Professional Documents

Culture Documents

Risk Assesment For Chamber Construction

Uploaded by

Sasi Kumar0 ratings0% found this document useful (0 votes)

115 views5 pagesOriginal Title

risk assesment for chamber construction

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

115 views5 pagesRisk Assesment For Chamber Construction

Uploaded by

Sasi KumarCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 5

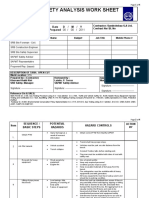

AL MARFAA ROAD CONTRACTING 6.

Risk Assessment for Chamber Construction PROJECT: Contract RM12B

Risk Risk Responsible

No Hazard Consequence Risk Level Prevention Risk Person

Level

S OP RR S OP RR

1 Hazards Personal 3 4 12 HR Ensure personnel working at 5 5 MR Site Engineer

during Injuries height wear a full body safety 1 ,Supervisor ,

scaffold Property harness having a “D-ring” on Foreman

erection & Damage the back. (100% Tie- ,Operator

Dismantling Off)Competent supervision

(fall of men Only essential personnel and

and equipment to be allowed on to

materials raised working platforms.

from height) Regular briefings, tool box talks

Scaffold to be given related to working

collapse at height.

All temporary working

platforms (scaffold systems )

shall be erected by trained and

certified personnel to accepted

design drawings

All scaffold systems shall be

regularly inspected by

competent persons every day &

recertified every 7 days.

All scaffold systems shall

display a valid (signed and

dated) scaffold tag to identify if

safe to use completed by

scaffold supervisor

Use double rail fixed barriers

and toe boards on leading

edges.

Ensure that scaffolding, steps

and ladders are installed as per

instructions, safety tagged and

secured for access and egress.

Scaffold will be checked for

fitness after erection by

competent individual.

Use of suitable load rated steel

life lines in absence of fixed

guard rails. ONLY to be installed

under supervision of the

Scaffolding Supervisor.

Adequate signage and exclusion

zones around temporary

structures

Structural design sign off before

loading by Scaffolding

Supervisor

No scaffold to be moved with

personal on scaffold.

Working at height training and &

harness training.

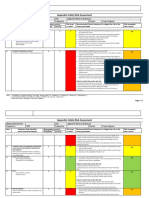

Hazards Do not use the red tagged

during Personal scaffold in for any reason. Only

Utilizing Injuries green tagged scaffold is safe to Site

2 scaffold after Property 3 4 12 ER use. 3 2 6 L engineer,

erection Damage All scaffold systems shall supervisor,

(fall from display a valid (signed and foreman

height dated) scaffold tag to identify if ,operator

Falling

Objects) safe to use.

Scaffold All scaffold systems shall be

collapse regularly inspected by

competent persons every day &

recertified every 7 days.

Do not alter a scaffold. Ask a

scaffolder to make any changes

you need and to be re-

inspected.

Set up exclusion zone around

scaffolding.

Do not remove guard-rails,

boards or any parts. The next

person to use that scaffold may

not know you have made

changes, and you may have

changed it from ‘’safe to use’’

status to ‘’harness required’’

status. If you need any

alterations on scaffolding,

please contact to Scaffolding

Supervisors. They will make the

necessary changes to make you

work safely.

All scaffolds are required to

have a ladder.

Ladders shall be inspected by

the user for damage prior to

use.

Do not overload scaffolds.

Never over reach from scaffold

3 Assessing People get 3 3 9 HR Wear correct hand gloves, 3 1 3 L

materials back pain, safety shoes, high reflecting

manual hand and leg jacket (PPE).

handling

injuries Specific manual handling

risks training held by HSE

department. Site Engineer

Regular briefings, tool box ,Supervisor ,

talks to be given related to Foreman

manual handling. ,Operator

Only pickup loads that can be

handled, around 15kg or less

or get the help of fellow

workers.

Proper communication

between people while

performing 2 or more man

lifting.

Ensure that the object is light

enough to lift, is stable and

unlikely to shift or move

Heavy or awkward loads

should be moved using a

handling aid. Make sure the

route is clear of obstructions.

Make sure there is

somewhere to put the load

down wherever it is to be

moved to.

Stand as close to the load as

possible, and spread your

feet to shoulder width, Bend

your knees and try and keep

the back's natural, upright

posture and grasp the load

firmly as close to the body as

you can.

