Professional Documents

Culture Documents

BK91-1344-INF-856-PIP-MR-000Material Requisition For Pipes, Valves and Not-Metallic Pipes

BK91-1344-INF-856-PIP-MR-000Material Requisition For Pipes, Valves and Not-Metallic Pipes

Uploaded by

SudeepDPoojaryOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BK91-1344-INF-856-PIP-MR-000Material Requisition For Pipes, Valves and Not-Metallic Pipes

BK91-1344-INF-856-PIP-MR-000Material Requisition For Pipes, Valves and Not-Metallic Pipes

Uploaded by

SudeepDPoojaryCopyright:

Available Formats

Doc No.

BK91-1344-INF-856-PIP-MR-0001

Material Requisition for Pipes, Valves and Not-metallic pipes Revision A

Date of Issue 26-Feb-24

Page No. 1 of 4

Provision of EPC for New Fire Training Ground and Props

Material Requisition for Pipes, Valves and Not-metallic pipes

Document No: BK91-1344-INF-856-PIP-MR-0001

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 2

Date: 06.07.2021

A ISSUED FOR APPROVAL 26-Feb-23 AB KA SD

REV. DESCRIPTION DATE PREP’D CHK’D REV’D

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 2

Date: 06.07.2021

Doc No. BK91-1344-INF-856-ELE-MR-0001

Material Requisition for Pipes, Valves and Not-metallic pipes Revision A

Date of Issue 20-Feb-24

Page No. 2 of 4

REV DATE REVISION DETAILS

A 26-02-2024 First Issue

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 2

Date: 06.07.2021

REQUISITION REQUISITION Material Requisition for Pipes, Valves and

CLIENT / PROJECT: Kuwait Energy Basra Limited (KEBL) BK91-1344-INF-856-PIP-MR-0001 DATE RAISED 27/02/2024 Page 3 of 4

NUMBER: DESCRIPTION: Not-metallic pipes

Provision of EPC for New Fire Training

CONTRACT No: BLK9-IRQ-SF-CON-1014 Project Title: SEE ATTACHED REQUIRED DELIVERY DATE: 13th April 2024

