Professional Documents

Culture Documents

JSA - Cable Drum Unloading by Using Crane

JSA - Cable Drum Unloading by Using Crane

Uploaded by

Sampath Kumar Kandasamy0 ratings0% found this document useful (0 votes)

2 views4 pagesOriginal Title

JSA - cable drum unloading by using crane

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views4 pagesJSA - Cable Drum Unloading by Using Crane

JSA - Cable Drum Unloading by Using Crane

Uploaded by

Sampath Kumar KandasamyCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 4

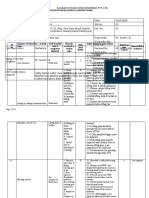

JOB SAFETY ANALYSIS

Job / Activity: Cable drum unloading by using mobile crane

Worksite: Equipment: crane, Trailer.

Type of Activity: Critical Non-Critical

Personal Protective Equipment & Tools: Hard Hat, Safety Shoes, Hand Gloves, Safety Harness, Goggles

Initial Risk

Sequence of Basic Job Steps Potential Hazards Precautions

Severity Likelihood Risk Rating

Take a Hot Work Permit from Asset Owner as per the

KOC - HSEMS Procedure - Doc. No. SA.KOC.004 “Permit

Non-compliance of to Work” & KOC.SA.013 - Mobile Equipment Procedure

KOC -HSEMS Severe Possible High Conduct Tool Box Talk & Continuous Gas Test

Procedures

Conduct Gas Test and ensure the specified Mobile Crane

Presence of movement route & Work area are free from Flammable

Flammable /Toxic Gas Severe Possible High /Toxic Gas or Vapor

or Vapor

Ensure the personnel involved in the jobs such as

Flagman, Rigger, Mobile CraneOperator , Work Site

Supervisor etc .are competent for the job and have Valid

KOC approved Third Party Certificates .

Lack of proper Severe Possible High Ensure proper planning and communication between the

Communication

personnel involved in the jobs such as Flagman, Rigger,

Mobile CraneOperator, Work Site Supervisor etc.

Ensure the site where the Mobile Crane is to be

deployed is thoroughly planned & inspected for proper

compacted ground & uniform level before working.

Ensurethat the Mobile crane is having the Load Chart

Planning Collapse of Mobile Severe Possible High and is working within the recommended SWL without

Crane overloading

Ensure that

Ensure that the Mobile CraneExhaust is mounted with

the Spark/Flame arrestor

Ensure that the Mobile Craneis equipped with two

approved and valid Fire Extinguishers.

Conduct Gas test and ensure there work area is gas

free.

Use Non-Sparking Tools during carrying or working with

Spark generation /Fire Severe Possible High Hazardous materials

Ensure that the personnel involved in the jobs such as

Flagman, Rigger, Mobile CraneOperator, Work Site

Supervisor etc. are trained in KOC HSEMS Emergency

procedures.

Conduct Lifting as per the KOC - HSEMS Procedures -

Doc. No KOC.SA.029 - Safety Procedure for Mechanical

Handling of Loads.

Use approved Third party certified & Valid Lifting Tools

and Tackles ( such as chain pulley,Web slings, rope slings

winch )

Ensure the availability of the Valid KOC approved Third

Party Certificates & KOC Clearance certificates for the

Lifting / Transportation of Materials Collapse of Boom Severe Possible High Mobile Crane & its accssories as per KOC HSEMS

procedures as per the KOC.SA.013 - Mobile Equipment

Procedure .

Loading and Unloading during Lifting is planned as per

the SWL of the BOOM.

Ensure proper wind up & housekeeping at worksite as

per the KOC - HSEMS Procedures - Doc.No. KOC.GE.034

Unauthorized entry of - Housekeeping Procedure

unwanted persons in The Scaffolding materials, lifting Tools, Tackles & other

Windup & Housekeeping Severe Possible High

the working at height materials are to be removed, replaced back & cleared after

area the work.

