Professional Documents

Culture Documents

Welding Procedure Specification (WPS) : Asme Ix & Asme B31.3

Welding Procedure Specification (WPS) : Asme Ix & Asme B31.3

Uploaded by

Elias JarjouraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specification (WPS) : Asme Ix & Asme B31.3

Welding Procedure Specification (WPS) : Asme Ix & Asme B31.3

Uploaded by

Elias JarjouraCopyright:

Available Formats

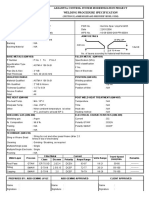

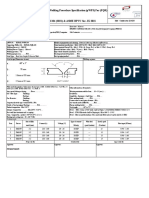

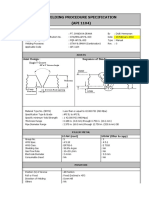

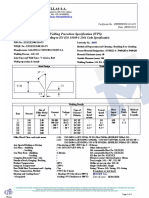

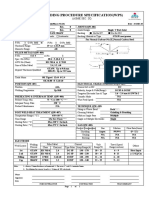

Welding Procedure Specification (WPS)

WPS #: MD-AS-WPS-01

PQR # : MD-AS-PQR-01

Welding Procedure Specification: ASME IX & ASME B31.3 Method of preparation and cleaning: Grinding / Wire brushing

Project Name: Wardiyeh Pipeline Parent material designation(s): API 5L , Grade B Seamless Pipe

Company Name: Awdeh Steel Company Material thickness (mm)2: 15.1mm

Mode(s) of metal transfer: N/A Outside diameter (mm)2: 273 mm / 219 mm

Joint type and weld type: Butt weld / Single side welding

Throat thickness (mm)2: N/A

Degree of mechanization: N/A

Deposited weld metal: GTAW 3mm / SMAW 7.7mm

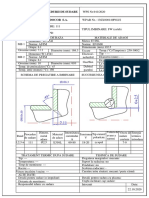

Weld preparation details (Sketch)1 Welding position: 6G ( HL 045)

Joint design Welding sequences

Welding details

Run Welding Size of Current Voltage2 Type of Wire feed Run out Arc energy1, 2/

process filler 2 V current/po- larity speed2 length1,2/ Heat input 1, 2

material A travel speed1

1-Root Pass GTAW 2.4mm 95-115 10-13 DCEN N/A 65-85 mm/min 0.6-1.17 kJ/mm

2-Hot Pass GTAW 2.4mm 160-190 10-13 DCEN N/A 95-150 mm/min 0.64-1.44 kJ/mm

3-Filling Pass 1 SMAW 3.2mm 95-140 18-30 DCEP N/A 60-150 mm/min 0.6-3.7 kJ/mm

E7018

4-Filling Pass 2 SMAW 3.2mm 95-140 18-30 DCEP N/A 60-150 mm/min 0.6-3.7 kJ/mm

E7018

5-Cap Pass 1 SMAW 3.2mm 95-130 18-30 DCEP N/A 100-165 mm/min 0.66-2.11 kJ/mm

E7018

6-Cap Pass 2 SMAW 3.2mm 95-130 18-30 DCEP N/A 100-165 mm/min 0.66-2.11 kJ/mm

E7018

7-Cap Pass 3 SMAW 3.2mm 95-130 18-30 DCEP N/A 100-165 mm/min 0.66-2.11 kJ/mm

E7018

Filler material designation and make: ESAB E7018& ESAB ER- 70S-6

Any special baking or drying: NO

Designation gas/flux: – shielding: Argon: 99.997% Other information1, e.g.:

– backing: NO Weaving (maximum width of run): Max 10mm

Gas flow rate – shielding: 10-20 L/min Oscillation: amplitude, frequency, dwell time: N/A

– backing: NO Pulse welding details: N/A

Tungsten electrode type/size: 2.4 mm EW th 2% Thoriated Distance contact tube/work piece: N/A

Details of back gouging/backing: N/A Plasma welding details: N/A

o

Preheating temperature: Min 25C (ambient Temperature) Torch angle: N/A

Interpass temperature: 215 Co Max

Postheating: N/A

Pre-heat maintenance temperature: N/A

Weld heat treatment and/or ageing: Time,

temperature, method: N/A

You might also like

- Draft WPS For Carbon Steel PipeDocument2 pagesDraft WPS For Carbon Steel Pipeabet_singkong893025% (4)

