Professional Documents

Culture Documents

HSE-HRA-FF-01 Welspun

HSE-HRA-FF-01 Welspun

Uploaded by

R. Ayyanuperumal AyyanuperumalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HSE-HRA-FF-01 Welspun

HSE-HRA-FF-01 Welspun

Uploaded by

R. Ayyanuperumal AyyanuperumalCopyright:

Available Formats

Welspun One Logistics Parks

Hazard Risk Assessment

Business / Project: COMPOUND WALL & LAND DEVELOPMENT

Method Statement Sheet: Risk Assessment Reference:

APPROVED BY

Assessor(s) – Name Position Signature Date

Name Position Signature Date

R.SEKAR General Manager – Operations

PRAVIEN Planning & Billing Engineer

SRI RAM K Project manager

R.AYYANUPERUMAL Sr.Safety officer

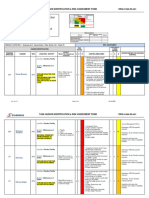

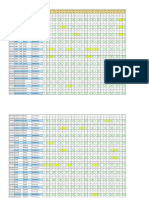

Date for Next Assessment Review: RISK MATRIX

Likelihood Severity Risk Factor Number (RFN/Residual Risk RR)

X =

Note: 1: Unlikely 1: Negligible 1-2: Trivial

Risks identified as “High risk” should be shown using the designation of “High risk” within the column of “Risk” on this assessment 2: Remote 2: Slight 3-5: Acceptable/Tolerable

document. 3: Quite possible 3: Moderate 6-9: Moderate (Acceptable with review)

New review – maximum of 90 days or if methodology risk/controls etc change.

4: Likely 4: High 10-15: Substantial

5: Very Likely 5: Very High 16-25: Intolerable/Unacceptable

Plant/Equipment : Dozar,Roller,Jcb,Cain Dozar Task Specific PPE : Helmet, Safety Shoes,Gumboot, Safety Foreman :

Jackets

Tools/Materials : Spade,Survey leveling Instrument

Consumables other resources – power/water etc : Permits : Permit for working on Excavtion Foreman or :

Signoff as specified

EHS-TMP-006 Rev 01 Page 1 of 8

June-2022

Welspun One Logistics Parks

Hazard Risk Assessment

Site – Relevant drawings (Drgs – XXX/XXX/T/XXXX) : Competent Person : Foreman :

Legend: A = Likelihood B = Severity C = Risk Factor Number (RFN/Residual Risk RR)

Sequential Job/Task Initial Responsible Person Re-

(Descripted in sufficient details to People at Risk Hazard Risk Assessment Control Measures (a single person for Assessment

enable assessment of risk) A B C each control) A B C

1) Wear nose mask all time and ensure face shield

while working nearby with other people.

2) Social distancing to be maintain by limiting four

1.Biological hazard person in one zone at different places,

3) Avoid gathering of workers during work. SiteEngineer

01.Engineer 2.Could 5 2 10 4) Frequent hand wash using sanitizer/soap oil. 3 2 6

COVID- 19 1)Infection spread Facility shall be provided at Fabrication yard,

02. Helper 3.Catch

Container location and working location.

5) Monitor body temperature before gate entry

4.through 6) Ensure only 8 labors entering as per Crisis

management team declared head count.

1.under over age

workers

2.health problem,

physical

1.Only medically fit workmen shall be

unfit,

deployed for this activity.

3.unauthorised entry , 2. Safety Induction & Job-specific training

4.unawareness of shall be provided.

site 3. Site safety rules & regulation shall be

1.Fall of Material condition and lack of SiteEngineer

01.Engineer explained in detail (use local language if

01.Mobilization of manpower 2.Fall of Person knowledge about his 3 2 6 required) prior to entry at the site premises. 3 1 3

02. Helper while unloading

activity, 4. HIRA briefing and Tool Box Talk shall be

materials conducted before the start of the activity.

5.entering site under

5. Emergency procedures should be

influence of alcohol,

explained in case emergency response.

6.entering under

construction site

without

PPE's.

EHS-TMP-006 Rev 01 Page 2 of 8

June-2022

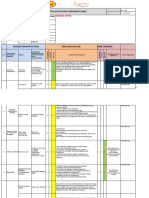

Welspun One Logistics Parks

Hazard Risk Assessment

Legend: A = Likelihood B = Severity C = Risk Factor Number (RFN/Residual Risk RR)

Sequential Job/Task Initial Responsible Person Re-

(Descripted in sufficient details to People at Risk Hazard Risk Assessment Control Measures (a single person for Assessment

enable assessment of risk) A B C each control) A B C

1. All personnel and workers including

operators must undergo & attend safety

induction at site.