Use the legs to lift the load in

a smooth motion as this

offers more leverage

reducing the strain on your

back.

Carry the load close to the body

with the elbows tucked into the

body. Avoid twisting the body as

much as possible by turning your

feet to position yourself with the

load.

4 UN- Injury to a 3 2 6 MR Provide the appropriate 3 1 3 LR site

Authorized member of fencing and/or barricades Engineer ,

entry by the public as per risk assessment. Superviso

others Apply appropriate r

signage and pedestrian

,Foreman

control.

Devise and implement safety

system for site inspection Officer

and security.

Ensure security and

equipment suitable to

minimize vandalism

Provide Warning sign

boards.

Site engineer must be on Site

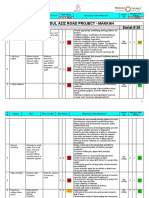

Hands/ Injury to 1 4 4 LR site 1 2 2 LR engineer,

Finger personnel Area drawings to be supervisor

5 injuries checked to establish , foreman

underground services safety

Necessary excavation Officer

permits from local

authority

Proper protection to the

hand while using the hand

tools

6 Heat High Body 5 3 15 Reduce activity levels 2 2 4 LR site

Stroke Temperatur and/or heat exposure. Engineer ,

e (over ER Drink fluids regularly. Superviso

40Degree Workers should check on r

Celsius has each other to help spot

,Foreman

hot, dry, red the symptoms which often

skin; a faint precede heat stroke. safety

pulse; a Officer

headache or

dizziness; in

later stages,

a person

may pass

out

7 Wrong Body Injury 4 3 12 HR Select proper lifting gear 3 2 6 MR

Selection Property Anchor Point Check

damage Lifting can only be

carried out with the

recommended lifting

gears and lifting

machines

To arrange proper lifting

gear and cranes

8 Wrong Body Injury 3 2 6 MR Competent & 1 3 3 LR

Assessme Experience lifting

nt supervisor (undergone

MOM lifting training)

Lifting supervisor to

assess the load and type

of lifting method to

used

9 Structure Body Injury 3 3 9 HR Welding eye lug must 3 2 6 MR

failure Property check by competent

(Eye lug) Damage person (e.g. safety

officer etc)

Verified the report prior

to lifting operation.

10 Falling Hand and 5 3 15 ER To be carried out be 3 2 6 MR

from finger qualified rigger

height (if injury Appropriate PPE used

rigging is (hand Glove etc.)

Select correct lifting

required

gear for the task (size

to be and capacity)

performe All loose items must be

d at secured / removed

height) Safety harness / safety

Falling belt to be used above

lifting 2m and on hanging

staging

gears

Ensure crane operator,

Improper rigger and signalman

handling have clear

communication (walkie

talkie)

11 Hit by Ensure tag line is

object installed

Restricte Ensure sufficient

d visibility manpower to handle tag

line

Foul

Don’t stand under

weather suspended load

Inadequa Ensure the immediate

te lighting lifting area is cordoned

Miscomm off

unication Stop crane movement if

load swing is too

extensive

Stop work during foul

weather

Use experience-lifting

crew for complicated

lift.

Swing slowing –

observed

You might also like

- 4.assembly & Erection of StructureDocument3 pages4.assembly & Erection of StructureFrancis Vinoj100% (1)

- JHA 15-Work at Height Using ScaffoldingDocument3 pagesJHA 15-Work at Height Using ScaffoldingWte SB100% (7)

- JSA For Working at HeightDocument2 pagesJSA For Working at HeightXUE JIANNo ratings yet

- Jsa For Hvac Equipment InstallDocument4 pagesJsa For Hvac Equipment Installpowergroup engineersNo ratings yet

- Specicifc Risk AssessmentDocument5 pagesSpecicifc Risk AssessmentAejaz MujawarNo ratings yet

- Testing Comissioning of Electrical SystemDocument8 pagesTesting Comissioning of Electrical Systemmo7d aliNo ratings yet

- Risk Assessment Form: Likelihood X Consequence RiskDocument1 pageRisk Assessment Form: Likelihood X Consequence RiskAijaz Ahmed Shaikh80% (5)

- Sra0019 Working at Height - ScaffoldDocument7 pagesSra0019 Working at Height - ScaffoldAjesh mohanNo ratings yet