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationGodwin A.udo-akanNo ratings yet

- Aluminium WPSDocument2 pagesAluminium WPSAnonymous yCpjZF1rF100% (1)

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- WPS GF170 As 1554.6Document1 pageWPS GF170 As 1554.6Syed Mahmud Habibur Rahman100% (1)

- Fire-X87 CatalogueDocument4 pagesFire-X87 Catalogueomar ayeshNo ratings yet

- As 1163 - Hollow Sections For Structural SteelDocument26 pagesAs 1163 - Hollow Sections For Structural SteelIrene YuNo ratings yet

- Welding Procedure Specifications (Wps - 6G) : 2mm (Max)Document2 pagesWelding Procedure Specifications (Wps - 6G) : 2mm (Max)Gbenga Mobolade100% (1)

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Document3 pagesWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Welding Procedure Specification (WPS) (As Per EN / ISO 15609-1)Document1 pageWelding Procedure Specification (WPS) (As Per EN / ISO 15609-1)ramesh rajaNo ratings yet

- WPS - Merd-01Document3 pagesWPS - Merd-01Phuong NguyenNo ratings yet

- WPS 141-111 P460QH To SameDocument1 pageWPS 141-111 P460QH To SameakisdassasNo ratings yet

- 2G & 5GDocument2 pages2G & 5GRahul MoottolikandyNo ratings yet

- WPS 2-A36 Rudder Shaft To FlangeDocument2 pagesWPS 2-A36 Rudder Shaft To FlangeNuwan RanaweeraNo ratings yet

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- Preliminary Welding Procedure Specification Pwps PDF FreeDocument1 pagePreliminary Welding Procedure Specification Pwps PDF FreeFirozNo ratings yet

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- Wps (Gtaw & Smaw)Document3 pagesWps (Gtaw & Smaw)Ramadhan AdityaNo ratings yet

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- PQR Format PDFDocument2 pagesPQR Format PDFHarshit Adwani100% (2)

- WPS 1-SS 316 Rudder Stock With Letter HeadDocument2 pagesWPS 1-SS 316 Rudder Stock With Letter HeadNuwan RanaweeraNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- WPS Racord Intepat 2335Document1 pageWPS Racord Intepat 2335Andrei UrsacheNo ratings yet

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- Nisoc: Preliminary Welding Procedure Specification (PWPS) For (PQR)Document3 pagesNisoc: Preliminary Welding Procedure Specification (PWPS) For (PQR)pejman.imaniNo ratings yet

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 pagesWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENo ratings yet

- Draft WPS Welder R0Document51 pagesDraft WPS Welder R0R Bernanda Argandhi SaputraNo ratings yet

- Welding Procedure Specification (WPS)Document3 pagesWelding Procedure Specification (WPS)Jignasa ShahNo ratings yet

- Metrode - P92 WPS PDFDocument3 pagesMetrode - P92 WPS PDFXing ChenNo ratings yet

- DraftDocument32 pagesDraftAnilkumarNo ratings yet

- WPS (Gtaw)Document2 pagesWPS (Gtaw)Ramadhan AdityaNo ratings yet

- WPS 141-121 P460QH To SameDocument2 pagesWPS 141-121 P460QH To SameakisdassasNo ratings yet

- En Iso 15609Document2 pagesEn Iso 15609Parminder SinghNo ratings yet

- PT - Bumi Laut Perkasa: AWS D1.1 Welding Procedure Specification (WPS)Document2 pagesPT - Bumi Laut Perkasa: AWS D1.1 Welding Procedure Specification (WPS)Wahyu Lailil FaisNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- P WPSDocument3 pagesP WPSAnilkumar G NairNo ratings yet

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- WCBDocument5 pagesWCBSuresh KrishnanNo ratings yet

- WPS 3-A36 Rudder Shaft To Rudder BladeDocument1 pageWPS 3-A36 Rudder Shaft To Rudder BladeNuwan RanaweeraNo ratings yet

- PQR 03 2014Document2 pagesPQR 03 2014vinuNo ratings yet

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- Draft WPSDocument32 pagesDraft WPSAnilkumar G NairNo ratings yet

- Wps Format Tube Welding Cs With Tig V&s JalashawaDocument3 pagesWps Format Tube Welding Cs With Tig V&s JalashawaVISAKHAPATNAM MALAYALEES WELFARE ASSOCIATIONNo ratings yet

