Professional Documents

Culture Documents

Gage Repeatability and Reproducibility Data Sheet Variable Data Results

Gage Repeatability and Reproducibility Data Sheet Variable Data Results

Uploaded by

amitvohraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gage Repeatability and Reproducibility Data Sheet Variable Data Results

Gage Repeatability and Reproducibility Data Sheet Variable Data Results

Uploaded by

amitvohraCopyright:

Available Formats

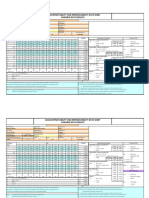

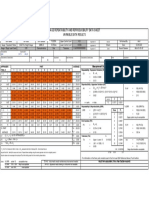

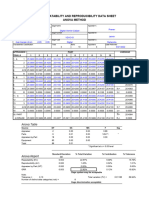

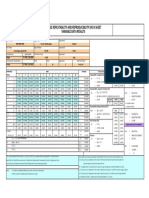

GAGE REPEATABILITY AND REPRODUCIBILITY DATA SHEET

VARIABLE DATA RESULTS

Part Name Support Gear Part Number P210514 Upper Control Limit 48.1 Appraiser A Gaurav Performed By Amit

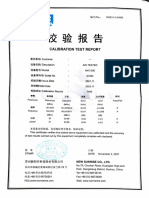

Gauge / Equipment Name DIGITAL Height Gauge DC-03 0-600mm Lower Control Limit 48.2 Appraiser B Bheem Date 13.04.2021

Gauge / Equip. Least Count 0.01 Characteristics Dim Tolerance -0.100000000000001 Appraiser C Sahil Record Number MSA-13-21-02

Characteristic Specification

DIM 48.1 48.2

Characteristic Classification Trials Parts Appraisers Date Performed Characteristic Classification Trials Parts Appraisers

3 10 3 3 10 3

APPRAISER/ PART AVERAGE Measurement Unit Analysis % Tolerance (Tol)

TRIAL # 1 2 3 4 5 6 7 8 9 10 Repeatability - Equipment Variation (EV)

1. A 1 48.152 48.122 48.182 48.153 48.132 48.190 48.150 48.150 48.150 48.150 48.153 EV = R x K1 Trials K1 % EV = 100 (EV/Tol)

2 2 48.152 48.120 48.178 48.155 48.136 48.188 48.160 48.160 48.160 48.160 48.157 = 0.007 x 0.5908 2 0.8862 = 100(0.004/0.017)

3 3 48.154 48.119 48.175 48.152 48.135 48.186 48.150 48.150 48.150 48.150 48.152 = 0.004 3 0.5908 = 25.76

4 AVE 48.15 48.12 48.18 48.15 48.13 48.19 48.15 48.15 48.15 48.15 xa= 48.154 Reproducibility - Appraiser Variation (AV)

5 R 0.00 0.00 0.01 0.00 0.00 0.00 0.01 0.01 0.01 0.01 ra= 0.006 AV = {(xDIFF x K2)2 - (EV2/nr)}1/2 % AV = 100 (AV/Tol)

6. B 1 48.153 48.123 48.181 48.150 48.136 48.190 48.150 48.170 48.150 48.150 48.155 = {(0.001 x 0.5231)^2 - (0.004 ^2/(10 x 3))}^1/2 = 100(0.018/0.017)

7 2 48.150 48.120 48.182 48.160 48.137 48.189 48.160 48.160 48.160 48.160 48.158 = 0.018 = 105.56

8 3 48.152 48.120 48.179 48.150 48.135 48.188 48.150 48.150 48.150 48.150 48.152 Appraisers 2 3

9 AVE 48.15 48.12 48.18 48.15 48.14 48.19 48.15 48.16 48.15 48.15 xb= 48.155 n = parts r = trials K2 0.7071 0.5231

10 R 0.00 0.00 0.00 0.01 0.00 0.00 0.01 0.02 0.01 0.01 rb= 0.007 Repeatability & Reproducibility (GRR) % GRR = 100 (GRR/Tol)

11. C 1 48.153 48.123 48.180 48.150 48.136 48.190 48.150 48.170 48.150 48.150 48.155 GRR = {(EV2 + AV2)}1/2 Parts K3 = 100(0.018/0.017)