- JSA Scafffolding Erection Dismantling ModificationDocument14 pagesJSA Scafffolding Erection Dismantling ModificationSheri DiĺlNo ratings yet

- Risk Assesment For GRP Pipe LayingDocument3 pagesRisk Assesment For GRP Pipe LayingSasi Kumar50% (4)

- RA Excavation For Hot WorkDocument4 pagesRA Excavation For Hot WorkSasi KumarNo ratings yet

- KAES-ERP-01 Rev 0Document76 pagesKAES-ERP-01 Rev 0firdous tantaryNo ratings yet

- JSA For Erection and Repair Work of TanksDocument19 pagesJSA For Erection and Repair Work of TanksMohamed Farouk100% (2)

- Hazard Profile Pipe Laying (Water Sewer) January 2010Document11 pagesHazard Profile Pipe Laying (Water Sewer) January 2010Mumtaz Ahmed Ghumman100% (2)

- RA For Installation of Air Colled ChillersDocument8 pagesRA For Installation of Air Colled ChillersAnandu Ashokan100% (2)

- Jsa Water Proofing For DHADocument13 pagesJsa Water Proofing For DHAAnonymous YmINeSIFNo ratings yet

- RA Excavation For ExcavationDocument13 pagesRA Excavation For ExcavationSasi KumarNo ratings yet

- 24 - Excavation and Trenching Procedure V2.0 PDFDocument46 pages24 - Excavation and Trenching Procedure V2.0 PDFSAFETY R50% (2)

- JSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware HouseDocument9 pagesJSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware Houseradeep100% (1)

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- Jha Swing Stage Scaffold PDFDocument2 pagesJha Swing Stage Scaffold PDFkaruna60% (5)

- HIRA No. 08 Rev 04 - Lifting ActivityDocument7 pagesHIRA No. 08 Rev 04 - Lifting ActivityVenkadesh PeriathambiNo ratings yet

- Incentive Program - GenericDocument16 pagesIncentive Program - GenericSasi Kumar100% (1)

- Risk Assessment Model For Pipe Rehabilitation and Replacement inDocument127 pagesRisk Assessment Model For Pipe Rehabilitation and Replacement inSasi KumarNo ratings yet

- Scaffolding Erection &dismanlting JSADocument7 pagesScaffolding Erection &dismanlting JSAShahid Bhatti100% (1)

- Jsa For Work at HeightsDocument4 pagesJsa For Work at Heightsjithin shankar100% (1)

- Manual of Standards On Laboratory Biosafety and Biosecurity (Published Copy) PDFDocument74 pagesManual of Standards On Laboratory Biosafety and Biosecurity (Published Copy) PDFErl Bryan Fisco100% (2)

- Safety Issues On Oil Terminals (UN)Document76 pagesSafety Issues On Oil Terminals (UN)MosaddekNo ratings yet

- Submittal Transmittal Sheet #: Project Name DB52-TH16-PQN-001 00 Submittal Title: Prequalification For ANTI TERMITEDocument1 pageSubmittal Transmittal Sheet #: Project Name DB52-TH16-PQN-001 00 Submittal Title: Prequalification For ANTI TERMITESasi KumarNo ratings yet

- Submittal Transmittal Sheet #: Project Name DB52-TH16-PQN-001 00 Submittal Title: Prequalification For ANTI TERMITEDocument1 pageSubmittal Transmittal Sheet #: Project Name DB52-TH16-PQN-001 00 Submittal Title: Prequalification For ANTI TERMITESasi KumarNo ratings yet

- Hse Monthly ReportDocument2 pagesHse Monthly Reportshubham dabasNo ratings yet

- DNV RP F107 PDFDocument45 pagesDNV RP F107 PDFaurovoraxNo ratings yet

- JSA SK Erection DismantlingDocument1 pageJSA SK Erection DismantlingSamuel Hugos100% (4)

- 15 Addc Induction Golden RuleDocument63 pages15 Addc Induction Golden RuleVenkadesh PeriathambiNo ratings yet

- Table 1 Risk Assessment Form (Hardness Testing)Document2 pagesTable 1 Risk Assessment Form (Hardness Testing)Owais MalikNo ratings yet