Additional Hazards (Other than indicated

above)

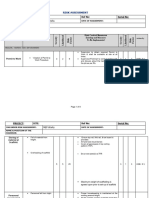

Name: Designation Company. Controlling

JSA Done (by Worksite Supervisor)

& Employee Id: Team:

Name: Designation Company. Controlling

JSA Reviewed (by Permit Applicant)

& Employee Id: Team:

Name: Designation Company. Controlling

JSA Authorized (by Permit Issuer) & Employee Id: Team:

FETY ANALYSIS

JSA Ref. No. JSA/KOC

Permit No.

Date:

ss, Goggles

Residual Risk

Severity Likelihood Risk Rating

Severe Very Unlikely Med

Severe Very Unlikely Med

Severe Very Unlikely Med

Severe Very Unlikely Med

Severe Very Unlikely Med

Severe Very Unlikely Med

Severe Very Unlikely Med

Signature: Date:

Signature: Date:

Signature: Date:

You might also like

- Risk Assessment For Kerb Stones, Wheel Stopper and Paving InterlocksDocument4 pagesRisk Assessment For Kerb Stones, Wheel Stopper and Paving Interlockspete chiz91% (23)

- JI 2027 JSA 039 Lifting and Rigging Activities by Tandem Lifting PDFDocument3 pagesJI 2027 JSA 039 Lifting and Rigging Activities by Tandem Lifting PDFYawar Qureshi100% (3)

- Risk Assessment - Distribution Board (DB) & Junction Box (JB) InstallationDocument6 pagesRisk Assessment - Distribution Board (DB) & Junction Box (JB) Installationnsadnan91% (11)

- Risk Assessment - Cg-4750-Installation of Lighting Protection Pole, Street Lighting Pole and Light FittingsDocument6 pagesRisk Assessment - Cg-4750-Installation of Lighting Protection Pole, Street Lighting Pole and Light Fittingsnsadnan86% (21)

- ISC-JSA Installation of Portable CabinDocument4 pagesISC-JSA Installation of Portable CabinSameer Almahboub25% (4)

- JSA - Fire Proofing WorksDocument5 pagesJSA - Fire Proofing WorksAnis Uddin100% (4)

- JSA Cable Laying PDFDocument2 pagesJSA Cable Laying PDFManoj WaskelNo ratings yet

- Petrofac: Job Safety AnalysisDocument3 pagesPetrofac: Job Safety AnalysisMon Trang Nguyễn100% (5)

- Final Copy - Open Pipe Muffler 24mar2021 - With EsigDocument5 pagesFinal Copy - Open Pipe Muffler 24mar2021 - With EsigPoblacion Polomolok100% (2)

- SkySim MD11 ChecklistDocument8 pagesSkySim MD11 ChecklistMarco LimaNo ratings yet

- Risk Assessment For External Façade & Canopies CleaningDocument6 pagesRisk Assessment For External Façade & Canopies Cleaningjulius0% (1)

- PJHA Form - Compi (Ash Bin) Piling of CHBDocument3 pagesPJHA Form - Compi (Ash Bin) Piling of CHBPaul TamayoNo ratings yet

- Jsa For Lifting Activities With Mechanical EquipmentDocument4 pagesJsa For Lifting Activities With Mechanical EquipmentMuhammad Umar GondalNo ratings yet

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatNo ratings yet

- Risk Assessment Distribution Board DB Junction Box Junction Box InstallationDocument6 pagesRisk Assessment Distribution Board DB Junction Box Junction Box InstallationAnonymous HeA9HEbtDmNo ratings yet

- Doosan Compressor P185WDZ and C185WDZDocument82 pagesDoosan Compressor P185WDZ and C185WDZDavid CraigNo ratings yet

- JSA #19 - Heavy Lifting in Hazardous AreaDocument1 pageJSA #19 - Heavy Lifting in Hazardous AreaMock ProjectNo ratings yet

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- Jsa For Cable LayingDocument2 pagesJsa For Cable LayingSabari VtNo ratings yet

- SEOT JSA For Vehicle EntryDocument3 pagesSEOT JSA For Vehicle EntryArchana SoorajNo ratings yet