- PIPING WPS and PQRDocument5 pagesPIPING WPS and PQRshibaprasad0115No ratings yet

- Welding Procedure Qualification Record: String or Weave Bead, Multipass, Single Electrode, Electrical Stick-Out:15-25mmDocument1 pageWelding Procedure Qualification Record: String or Weave Bead, Multipass, Single Electrode, Electrical Stick-Out:15-25mmBhanu Pratap ChoudhuryNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- PQR For 32 MM PlateDocument1 pagePQR For 32 MM PlateMuhammed MubeenNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- 3 RFP Documents ICLM DB 588Document8 pages3 RFP Documents ICLM DB 588Elias JarjouraNo ratings yet

- 2 - Preventive Maintenance Calendar - M-F-PMC-001-PE - RevDocument3 pages2 - Preventive Maintenance Calendar - M-F-PMC-001-PE - RevElias JarjouraNo ratings yet

- 17 OilProcess RepoDocument1 page17 OilProcess RepoElias JarjouraNo ratings yet

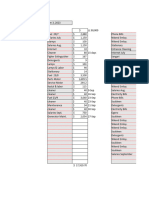

- Expenses Term 3Document2 pagesExpenses Term 3Elias JarjouraNo ratings yet

- 20230104103709 (2)Document31 pages20230104103709 (2)Elias JarjouraNo ratings yet

- 00.1 App 1 List of Internal Documents Integrated Preview ENDocument1 page00.1 App 1 List of Internal Documents Integrated Preview ENblitzkrigNo ratings yet

- Jarjoura's Site VisitDocument15 pagesJarjoura's Site VisitElias JarjouraNo ratings yet

- 5ffcacac1fcf866bc8f2ea63 - Fulcrum Checklist - Gas Station Inspection ChecklistDocument4 pages5ffcacac1fcf866bc8f2ea63 - Fulcrum Checklist - Gas Station Inspection ChecklistElias JarjouraNo ratings yet

- Operation ManualDocument71 pagesOperation ManualElias JarjouraNo ratings yet

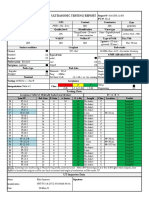

- Ultrasonic Testing Report: Famsco - LebanonDocument1 pageUltrasonic Testing Report: Famsco - LebanonElias JarjouraNo ratings yet

- PA UTR 2021 053 (Final)Document1 pagePA UTR 2021 053 (Final)Elias JarjouraNo ratings yet

- Sigma Ochart 20210608Document1 pageSigma Ochart 20210608Elias JarjouraNo ratings yet

- Iso 22991 2004 en PDFDocument11 pagesIso 22991 2004 en PDFElias JarjouraNo ratings yet

- CP-136: API-650 Code Annex-U Requirements For Ultrasonic Examination in Lieu of RadiographyDocument11 pagesCP-136: API-650 Code Annex-U Requirements For Ultrasonic Examination in Lieu of RadiographyElias JarjouraNo ratings yet

- EHQMS Internal Audit ChecklistDocument1 pageEHQMS Internal Audit ChecklistElias JarjouraNo ratings yet

- Quality Management System Diffusion Matrix - RemarksDocument6 pagesQuality Management System Diffusion Matrix - RemarksElias JarjouraNo ratings yet

- LPG-BUS-HSE-IST-0007 - Safety Data Sheet - Liquefied Petroleum GasDocument10 pagesLPG-BUS-HSE-IST-0007 - Safety Data Sheet - Liquefied Petroleum GasElias Jarjoura100% (1)

- GS0303 Stage 1 Audit Report-SigmaDocument7 pagesGS0303 Stage 1 Audit Report-SigmaElias JarjouraNo ratings yet

- Inspection Certificate - 2Document5 pagesInspection Certificate - 2Elias JarjouraNo ratings yet

- Communication Procedure: Purpose and ApplicationDocument2 pagesCommunication Procedure: Purpose and ApplicationElias JarjouraNo ratings yet

- 2018 Diamond Chain Catalog LinksDocument98 pages2018 Diamond Chain Catalog LinksLucas MaldonadoNo ratings yet