Ground & Props

(x- AS APPLICABLE) EXPEDITING: (PLACE X IN FIELD

PROJECT No: 1344 SITE LOCATION: BLOCK 9 BOX FOR APPLICABLE TYPE

DATA SHEETS x REQUIRED) DESK

TASK No: WORKPACK / WORK SDRL EQUIPMENT CRITICALITY: Yes

NA BLK9-IRQ-SF-CON-1014

ORDER: OTHERS

INSPECTION

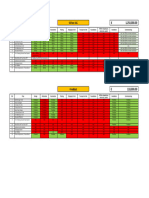

ITEM Part no QTY UOM LINE DESCRIPTION CERTIFICATION CODE LINE COST TOTAL COST

LEVEL

1 PIPE

1.1 744 m 6" PIPE API spec 15LE, HDPE, PE 100, PN16, SDR11, ISO4427, UVPROTECTED

1.2 108 m 6" PIPE SCH 40 ASME B36.10M BE ASTM A 106 Gr. B HDG SMLS GALVANIZED

1.3 108 m 3" PIPE SCH 40 ASME B36.10M BE ASTM A 106 Gr. B SMLS

1.4 156 m 2" PIPE SCH 40 ASME B36.10M BE ASTM A 106 Gr. B SMLS

2 FITTINGS

2.1 3 EA WELDOLET , 3"x3/4" WELDOLET SCH 40 x 80 MSS SP-97 ASTM A105

2.3 14 EA 6" ELBOW 90 DEG API SPEC 15LE, HDPE, PE 100, PN16, SDR11, ISO4427, UV PROTECTED

2.4 7 EA 6" ELBOW 90 DEG SCH 40 ASME B16.9 BW ASTM A234 Gr.WPB HDG SMLS GALVANIZED

2.5 4 EA 3" ELBOW 90 DEG SCH 40 ASME B16.9 BW ASTM A234 Gr.WPB SMLS

2.6 45 EA 2" ELBOW 90 DEG SCH 40 ASME B16.9 BW ASTM A234 Gr.WPB SMLS

2.7 3 EA 3"x2" CONCENTRIC REDUCER SCH 40 ASME B16.9 BW ASTM A234 Gr.WPB

2.8 1 EA 8"x6" ECCENTRIC REDUCER API SPEC 15LE, HDPE, PE 100, PN16, SDR11, ISO4427, UV PROTECTED

2.9 9 EA 3" x 2" ECCENTRIC REDUCER SCH 40 ASME B16.9 BW ASTM A234 Gr.WPB

2.10 4 EA 3" x 1.5" ECCENTRIC REDUCER SCH 40 ASME B16.9 BW ASTM A234 Gr.WP

2.11 6 EA 2"x1" ECCENTRIC REDUCER SCH 40 ASME B16.9 BW ASTM A234 Gr.WPB SMLS

2.12 1 EA 8" EQUAL TEE API spec 15LE, HDPE, PE 100, PN16, SDR11, ISO4427, UV PROTECTED

2.13 4 EA 6" EQUAL TEE SCH 40 ASME B16.9 BW ASTM A234 Gr.WPB HDG SMLS (GALVANIZED)

2.14 7 EA 3" EQUAL TEE SCH 40 ASME B16.9 BW ASTM A234 Gr.WPB SMLS

2.15 7 EA 2" EQUAL TEE SCH 40 ASME B16.9 BW ASTM A234 Gr.WPB SMLS

3 FLANGES

6" FLANGE ADAPTOR RATING #150, HDPE, PE 100, PN16, SDR11, ISO4427, UV PROTECTED SUITABLE FOR

3.1 4 EA

FLANGE CONNECTION TO ASMEB16.5

3.2 1 EA 6" FLANGE WELD NECK SCH 40 ASME B16.5 FF ASTM A105 + HDG (GALVANIZED)

3.3 6 EA 6" FLANGE WELD NECK SCH 40 ASME B16.5 RF ASTM A105 + HDG (GALVANIZED)

3.4 9 EA 3" FLANGE WELD NECK SCH 40 ASME B16.5 RF ASTM A105

3.5 42 EA 2" FLANGE WELD NECK SCH 40 ASME B16.5 RF ASTM A105

3.6 12 EA 1.5" FLANGE WELD NECK SCH 40 ASME B16.5 RF ASTM A105

3.7 12 EA 1" FLANGE WELD NECK SCH 40 ASME B16.5 RF ASTM A105

3.8 4 EA 3/4" FLANGE WELD NECK SCH 40 ASME B16.5 RF ASTM A105

3.9 2 EA 6" FLANGE BLIND ASME B16.5 RF ASTM A105 + HDG (GALVANIZED)