12 2 48.150 48.123 48.170 48.160 48.138 48.188 48.160 48.160 48.151 48.160 48.156 = {(0.004^2 + 0.018^2)}^1/2 2 0.7071 = 108.65

13 3 48.153 48.120 48.160 48.150 48.139 48.190 48.150 48.150 48.150 48.150 48.151 = 0.018 3 0.5231 Gage system not acceptable

14 AVE 48.15 48.12 48.17 48.15 48.14 48.19 48.15 48.16 48.15 48.15 x c= 48.154 Part Variation (PV) 4 0.4467

15 R 0.00 0.00 0.02 0.01 0.00 0.00 0.01 0.02 0.00 0.01 rc= 0.008 PV = RP x K3 5 0.4030 % PV = 100 (PV/Tol)

16. PART X= 48.154 = 0.068 x 0.3146 6 0.3742 = 100(0.021/0.017)

AVERAGE 48.15 48.12 48.18 48.15 48.14 48.19 48.15 48.16 48.15 48.15 Rp= 0.068 = 0.021 7 0.3534 = 127.73

17 (ra + rb + rc) / (# OF APPRAISERS) = R= 0.007 Tolerance (Tol) tv 8 0.3375

18 xDIFF = (Max x - Min x) = xDIFF 0.001 Tol = Upper - Lower / 6 0.027948 9 0.3249 ndc = 1.41(PV/GRR)

19 * UCLR = R x D4 UCL 0.019 = ( 48.1 - 48.2 ) / 6 10 0.3146 = 1.41(0.021/0.018)

= 0.017 = 1

* D4 =3.27 for 2 trials and 2.58 for 3 trials. UCLR represents the limit of individual R's. Circle those that are 1.41 0.361538 Gage discrimination not acceptable

beyond this limit. Identify the cause and correct. Repeat these readings using the same appraiser and unit as originally used or 0.156 0.04 3.9

discard values and re-average and recompute R and the limiting value from the remaining observations.

For information on the theory and constants used in the form see MSA Reference Manual, Fourth edition.

Notes: % GRR under 10 acceptable msa EV>AV : instruments needs maintenance,improvement needed ndc≥5 then acceptable ( if less than 5 action required)

% GRR 10% - 30% May be acceptable AV>EV : Appraiser needs training or instrument not readable

% GRR over 30% unacceptable

You might also like

- Cubuilt Cepl VC 02 MsaDocument1 pageCubuilt Cepl VC 02 MsaCu Built Engineers Pvt. Ltd.No ratings yet

- Hypothesis Testing RoadmapDocument2 pagesHypothesis Testing RoadmapRam KumarNo ratings yet

- Gauge Repeatability & Reproducability Study: Results / EvaluationDocument3 pagesGauge Repeatability & Reproducability Study: Results / EvaluationPrasad Shridhar KulkarniNo ratings yet

- PETREL 12 Well EngineeringDocument30 pagesPETREL 12 Well EngineeringKuala TamboraNo ratings yet

- Design Calculation For Raising PlateformDocument15 pagesDesign Calculation For Raising PlateformAbdul Hameed100% (1)

- Design of Davit Arm & SupportDocument4 pagesDesign of Davit Arm & Supportorode franklynNo ratings yet

- 30m Anchor and Base Plate MonopoleDocument6 pages30m Anchor and Base Plate MonopoleEhtesham AliNo ratings yet

- BUllYING RESEARCHDocument49 pagesBUllYING RESEARCHGinno Marcelo100% (2)

- Levels of CommunicationDocument3 pagesLevels of CommunicationAiyaz ShaikhNo ratings yet

- Eu Furniture MarketDocument307 pagesEu Furniture MarketCarolina0% (1)

- Heat Rate Improvement Reference Manual TR-109546Document301 pagesHeat Rate Improvement Reference Manual TR-109546AntoniusMahendraAdhi100% (5)

- GR&R Variable October 2019 Check - As FoundDocument5 pagesGR&R Variable October 2019 Check - As FoundxharpreetxNo ratings yet

- Gauge Repeatability and Reproducibility Data Sheet Variable Data ResultsDocument5 pagesGauge Repeatability and Reproducibility Data Sheet Variable Data ResultsSharif KhanNo ratings yet

