Professional Documents

Culture Documents

Non-Conformity Cum Resolution Report (NCR)

Uploaded by

Deepak UpadhayayOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Non-Conformity Cum Resolution Report (NCR)

Uploaded by

Deepak UpadhayayCopyright:

Available Formats

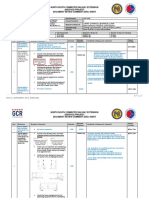

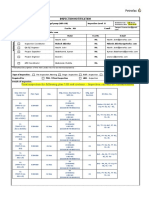

NON-CONFORMITY CUM RESOLUTION NCR No.

: MTHL-

REPORT (NCR) OSD-NCR-006

Date: 31-May-2021

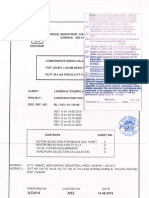

Project & Customer : MTHL (Pck-02) & MMRDA Subcontractor /Supplier : M/s. DWST

W.O / PO No. : ---- Package / Equipment : OSD Assembly

Drg. No. & Rev. No. : SW-02-S373 B0 (J37), SW- MRR / IMIR No. & Date : NA

02-S379 B0 (J40) & SE-02-S363 B0 (J32), Part / Item Description : TCB Bolts (M22) of 105 &

115 mm lengths, S10T Grade

Line / Joint No. / Location / Structure No.: NA

*Category of NCR: ☒ Major ☐ Minor

Specified Requirement Description of Non-Conformity

As per Bolt tightening procedure No. DWST- The bolts of following sizes were failed in the

MTHL-QP-014, Rev-02, the performance of the performance testing. However, these rejected bolts

bolts shall be determined by testing the bolts were already tightened in Large-block transverse

using axial force meter, before assembly. joints.

After satisfactory testing results, bolts shall be Sr. Length LB Joint Batch No. Rej.

issued to assembly and further tightening. No (mm) Assy. No. Qty.

No.

1 115 SE2- J32 B1283013A 612

B4

2 105 SW2- J37 B1283012A 652

B5

3 115 SW2- J40 B1283013A 612

B5

All the values (*) are out of the tolerance limits.

Quality Manager (DTJV) :

Rahul Jaitpal

Non-Conformity related to (Tick appropriate reason):

☐ Drawing revision / Modification / drawing error; ☐ Mismatch of Civil drg. with Mech & Elec drg, ☐ Defective workmanship / Materials /

Equipment, ☐Transit Damages, ☐ Mishandling of items at site, ☐ Improper storage, ☐ Inspection Error, ☐ Approved Procedures /

FQP / QAP not followed, ☐ Natural Calamities, ☐ Inadequate Inputs / Resources/ QA System / Materials

Proposed Resolution (Tick appropriate box): ☐ Accept as it is ☒ Rework ☐ Repair ☐ Reject

Details of Rework / Repair / Reason for accepting as it is :

Quality Manager (Sub- Manager (DTJV) : Agreed date of closure:

contractor/ Supplier) :

Final Disposition: ☐ Accepted ☐ Accepted with deviation ☐ Rejected

Non Conformity related to (Tick appropriate reason):

(i) Drawing revision / Modification / drawing error, (ii) Mismatch of Civil drg. with Mech & Elec drg, (ii) Defective workmanship / Materials /

Equipment, (iv) Transit Damages, (v) Mishandling of items at site, (vi) Improper storage, (vii) Inspection Error, (viii) Approved Procedures

/ FQP / QAP not followed, (ix) Natural Calamities, (x) Inadequate Inputs / Resources/ QA System / Materials

Details of Correction done:

Quality Manager (Sub- FQE / Quality Customer** Actual date of closure:

contractor/ Supplier) : Manager (DTJV) :

Root Cause Analysis by 5 Why Method:

Why

Why

Why

Why

Why

Quality Manager (Sub-contractor/ Supplier) : Quality Manager (DTJV) :

Corrective Action based on 5 Why Analysis:

Quality Manager (Sub-contractor/ Supplier) : Quality Manager (DTJV) :

* Major: Non-conformities which require Engineering / Customer approval / Revision of drawing / Major Rework.