2. Before starting the activity area clearance

should be obtain from client.

1. sharp objects 3. Safety Officer to conduct proper job specific

training to worker & personnel prior to carry-

2. vehicle equipment

out works and deploy on site.

movement. 4.Physically inspect work area prior to

3.snake poisoning start of work

1.Lack of 4.Staff, works & 5. Follow good housekeeping

1.Helper & Communication operators unfamiliar 6. Wear light colored cotton clothing. Site Engineer

2.Area Preparation work Driver Unathorized entry with HSE rules & 3 2 6 7. Ensure that all drivers and operators 3 1 3

procedures on-site have valid driving license.

project 8. Hand gloves while handling sharp edges

or operating power tools machinery.

9. First Aid facility shall be provided.

10. Adequate drinking water facilities.

11. Rest room facilities.

12. Keep patient calm, wash with plenty of

water and soap, and first apply a

constructive bandage on the heart side of

the bite applied for continuously 20

13. Pre-inspection of all power tools and hand

tools shall be done.

14. All workmen must be use the required

PPE's as per activity considerations as Safety

helmets, Safety Shoes, High visibility clothing,

hand gloves, ear plugs and nose mask.

EHS-TMP-006 Rev 01 Page 3 of 8

June-2022

Welspun One Logistics Parks

Hazard Risk Assessment

Legend: A = Likelihood B = Severity C = Risk Factor Number (RFN/Residual Risk RR)

Sequential Job/Task Initial Responsible Person Re-

(Descripted in sufficient details to People at Risk Hazard Risk Assessment Control Measures (a single person for Assessment

enable assessment of risk) A B C each control) A B C

01.Licenced drivers to be checked for delivery

vehicles

02.Lifting permit to be obtained

3.Trained & competent lifting operators &

supervisors to be deployed

4.Crane / farina inspection to be done

1.Fall of Material SiteEngineer

01.Driver& 01.Body parts injury 5.Lifting appliances & gears statutory

3.Unloading 2.Fall of Person 3 3 9 certificates to be checked 2 3 6

Helpers while unloading 02.Serious injury

6.Induction of the operators to be done

materials 7.Tag line to be used

8.Exclusion zone to be established

9.Signage’s to be displayed

10.Crane must be marched on firm, levelled

surface

11.Crane out riggers to be fully extended

12.Weather condition to be checked before to

lift

1.PPE (gum boot , red jacket, hard hat /

helmet ,goggles

2.Kept anti venom stand by at OHC

3.supervisor should be available at work area

4.necessary instruction/guidelines should be

given to workers by supervisor .

5.proper supervision is required by supervisor.

6.only demarked access way to be followed as

1.Fire per instruction of shift in-charge process.

1.Snake Bite / SiteEngineer

1.Helpers 2.Flying 7.must wear gum boot.

insects 8.immediately grass should be removed from

4.Grass cutter work 3.Particles 5 3 15 2 3 6

2.Fall hazard the said area.

4.Pour water 9.shifting of grass from location.

3.mud and sludge 5.Lonely work 10.pour water on stacked dry grass and keep

the same in wet condition.

11.Don’t entertain to do work lonely.

12.During shifting of grass the grass heap to

be covered with plastic cover .

13.safe sped limit to be followed inside the

plant.

14.spark arrestor for tractor to be ensured in

working condition.

EHS-TMP-006 Rev 01 Page 4 of 8

June-2022

Welspun One Logistics Parks

Hazard Risk Assessment

Legend: A = Likelihood B = Severity C = Risk Factor Number (RFN/Residual Risk RR)

Sequential Job/Task Initial Responsible Person Re-

(Descripted in sufficient details to People at Risk Hazard Risk Assessment Control Measures (a single person for Assessment

enable assessment of risk) A B C each control) A B C

1. Fatality /

1. Work near to the severe injury due to hit

moving Vehicles / by the moving

equipment. vehicles / equipment.

2. Manual cutting & 2. Fall from height and

material handling may result into 1. Barricading the work area.