3.10 1 EA 3" FLANGE BLIND ASME B16.5 RF ASTM A105

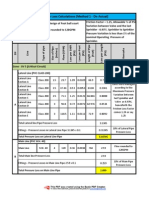

4 VALVES

GA-1G32F - 6" GATE VALVE (WEDGE GATE) ,150 LB FF, BODY MATERIAL-CARBON STEEL ASTM A216 WCB,

TRIM MATERIAL-GATE: ASTM A217 CA15, SEAT/SEAL: ASTM A182 F6A /HF, STEM: ASTM A182 F6A,

4.1 2 EA

HANDWHEEL OPERATION, BODY CONSTRUCTION- BOLTED BONNET, RISING STEM OUTSIDE

SCREW AND YOKE TRIM CONSTRUCTION-WEDGE TYPE

GA-1A13 - 3" GATE VALVE (WEDGE GATE) ,150 LB RF, BODY MATERIAL-CARBON STEEL ASTM A216 WCB,

TRIM MATERIAL-GATE: ASTM A217 CA15, SEAT/SEAL: ASTM A182 F6A /HF, STEM: ASTM A182 F6A,

4.2 1 EA

HANDWHEEL OPERATION, BODY CONSTRUCTION- BOLTED BONNET, RISING STEM OUTSIDE

SCREW AND YOKE TRIM CONSTRUCTION-WEDGE TYPE

GA-1A13 - 2" GATE VALVE (WEDGE GATE) ,150 LB RF, BODY MATERIAL-CARBON STEEL ASTM A216 WCB,

TRIM MATERIAL-GATE: ASTM A217 CA15, SEAT/SEAL: ASTM A182 F6A /HF, STEM: ASTM A182 F6A,

4.3 10 EA

HANDWHEEL OPERATION, BODY CONSTRUCTION- BOLTED BONNET, RISING STEM OUTSIDE

SCREW AND YOKE TRIM CONSTRUCTION-WEDGE TYPE

GA-1A13 - 1.5" GATE VALVE (WEDGE GATE) ,150 LB RF, BODY MATERIAL-CARBON STEEL ASTM A216 WCB,

TRIM MATERIAL-GATE: ASTM A217 CA15, SEAT/SEAL: ASTM A182 F6A /HF, STEM: ASTM A182 F6A,

4.4 2 EA

HANDWHEEL OPERATION, BODY CONSTRUCTION- BOLTED BONNET, RISING STEM OUTSIDE

SCREW AND YOKE TRIM CONSTRUCTION-WEDGE TYPE

GA-1A12 - 1" GATE VALVE (WEDGE GATE) ,150 LB RF, BODY MATERIAL-CARBON STEEL ASTM A105N,

TRIM MATERIAL-GATE: ASTM A182 F6A, SEAT/SEAL: ASTM A182 F6A /HF, STEM: ASTM A182 F6A,

4.5 2 EA

HANDWHEEL OPERATION, BODY CONSTRUCTION- BOLTED BONNET, RISING STEM OUTSIDE

SCREW AND YOKE TRIM CONSTRUCTION-WEDGE TYPE.