* Minor: Non-conformities which do not fall in the above categories. 5 Why Analysis is not required for Minor NCs.

Distribution: DTJV / GC ** ** If applicable

Form No. FQ/008, Rev No. 5

You might also like

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- BHCP1-JEL-RFI-M00-Z0696 - A - RFI Fit-Up Nozzle SW1 (R)Document5 pagesBHCP1-JEL-RFI-M00-Z0696 - A - RFI Fit-Up Nozzle SW1 (R)biruhtayibaNo ratings yet

- Service Technical Report: Prod. ChangeDocument3 pagesService Technical Report: Prod. ChangeTechniekerNo ratings yet

- Service Technical Report: Prod. ChangeDocument3 pagesService Technical Report: Prod. ChangeTechniekerNo ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- CFS 504 100 57 60D SL GL NSG - CLF500173 A2Document3 pagesCFS 504 100 57 60D SL GL NSG - CLF500173 A2ganesangNo ratings yet

- Wire PDFDocument3 pagesWire PDFm.aliNo ratings yet

- LA Ravi Sir NC 7Document6 pagesLA Ravi Sir NC 7mangalamtestingbureaNo ratings yet

- Service Technical Report: Prod. ChangeDocument3 pagesService Technical Report: Prod. ChangeTechniekerNo ratings yet

- North South Commuter Railway Extension (Nscr-Ex) Project Document Review Comment (DRC) SheetDocument24 pagesNorth South Commuter Railway Extension (Nscr-Ex) Project Document Review Comment (DRC) SheetChristopher RomeronaNo ratings yet

- 1.5MM 304Document1 page1.5MM 304pankaj kumarNo ratings yet

- WI-NG-6460-002-065 Work Instruction For Circuit Breaker Fail Protection (5062) Rev00Document6 pagesWI-NG-6460-002-065 Work Instruction For Circuit Breaker Fail Protection (5062) Rev00Mohamed NasrNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- Gpti Qicl J931 Mut 002Document2 pagesGpti Qicl J931 Mut 002uselessinstaid52No ratings yet

- Failure Analysis Report AFA 1Document5 pagesFailure Analysis Report AFA 1bartanto59No ratings yet

- Gpti Qicl J931 Mut 004Document3 pagesGpti Qicl J931 Mut 004uselessinstaid52No ratings yet

- DRP001 Ouf Gal Pro Q 000 064 S1Document26 pagesDRP001 Ouf Gal Pro Q 000 064 S1Rafat KhanNo ratings yet

- Bis-Dk-Rt-1049 - Ip2022-CeDocument2 pagesBis-Dk-Rt-1049 - Ip2022-CeTomasPavlovicNo ratings yet

- WI-NG-6460-002-022 Work Instruction-NER Rev00Document5 pagesWI-NG-6460-002-022 Work Instruction-NER Rev00NaveenNavabNo ratings yet

- Examination Data Sheet: Walter TostoDocument3 pagesExamination Data Sheet: Walter TostoasdasdasdasdNo ratings yet

- E84 in TN CMBR GVRD NB 0001 502Document35 pagesE84 in TN CMBR GVRD NB 0001 502Balaji SowrirajanNo ratings yet

- QT1 1 L18 61 Nde 000008Document4 pagesQT1 1 L18 61 Nde 000008Triệu HiếuNo ratings yet

- Bis-Dk-Rt-1051 - Ip2022-NaDocument2 pagesBis-Dk-Rt-1051 - Ip2022-NaTomasPavlovicNo ratings yet

- Technical Description WSMB2015 ElectronicsDocument49 pagesTechnical Description WSMB2015 ElectronicszaizamNo ratings yet

- VT Report Outside 1 10-10Document8 pagesVT Report Outside 1 10-10Armnn RasmoNo ratings yet