- Cable Laying - Docx4Document2 pagesCable Laying - Docx4Dhaneswar SwainNo ratings yet

- Jsa Setting Crane and Lifting GeneratorDocument2 pagesJsa Setting Crane and Lifting GeneratorSeppy FajrianiNo ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair Vanmazhy100% (1)

- DB Termination JhaDocument2 pagesDB Termination JhafatimahNo ratings yet

- Job Safety Analysis - Cone ErectionDocument6 pagesJob Safety Analysis - Cone ErectionEslam lotfy- Eslam elsadatNo ratings yet

- JSA GC-10 Crane LiftDocument5 pagesJSA GC-10 Crane LiftMahmud ShalehudinNo ratings yet

- 50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Document3 pages50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Raza Muhammad SoomroNo ratings yet

- Risk Assesment V1Document59 pagesRisk Assesment V1jcsasiaNo ratings yet

- Jsa Cooling TowerDocument5 pagesJsa Cooling TowerRavi thokalNo ratings yet

- Attachment 8 RA LiftingDocument5 pagesAttachment 8 RA Liftingathul subash100% (2)

- Deep Excavation Risk AssessmentDocument12 pagesDeep Excavation Risk Assessmentdonfrancis639No ratings yet

- JSA For Scaffolding Erection Dismantling and Modification WorkDocument17 pagesJSA For Scaffolding Erection Dismantling and Modification Workshane.ramirez1980No ratings yet

- JSA Hot Work and ModificationDocument19 pagesJSA Hot Work and ModificationBrings MotoVlogNo ratings yet

- Jsa (Ercction of Tower Crane) G-11Document4 pagesJsa (Ercction of Tower Crane) G-11khurram shahzadNo ratings yet

- 4.assembly & Erection of StructureDocument3 pages4.assembly & Erection of StructureFrancis Vinoj100% (2)

- Petrofac: Job Safety AnalysisDocument2 pagesPetrofac: Job Safety AnalysisMon Trang Nguyễn100% (1)

- CTRA-20-TM-035-Lagoon Cleaning-R1-Not ApprovedDocument7 pagesCTRA-20-TM-035-Lagoon Cleaning-R1-Not ApprovedMohamed RizwanNo ratings yet

- 03 - C (JOB SAFETY ANALYSIS For LOX Tank-C)Document3 pages03 - C (JOB SAFETY ANALYSIS For LOX Tank-C)AhmedNo ratings yet

- JSA For SURGE VESSEL WorkDocument6 pagesJSA For SURGE VESSEL Workathul subashNo ratings yet

- Job Safety Analysis 14 For Cable Laying and PullingDocument4 pagesJob Safety Analysis 14 For Cable Laying and PullingBishop Ojonuguwa Ameh100% (1)

- JSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware HouseDocument9 pagesJSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware Houseradeep100% (1)

- PCW Pipe Installation JhaDocument2 pagesPCW Pipe Installation Jhafatimah100% (1)

- 3 - RA-mepDocument9 pages3 - RA-mephsem Al EimaraNo ratings yet

- JHA - LiftingDocument3 pagesJHA - Liftingmark jayson yabesNo ratings yet

- 1..loading Unloading and Erection of Steel StructuresDocument2 pages1..loading Unloading and Erection of Steel StructuresFrancis VinojNo ratings yet

- Job Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectDocument5 pagesJob Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectShilpiengg SafetyNo ratings yet

- 5.19 JSP Self Levelling Epoxy Painting ActivityDocument8 pages5.19 JSP Self Levelling Epoxy Painting Activitymuhammad.younisNo ratings yet

- JSA For Road BarrierDocument3 pagesJSA For Road BarrierMohammed MinhajNo ratings yet

- GOSP-5 (60) Placing Red Tile &caution Tape Inside The TrenchDocument6 pagesGOSP-5 (60) Placing Red Tile &caution Tape Inside The TrenchShahid BhattiNo ratings yet

- Risk Assessment - BLOCK WORKSDocument9 pagesRisk Assessment - BLOCK WORKSShah Muzzamil100% (1)