- Female LeadershipDocument36 pagesFemale LeadershipBilu100% (1)

- High MastDocument16 pagesHigh MastIam VinitNo ratings yet

- Annual Instructional Supervisory Plan NewDocument4 pagesAnnual Instructional Supervisory Plan NewJosephDulatre100% (4)

- Optimum Array Processing: Part IV of Detection, Estimation, and Modulation TheoryFrom EverandOptimum Array Processing: Part IV of Detection, Estimation, and Modulation TheoryNo ratings yet

- Final Na Print NowDocument32 pagesFinal Na Print NowCharlott Chen AlvarezNo ratings yet

- Mcdonalds SCM Project Report Plagiarism ReportDocument75 pagesMcdonalds SCM Project Report Plagiarism Reportsantosh kumarNo ratings yet

- Msa VV401Document1 pageMsa VV401amitvohraNo ratings yet

- Msa mm01Document1 pageMsa mm01amitvohraNo ratings yet

- GR&R (9.50)Document1 pageGR&R (9.50)Quality VenusNo ratings yet

- MSA of Sealing Plate DC-12Document2 pagesMSA of Sealing Plate DC-12RahulNo ratings yet

- Averages (X Bar Chart) : Gage R AnalysisDocument1 pageAverages (X Bar Chart) : Gage R AnalysisFernando BeltránNo ratings yet

- Msa hg01Document1 pageMsa hg01amitvohraNo ratings yet

- Interpretation of Core Test Results (Grade M 40 at FG Yard) : Patch 01 & 02Document2 pagesInterpretation of Core Test Results (Grade M 40 at FG Yard) : Patch 01 & 02Sasanka SekharNo ratings yet

- Tank 264Document4 pagesTank 264Vipul SharmaNo ratings yet

- Transverse Vibrations of A BeamDocument10 pagesTransverse Vibrations of A Beammazen ashaNo ratings yet

- ADAPT TN294 RC DFLTN Crack Ex 12Document7 pagesADAPT TN294 RC DFLTN Crack Ex 12CarsonBakerNo ratings yet

- Tank 265Document4 pagesTank 265Vipul SharmaNo ratings yet

- Contoh Perhitungan Uji Triaxial: Vertical Dial (Div) Vertical Dial (CM) Vertical Dial (Div)Document26 pagesContoh Perhitungan Uji Triaxial: Vertical Dial (Div) Vertical Dial (CM) Vertical Dial (Div)Yoga PriyantNo ratings yet

- Mat Foundation Design: Soil Data MaterialsDocument2 pagesMat Foundation Design: Soil Data MaterialsYisrael AshkenazimNo ratings yet

- GR&R Data Sheet GR&R Data Sheet: Variable Data Results - Total Variation Variable Data Results - Total VariationDocument4 pagesGR&R Data Sheet GR&R Data Sheet: Variable Data Results - Total Variation Variable Data Results - Total VariationRahulNo ratings yet

- Design and Analysis ReportDocument8 pagesDesign and Analysis ReportIfiokobong AkpanNo ratings yet

- Marin E: 124 DescriptionDocument1 pageMarin E: 124 Descriptionshaikh junaidNo ratings yet

- Camera Calibration ReportDocument5 pagesCamera Calibration ReportadintNo ratings yet

- R&R Probador de Fugas 5 Piezas, 3 Intentos, 2 Operadores, 0a4Document3 pagesR&R Probador de Fugas 5 Piezas, 3 Intentos, 2 Operadores, 0a4Jesus HernandezNo ratings yet

- Tabla de Impedancia Cables Media TensionDocument7 pagesTabla de Impedancia Cables Media Tensionvcontrerasj72No ratings yet

- Factor Analysis: NotesDocument6 pagesFactor Analysis: NotesInthiyaz KothapalleNo ratings yet

- Msa (25.40)Document1 pageMsa (25.40)Quality VenusNo ratings yet

- Reliability: NotesDocument37 pagesReliability: NotesryntubbNo ratings yet

- Reliability: NotesDocument37 pagesReliability: NotesRahul PaulNo ratings yet

- Tank 266Document4 pagesTank 266Vipul SharmaNo ratings yet

- 518kHz Navtex ReceptionDocument18 pages518kHz Navtex ReceptionJose Antonio López FernándezNo ratings yet