- RDJ ITP 06 I 05 - Inspection and Test Plan For Fiber Optic Cabling and Termination - EN Rev00Document3 pagesRDJ ITP 06 I 05 - Inspection and Test Plan For Fiber Optic Cabling and Termination - EN Rev00محمد رمضانNo ratings yet

- Calibration CertificateDocument1 pageCalibration Certificatesathish K KumarNo ratings yet

- Req - 10546 - 003705 - 001 Oi-4408 MR Prabuddha PDFDocument3 pagesReq - 10546 - 003705 - 001 Oi-4408 MR Prabuddha PDFMadusanka WeebeddaNo ratings yet

- MIghty Machine RejectDocument1 pageMIghty Machine RejectMohammad Shanawaz MNo ratings yet

- Mechanical Past Year PaperDocument7 pagesMechanical Past Year PaperKriti PatelNo ratings yet

- Nfe1-Gac-Qm-Wps-00034 - 0001 - 0-C (Gac-Wps-S-004)Document7 pagesNfe1-Gac-Qm-Wps-00034 - 0001 - 0-C (Gac-Wps-S-004)rajan chaubeyNo ratings yet

- Nfe1-Gac-Qm-Wps-00033 - 0001 - 0-C (Gac-Wps-S-003)Document45 pagesNfe1-Gac-Qm-Wps-00033 - 0001 - 0-C (Gac-Wps-S-003)rajan chaubeyNo ratings yet

- 64-cbc Temp Controller Calibration CartificateDocument1 page64-cbc Temp Controller Calibration CartificateCustomer SupportNo ratings yet

- RR3-3269 Eo1352Document2 pagesRR3-3269 Eo1352Deepak HoleNo ratings yet

- Gpti Qicl J931 Mut 041Document3 pagesGpti Qicl J931 Mut 041uselessinstaid52No ratings yet

- 652-100-FINAL (ITP) Rev1Document4 pages652-100-FINAL (ITP) Rev1Anonymous AdofXEYAgENo ratings yet

- Sample FMEADocument20 pagesSample FMEATaufikRasyadiNo ratings yet

- PQR FLow LineDocument2 pagesPQR FLow Linesar sarNo ratings yet

- Epc3-Brt Pj. - Motor Operated ValvesDocument9 pagesEpc3-Brt Pj. - Motor Operated ValvesUsman ArifNo ratings yet

- 72-00-00 ENGINE - INSPECTION/CHECK-2 Pratt & Whitney CanadaDocument78 pages72-00-00 ENGINE - INSPECTION/CHECK-2 Pratt & Whitney CanadaAlexandre Manco100% (1)

- 304 1.5MM PCDocument1 page304 1.5MM PCsabir hussain100% (1)

- Roundness Check Record of 1St Shell CourseDocument1 pageRoundness Check Record of 1St Shell CourseRhannie GarciaNo ratings yet

- Kiem Tra Thiet Bi Truoc Khi Dong Dien (E-Ver RC2) - 2Document5 pagesKiem Tra Thiet Bi Truoc Khi Dong Dien (E-Ver RC2) - 2Thái TrầnNo ratings yet

- Inspection Notification (RFI) - 110 - 020 Rev 01Document2 pagesInspection Notification (RFI) - 110 - 020 Rev 01AliasgarNo ratings yet

- Sample MTC: Material Test CertificateDocument2 pagesSample MTC: Material Test CertificateSameer KmNo ratings yet

- VD V013 ZPM Pro 1507Document105 pagesVD V013 ZPM Pro 1507abdulNo ratings yet

- Quotation: M/S Dalhia Energy Service LTDDocument3 pagesQuotation: M/S Dalhia Energy Service LTDPawan MouryaNo ratings yet

- Failure ReportDocument2 pagesFailure Reportchristian samaritaNo ratings yet

- KCG057QV1DB G500 KyoceraDocument51 pagesKCG057QV1DB G500 Kyocerarodrigootavio5No ratings yet