4. Removal / cleaning of Surface encumbrances 3. Fall from height multiple injuries / 2 4 8 2. Engaging the competent operators. 1 4 4

trees, heap of soil, existing roads 4. Electrocution while fatality. 3. Taking approval from relevant authorities and SiteEngineer

01.Driver& 3. Cut injuries while ensure PTW.

using power tools

Helpers doing manual material 4. Imparting the HIRA talks before start of work.

5. Presence of

underground / handling.i.e. Shifting / 5. Avoiding the manual material handling as much

overhead services / pulling / pushing. as possible and introducing mechanical material

utilities; 4. Electrical handling for the removal of surface encumbrances.

6. Use of sharp hand burn/fatality

tools.

1. The radius where the Bucket is operated should

be barricaded.

1.Entanglement, & 2. Signal man should be made available to guide

slip or trip 1.Broken the operator

2.Physical hazards bones.dislocation,cut 3. Ensuring restriction of unauthorized personnel

wound to enter in the excavation area.

5.Removal of Soil 01.Operator& 3.movement of 2.hearing loss, 3 3 9 4. Ensuring all the personnel must wear reflective 2 2 4

machine and bucket

Helper disturbance of sleeping jacket. SiteEngineer

and person being hit

5. Ensuring by that JCB / excavator operator must

4.noise of machines aware of the surrounding area.

6. Operator should not use mobile phone or hear

music by inserting the head phone in the ear.

7. While swinging / reversing - indication horn

should be ON.

EHS-TMP-006 Rev 01 Page 5 of 8

June-2022

Welspun One Logistics Parks

Hazard Risk Assessment

Legend: A = Likelihood B = Severity C = Risk Factor Number (RFN/Residual Risk RR)

Sequential Job/Task Initial Responsible Person Re-

(Descripted in sufficient details to People at Risk Hazard Risk Assessment Control Measures (a single person for Assessment

enable assessment of risk) A B C each control) A B C

Following DOs & DON'Ts as listed below:

1. Don't leave the keys in the cabin.

2. Don't allow any other person / cleaner to drive

the vehicle.

3. Don't use Mobile phone while driving the

vehicle.

4. Parking of vehicles near the excavated area is

01.Operator ,

1.Speed, Hit, slip, trip 1.Collision Overturn strictly prohibited and also not in the access path SiteEngineer

Signal man

6.Heavy Vehicle movement & fall. Topple Fire 5. Minimum of 3 meters’ distance to be

&Helper 1 4 4

( DOZER,ROLLAR,CHAIN DOZER) 2. Entanglement,& 2.Hit by bucket 3 4 21 maintained from the excavation with parking light

Slip or trip 3.Physicalinjury/fatal and display signage.

3.workmen close to due to hit by 6. Avoid unnecessary parking.

the moving machinery. 7. Bank man or helper to deploy.

equipment/macinery. 8. First aid box and fire extinguisher must be kept

inside the cabin.

9. Maintenance to be carried out by an experience

mechanic.

10. Other than construction vehicles should not

take into the work locations.

1. Engaging trained personnel

2. Engaging a signal person wherever loading /

unloading in progress.

3. No personnel should come in the approach /

radius of the JCB bucket while loading sand in the

truck.

1.Workmen close to 4. Ensure that no personnel should stand in

7.Loading / Unloading of soil the moving 1.Physical injury/fatal thevicinity of loading activity.

equipment / due to hit by 5. Signal man should communicate once the

01.Operator& machinery. machinery. 4 5 9 loading has been completed in the truck & he 2 3 6

Signal man 2.Failure of lifting 2.Personal injury or should simultaneously inform the truck driver & SiteEngineer

gear fatal accident JCBoperator.

3.Topping of vehicle 3.property damage 6. Ensure that there must be a clear understanding

4.Miscommunication / communication between operator & signalmen.

between operator 7. Not overload the trucks since there is possibility

and signalman of skidding while travelling on the ramp.

8. Ensuring no personnel movement on ramps

whereas trucks are plying on the ramp.

9. Providing signal men, caution boards

&barricading.

EHS-TMP-006 Rev 01 Page 6 of 8

June-2022

Welspun One Logistics Parks

Hazard Risk Assessment

Legend: A = Likelihood B = Severity C = Risk Factor Number (RFN/Residual Risk RR)

Sequential Job/Task Initial Responsible Person Re-

(Descripted in sufficient details to People at Risk Hazard Risk Assessment Control Measures (a single person for Assessment

enable assessment of risk) A B C each control) A B C

1. Work near to the

moving Vehicles / 1. Barricading the vehicle movement area and

equipment. define pedestrian movement area separately.