GA-1A12 - 3/4" GATE VALVE (WEDGE GATE) ,150 LB RF, BODY MATERIAL-CARBON STEEL ASTM A105N, TRIM

MATERIAL-GATE: ASTM A182 F6A, SEAT/SEAL: ASTM A182 F6A /HF,

4.6 3 EA

STEM: ASTM A182 F6A, HANDWHEEL OPERATION, BODY CONSTRUCTION- BOLTED BONNET, RISING STEM

OUTSIDE SCREW AND YOKE TRIM CONSTRUCTION-WEDGE TYPE

CK-1A11 (LIFT) - 1" CHECK VALVE. 150 LB RF, BODY MATERIAL-CARBON STEEL ASTM A105N,

4.7 2 EA TRIM MATERIAL-DISC: ASTM A182 F6A, SEAT/SEAL: ASTM A182 F6A/HF, SPRING: INCONEL 718 BODY

CONSTRUCTION- LIFT PISTON WITH SPRING

4.8 1 EA SDV - SHUTDOWN VALVE

4.9 1 EA PCV - PRESSURE CONTROL VALVE

4.10 1 EA PCV - PRESSURE CONTROL VALVE

4.11 2 EA PSV - PRESSURE SAFETY VALVE

5 STRAINER

5.1 1 EA STRAINER

6 HOSE

6.1 2 EA HOSE

6.2 4 EA HOSE COUPLING

7 GASKET

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 2

Date: 06.07.2021

INSPECTION

ITEM Part no QTY UOM LINE DESCRIPTION CERTIFICATION CODE LINE COST TOTAL COST

LEVEL

PIPE

NON-METALLIC FLAT GASKET, NEOPRENE SHORE A, HARDNESS 55 TO

7.1 5 EA

65, 3.2MM THK, ASME B16.21 RATING #150

GASKET SPIRALLY WOUND /W SS INNER & CS OUTER RINGS, SS

7.2 6 EA

316L/FG, 4.5MM THK, ASME B16.20 RATING #150

GASKET SPIRALLY WOUND /W SS INNER & CS OUTER RINGS, SS

7.3 7 EA

316L/FG, 4.5MM THK, ASME B16.20 RATING #150

GASKET SPIRALLY WOUND /W SS INNER & CS OUTER RINGS, SS

7.4 32 EA

316L/FG, 4.5MM THK, ASME B16.20 RATING #150

GASKET SPIRALLY WOUND /W SS INNER & CS OUTER RINGS, SS

7.5 13 EA

316L/FG, 4.5MM THK, ASME B16.20 RATING #150

GASKET SPIRALLY WOUND /W SS INNER & CS OUTER RINGS, SS

7.6 13 EA

316L/FG, 4.5MM THK, ASME B16.20 RATING #150

GASKET SPIRALLY WOUND /W SS INNER & CS OUTER RINGS, SS

7.7 4 EA

316L/FG, 4.5MM THK, ASME B16.20 RATING #150

8 STUDBOLT

STUD BOLTS, ALLOY STEEL, ASTM A193-B7/A194-2H+ZN NI COATED

8.1 32 EA +FCC, WITH TWO HVY HEXAGONAL NUTS & 2 WASHER, ASME

B18.31.2/B18.2.2

STUD BOLTS, ALLOY STEEL, ASTM A193-B7/A194-2H+ZN NI COATED

8.2 56 EA +FCC, FULL LENGTH, /W TWO HVY HEXAGONAL NUTS, ASME

B18.31.2/B18.2.2

STUD BOLTS, ALLOY STEEL, ASTM A193-B7/A194-2H+ZN NI COATED

8.3 48 EA +FCC, FULL LENGTH, /W TWO HVY HEXAGONAL NUTS, ASME

B18.31.2/B18.2.2

STUD BOLTS, ALLOY STEEL, ASTM A193-B7/A194-2H+ZN NI COATED

8.4 168 EA +FCC, FULL LENGTH, /W TWO HVY HEXAGONAL NUTS, ASME -

B18.31.2/B18.2.2

STUD BOLTS, ALLOY STEEL, ASTM A193-B7/A194-2H+ZN NI COATED

8.5 48 EA +FCC, FULL LENGTH, /W TWO HVY HEXAGONAL NUTS, ASME -

B18.31.2/B18.2.2

STUD BOLTS, ALLOY STEEL, ASTM A193-B7/A194-2H+ZN NI COATED

8.6 48 EA +FCC, FULL LENGTH, /W TWO HVY HEXAGONAL NUTS, ASME

B18.31.2/B18.2.2

STUD BOLTS, ALLOY STEEL, ASTM A193-B7/A194-2H+ZN NI COATED

8.7 16 EA +FCC, FULL LENGTH, /W TWO HVY HEXAGONAL NUTS, ASME

B18.31.2/B18.2.2

DELIVERY SHIPPING

FAO: COST TYPE:

ADDRESS: INSTRUCTIONS:

UMM QASR -MARINE TERMINAL REIMBURSABLE NOT TO EXCEED COST: TOTAL COST: -

N/A

NON-

NR

REIMBURSABLE

POSITION NAME SIGNATURE DATE INSPECTION LEVEL DEFINITIONS NOTES REVISION

LEVEL I - Surveillance and / or Final Inspection and Release at Supplier’s

premises by AAC

LEVEL II – Third party Inspection by Discipline Engineer / Designer (Report /

ORIGINATOR: 27/02/2024 IRC must be produced)

LEVELIII- Goods Receipt Inspection at Warehouse by AAC

LEVEL IV – No AAC Inspection. KEBL placed TPI on the Supplier’s Quality

System

CLIENT (IF REQUIRED)

CHECK: 20/02/2024

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 2

Date: 06.07.2021

REQUISITION Material Requisition for Pipes, Valves

CLIENT / PROJECT: Kuwait Energy Basra Limited (KEBL) BK91-1344-INF-856-PIP-MR-0001 REQUISITION DESCRIPTION: DATE RAISED 26/02/2024 Page 4 of 4

NUMBER: and Not-metallic pipes

LINE COST TOTAL COST

PART / CODE INSPECTION

ITEM QTY UOM LINE DESCRIPTION CERTIFICATION CODE (State Currency) (State Currency)

NUMBER LEVEL

ATTACHMENT TO THE MATERIAL REQUISITION

1 Data Sheet -

BK91-1344-INF-856-PIP-DAS-0001_Data Sheet for Pipes -

BK91-1344-INF-856-PIP-DAS-0002_Data Sheet for Valves -

BK91-1344-INF-856-PIP-DAS-0003_Data Sheet for Non-metallic Pipes -

2 Specification -

BK91-1344-INF-856-PIP-SPC-0004_Specification for Piping Materials Class

BK91-1344-INF-856-PIP-SPC-0005_Specification for Valves

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 2

Date: 06.07.2021

You might also like

- Routine Pile Load Test 225 A-2 Design R-0Document7 pagesRoutine Pile Load Test 225 A-2 Design R-0Kishore KumarNo ratings yet

- Tech Final-1Document200 pagesTech Final-1dhruba30No ratings yet

- Spam Karian Timur Pipeline ProjectDocument14 pagesSpam Karian Timur Pipeline ProjectTeguh SilaNo ratings yet

- 11 86 Me DTS 00008Document3 pages11 86 Me DTS 00008Erdal CanNo ratings yet

- 3.1 Fabrication and Installation of PipingDocument45 pages3.1 Fabrication and Installation of PipingArie100% (1)

