Professional Documents

Culture Documents

Pipes. Maxi 5 PDF

Pipes. Maxi 5 PDF

Uploaded by

Nasrul AdliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipes. Maxi 5 PDF

Pipes. Maxi 5 PDF

Uploaded by

Nasrul AdliCopyright:

Available Formats

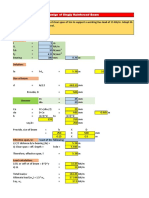

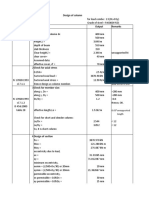

rength Corrosion allowance Pipe dimensions

le A-1 TC = 1.59 mm The schedule is to be determined

25 ksi Thread depth

TD = 0 mm Schedule initially assumed

llowable stress at Mill tolerance Sch = 40S

erature MT = 12.5 %

le A-1 Exterior diameter (of SS pipe)

72 F Note. dn = 300 mm

16.7 ksi The above values are not considered de = Pipe_SS_Dext_dn

115.1 MPa in the example of the reference [1]. de = 323.85 mm

de = 0.324 m

ending stress

allow * 0.3 Interior diameter

115.1 MPa dn = 300 mm

34.54 MPa di = Pipe_SS_Dint_dn_sch

3.5E+07 Pa Sch = 40S

di = 304.8 mm

ity module di = 0.305 m

6

2E+11 Pa www.piping-tools.net

Pipes. Maximum span between pipe supports for a g

cjcruz@piping-tools.net

Deflection Result

Deflection at ther center of a simple For

supported beam with a uniform load Lselected = 10 m

w and a concentrated load "wc". there is a deflextion

2 - 4*a*c)^0.5 ) / (2*a) (from sheet equations) ycalc = 9.90 mm

245

90.82 5 w L4 + 8 w c L3 Requirement

y= (q)

-12,396 384 E I ycalc <= Lselected / 600

10.411 m Lselected = 10 m

Deflection value for the Lselected / 600 = 0.0167 m

10 m selected length Lselected / 600 = 16.67 mm

ycalc = (5*w*L^4 + 8*wc*L^3) / (384*E*I)

You might also like

- Asme Om3Document31 pagesAsme Om3Carlos SandinoNo ratings yet

- Pumping and Piping Systems: Xavier University - Ateneo de Cagayan College of Engineering Cagayan de Oro CityDocument34 pagesPumping and Piping Systems: Xavier University - Ateneo de Cagayan College of Engineering Cagayan de Oro CityGab LibetarioNo ratings yet

- Anchor Bolt Reinforcement CheckDocument3 pagesAnchor Bolt Reinforcement CheckdantevariasNo ratings yet

- Portal FrameDocument26 pagesPortal FrameScribd Saya86% (7)

- Cable Impedance CalculationsDocument4 pagesCable Impedance CalculationsJoseph PoplingerNo ratings yet

- Singly Reinforced Beam ExcelDocument3 pagesSingly Reinforced Beam ExcelVEERKUMAR100% (3)

- B31 3 (Mygaz) - 1Document1 pageB31 3 (Mygaz) - 1Nasrul AdliNo ratings yet

- Pipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressDocument75 pagesPipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressMarius GhitaNo ratings yet

- One Way Slab and Standard HooksDocument21 pagesOne Way Slab and Standard Hooksmuhammad rid100% (1)

- Assignment CSTT 1Document21 pagesAssignment CSTT 1KHÁNH VÕ ĐĂNGNo ratings yet

- Pipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressDocument75 pagesPipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressTushar ChoudharyNo ratings yet

- Pipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressDocument75 pagesPipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressBharath YemireddyNo ratings yet

- Pumping System Between Two Water Tanks: S - Min S N, S S Pipe - Suct PumpDocument18 pagesPumping System Between Two Water Tanks: S - Min S N, S S Pipe - Suct PumpSaeed SalmanizadeganNo ratings yet

- Maximum Span Between Pipe Supports For A Given Maximum Bending StressDocument76 pagesMaximum Span Between Pipe Supports For A Given Maximum Bending Stresserodrguez100% (1)

- AISC Verification Example-Pipe Shear Lag Connection in BracingDocument4 pagesAISC Verification Example-Pipe Shear Lag Connection in BracingDadypees100% (1)