2. Topple of vehicle 1. Fatal / severe injury 2. Ensuring that vehicle movement area is levelled

8.Surface levelling (general cutting / filling) 01.Driver& due to uneven ground due to hit by the 3 4 5 and well compacted. 1 4 4

Helper surface. moving vehicles / 3. Prior information to the concern departments of SiteEngineer

3. Presence of equipment. utility services and ensure de-energize / isolation

overhead / of source.

underground utilities.

1. Use of pesticide / bleaching powder / carbolic

01.Presence of Loss of consciousness acid

poisonous / heart attack / fatal 2. Ensure availability of emergency vehicle and

reptiles/inspects 02.Slip / trip/ fall may contact details/ tie up with local hospitals

02.Working near to result injury to the

the moving vehicles / personnel. 3.1. Ensuring general levelling of surface for

construction vehicles 03.Hit by the vehicle movement

Engineer 03.Improper Access / vehicles. 2. Deployment of flagman

&Helper working on uneven 04.1. Sun stroke due 3. Ensuring barricades to the work location at

to de-hydration. valley

ground surface;

2. Injuries / fell in sick / steep access / ramps are existing.

04.Working in

due to adverse 04.1. Ensuring competent driver.

extreme climatic

9.Surveying weather. 2. Displaying sign boards / caution boards.

conditions 4 6 24 3. Providing training / awareness & close SiteEngineer 4 3 12

05.Hit by the survey

05.Manual handling

instruments while monitoring

of survey instruments

shifting manually and 4. Using high visibility clothing.

while shifting

may receive injury. 05.1. Ensure availability of drinking water

manually.

2. Provide temporary rest sheds

3. Avoiding the work during extreme climatic

conditions e.g. Excessive cold/hot.

06.1. Ensuring supervision for safe execution of

work.

2. Creating awareness on manual material

handling by imparting training before start of

work.

3. Using appropriate PPE in the form of safety

shoes & hand gloves.

EHS-TMP-006 Rev 01 Page 7 of 8

June-2022

Welspun One Logistics Parks

Hazard Risk Assessment

Legend: A = Likelihood B = Severity C = Risk Factor Number (RFN/Residual Risk RR)

Sequential Job/Task Initial Responsible Person Re-

(Descripted in sufficient details to People at Risk Hazard Risk Assessment Control Measures (a single person for Assessment

enable assessment of risk) A B C each control) A B C

Including plying of Injury to personnel / 1.Vehiclemovement areamust be

10.Backfilling, Grading & Dumping Operator& vehicles on the fatal due to toppling of demarcated. SiteEngineer

2 4 8 2 2 4

Signal man uneven ground vehicle / equipment 2. Soil strengthening of vehicle movement

surface/ loose soil. / stuck in loose soil. area / road being done.

3. Impart HIRA Talk.

1. Stack the reinforcement rod on the base of the

concrete sleeper / concrete blocks & not on the

Injury / fatal due to: ground directly.

1. Over stacking of 1. Collapse of material 2. Material should not be stacked more than 3

Engineers &

Helpers material/ unstable on to workmen 2.Shift / layers of bundle.

11.Stacking of material manner collapse of stacked 3. All the bars should be tied - minimum at 3

2. Poor material material. places & especially at the end so that they are not

handling without 3. Hit by the loading/ 4 4 16 open. SiteEngineer 2 3 6

assessment unloading equipment. 4. Reinforcement should be laid in such a manner

3.Mechanical material that it does not block the passage.

handling 5. Soft barricading should be provided around the

area

6. Gap should be provided for easy lifting /

inspection of the material.

7. All the personnel should wear appropriate PPE.

1) Eye injury and 1) Gloves

irritation 2) Apron

Helper& 1.Physical Hazard 2) Inhalation 3) long sleeves SiteEngineer

2 3 6 1 2 2

12.House keeping Engineer 2.Prevent slip , 3) Foot injury 4) Wear respirator if needed

trips and falls 4) Hand injury 5) Wear Face Shield

5) Electric shock 6) Goggles

EHS-TMP-006 Rev 01 Page 8 of 8

June-2022

You might also like

- Premiertrak 400 - R400 (T4) Operations Manual Revision 1.0 (En)Document298 pagesPremiertrak 400 - R400 (T4) Operations Manual Revision 1.0 (En)Giuro Kralev83% (18)