- Inspection Test and Plan For Storage Tank For Material Carbon SteelDocument5 pagesInspection Test and Plan For Storage Tank For Material Carbon SteelPLTU SULUT QC PASTINo ratings yet

- Subsea Cable Sizing400Sq - MMDocument206 pagesSubsea Cable Sizing400Sq - MMAmir NazihNo ratings yet

- Alarm Trip SettingsDocument6 pagesAlarm Trip Settingsavenir334No ratings yet

- Request For Inspection: EPIC For Facilities Modifications at RG PlantDocument8 pagesRequest For Inspection: EPIC For Facilities Modifications at RG PlantBasker BaluNo ratings yet

- HFY4 5030 VED 003 GEN VDR 0001 - A VDR For Electric Overhead Crane - Code BDocument4 pagesHFY4 5030 VED 003 GEN VDR 0001 - A VDR For Electric Overhead Crane - Code BaymanNo ratings yet

- A05 004 Inspection Test Plan Shell Tube Heat Exchangers 5 210D HA 01 A B C D PDFDocument14 pagesA05 004 Inspection Test Plan Shell Tube Heat Exchangers 5 210D HA 01 A B C D PDFfdfazfzNo ratings yet

- RFA & RFI For 400KV Gantry Verticality CheckingDocument3 pagesRFA & RFI For 400KV Gantry Verticality Checkingsathya2040No ratings yet

- Painting Specification Plan For Combustion Air PreheaterDocument4 pagesPainting Specification Plan For Combustion Air PreheaterNamta GeorgeNo ratings yet

- Pending List PDFDocument2 pagesPending List PDFProduction Unit IVNo ratings yet

- Imir 251Document9 pagesImir 251onshorequalitykclNo ratings yet

- 4442 16 MS 0015 - 2Document42 pages4442 16 MS 0015 - 2Vasu SNo ratings yet

- BK91-1344-INF-856-GEO-RPT-0001 - A - Geotechnical Investigation ReportDocument125 pagesBK91-1344-INF-856-GEO-RPT-0001 - A - Geotechnical Investigation ReportSudeepDPoojaryNo ratings yet

- Itp ElectricalDocument31 pagesItp ElectricalAnonymous e8rOBLYx0100% (4)

- For Approval: Refractory Installation ProcedureDocument16 pagesFor Approval: Refractory Installation ProcedureLuis EscobedoNo ratings yet

- HYEN-RFQ-ME-004 - RFQ For FET - Rev.C - 210218Document22 pagesHYEN-RFQ-ME-004 - RFQ For FET - Rev.C - 210218MouiciNo ratings yet

- D 111214 DTS 004 Rev.001 Safety Induction TrainingDocument68 pagesD 111214 DTS 004 Rev.001 Safety Induction TrainingBelal ElsayedNo ratings yet

- E84 in TN CMBR GVRD NB 0001 502Document35 pagesE84 in TN CMBR GVRD NB 0001 502Balaji SowrirajanNo ratings yet

- Instrument Pressure Piping Hook-Up (N-Htr/Plant Area) : Contractor Doc. #Document82 pagesInstrument Pressure Piping Hook-Up (N-Htr/Plant Area) : Contractor Doc. #Tahir100% (1)

- Sheet 1 of 4: Rev - No Date Description Prepd CHKD AppvdDocument4 pagesSheet 1 of 4: Rev - No Date Description Prepd CHKD AppvdHafidz FirmansyahNo ratings yet

- Flanges ANSI16 5###Document48 pagesFlanges ANSI16 5###kunal shahNo ratings yet

- 0.1 - RFQ - Utility Boiler PacakgeDocument8 pages0.1 - RFQ - Utility Boiler Pacakgeabdelkader benabdallahNo ratings yet

- Spp-0401409-Gg-01!15!24-014 - Rev1 - Datasheet For Telecom and Fiber Optic CableDocument14 pagesSpp-0401409-Gg-01!15!24-014 - Rev1 - Datasheet For Telecom and Fiber Optic Cablechandrahai hrangkhawlNo ratings yet

- MR For Pipeline Bulk Materials, Rev.ADocument31 pagesMR For Pipeline Bulk Materials, Rev.ASandeepNBabuNo ratings yet

- IS-REKA-59.1-KU002 Inpection Sheet of Underframe Kereta UkurDocument7 pagesIS-REKA-59.1-KU002 Inpection Sheet of Underframe Kereta UkurBhimantara Yudha PrawiraNo ratings yet