- Housekeeping JsaDocument9 pagesHousekeeping JsaShahid BhattiNo ratings yet

- JSA 02-03 Vertical Borehole and Anode Bed InstallationDocument5 pagesJSA 02-03 Vertical Borehole and Anode Bed InstallationHaleemUrRashidBangash50% (2)

- JSA-Hydraulic Press Testing For PilesDocument6 pagesJSA-Hydraulic Press Testing For PilesUMUTNo ratings yet

- 2..loading Unloading and Installation of PipingDocument3 pages2..loading Unloading and Installation of PipingFrancis VinojNo ratings yet

- Risk Assessment CG 4750 Installation of Lighting Protection Pole Street Lighting Pole and Light FittingsDocument5 pagesRisk Assessment CG 4750 Installation of Lighting Protection Pole Street Lighting Pole and Light FittingsEm NiaxNo ratings yet

- JSA-Batching-Plant - Doc HPGR SMDDocument2 pagesJSA-Batching-Plant - Doc HPGR SMDMalefane Cortez TlatlaneNo ratings yet

- 8.safety Plan - SS 7914Document3 pages8.safety Plan - SS 7914GANESH KNo ratings yet

- JSA - Blooming Mill T-U-V Bay Axis 42 To 48Document6 pagesJSA - Blooming Mill T-U-V Bay Axis 42 To 48mohanNo ratings yet

- MCD - JHA - 014 - Repainting McDonalds PylonDocument3 pagesMCD - JHA - 014 - Repainting McDonalds Pylondini lalalaNo ratings yet

- Emergency Plan For LiftDocument8 pagesEmergency Plan For LiftScribdTranslationsNo ratings yet

- JSA For Hydro Jetting, Removal and Cleaning of SludgeDocument18 pagesJSA For Hydro Jetting, Removal and Cleaning of Sludgesk sajidNo ratings yet

- Bannari Amman Institute of Technology: Monthly News LetterDocument50 pagesBannari Amman Institute of Technology: Monthly News LetterSampath Kumar KandasamyNo ratings yet

- JSA - Working at HeightDocument5 pagesJSA - Working at HeightSampath Kumar KandasamyNo ratings yet

- JSA - Manual PaintingDocument4 pagesJSA - Manual PaintingSampath Kumar KandasamyNo ratings yet

- Condition: GatchDocument4 pagesCondition: GatchSampath Kumar KandasamyNo ratings yet

- Testimonials FloridaDocument232 pagesTestimonials FloridaSampath Kumar KandasamyNo ratings yet

- Foundation Design f1Document2 pagesFoundation Design f1Sampath Kumar KandasamyNo ratings yet

- Storage Tank Foundation StandardDocument6 pagesStorage Tank Foundation StandardSampath Kumar KandasamyNo ratings yet

- Valve Box StandardDocument2 pagesValve Box StandardSampath Kumar KandasamyNo ratings yet

- K2-Construction Plan Report 1Nov12-Appendix B-Hydrogeological Assessment-Appendix B-Dewatering CalculationsDocument3 pagesK2-Construction Plan Report 1Nov12-Appendix B-Hydrogeological Assessment-Appendix B-Dewatering CalculationsSampath Kumar KandasamyNo ratings yet

- Back Fill StandardDocument3 pagesBack Fill StandardSampath Kumar KandasamyNo ratings yet

- Blast Shelter 8Document2 pagesBlast Shelter 8Sampath Kumar KandasamyNo ratings yet

- Blast WallDocument14 pagesBlast WallSampath Kumar KandasamyNo ratings yet

- Portable Accommodation Modules Guide Feb20Document48 pagesPortable Accommodation Modules Guide Feb20Sampath Kumar KandasamyNo ratings yet

- Client: Project: Location: BY: Date:: API RP-2FB Blast CalculationsDocument33 pagesClient: Project: Location: BY: Date:: API RP-2FB Blast CalculationsSampath Kumar KandasamyNo ratings yet

- Technical Bid-2 RSO Navsari-52Document248 pagesTechnical Bid-2 RSO Navsari-52Sampath Kumar KandasamyNo ratings yet