- Basic of Civil EngineeringsDocument23 pagesBasic of Civil EngineeringsPAWANNo ratings yet

- Design of Beam: Tension Bars Comp. Bars StirrupsDocument10 pagesDesign of Beam: Tension Bars Comp. Bars StirrupsJudy Ann CastorNo ratings yet

- Bole Tower C - Shoring Design - SW - 3b - Rear River Side - 11m - Per Site Condition and LogDocument3 pagesBole Tower C - Shoring Design - SW - 3b - Rear River Side - 11m - Per Site Condition and LogGeorge HaileNo ratings yet

- Punching Shear CheckDocument4 pagesPunching Shear CheckvivekNo ratings yet

- Doubly Reinforced BeamDocument2 pagesDoubly Reinforced BeamG.DhanabalNo ratings yet

- Wall FootingDocument7 pagesWall FootingKramyer100% (1)

- Whalen Uy Residences 2CS-1 125.00 125.00 3.00 Ksi 40 Ksi 10 12.00 0.50 MDocument1 pageWhalen Uy Residences 2CS-1 125.00 125.00 3.00 Ksi 40 Ksi 10 12.00 0.50 MWilliam ProvidoNo ratings yet

- Circular Section ShearDocument9 pagesCircular Section ShearSumedha MayadunnaNo ratings yet

- Solutions To RC ProbsDocument16 pagesSolutions To RC ProbsJosephNo ratings yet

- Project: MWA Contract: 9D Section: Temp. Ring Beam 1 ST Level 9D-5Document1 pageProject: MWA Contract: 9D Section: Temp. Ring Beam 1 ST Level 9D-5keaoreNo ratings yet

- Design of PierDocument18 pagesDesign of PierMrinal kayalNo ratings yet

- Design of StaircaseDocument8 pagesDesign of StaircaseAnish NeupaneNo ratings yet

- Footing Subjected To Eccentric LoadingDocument5 pagesFooting Subjected To Eccentric LoadingPratik DhariwalNo ratings yet

- Ese-2016: Test Series: Subjectwise Test No. 10 (Conventional)Document11 pagesEse-2016: Test Series: Subjectwise Test No. 10 (Conventional)CgpscAspirantNo ratings yet

- Appendix A3Document6 pagesAppendix A3Thomas Stephen100% (1)

- Design of Column: Axial Stress 0.1fckDocument22 pagesDesign of Column: Axial Stress 0.1fckSudip ShresthaNo ratings yet

- Connection Design: Given DataDocument2 pagesConnection Design: Given Datasyed muneeb haiderNo ratings yet

- B 1Document6 pagesB 1clarkgaguiNo ratings yet

- Design of Two Way SlabsDocument16 pagesDesign of Two Way SlabsPRAKASHNo ratings yet

- SPT Girder L 38.75m, S 2.26m (43 Strands) - 0507Document53 pagesSPT Girder L 38.75m, S 2.26m (43 Strands) - 0507Trần Dinh BảoNo ratings yet

- Appendix A1Document22 pagesAppendix A1Thomas StephenNo ratings yet

- Perhitungan Tulangan Kolom: Pengaku (H 350mm)Document1 pagePerhitungan Tulangan Kolom: Pengaku (H 350mm)DonzNo ratings yet

- Metal Deck 2 WayDocument3 pagesMetal Deck 2 Waymjfprgc0% (1)

- RCC - 2-Way Slab DesignDocument1 pageRCC - 2-Way Slab DesignParth PatelNo ratings yet

- Beam Design RusselDocument155 pagesBeam Design RusselRonald CostalesNo ratings yet

- RC21 ServiceDocument32 pagesRC21 ServiceMuhammedNo ratings yet

- Shs End Plate Moment ConnectionDocument7 pagesShs End Plate Moment ConnectionShindiya LalNo ratings yet

- RCC BEAM - Singly - Solution PDFDocument3 pagesRCC BEAM - Singly - Solution PDFJOHN MAKOTONo ratings yet

- First Flooor BeamsDocument10 pagesFirst Flooor BeamsanushyasanjeevaniNo ratings yet

- Calculation Sheet of Pc-I Pre-Tensioning 24.54M: 1. Initial DataDocument63 pagesCalculation Sheet of Pc-I Pre-Tensioning 24.54M: 1. Initial DataSumane Suma100% (3)