- Hse PlanDocument62 pagesHse Plannsadnan64% (11)

- Soft Landscaping ROW Area Risk AssessmentDocument11 pagesSoft Landscaping ROW Area Risk AssessmentSIBIN100% (3)

- Epoxy PaintingDocument4 pagesEpoxy PaintingSaleem BashaNo ratings yet

- RA For Installation & Dismantling of Loading Platform A69Document15 pagesRA For Installation & Dismantling of Loading Platform A69Sajid ShahNo ratings yet

- 18 - Confined Space THA-AHADocument7 pages18 - Confined Space THA-AHAJojolas50% (2)

- L Risk Assessment Code (RAC) MatrixDocument6 pagesL Risk Assessment Code (RAC) MatrixMario Marasigan50% (2)

- DN Tanks: Step1: Review Each "Hazard" With Identified Safety "Controls" and Determine RAC (See Above)Document6 pagesDN Tanks: Step1: Review Each "Hazard" With Identified Safety "Controls" and Determine RAC (See Above)JojolasNo ratings yet

- 9 - Aerial Lifts and Scissor Lifts THA-AHADocument5 pages9 - Aerial Lifts and Scissor Lifts THA-AHAJojolas100% (2)

- Hoarding Install and DismantleDocument5 pagesHoarding Install and Dismantleஅருண்ராஜ் கிருஷ்ணன்சாமி100% (1)

- DR Barbara Lane Report - Appendix D - 1 PDFDocument45 pagesDR Barbara Lane Report - Appendix D - 1 PDFRauf HuseynovNo ratings yet

- RMIT Risk Assessment FormDocument3 pagesRMIT Risk Assessment FormJas DhillonNo ratings yet

- 09 Safe Handling of ChemicalsDocument23 pages09 Safe Handling of ChemicalsOladimeji Taiwo100% (1)

- Welspun One Logistics Parks: Hazard Risk AssessmentDocument2 pagesWelspun One Logistics Parks: Hazard Risk AssessmentR. Ayyanuperumal AyyanuperumalNo ratings yet

- CRA For Beam Stregthening WorksDocument4 pagesCRA For Beam Stregthening WorksVikki P ReddiNo ratings yet

- HIRA Electrical Works HRC 002Document7 pagesHIRA Electrical Works HRC 002syed khaja misbhuddinNo ratings yet

- DAIS I1912 HSE CRA AIPL 08 (Installation of Pelmet)Document2 pagesDAIS I1912 HSE CRA AIPL 08 (Installation of Pelmet)Aiplshubh ChavanNo ratings yet

- CRA - Structural Steel Staircase Fabrication Works at Leighton Plant YardDocument4 pagesCRA - Structural Steel Staircase Fabrication Works at Leighton Plant YardRiyas Mangodan100% (1)

- HIRA For DAHU - EXH Unit Romp 05Document8 pagesHIRA For DAHU - EXH Unit Romp 05syed khaja misbhuddinNo ratings yet

- Crane-Hydra-deployment For Lifting-Lowering-Risk AssessmentDocument4 pagesCrane-Hydra-deployment For Lifting-Lowering-Risk AssessmentAhmed El-sherpiniNo ratings yet

- Building Materials Risk AssessmentDocument3 pagesBuilding Materials Risk AssessmentAhmed El-sherpiniNo ratings yet

- RA For Installation & Dismantling of Loading Platform A69Document8 pagesRA For Installation & Dismantling of Loading Platform A69Sajid ShahNo ratings yet

- Abrasive Wheels Risk AssessmentDocument4 pagesAbrasive Wheels Risk AssessmentAhmed El-sherpiniNo ratings yet

- Risk Assessment (Night Shift) BND3Document11 pagesRisk Assessment (Night Shift) BND3Shazayn KhanNo ratings yet

- DAIS-I1912-HSE-CRA-AIPL-04-00 (Painting Work)Document3 pagesDAIS-I1912-HSE-CRA-AIPL-04-00 (Painting Work)Aiplshubh ChavanNo ratings yet

- RISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023Document6 pagesRISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023arabiangulfdoorest2008No ratings yet

- Bidaa Tower Risk Assessment From CALISTO UpdatedDocument5 pagesBidaa Tower Risk Assessment From CALISTO Updatedirshad gNo ratings yet

- HIRA - 04-Construction of Ball Handling Pit Rev-01Document30 pagesHIRA - 04-Construction of Ball Handling Pit Rev-01Bhagat DeepakNo ratings yet