- Fire Extinguisher InspectionDocument4 pagesFire Extinguisher InspectionR Sahadeo ReddyNo ratings yet

- OPGW Earth Wire Suspension Set - (180 951-254)Document11 pagesOPGW Earth Wire Suspension Set - (180 951-254)MohammadEhtashamNo ratings yet

- LUC-Ex-CIV-MECH-MELE-002 V4Document1 pageLUC-Ex-CIV-MECH-MELE-002 V4Mr ElEcTrOnNo ratings yet

- Fitup ReportDocument2 pagesFitup ReportMohd SaffririzalNo ratings yet

- LIFTWELL PRESSURIZATION FAN TDS-PML HO APPROVED WITH COMMENTS - GDPL CommentedDocument25 pagesLIFTWELL PRESSURIZATION FAN TDS-PML HO APPROVED WITH COMMENTS - GDPL CommentedshafeeqadeptNo ratings yet

- Specification For Piping MaterialDocument9 pagesSpecification For Piping MaterialAgus SupriadiNo ratings yet

- Okan Ggcpdebottlenecking Project: Welding Procedure Specification FOR Pipe To FlangeDocument4 pagesOkan Ggcpdebottlenecking Project: Welding Procedure Specification FOR Pipe To FlangeNilesh KabadeNo ratings yet

- Signature Not Verified: Digitally Signed by Manish Kumar Date: 2019.07.26 15:58:08 IST Reason: CAT I Location: NtpceocDocument56 pagesSignature Not Verified: Digitally Signed by Manish Kumar Date: 2019.07.26 15:58:08 IST Reason: CAT I Location: NtpceocpraveshjhambNo ratings yet

- QAP-UEPL-BHOPAL-54-9550-01 Rev.03Document6 pagesQAP-UEPL-BHOPAL-54-9550-01 Rev.03udayakarnaNo ratings yet

- B-PE-I-433-18-002-004-00 - Instrument Cable Schedule - Approved As NoteDocument3 pagesB-PE-I-433-18-002-004-00 - Instrument Cable Schedule - Approved As NoteMuhammad TeguhNo ratings yet

- Example Generator Fuel Fill PointsDocument19 pagesExample Generator Fuel Fill PointsSlick72No ratings yet

- 402-91-EL-LIS-00003 Rev B - SignedDocument14 pages402-91-EL-LIS-00003 Rev B - SignedKrishnan KrishNo ratings yet

- LadderDocument1 pageLaddertinNo ratings yet

- Cofferdam Analysis of Malolos Project-Subbase Railway Deformation-Signed BWDocument39 pagesCofferdam Analysis of Malolos Project-Subbase Railway Deformation-Signed BWFilipus Ivan DenataNo ratings yet

- Fencing and GateDocument16 pagesFencing and Gatemustika05No ratings yet

- NPT10111-PE-V-DS-621101-030 - Instrument Datasheet - Level Gauge F & B Rev-00Document6 pagesNPT10111-PE-V-DS-621101-030 - Instrument Datasheet - Level Gauge F & B Rev-00kkumar_717405No ratings yet

- Afd Sabtank CCR T 002 19Document9 pagesAfd Sabtank CCR T 002 19smart_onyx17No ratings yet

- Specification For Piping Thermal InsulationDocument14 pagesSpecification For Piping Thermal InsulationAgus SupriadiNo ratings yet

- 3n4 - RAM - Oman Concrete Mix Design ApprovalDocument2 pages3n4 - RAM - Oman Concrete Mix Design ApprovalMohammad AftabNo ratings yet

- Itp Piping Rev 0Document2 pagesItp Piping Rev 0Angel Rebollo100% (1)

- TPS 8735Document114 pagesTPS 8735mech1kingNo ratings yet

- Barracuda and Caratinga Crude Oil Fields Production Facilities ProjectDocument87 pagesBarracuda and Caratinga Crude Oil Fields Production Facilities ProjectneivaprojetosNo ratings yet

- 86-0284-DS-1054-0 (DS of Fire Cabinet)Document2 pages86-0284-DS-1054-0 (DS of Fire Cabinet)Huraira AliNo ratings yet

- OPGW Earth Wire Tension Set For Branching Two OPGW Earth Wires - (180 953-593)Document12 pagesOPGW Earth Wire Tension Set For Branching Two OPGW Earth Wires - (180 953-593)MohammadEhtashamNo ratings yet