- JSA Mobile CranesDocument2 pagesJSA Mobile CranesAmanya DickallansNo ratings yet

- 6.risk Assessment of Epoxy Coating System (Rev-2) NEW OKDocument7 pages6.risk Assessment of Epoxy Coating System (Rev-2) NEW OKRisal SinuNo ratings yet

- Emediong U. - Risk Assessment Matrix 1 WorkingDocument20 pagesEmediong U. - Risk Assessment Matrix 1 WorkingsterlingNo ratings yet

- RA Excavation For Trial TrenchDocument9 pagesRA Excavation For Trial TrenchSasi KumarNo ratings yet

- TBA 19 Electrical Manual PDFDocument1,256 pagesTBA 19 Electrical Manual PDFSuryakant SinghNo ratings yet

- Risk Assesment For Chamber ConstructionDocument5 pagesRisk Assesment For Chamber ConstructionSasi KumarNo ratings yet

- JHA 01 Erecting Fixed ScaffoldingDocument4 pagesJHA 01 Erecting Fixed Scaffoldingadil khan100% (1)

- JSA - Acoustic EyeDocument2 pagesJSA - Acoustic EyeRonel John CustodioNo ratings yet

- Work at Height - JSADocument2 pagesWork at Height - JSARanadheer Reddy KanthalaNo ratings yet

- Annexure On Safety RequirementsDocument8 pagesAnnexure On Safety RequirementsPatel KuldeepNo ratings yet

- SL Work Activity Potential Hazards Preventive Measures/Action TakenDocument28 pagesSL Work Activity Potential Hazards Preventive Measures/Action TakenDarius DsouzaNo ratings yet

- JSA For Hydro Test Activites GenericDocument4 pagesJSA For Hydro Test Activites GenericMajdiSahnounNo ratings yet

- Job Hazard Analysis: Operation: Hazard: Action To Be TakenDocument6 pagesJob Hazard Analysis: Operation: Hazard: Action To Be TakenPaul MatherNo ratings yet

- Scaffolding ErectionDocument3 pagesScaffolding Erectionm.umarNo ratings yet

- Generic Risk Assessment For Use Of: Tower Scaffolds: Estates FacilitiesDocument8 pagesGeneric Risk Assessment For Use Of: Tower Scaffolds: Estates FacilitiesemmyNo ratings yet

- Job Safety Analysis For Geo Tech InvestigationDocument2 pagesJob Safety Analysis For Geo Tech InvestigationKarthi KeyanNo ratings yet

- New JuneDocument6 pagesNew JuneShovon khanNo ratings yet

- Mining Excavator Slewing Gear en 95Document1 pageMining Excavator Slewing Gear en 95plennyNo ratings yet

- Att.13 Safety Work Practice of Elevate Work 附件13:高空作业安全规程Document16 pagesAtt.13 Safety Work Practice of Elevate Work 附件13:高空作业安全规程Fuad NuzulaNo ratings yet

- 12. Job-safety Painting 内墙油漆工作安全分析Document2 pages12. Job-safety Painting 内墙油漆工作安全分析ADEN LIUNo ratings yet

- FPS 013 - Use of Boatswain chairREV1Document4 pagesFPS 013 - Use of Boatswain chairREV1grantNo ratings yet

- JSA - Structural Steel Errection Anerrection and DismantlingDocument5 pagesJSA - Structural Steel Errection Anerrection and DismantlingSwaroop CherryNo ratings yet

- 1.method Statement and Risk Assesment - SM ProductionDocument11 pages1.method Statement and Risk Assesment - SM ProductionAbdul HameedNo ratings yet

- Job Safety & Environmental Analysis WorksheetDocument2 pagesJob Safety & Environmental Analysis WorksheetCherry BetonioNo ratings yet

- 29CFR1926 600Document1 page29CFR1926 600PaulaErikaMANo ratings yet

- RISK ASSESSMENT - Screen RepairingDocument6 pagesRISK ASSESSMENT - Screen RepairingEricNo ratings yet

- UNIT 5 Scaffolds and LaddersDocument87 pagesUNIT 5 Scaffolds and Laddersmohsin khanNo ratings yet

- 20 RA Masonary WorkDocument3 pages20 RA Masonary WorkravindraNo ratings yet

- Example Risk AssessmentDocument7 pagesExample Risk AssessmentLerato RamatsuiNo ratings yet