- Comments : 437AL, 438AR, 451AL, 452AR 460Document9 pagesComments : 437AL, 438AR, 451AL, 452AR 460Suman BajracharyaNo ratings yet

- Webco 3rd Party Monitoring Audit Report - Rev 9 18 2015Document7 pagesWebco 3rd Party Monitoring Audit Report - Rev 9 18 2015virous08No ratings yet

- Maintenance Guide: Samsung Smart Digital Radiography SolutionDocument8 pagesMaintenance Guide: Samsung Smart Digital Radiography SolutionЮрий ОгаревNo ratings yet

- JL FD Carrier Manual TechnicalDocument7 pagesJL FD Carrier Manual Technicalsavic11No ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument4 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- Ahp 2X660 (WPS) )Document17 pagesAhp 2X660 (WPS) )Hema NandhNo ratings yet

- Certificate of ComplianceDocument7 pagesCertificate of ComplianceNabilah HusnaNo ratings yet

- 30 MM Gi Threaded Rod GR 8.8 - Tbi PDFDocument1 page30 MM Gi Threaded Rod GR 8.8 - Tbi PDFm.aliNo ratings yet

- NER Commissioning Rev01Document7 pagesNER Commissioning Rev01pradeepmv159No ratings yet

- LP Bypass Spray Control Valve Seal KitDocument6 pagesLP Bypass Spray Control Valve Seal KitsoorajssNo ratings yet

- 3100 KA107 DRE225S4 RS ProductData en DEDocument2 pages3100 KA107 DRE225S4 RS ProductData en DEProdução PelotasNo ratings yet

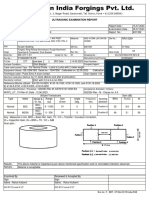

- NTPC Approved UT Procedure For ForgingDocument2 pagesNTPC Approved UT Procedure For ForgingDeepak UpadhayayNo ratings yet

- Sizing Calculations - ApprovedDocument14 pagesSizing Calculations - ApprovedDeepak UpadhayayNo ratings yet

- Salary Slip Deepak Upadhyay: Daewoo ST India Private LimitedDocument1 pageSalary Slip Deepak Upadhyay: Daewoo ST India Private LimitedDeepak UpadhayayNo ratings yet

- Employees' Provident Fund Organisation, India: Member Service HistoryDocument1 pageEmployees' Provident Fund Organisation, India: Member Service HistoryDeepak UpadhayayNo ratings yet

- TC File For BO 012 01 - CompressedDocument85 pagesTC File For BO 012 01 - CompressedDeepak UpadhayayNo ratings yet

- DWST-MTHL-QP014 BoltTighteningProcedureDocument11 pagesDWST-MTHL-QP014 BoltTighteningProcedureDeepak Upadhayay0% (1)

- DWST-MTHL-QP009 Non-Conforming Item Control ProcedureDocument15 pagesDWST-MTHL-QP009 Non-Conforming Item Control ProcedureDeepak UpadhayayNo ratings yet

- DWST-MTHL-QP006 WPSDocument21 pagesDWST-MTHL-QP006 WPSDeepak UpadhayayNo ratings yet

- DWST-MTHL-QP001 QualityPlanDocument37 pagesDWST-MTHL-QP001 QualityPlanDeepak UpadhayayNo ratings yet

- DWST-MTHL-QP007 Painting ProcedureDocument31 pagesDWST-MTHL-QP007 Painting ProcedureDeepak UpadhayayNo ratings yet

- OpTransactionHistory18 08 2021Document9 pagesOpTransactionHistory18 08 2021Deepak UpadhayayNo ratings yet

- DWST MTHL Qp001 QualityplanDocument40 pagesDWST MTHL Qp001 QualityplanDeepak UpadhayayNo ratings yet

- Material ManagementDocument53 pagesMaterial Managementamulaathi87% (15)

- Construction Management Term PaperDocument5 pagesConstruction Management Term Paperbctfnerif100% (1)

- AlternativeDocument15 pagesAlternativeDo NotNo ratings yet

- Column Flouris Aviation Project-Man PreviewDocument2 pagesColumn Flouris Aviation Project-Man PreviewW.J. ZondagNo ratings yet