- RA (Draft - Version - Unloading Water Cool Chiller)Document5 pagesRA (Draft - Version - Unloading Water Cool Chiller)Yan Naing HtooNo ratings yet

- AHA Ductbank InstallationDocument5 pagesAHA Ductbank InstallationYug DobariyaNo ratings yet

- RISK Assement AGE WEATHERFORDDocument6 pagesRISK Assement AGE WEATHERFORDarabiangulfdoorest2008No ratings yet

- Al Qooz Contracting LLC: Hazard Identification and Risk AssesmentDocument8 pagesAl Qooz Contracting LLC: Hazard Identification and Risk Assesmentشاز إياس100% (1)

- I2114-LI-HSE-CRA-005 (01) Raft ConcreteDocument7 pagesI2114-LI-HSE-CRA-005 (01) Raft ConcretePrasant Kumar SahooNo ratings yet

- RA (Working at Height)Document4 pagesRA (Working at Height)Yan Naing HtooNo ratings yet

- Rev 1 - Risk AssessmentDocument1 pageRev 1 - Risk AssessmentKhaled AlshomaliNo ratings yet

- Gadzoom Sample Activity Hazard Analysis TemplateDocument8 pagesGadzoom Sample Activity Hazard Analysis TemplateΝικολιδάκης ΒαγγέληςNo ratings yet

- RA For Builders Work A59Document11 pagesRA For Builders Work A59Sajid ShahNo ratings yet

- Risk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiDocument4 pagesRisk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiSamboy Dionisio0% (1)

- Sample Work Activity Ra Template 2016Document13 pagesSample Work Activity Ra Template 2016deboy90832No ratings yet

- 1 - Construction Mobilization THA-AHADocument5 pages1 - Construction Mobilization THA-AHAJojolas0% (1)

- 3 - Pipe Blocks & Sumps THA-AHADocument6 pages3 - Pipe Blocks & Sumps THA-AHAJojolasNo ratings yet

- Ra - Acoustic Wall Panel - Rev 01Document3 pagesRa - Acoustic Wall Panel - Rev 01ameen jouharNo ratings yet

- Risk Assessment For NDTDocument14 pagesRisk Assessment For NDTNestor Mijares100% (1)

- 1.ooreedoo - RA For Maintenance of Chillers. RevisedDocument6 pages1.ooreedoo - RA For Maintenance of Chillers. RevisedstarwingsNo ratings yet

- HIRADC Erection Steel FrameDocument7 pagesHIRADC Erection Steel FrameCrystin Rotua Hasmi PanjaitanNo ratings yet

- 4 - Powered Industrial Truck THA-AHADocument5 pages4 - Powered Industrial Truck THA-AHAJojolasNo ratings yet

- Scout Safe Risk AssessmentDocument1 pageScout Safe Risk Assessmentapi-348870392No ratings yet

- Risk Assesment - Floor Chasing and ScreedingDocument3 pagesRisk Assesment - Floor Chasing and Screedingirfan vpNo ratings yet

- Brick Laying Risk Assessment (SWMS)Document8 pagesBrick Laying Risk Assessment (SWMS)lenindraNo ratings yet

- 9.risk Assessment - Working in PantryDocument2 pages9.risk Assessment - Working in PantryManzur AhmadNo ratings yet

- Rev-01-Mariner WorkDocument40 pagesRev-01-Mariner Workrohit kumarNo ratings yet

- RA FormatDocument4 pagesRA Formatumesh kumarNo ratings yet

- Excavation RA d5chvjDocument4 pagesExcavation RA d5chvjmurasolimaranNo ratings yet

- Lifting Operations RA LdwcnsDocument3 pagesLifting Operations RA LdwcnsUmair Khan100% (1)

- Decking Risk AssessmentDocument4 pagesDecking Risk AssessmentReagan MukeboNo ratings yet

- Excavation Permmit To WorkDocument3 pagesExcavation Permmit To WorkWilson Wambua0% (1)

- Hirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODDocument4 pagesHirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODMohd Faiz MohdNo ratings yet

- Ehs Risk Register / Assessment: Name of The Project Reference No Activities CoveredDocument7 pagesEhs Risk Register / Assessment: Name of The Project Reference No Activities CoveredNirajan MarwaitNo ratings yet

- RA For Summer Heat Stress Management A71Document4 pagesRA For Summer Heat Stress Management A71Sajid Shah100% (2)