- The Purpose of This Worksheet Is To Design The Stairway From EL (+) 1500 To EL (+) 6500 From The Boatlanding To The JacketDocument10 pagesThe Purpose of This Worksheet Is To Design The Stairway From EL (+) 1500 To EL (+) 6500 From The Boatlanding To The JacketThomas StephenNo ratings yet

- Reference: ACI 318M 2014 Chapter 11.1 Special Reinforcement Details For Seismic ZonesDocument4 pagesReference: ACI 318M 2014 Chapter 11.1 Special Reinforcement Details For Seismic ZonesTri SetiyonoNo ratings yet

- Powerscrew SampleDocument3 pagesPowerscrew Sampleemilianojr gameNo ratings yet

- 6 R Design 13.88 Section A-ADocument4 pages6 R Design 13.88 Section A-AsudipNo ratings yet

- 7 R Design 13.88 Section B-BDocument4 pages7 R Design 13.88 Section B-BsudipNo ratings yet

- ELEC E8409 Answers 2Document8 pagesELEC E8409 Answers 2Ismail DriouchNo ratings yet

- Some Notes: Changes in Highlighted Rows Is Required As Per DesignDocument3 pagesSome Notes: Changes in Highlighted Rows Is Required As Per Designer.praveenraj30No ratings yet

- Design of Cantilever Slab: Change 180 167.4667Document2 pagesDesign of Cantilever Slab: Change 180 167.4667madasamya20No ratings yet

- Rectangular Beam Design - 2010 NSCPDocument2 pagesRectangular Beam Design - 2010 NSCPrenzo1221No ratings yet

- BS5400 R.C Design With Crack WidthDocument9 pagesBS5400 R.C Design With Crack WidthWangTF100% (4)

- Design of Slabs1Document8 pagesDesign of Slabs1Tonette AmorNo ratings yet

- CENG314-Chapter-6&7-Serviceability & BondDocument18 pagesCENG314-Chapter-6&7-Serviceability & BondDana AlkhashramNo ratings yet

- FRAME A BEAM 1-2 - 3bDocument6 pagesFRAME A BEAM 1-2 - 3bMervin CulminasNo ratings yet

- RC-1 Example 3.1Document7 pagesRC-1 Example 3.1rabia jemal100% (2)

- Handout 4: Design of Slabs A. ONE-WAY SLABS - Supported On Two Edges and Bends in Only One Direction. Please ReadDocument7 pagesHandout 4: Design of Slabs A. ONE-WAY SLABS - Supported On Two Edges and Bends in Only One Direction. Please ReadKevin MedinaNo ratings yet

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- Differential Forms on Electromagnetic NetworksFrom EverandDifferential Forms on Electromagnetic NetworksRating: 4 out of 5 stars4/5 (1)

- Job Information: Engineer Checked Approved Name: Date: Structure TypeDocument2 pagesJob Information: Engineer Checked Approved Name: Date: Structure TypeNasrul AdliNo ratings yet

- Piping Engineering - Tank Nozzle Loads 1Document1 pagePiping Engineering - Tank Nozzle Loads 1Nasrul Adli100% (1)

- Exhibit II Compliance To Technical RequirementsDocument1 pageExhibit II Compliance To Technical RequirementsNasrul AdliNo ratings yet

- Asme Sect8 Div1 - SAMPLE Calculation-COVERDocument1 pageAsme Sect8 Div1 - SAMPLE Calculation-COVERNasrul AdliNo ratings yet

- Malaysia Public Holidays & School Holidays 2018 CalendaR-ALL PDFDocument4 pagesMalaysia Public Holidays & School Holidays 2018 CalendaR-ALL PDFNasrul AdliNo ratings yet

- What Is Piping 2Document1 pageWhat Is Piping 2Nasrul AdliNo ratings yet

- PDMS 2Document1 pagePDMS 2Nasrul AdliNo ratings yet

- Pipes. Maxi 8 PDFDocument1 pagePipes. Maxi 8 PDFNasrul AdliNo ratings yet

- Shear Lug Verification Example 12Document1 pageShear Lug Verification Example 12Nasrul AdliNo ratings yet

