coating On Elastomer SealsDocument19 pagesPECVD Coating On Elastomer SealsAndrew SpiteriNo ratings yet

- Cosme Lab3 Mens Toiletries Group 1Document54 pagesCosme Lab3 Mens Toiletries Group 1just loveNo ratings yet

- Zn-Containing Ionic Liquids For The Extractive Denitrogenation of A Model Oil - A Mechanistic ConsiderationDocument7 pagesZn-Containing Ionic Liquids For The Extractive Denitrogenation of A Model Oil - A Mechanistic ConsiderationJohnSmithNo ratings yet

- Research Paper Example Bioplastics Bosepo 2013 PDFDocument29 pagesResearch Paper Example Bioplastics Bosepo 2013 PDF잔나라치No ratings yet

- Lecture 1 Bacterial StructureDocument38 pagesLecture 1 Bacterial StructureAyat MostafaNo ratings yet

- Wat 14Document48 pagesWat 14kky chanNo ratings yet

- 703 1291 1 PBDocument8 pages703 1291 1 PBveereshchiremathNo ratings yet

- Range Sulfur Batubara KalimantanDocument5 pagesRange Sulfur Batubara KalimantanR Kibik ShtNo ratings yet

- Yemigeba DocumentDocument78 pagesYemigeba DocumentDemelashNo ratings yet

- Inglés Técnico para Profesionales Metalúrgicos Technical English For MetallurgistsDocument5 pagesInglés Técnico para Profesionales Metalúrgicos Technical English For MetallurgistspirometalNo ratings yet

- 4.2 Specific Heat CapacityDocument25 pages4.2 Specific Heat CapacityNoratiqah Binti Mohd AminNo ratings yet

- LIPIDSDocument2 pagesLIPIDSAucel Jade ZafraNo ratings yet

- Chemicals For Cooling Watertreatment: KURITA F-4900Document1 pageChemicals For Cooling Watertreatment: KURITA F-4900bestyanuarNo ratings yet

- What Is The Difference Between FKM and EPDM - FKM Vs EPDMDocument4 pagesWhat Is The Difference Between FKM and EPDM - FKM Vs EPDMMAMI RAKOTOMAHANINANo ratings yet

- Carten Et Al 1988 Henderson Porphyry USTsDocument31 pagesCarten Et Al 1988 Henderson Porphyry USTsGuillermo Hermoza MedinaNo ratings yet

- Gas Turbine Spare PartsDocument16 pagesGas Turbine Spare PartsMorgen GumpNo ratings yet

- C S C U S A: Ontainment Ystem Hallenges Nder Evere CcidentsDocument48 pagesC S C U S A: Ontainment Ystem Hallenges Nder Evere CcidentsSiddhartha GaubaNo ratings yet

- Bio Chem Prelims Hand OutsDocument18 pagesBio Chem Prelims Hand Outsnina grace joyNo ratings yet

- Water: Shield Polyethylene Piping SystemDocument8 pagesWater: Shield Polyethylene Piping SystemRajiv R'n'bNo ratings yet

- One Way SlabDocument2 pagesOne Way SlabpolarisNo ratings yet