- Risk Assessment WorksheetDocument1 pageRisk Assessment WorksheetadnanNo ratings yet

- Activity Hazards Analysis (AHA) : Severity ProbabilityDocument8 pagesActivity Hazards Analysis (AHA) : Severity ProbabilitySAsaNo ratings yet

- AHA Flushing & Disinfection of Water SupplyDocument5 pagesAHA Flushing & Disinfection of Water SupplyLawrence adeleke OmisakinNo ratings yet

- Demolisation AhaDocument3 pagesDemolisation AhaLawrence adeleke OmisakinNo ratings yet

- Triple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsFrom EverandTriple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsNo ratings yet

- Ilovepdf MergedDocument36 pagesIlovepdf MergedR. Ayyanuperumal AyyanuperumalNo ratings yet

- Wel 16 - 28Document3 pagesWel 16 - 28R. Ayyanuperumal AyyanuperumalNo ratings yet

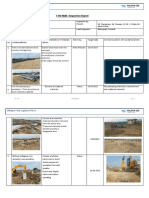

- EHS Walk / Inspection: Welspun One Logistics ParksDocument4 pagesEHS Walk / Inspection: Welspun One Logistics ParksR. Ayyanuperumal AyyanuperumalNo ratings yet

- M/S. Rar Retail & Infra LLP Chinnambedu Through: M/s. Welspun One Logistics ParkDocument1 pageM/S. Rar Retail & Infra LLP Chinnambedu Through: M/s. Welspun One Logistics ParkR. Ayyanuperumal AyyanuperumalNo ratings yet

- Welspun One Logistics Parks: Hazard Risk AssessmentDocument2 pagesWelspun One Logistics Parks: Hazard Risk AssessmentR. Ayyanuperumal AyyanuperumalNo ratings yet

- Clinton Joseph MurrayDocument2 pagesClinton Joseph MurrayR. Ayyanuperumal AyyanuperumalNo ratings yet

- Power ToolDocument1 pagePower ToolR. Ayyanuperumal AyyanuperumalNo ratings yet

- Work Method StatementDocument20 pagesWork Method StatementR. Ayyanuperumal AyyanuperumalNo ratings yet

- Clinton Joseph MurrayDocument2 pagesClinton Joseph MurrayR. Ayyanuperumal AyyanuperumalNo ratings yet

- CertificateDocument1 pageCertificateR. Ayyanuperumal AyyanuperumalNo ratings yet

- Safety Non-Conformance-040121Document2 pagesSafety Non-Conformance-040121R. Ayyanuperumal AyyanuperumalNo ratings yet

- WELSPUNDocument7 pagesWELSPUNR. Ayyanuperumal AyyanuperumalNo ratings yet

- CertificateDocument1 pageCertificateR. Ayyanuperumal AyyanuperumalNo ratings yet

- CertificateDocument1 pageCertificateR. Ayyanuperumal AyyanuperumalNo ratings yet

- Safety Non-Conformance-250122Document2 pagesSafety Non-Conformance-250122R. Ayyanuperumal AyyanuperumalNo ratings yet

- Certificate 2Document1 pageCertificate 2R. Ayyanuperumal AyyanuperumalNo ratings yet

- Certificate 2Document1 pageCertificate 2R. Ayyanuperumal AyyanuperumalNo ratings yet

- CertificateDocument1 pageCertificateR. Ayyanuperumal AyyanuperumalNo ratings yet

- HIRA Cage Ladder InstallationDocument9 pagesHIRA Cage Ladder InstallationR. Ayyanuperumal AyyanuperumalNo ratings yet

- HIRA Cage Ladder & Life Line Installation01Document3 pagesHIRA Cage Ladder & Life Line Installation01R. Ayyanuperumal Ayyanuperumal100% (1)

- HIRA Format (2) NEXTEER SITEDocument20 pagesHIRA Format (2) NEXTEER SITER. Ayyanuperumal AyyanuperumalNo ratings yet

- Construction Induction - PowerPoint - WEB SAMPLE 1Document25 pagesConstruction Induction - PowerPoint - WEB SAMPLE 1R. Ayyanuperumal AyyanuperumalNo ratings yet

- MSRA FOR Line Marking WorkDocument24 pagesMSRA FOR Line Marking WorkR. Ayyanuperumal Ayyanuperumal100% (1)

- Aros Site01Document24 pagesAros Site01R. Ayyanuperumal AyyanuperumalNo ratings yet