- JSA For Scaffolding Erection Dismantling and Modification WorkDocument17 pagesJSA For Scaffolding Erection Dismantling and Modification Workshane.ramirez1980No ratings yet

- 10-Risk AssessmentFor Scaffolding WorkDocument1 page10-Risk AssessmentFor Scaffolding WorkNouman AliNo ratings yet

- Shoring TRADocument1 pageShoring TRAsyednehal1111No ratings yet

- Jsa (Ercction of Tower Crane) G-11Document4 pagesJsa (Ercction of Tower Crane) G-11khurram shahzadNo ratings yet

- Hazard Analysis LulDocument21 pagesHazard Analysis LulKarl Ethan MontefalcoNo ratings yet

- Jsa For Hydro Test Activites GenericDocument4 pagesJsa For Hydro Test Activites GenericShahid RazaNo ratings yet

- JSA For SURGE VESSEL WorkDocument6 pagesJSA For SURGE VESSEL Workathul subashNo ratings yet

- AHA Wall DemolishingDocument4 pagesAHA Wall Demolishinganilkumaranoop74No ratings yet

- Job Safety Analysis: Work at HeightDocument2 pagesJob Safety Analysis: Work at Heightmuhammad imtiazNo ratings yet

- JSA - Cast in Place Reinforced Concrete ChamberDocument8 pagesJSA - Cast in Place Reinforced Concrete ChamberSkinhead TvNo ratings yet

- 1..loading Unloading and Erection of Steel StructuresDocument2 pages1..loading Unloading and Erection of Steel StructuresFrancis VinojNo ratings yet

- JSA Working at Height PDFDocument2 pagesJSA Working at Height PDFVishnu VijayanNo ratings yet

- Concise Encyclopedia of System Safety: Definition of Terms and ConceptsFrom EverandConcise Encyclopedia of System Safety: Definition of Terms and ConceptsNo ratings yet

- You Are Looking So CuteDocument5 pagesYou Are Looking So CuteSasi KumarNo ratings yet

- HSE Internal Data Record Kumar DB 01Document16 pagesHSE Internal Data Record Kumar DB 01Sasi KumarNo ratings yet

- I Love You PanniDocument6 pagesI Love You PanniSasi KumarNo ratings yet

- KDC HSE-IIPPManual v.2015Document156 pagesKDC HSE-IIPPManual v.2015Sasi KumarNo ratings yet

- Espoo Report Chapter 5 Risk Assessment - 20090201 PDFDocument69 pagesEspoo Report Chapter 5 Risk Assessment - 20090201 PDFMOHAMEDNo ratings yet

- Hindustan Prefab Limited: (A Govt. of India Enterprises) Abstract of CostDocument4 pagesHindustan Prefab Limited: (A Govt. of India Enterprises) Abstract of CostSasi KumarNo ratings yet

- New Employee Safety Orientation EnglishDocument32 pagesNew Employee Safety Orientation Englishjhay lagmanNo ratings yet

- Hindustan Prefab Limited KayamkulamDocument1 pageHindustan Prefab Limited KayamkulamSasi KumarNo ratings yet

- Hindustan Prefab Limited: (A Govt. of India Enterprises) Abstract of CostDocument8 pagesHindustan Prefab Limited: (A Govt. of India Enterprises) Abstract of CostSasi KumarNo ratings yet

- Hindustan Prefab Limited: S.O Ae/Aee Project Manager ContractorDocument10 pagesHindustan Prefab Limited: S.O Ae/Aee Project Manager ContractorSasi KumarNo ratings yet

- Hindustan Prefab Limited TrivandrumDocument1 pageHindustan Prefab Limited TrivandrumSasi KumarNo ratings yet

- Labour Work ReportDocument4 pagesLabour Work ReportSasi KumarNo ratings yet

- Monthly Fire Safety InspectionDocument1 pageMonthly Fire Safety InspectionSasi KumarNo ratings yet

- Excavation, Trenching and Shoring Operations: The Dynamics and Dangers of Working With DirtDocument12 pagesExcavation, Trenching and Shoring Operations: The Dynamics and Dangers of Working With DirtShoeb MohammedNo ratings yet

- Hindustan Prefab Limited: S.O Ae/Aee Project Manager ContractorDocument10 pagesHindustan Prefab Limited: S.O Ae/Aee Project Manager ContractorSasi KumarNo ratings yet