- By: Arma, Jeanevive L. Azores, Dennice E. Martin, Nicole M. Masongsong, Jayka C. Mayor, Jessica D. Salamanca, Danica Mae CDocument11 pagesBy: Arma, Jeanevive L. Azores, Dennice E. Martin, Nicole M. Masongsong, Jayka C. Mayor, Jessica D. Salamanca, Danica Mae CJayka MasongsongNo ratings yet

- Staff Right Cover Letter - IBM ASEAN Permanent Placement RFP 2009 - 001Document2 pagesStaff Right Cover Letter - IBM ASEAN Permanent Placement RFP 2009 - 001jun_diazNo ratings yet

- Kotler Pom 15e 18Document33 pagesKotler Pom 15e 18jemblem66No ratings yet

- HRM NotesDocument2 pagesHRM NotesPrakash MahatoNo ratings yet

- Math Review 10 20222023Document1 pageMath Review 10 20222023Bui VyNo ratings yet

- Groupe Psa Case Submission: (Submitted by Mohit Singh - BJ22024)Document2 pagesGroupe Psa Case Submission: (Submitted by Mohit Singh - BJ22024)MOHIT SINGHNo ratings yet

- Chapter Five: Event MarketingDocument31 pagesChapter Five: Event MarketingHEC IPFPNo ratings yet

- Sathaye CollegeDocument5 pagesSathaye CollegeSuyash ShettyNo ratings yet

- Gi Group India A Corporate Presentation 2016 Ver 8 OnlineDocument28 pagesGi Group India A Corporate Presentation 2016 Ver 8 OnlineAllwin LNo ratings yet

- BUS 2201 Marketing P Unit 4 DA AssignmentsDocument3 pagesBUS 2201 Marketing P Unit 4 DA AssignmentsMamu KamNo ratings yet

- Project Quality Plan (JFJS-788)Document18 pagesProject Quality Plan (JFJS-788)mominNo ratings yet

- Executive Position Description - Power/mationDocument6 pagesExecutive Position Description - Power/mationKeyStoneSearchNo ratings yet

- Unit - I SM PPT CompleteDocument41 pagesUnit - I SM PPT CompleteVs SivaramanNo ratings yet

- Start Up PLDT Final PaperDocument13 pagesStart Up PLDT Final PaperYaba, Brixzel F.No ratings yet

- Procedure For Project Charter - 25 Aug 2011Document15 pagesProcedure For Project Charter - 25 Aug 2011Atif Mumtaz KhanNo ratings yet

- A2 Sajjad Mubin PDFDocument22 pagesA2 Sajjad Mubin PDFSajjad MubinNo ratings yet

- ISE 251 Session 1Document65 pagesISE 251 Session 1MasoudHabibzadahNo ratings yet

- Production Management Unit 1Document92 pagesProduction Management Unit 1Vikas Singh100% (1)

- PESTEL Analysis of Indian Capital MarketDocument4 pagesPESTEL Analysis of Indian Capital Marketdharmendra kumarNo ratings yet

- Laudon Emis13 PPT ch02Document47 pagesLaudon Emis13 PPT ch02Hafiz khalidNo ratings yet

- Mba 576Document6 pagesMba 576Hillary OdhiamboNo ratings yet

- Appendix To ISSAI 5000 EDocument4 pagesAppendix To ISSAI 5000 EAli HabibNo ratings yet

- MPR On RM and AMWAYDocument59 pagesMPR On RM and AMWAYIshaanGulatiNo ratings yet

- Web Advert 230513Document6 pagesWeb Advert 230513ToMemNo ratings yet

- Project Report by Afnan AlamDocument57 pagesProject Report by Afnan AlamDj debanuj BasuNo ratings yet

- ELEC 121 - Philippine Popular CultureDocument10 pagesELEC 121 - Philippine Popular CultureMARITONI MEDALLANo ratings yet