- Merchant Shipping (Registration of Indian Ships) Rules, 1960Document12 pagesMerchant Shipping (Registration of Indian Ships) Rules, 1960PeteNo ratings yet

- Bentley BrochureDocument8 pagesBentley BrochureNikolas sparskos BakoyiannisNo ratings yet

- Shafee J SayedDocument109 pagesShafee J Sayedrohit salunkheNo ratings yet

- Karma Spotter Training EngDocument57 pagesKarma Spotter Training EngMouctar GUINDONo ratings yet

- E7 - Revision - Second Mid-Term Test (23 - 24)Document10 pagesE7 - Revision - Second Mid-Term Test (23 - 24)Thanh GiangNo ratings yet

- Free Time Offer For Maersk SPOTDocument239 pagesFree Time Offer For Maersk SPOTegemenNo ratings yet

- Electrical+system New ModelDocument54 pagesElectrical+system New ModelTimkenNo ratings yet

- A Financial and Operational Analysis of 2GO Travels 1 SWOTDocument5 pagesA Financial and Operational Analysis of 2GO Travels 1 SWOTAndrea Bren Nicole MercadoNo ratings yet

- Kallada Tours Travels PDFDocument2 pagesKallada Tours Travels PDFBasil Ibnu Abdul LatheefNo ratings yet

- Cat DE1100 GC: ® Diesel Generator SetsDocument4 pagesCat DE1100 GC: ® Diesel Generator SetsJustUhhIDK2No ratings yet

- SHAKILMONJURAHMODMRDocument1 pageSHAKILMONJURAHMODMRMahbub IslamNo ratings yet

- TSLA Q1 2024 UpdateDocument31 pagesTSLA Q1 2024 UpdateSimon AlvarezNo ratings yet

- ITF IMEC International IBF CBA 2024-2025Document16 pagesITF IMEC International IBF CBA 2024-2025gmNo ratings yet

- Sodapdf ResizedDocument4 pagesSodapdf Resizedtavo rodriguezNo ratings yet

- Discrimination 1Document1 pageDiscrimination 1abcdNo ratings yet

- Insurance PolicyDocument3 pagesInsurance PolicyJafar APNo ratings yet

- International LogisticsDocument9 pagesInternational Logisticsanshul agarwalNo ratings yet

- Microsoft Word - Cruise Control For BMW E36Document2 pagesMicrosoft Word - Cruise Control For BMW E36xifiv92318No ratings yet

- 4 SPEED FWD (Electronic Control) With LU Con Vert Er: Revision 07/2011Document5 pages4 SPEED FWD (Electronic Control) With LU Con Vert Er: Revision 07/2011Вадим УрупаNo ratings yet

- Gross: 216 KW 290 HP / 2000 Min Net: 213 KW 286 HP / 2000 Min 21650 KG (With Ripper 24380 KG) 4.32 MDocument20 pagesGross: 216 KW 290 HP / 2000 Min Net: 213 KW 286 HP / 2000 Min 21650 KG (With Ripper 24380 KG) 4.32 Mمحمد عابدينNo ratings yet

- DP Sea Time Confirmation LetterDocument1 pageDP Sea Time Confirmation LetterOvi100% (1)

- Bus251 Report Group 3Document19 pagesBus251 Report Group 3Nahid KhanNo ratings yet

- Bobcat s250Document3 pagesBobcat s250Tarek TorbeyNo ratings yet

- Case 570T TLBDocument16 pagesCase 570T TLBDlamini Innocent ThulaniNo ratings yet

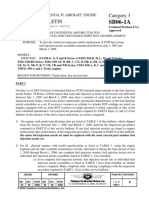

- Service Bulletin Category 3: Teledyne Continental Aircraft EngineDocument23 pagesService Bulletin Category 3: Teledyne Continental Aircraft EngineizabelNo ratings yet

- 2019 AnnualDocument371 pages2019 Annualoctober monthNo ratings yet

- ReceiptDocument4 pagesReceiptAnas MohamedNo ratings yet