- 2012-10-17 Final Audit Report On Project Management Practice PDFDocument20 pages2012-10-17 Final Audit Report On Project Management Practice PDFmrreezmanNo ratings yet

- Welding Machine Daily Inspection ChecklistDocument1 pageWelding Machine Daily Inspection ChecklistSasi KumarNo ratings yet

- Project: Location: Date:: Check Sheet For ExcavatorDocument1 pageProject: Location: Date:: Check Sheet For ExcavatorSasi KumarNo ratings yet

- Forklift Truck Checklist: Signature of Site in Charge: Signature of Site EngineerDocument1 pageForklift Truck Checklist: Signature of Site in Charge: Signature of Site EngineerSasi KumarNo ratings yet

- Analisis Kerentanan Bangunan Rangka Beton Dengan Dan Tanpa Shear WallsDocument8 pagesAnalisis Kerentanan Bangunan Rangka Beton Dengan Dan Tanpa Shear WallsAngga DestyaNo ratings yet

- SUN2000 - (2KTL-6KTL) - L1 User ManualDocument137 pagesSUN2000 - (2KTL-6KTL) - L1 User ManualMuresan AlinaNo ratings yet

- Electronic Liquid Weigher 2005Document38 pagesElectronic Liquid Weigher 2005Gheorghe Claudiu100% (1)

- MSDS To 1020 60 U PDFDocument8 pagesMSDS To 1020 60 U PDFanisaanNo ratings yet

- l77 - Guidance From The Licensing Authority On The Adventure Activities Licensing Regulations 2004Document47 pagesl77 - Guidance From The Licensing Authority On The Adventure Activities Licensing Regulations 2004VIRUPAKSHA KOOLINo ratings yet

- Public Version of HPC PCSR3 Sub-Chapter 3.2 - Classification of Structures, Systems, Safety Features and ComponentsDocument87 pagesPublic Version of HPC PCSR3 Sub-Chapter 3.2 - Classification of Structures, Systems, Safety Features and ComponentsEm GerNo ratings yet

- Needs Assessment: Dr. Sylvia A. DelosaDocument38 pagesNeeds Assessment: Dr. Sylvia A. Delosaaj karimNo ratings yet

- Group 3 Industrial HygieneDocument20 pagesGroup 3 Industrial HygieneMary Adela Dela CruzNo ratings yet

- Sodium Lauryl SulphateDocument6 pagesSodium Lauryl SulphateIbrahim MoNo ratings yet

- Chlorpheniramine (Maleate)Document5 pagesChlorpheniramine (Maleate)Eka KusyantoNo ratings yet

- Auda GDR 2013 PDFDocument277 pagesAuda GDR 2013 PDFakshay khanejaNo ratings yet

- Surat Izin Kerja AmanDocument1 pageSurat Izin Kerja AmanNUNIK CELLNo ratings yet

- 01 Hans Robot Elfin Maunal Hardware Installation EN PDFDocument36 pages01 Hans Robot Elfin Maunal Hardware Installation EN PDF123qweNo ratings yet

- Effectively Managed EmergencyDocument2 pagesEffectively Managed EmergencyMuhammad RamzanNo ratings yet

- 003 Fence RelocationDocument2 pages003 Fence RelocationCan BolkanNo ratings yet

- Building Safety Competence Information For Principal Contractors and Principal DesignersDocument13 pagesBuilding Safety Competence Information For Principal Contractors and Principal DesignersbesongNo ratings yet

- HYSAFE D113 Version 1.1Document89 pagesHYSAFE D113 Version 1.1aristote onassisNo ratings yet

- Pneudri DH SeriesDocument137 pagesPneudri DH SeriesBerryNo ratings yet

- Disaster Risk Management Thesis TopicsDocument5 pagesDisaster Risk Management Thesis Topicsybkpdsgig100% (2)

- Personal Protective Equipment (PPE)Document52 pagesPersonal Protective Equipment (PPE)Yeyeri SantosNo ratings yet

- Product Liability Seminar SlidesDocument90 pagesProduct Liability Seminar Slidessushilk28No ratings yet

- Signal Man For RiggerDocument1 pageSignal Man For RiggerAndi ZoellNo ratings yet