- Pipes. Maxi 8 PDFDocument1 pagePipes. Maxi 8 PDFNasrul AdliNo ratings yet

- Shear Lug Verification Example 3Document1 pageShear Lug Verification Example 3Nasrul AdliNo ratings yet

- Shear Lug Verification Example 2Document1 pageShear Lug Verification Example 2Nasrul AdliNo ratings yet

- Shear Lug Verification Example 12Document1 pageShear Lug Verification Example 12Nasrul AdliNo ratings yet

- Shear Lug Verification Example 4Document1 pageShear Lug Verification Example 4Nasrul AdliNo ratings yet

- Structural Systems For High Rise BuildingsDocument7 pagesStructural Systems For High Rise BuildingsSuncica Zurkovic100% (1)

- FortranDocument11 pagesFortranwilrocaNo ratings yet

- (C) 2017 Second Wind Productions, LLC: (S) Values in Fractional FormDocument21 pages(C) 2017 Second Wind Productions, LLC: (S) Values in Fractional FormAhsan AliNo ratings yet

- Ansys BT Bike BikeDocument16 pagesAnsys BT Bike BikecreativenggNo ratings yet

- Boeing Design Manual: 2.1 Statically Determinate and Indeterminate Beams (Continued)Document39 pagesBoeing Design Manual: 2.1 Statically Determinate and Indeterminate Beams (Continued)Carla BelelliNo ratings yet

- Stiffness TesterDocument6 pagesStiffness TesterTJPRC PublicationsNo ratings yet

- Ruukki Sandwich Panel Product Description 03 2021Document20 pagesRuukki Sandwich Panel Product Description 03 2021Mim MiNo ratings yet

- Rationale For The ACI 440.1R-06 Indirect Deflection Control Design ProvisionsDocument20 pagesRationale For The ACI 440.1R-06 Indirect Deflection Control Design ProvisionsmirzaNo ratings yet

- Beam CantileverDocument11 pagesBeam CantileverReyginald MarronNo ratings yet

- Deflection of BeamsDocument109 pagesDeflection of BeamsNadir Khattak Jr.100% (1)

- Lecture On SpringsDocument43 pagesLecture On SpringsAbreo Dan Vincent AlmineNo ratings yet

- Design of Slabs 1-1Document25 pagesDesign of Slabs 1-1Wilbert Reuyan100% (2)

- DTP - Deerfield River BridgeDocument5 pagesDTP - Deerfield River Bridgefdesdunes00No ratings yet

- Cable Tray Load Calculation PDFDocument10 pagesCable Tray Load Calculation PDFu5ur5zoro5luNo ratings yet

- Statically IndeterminateDocument4 pagesStatically IndeterminateAGEGTAMNo ratings yet

- A State of The Art Review On Tensile Membrane Action I - 2022 - Journal of BuildDocument15 pagesA State of The Art Review On Tensile Membrane Action I - 2022 - Journal of BuildAliNo ratings yet

- CE Review For Nov 2022 - Theory 3: Figure P-736Document1 pageCE Review For Nov 2022 - Theory 3: Figure P-736JuDeNo ratings yet

- 2-2 SyllabusDocument15 pages2-2 SyllabusnikaNo ratings yet

- Structure Stiffness S13Document40 pagesStructure Stiffness S13MerdekaSandiTazakkaNo ratings yet

- Effect of Skew Angle On Static Behaviour 1Document77 pagesEffect of Skew Angle On Static Behaviour 1Sindhu BvNo ratings yet

- High Rise Part B To DDocument32 pagesHigh Rise Part B To DAnnie JiangNo ratings yet

- Deflection - Ontario Building CodeDocument2 pagesDeflection - Ontario Building CodechidsalazarNo ratings yet

- 6 4uDocument7 pages6 4uElsayed Salah HamoudaNo ratings yet

- Structural Design - 2012 - Strip - MethodDocument25 pagesStructural Design - 2012 - Strip - MethodmigunsamNo ratings yet

- Appendix CBDocument63 pagesAppendix CBHundeejireenyaNo ratings yet

- Beam DeflectionsDocument4 pagesBeam DeflectionsUğur DündarNo ratings yet

- ST10/ST11: Understanding Structural BehaviourDocument8 pagesST10/ST11: Understanding Structural BehaviourmrswcecivilNo ratings yet