- KISR7-SGRE 'A'-C-22-0875-Design Calculation For Oil Collection TankDocument23 pagesKISR7-SGRE 'A'-C-22-0875-Design Calculation For Oil Collection TankSenthilkumar K100% (1)

- MKCDR01 C5129Document66 pagesMKCDR01 C5129Nasib JabiyevNo ratings yet

- Submersible PumpDocument105 pagesSubmersible PumpRamKS80100% (1)

- Method Statement For BrickworksDocument28 pagesMethod Statement For BrickworksKAKA100% (9)

- Es0154-75440100-Cal-0083 - R0Document59 pagesEs0154-75440100-Cal-0083 - R0அம்ரு சாந்திவேலுNo ratings yet

- Material Receiving Inspection Report Discipline: Quality Control FormDocument15 pagesMaterial Receiving Inspection Report Discipline: Quality Control FormSREENATH SOMANATHAN NAIRNo ratings yet

- Fluidized Bed Boilers: Design and ApplicationFrom EverandFluidized Bed Boilers: Design and ApplicationRating: 4.5 out of 5 stars4.5/5 (4)

- Pages From ANRD-INF-MFC-AA-6603-0020 - 002 - CommentedDocument6 pagesPages From ANRD-INF-MFC-AA-6603-0020 - 002 - CommentedSudeepDPoojaryNo ratings yet

- Geogrid: Secugrid® Q (PP)Document2 pagesGeogrid: Secugrid® Q (PP)SudeepDPoojaryNo ratings yet

- BK91-1344-INF-856-ELE-LST-0004 - A - Hazardous Area Classification List - C2Document3 pagesBK91-1344-INF-856-ELE-LST-0004 - A - Hazardous Area Classification List - C2SudeepDPoojaryNo ratings yet

- SwiftDocument1 pageSwiftSudeepDPoojaryNo ratings yet

- BK91-1344-856-ELE-TQY-0001 - A - Power Source Change Due To Voltage DropDocument3 pagesBK91-1344-856-ELE-TQY-0001 - A - Power Source Change Due To Voltage DropSudeepDPoojaryNo ratings yet

- HSE Training Matrix DraftDocument11 pagesHSE Training Matrix DraftSudeepDPoojaryNo ratings yet

- Draft Engineering WBSDocument2 pagesDraft Engineering WBSSudeepDPoojaryNo ratings yet

- Anrd Inf MFC Ci 4018 0028 - 002Document1 pageAnrd Inf MFC Ci 4018 0028 - 002SudeepDPoojaryNo ratings yet

- R Scan0174Document2 pagesR Scan0174SudeepDPoojaryNo ratings yet

- Pages From BK91-1331 - GEN-KMS - KEB-LET-0001 - Bank Guarantee Letter For Contract RequirementsDocument2 pagesPages From BK91-1331 - GEN-KMS - KEB-LET-0001 - Bank Guarantee Letter For Contract RequirementsSudeepDPoojaryNo ratings yet

- 05 Exhibit 1 of Annexure II - Scope of WorkDocument16 pages05 Exhibit 1 of Annexure II - Scope of WorkSudeepDPoojary100% (1)

- AttachmentsDocument27 pagesAttachmentsSudeepDPoojaryNo ratings yet

- SDocument2 pagesSSudeepDPoojaryNo ratings yet

- Ol 20599389Document1 pageOl 20599389SudeepDPoojaryNo ratings yet

- Fire Fighting Props (Resposiblity Comparision)Document1 pageFire Fighting Props (Resposiblity Comparision)SudeepDPoojaryNo ratings yet

- ANRD-INF-MFC-FA-5765-0002 - 001 - Planning PackageDocument4 pagesANRD-INF-MFC-FA-5765-0002 - 001 - Planning PackageSudeepDPoojaryNo ratings yet

- ANRD-INF-MFC-HP-5798-0001 - 001 - KBR FSM Review 001Document27 pagesANRD-INF-MFC-HP-5798-0001 - 001 - KBR FSM Review 001SudeepDPoojaryNo ratings yet

- Financial Statement - 2020Document11 pagesFinancial Statement - 2020SudeepDPoojaryNo ratings yet

- 23.1) Preliminary Technical Document Register (TDR)Document3 pages23.1) Preliminary Technical Document Register (TDR)SudeepDPoojaryNo ratings yet