- ITP Steel Structure Work Rev.0 - WTL - P.pea - 2Document2 pagesITP Steel Structure Work Rev.0 - WTL - P.pea - 2nuntaricherdchaiNo ratings yet

- Lesson 3. Welding PositionsDocument2 pagesLesson 3. Welding PositionsElla MaeNo ratings yet

- OS Vehicle Body Repairing and P L2Document62 pagesOS Vehicle Body Repairing and P L2Aida Mohammed100% (1)

- Indo Danish Tool Room: Industrial TrainingDocument28 pagesIndo Danish Tool Room: Industrial TrainingPriyanshu KumarNo ratings yet

- L1-CHE-SPE-059 Hard-Drawn Copper Solid Dropper Wire 21.15mm 2Document6 pagesL1-CHE-SPE-059 Hard-Drawn Copper Solid Dropper Wire 21.15mm 2CK TangNo ratings yet

- KU-TWK-00-PI-SPC-0001 - 0 - General Welding Specification - UpdatedDocument13 pagesKU-TWK-00-PI-SPC-0001 - 0 - General Welding Specification - Updatedbmanojkumar16No ratings yet

- Chapter 1 NDTDocument13 pagesChapter 1 NDTNurjihan Binti Aimi100% (1)

- Charoong Thai Wire & Cable Public Company Limited: CTW - Aluminum RodDocument1 pageCharoong Thai Wire & Cable Public Company Limited: CTW - Aluminum RodAchint KumarNo ratings yet

- Aws WJ 201905 PDFDocument130 pagesAws WJ 201905 PDFMarcelo LacerdaNo ratings yet

- Phastite by ParkerDocument24 pagesPhastite by Parkerangstrom_101890No ratings yet

- Astm E543-21Document14 pagesAstm E543-21Edson ReisNo ratings yet

- Astm A265 2009Document6 pagesAstm A265 2009Alexandre Amaro VieiraNo ratings yet

- Main Defects Observed in Aluminum Alloy Parts Produced by SLMDocument31 pagesMain Defects Observed in Aluminum Alloy Parts Produced by SLMAnas RaisNo ratings yet

- Instruction Manual and Spare Parts List: Welding Torch PKI 250/500/630/300 PP S4C / S4Cplus / PIBDocument46 pagesInstruction Manual and Spare Parts List: Welding Torch PKI 250/500/630/300 PP S4C / S4Cplus / PIBAsim PedicNo ratings yet

- Guided Retainers: Superior Guidance & RetentionDocument6 pagesGuided Retainers: Superior Guidance & RetentionSIMONENo ratings yet

- ValvesDocument47 pagesValveshassan hamdyNo ratings yet

- Nucor Fastener Finished Hex Nuts Are All Formed On PreciDocument2 pagesNucor Fastener Finished Hex Nuts Are All Formed On PreciJuan DomeNo ratings yet

- MetFloor MagnelisDocument1 pageMetFloor Magnelismatan dvirNo ratings yet

- Sheet Metal and TinsmithryDocument22 pagesSheet Metal and TinsmithryVictor EvangelioNo ratings yet

- Kester - Catalogue - Kester - Consommables Pour L'électronique - 2010Document18 pagesKester - Catalogue - Kester - Consommables Pour L'électronique - 2010ZorbanfrNo ratings yet

- Technical Data: Model Model HSM 100 H/HSM 100 P/HSM 250 H/HSM 250 PDocument2 pagesTechnical Data: Model Model HSM 100 H/HSM 100 P/HSM 250 H/HSM 250 PAnonymous 1oWzM3No ratings yet

- Steel Industry Analysis of BangladeshDocument30 pagesSteel Industry Analysis of BangladeshMonir Hosen69% (13)

- Sliding Door Detail 1Document1 pageSliding Door Detail 1Daniel NamanyaNo ratings yet

- Australia Catalogue 2015Document36 pagesAustralia Catalogue 2015Hen Drix LevaNo ratings yet

- ALPHA SACX PLUS 0307 Wave SolderDocument5 pagesALPHA SACX PLUS 0307 Wave SolderVimal Kumar VarmaNo ratings yet

- TUV India PRESSURE VESSEL InspectionDocument24 pagesTUV India PRESSURE VESSEL InspectionParthiban NCNo ratings yet

- Roof Ridge: Flat Steel SheetsDocument1 pageRoof Ridge: Flat Steel SheetsMarin ProstranNo ratings yet