- Lumax Quality System: Gauge TypeDocument4 pagesLumax Quality System: Gauge TypeHarkesh KumarNo ratings yet

- Trial EmbankmentDocument3 pagesTrial EmbankmentAhmad Rifqi syauqieNo ratings yet

- Graphs 111Document5 pagesGraphs 111sudhir kumarNo ratings yet

- Gauge Repeatability and Reproducibility Data Sheet Variable Data ResultsDocument1 pageGauge Repeatability and Reproducibility Data Sheet Variable Data ResultsSharif KhanNo ratings yet

- Results & DiscussionDocument6 pagesResults & DiscussionSung Tze LauNo ratings yet

- Reccomendation & Oss Data List: SectorDocument10 pagesReccomendation & Oss Data List: SectorAbdul FatahNo ratings yet

- Chapter 10Document5 pagesChapter 10Richelle DandoNo ratings yet

- REPETIBILIDAD Y REPRODUCIBILIDAD Parte 2Document6 pagesREPETIBILIDAD Y REPRODUCIBILIDAD Parte 2Juan Manuel De La CruzNo ratings yet

- Alinamiento Antenas SRT IfDocument5 pagesAlinamiento Antenas SRT IfJoseMiguelBlancoAlvarezNo ratings yet

- Assessment FactorDocument11 pagesAssessment FactorMurtaza IoBMNo ratings yet

- Single Cell Functional Test Report: Circle-Up EastDocument11 pagesSingle Cell Functional Test Report: Circle-Up EastAshish JaiswalNo ratings yet

- 249-317 Tec Aero Tue-C-100-293Document1 page249-317 Tec Aero Tue-C-100-293KiranNo ratings yet

- Cerato (LD) Advanced Alpha Automatic TransaxleDocument73 pagesCerato (LD) Advanced Alpha Automatic TransaxleM aliNo ratings yet

- THI - BAI TAP MẪU - 2.1GRR - Xbar-R - METHOD - MSA - MANUADocument11 pagesTHI - BAI TAP MẪU - 2.1GRR - Xbar-R - METHOD - MSA - MANUAHung PhamNo ratings yet

- Experiment 4 Pump CharacteristicsDocument7 pagesExperiment 4 Pump CharacteristicsJam JoNo ratings yet

- G R&RDocument12 pagesG R&Rpradeep kumarNo ratings yet

- GageRR Analisis RRDocument2 pagesGageRR Analisis RRYli S'cNo ratings yet

- PLUM - Ordinal Regression: WarningsDocument3 pagesPLUM - Ordinal Regression: WarningsAnastasia WijayaNo ratings yet

- Wagnr Beam Chandigarh 2Document6 pagesWagnr Beam Chandigarh 2Komborerai MuvhiringiNo ratings yet

- TEST REPORT FOR BRIDGE FinalDocument13 pagesTEST REPORT FOR BRIDGE FinalAjithKumar VeeramaniNo ratings yet

- Aircraft Design Project Ii: Infant Jesus College of EngineeringDocument25 pagesAircraft Design Project Ii: Infant Jesus College of Engineeringmaridurai mathanGNo ratings yet

- Jabel-BeamDesig Shear & Bending MonentDocument34 pagesJabel-BeamDesig Shear & Bending Monentjamesbeth162No ratings yet

- Turning Moment Diagram of Single Cylinder EngineDocument17 pagesTurning Moment Diagram of Single Cylinder EngineBuddhima Nivantha BandaraNo ratings yet

- Wind Energy 004Document17 pagesWind Energy 004Ankam VinodNo ratings yet

- 11 - 030215-030191 - 40 - 128 - 4+0 - UBT - Link1 - 2 - 3 - 4 (Upg Conf & Ant) - Rev01Document8 pages11 - 030215-030191 - 40 - 128 - 4+0 - UBT - Link1 - 2 - 3 - 4 (Upg Conf & Ant) - Rev01citius yogaNo ratings yet

- Factor Analysis: NotesDocument13 pagesFactor Analysis: NotesShankeyNo ratings yet