- Schéma Hy 227B 01Document2 pagesSchéma Hy 227B 01Juju100% (1)

- Fluid Mechanics 2 Lab ManualDocument50 pagesFluid Mechanics 2 Lab ManualMuhammad IsmailNo ratings yet

- The Slow Motion of A Sphere Through A Viscous Fluid Towards A Plane SurfaceDocument10 pagesThe Slow Motion of A Sphere Through A Viscous Fluid Towards A Plane SurfaceOscar A. LuévanoNo ratings yet

- H. W. Liepmann, A. Roshko - Elements of Gasdynamics (2002, Dover Publications) - Libgen - LiDocument232 pagesH. W. Liepmann, A. Roshko - Elements of Gasdynamics (2002, Dover Publications) - Libgen - LiDev100% (1)

- Flow Measurement Lecture 1Document37 pagesFlow Measurement Lecture 1Rahul KalraNo ratings yet

- (G6) Orifice Under Varying HeadDocument5 pages(G6) Orifice Under Varying HeadDane JonesNo ratings yet

- Integral Analysis of The Boundary LayerDocument12 pagesIntegral Analysis of The Boundary LayerPung Kang QinNo ratings yet

- EST.2833 Maturity Assessment For Engineering DeliverablesDocument24 pagesEST.2833 Maturity Assessment For Engineering DeliverablesSidney Porter100% (1)

- A Physical Description of Flight Revisited ©: David AndersonDocument14 pagesA Physical Description of Flight Revisited ©: David Andersonleonardo chavezNo ratings yet

- LSV-08-2 NCPDocument2 pagesLSV-08-2 NCPishtiaqNo ratings yet

- VENTURIDocument2 pagesVENTURIMustafa Darweesh SalehNo ratings yet

- Pneumatic SymbolsDocument3 pagesPneumatic Symbolsaur_nszzNo ratings yet

- Pipe FittingsDocument32 pagesPipe Fittingsalinor_tn100% (5)

- Single Counterbalance: DescriptionDocument2 pagesSingle Counterbalance: DescriptionAtaa AssaadNo ratings yet

- DB 01.01.26.04 Pump S200 SSDocument2 pagesDB 01.01.26.04 Pump S200 SSPRAMOD KUMARNo ratings yet

- Solidworks Flow Simulation Project Report: (Company Logo Here)Document14 pagesSolidworks Flow Simulation Project Report: (Company Logo Here)brayanNo ratings yet

- Petroleum Engineering 325 Petroleum Production Systems: Wellbore Flow Performance I Single-Phase FlowDocument51 pagesPetroleum Engineering 325 Petroleum Production Systems: Wellbore Flow Performance I Single-Phase FlowBruno ReinosoNo ratings yet

- Pressure-Relief ValvesDocument11 pagesPressure-Relief ValvesbalaNo ratings yet

- Introduction To CFDDocument8 pagesIntroduction To CFDsasa_22No ratings yet

- Crane Fluid Flow ProblemsDocument276 pagesCrane Fluid Flow ProblemsDanny Nguyen100% (2)

- FMDS0311Document15 pagesFMDS0311Sandeep YadavNo ratings yet

- Computational Fluid Dynamics in Practice BOOK PDFDocument209 pagesComputational Fluid Dynamics in Practice BOOK PDFZikic Dejan100% (2)

- Consolidated Relief Valves SRVDocument498 pagesConsolidated Relief Valves SRVHitesh PanchalNo ratings yet

- Isolation Valve Linear MovementDocument8 pagesIsolation Valve Linear MovementAjit PatilNo ratings yet

- Book 2: Chapter 4 - Fluid Flow: Application LimitationsDocument20 pagesBook 2: Chapter 4 - Fluid Flow: Application LimitationsVaniya GoelNo ratings yet

- Ata 29Document132 pagesAta 29Geovanni Riquelme LooNo ratings yet

- How Squat, Bank and Bank Cushion Effects Influence Ships in Restricted WatersDocument6 pagesHow Squat, Bank and Bank Cushion Effects Influence Ships in Restricted Watersconcrete designNo ratings yet

- Chapter Five FluidDocument43 pagesChapter Five FluidALNo ratings yet

- Friction Loss Calculations of Irrigation Design A Foot Ball CourtDocument13 pagesFriction Loss Calculations of Irrigation Design A Foot Ball Courtmathewmanjooran100% (2)