- Hira Arvos SiteDocument7 pagesHira Arvos SiteR. Ayyanuperumal AyyanuperumalNo ratings yet

- MSRA For DICV - Fixing of ShutterDocument3 pagesMSRA For DICV - Fixing of ShutterR. Ayyanuperumal AyyanuperumalNo ratings yet

- HIRA Format (2) Structural WorkDocument9 pagesHIRA Format (2) Structural WorkR. Ayyanuperumal AyyanuperumalNo ratings yet

- Pakistan Hse Requirements and Guidlines For Drilling OperationsDocument52 pagesPakistan Hse Requirements and Guidlines For Drilling OperationstyoNo ratings yet

- Tadano TM 1800 PDFDocument151 pagesTadano TM 1800 PDFharoun100% (1)

- Biomultis Ep 0 c37mnmnjc Belgium English 20230109Document13 pagesBiomultis Ep 0 c37mnmnjc Belgium English 20230109Pierre-Olivier MouthuyNo ratings yet

- Asd Darmex - Agro - Sustainability - Reporting - November - 2019 - PT. - DMPDocument139 pagesAsd Darmex - Agro - Sustainability - Reporting - November - 2019 - PT. - DMPbudak kecikNo ratings yet

- Safety Culture Assessment in Petrochemical IndustryDocument11 pagesSafety Culture Assessment in Petrochemical IndustryDHRUV SONAGARANo ratings yet

- MSDS - Sulfochem (TM) TD-3 PHP SurfactantDocument11 pagesMSDS - Sulfochem (TM) TD-3 PHP SurfactantfredNo ratings yet

- Forest Fires Jiya - 9E-2Document8 pagesForest Fires Jiya - 9E-2Jiya MerjaNo ratings yet

- GuidanceNotes EN131 Version2Document10 pagesGuidanceNotes EN131 Version2Javier Quintero SaavedraNo ratings yet

- Oxalic Acid - 10% Solution MSDS: Section 1: Chemical Product and Company IdentificationDocument5 pagesOxalic Acid - 10% Solution MSDS: Section 1: Chemical Product and Company IdentificationphyphoNo ratings yet

- Noise Toolbox Talk Supporting NotesDocument11 pagesNoise Toolbox Talk Supporting NotesNishadh 83No ratings yet

- Risks and Opportunities ProcedureDocument8 pagesRisks and Opportunities ProcedureloganathanNo ratings yet

- Material Safety Data Sheet: Section 1. Chemical Product and Company IdentificationDocument8 pagesMaterial Safety Data Sheet: Section 1. Chemical Product and Company IdentificationariosiNo ratings yet

- Mse Controlled Document: MSE/32 RPA Ond/Osd/ UWDDocument5 pagesMse Controlled Document: MSE/32 RPA Ond/Osd/ UWDDevakumarMSDevanNo ratings yet

- Modular Shoring System 2008Document36 pagesModular Shoring System 2008VaishamNo ratings yet

- 3 Ashrie EL KeluarDocument3 pages3 Ashrie EL KeluarapihmarcNo ratings yet

- UN IEDD Standards-1Document146 pagesUN IEDD Standards-1Milosevic GoranNo ratings yet

- Norme CEI Internationale IEC International 62305-2 StandardDocument1 pageNorme CEI Internationale IEC International 62305-2 StandardFredy GarciaNo ratings yet

- RA For Casting Platform ArmDocument7 pagesRA For Casting Platform Armvinay santoshNo ratings yet

- Olp CommunicationDocument2 pagesOlp Communicationlea karen GelidoNo ratings yet

- After Inspection Report Re. NGCP Ambuklao May 29 2023Document4 pagesAfter Inspection Report Re. NGCP Ambuklao May 29 2023Fake EmailNo ratings yet

- LENCE 8400 PROTEC ManualDocument198 pagesLENCE 8400 PROTEC ManualTomislav LoinaNo ratings yet

- OHS WorkplaceAssessment InspectionChecklistDocument9 pagesOHS WorkplaceAssessment InspectionChecklistAldrin ZlmdNo ratings yet

- MSDS Map ProDocument7 pagesMSDS Map ProoscarNo ratings yet

- 1.1. Hse Key Management StandardDocument26 pages1.1. Hse Key Management StandardagumsyahNo ratings yet

- RA Hot Works in Enclosed SpaceDocument2 pagesRA Hot Works in Enclosed SpaceMartinNo ratings yet