- Tape Test Inspection Report: S.M.B, Brake Pedal, Rocker Link, Toe HookDocument2 pagesTape Test Inspection Report: S.M.B, Brake Pedal, Rocker Link, Toe HookamitvohraNo ratings yet

- Callibration & Validation For Instruments in Kapotech IndustriesDocument5 pagesCallibration & Validation For Instruments in Kapotech IndustriesamitvohraNo ratings yet

- Daily Report SheetDocument18 pagesDaily Report SheetamitvohraNo ratings yet

- Inspection Report For Grey PrimerDocument1 pageInspection Report For Grey PrimeramitvohraNo ratings yet

- P10004382A - (AQP) Clutch PedalDocument7 pagesP10004382A - (AQP) Clutch PedalamitvohraNo ratings yet

- Kaizen Sheet (F16)Document1 pageKaizen Sheet (F16)amitvohraNo ratings yet

- Berger Paints India LimitedDocument4 pagesBerger Paints India LimitedamitvohraNo ratings yet

- Msa VV401Document1 pageMsa VV401amitvohraNo ratings yet

- Statistical Process Control Study: Process Is Good But Still Improvement Is RequiredDocument1 pageStatistical Process Control Study: Process Is Good But Still Improvement Is RequiredamitvohraNo ratings yet

- Msa mm01Document1 pageMsa mm01amitvohraNo ratings yet

- Msa hg01Document1 pageMsa hg01amitvohraNo ratings yet

- Managerial Economics: University of CalicutDocument73 pagesManagerial Economics: University of CalicutaaNo ratings yet

- QSEV Introduction Final RAHDocument29 pagesQSEV Introduction Final RAHPrapti SuraniNo ratings yet

- The Level of Satisfaction in The ImplemeDocument10 pagesThe Level of Satisfaction in The ImplemeFranchess Isabelle SeñoresNo ratings yet

- ENT Repreneurship (MGM-552) : AssignmentDocument4 pagesENT Repreneurship (MGM-552) : AssignmentSaniya sohailNo ratings yet

- Assignment of Busienss Research Methods KMBN 203Document5 pagesAssignment of Busienss Research Methods KMBN 203Yogesh RajputNo ratings yet

- College Prospectus 2022-23 MirandaDocument89 pagesCollege Prospectus 2022-23 MirandaamritharukNo ratings yet

- Transportation orDocument5 pagesTransportation orAaditya shahNo ratings yet

- Innovation Health and Wealth Report 2012dh - 134597Document36 pagesInnovation Health and Wealth Report 2012dh - 134597Alejandro CardonaNo ratings yet

- Gender SensitizationDocument3 pagesGender SensitizationakttripathiNo ratings yet

- Index Crime and Non Index CrimeDocument18 pagesIndex Crime and Non Index CrimeJemwel CalindongNo ratings yet

- Unprogrammed Decision Making : Massachusetts Institute of TechnologyDocument15 pagesUnprogrammed Decision Making : Massachusetts Institute of TechnologyamnaNo ratings yet

- Chapter 1Document19 pagesChapter 1Nikko Paulo100% (1)

- DS Fresher ResumeDocument3 pagesDS Fresher ResumeSandharshan Shetty MNo ratings yet

- Division of City Schools Division of Pasay Pasay City West High School Science Technology Engineering MathematicsDocument21 pagesDivision of City Schools Division of Pasay Pasay City West High School Science Technology Engineering MathematicsMa. Charlene Stephanie HilvanoNo ratings yet

- HSS Practical Guideline New 2023 PDFDocument113 pagesHSS Practical Guideline New 2023 PDFAlpha Online ClassNo ratings yet

- Appendix 6 Guideline On Regulatory Control of Api PDFDocument23 pagesAppendix 6 Guideline On Regulatory Control of Api PDFveeru_1319No ratings yet

- Apa Manual Chapter 2 SummaryDocument8 pagesApa Manual Chapter 2 SummaryAsma Masood0% (1)

- Cara Cara Buat Rujukan (Referencing)Document17 pagesCara Cara Buat Rujukan (Referencing)Hitsugaya TaichouNo ratings yet

- Case Study For Hardbound-1Document201 pagesCase Study For Hardbound-1Charchar Maglasang PonganNo ratings yet

- Schachter and SingerDocument2 pagesSchachter and SingerCorinne PothinNo ratings yet