Professional Documents

Culture Documents

IOTDE-PIP-CL-004 Rev 0 Check List For Nozzle and Cleat Orientation Drawing

Uploaded by

Arindom Kundu0 ratings0% found this document useful (0 votes)

17 views2 pagesOriginal Title

IOTDE-PIP-CL-004 Rev 0 Check List for Nozzle and cleat orientation drawing

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views2 pagesIOTDE-PIP-CL-004 Rev 0 Check List For Nozzle and Cleat Orientation Drawing

Uploaded by

Arindom KunduCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

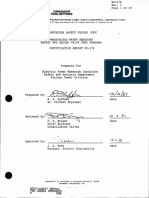

SHEET 1 OF 2

CHECK LIST FOR NOZZLE AND CLEAT Document No.

ORIENTATION DRAWING IOTDE-PIP-CL-004

Rev - 0

JOB No:

PROJECT:

DOCUMENT NUMBER

REVISION DATE PREPARED BY CHECKED BY APPROVED BY

CHECK LIST YES NO N/A COMMENTS

1 Check the Nozzle orientation drawing with P & ID

Number of nozzles, nozzle tags,nozzle sizes, any

specific requirements indicated in P & ID

2 Check Nozzle orientation with Process Data sheet, Check relative orientations of

Equipment specification to take care of process Nozzles ( e.g.,inlet w.r.to

requirements outlet) particularly when

internals / baffles are present.

3 Check Nozzle orientation with vendor drawing Nozzle orientation drawing is

the input for Vendor drg. Is it

needed to be checked with

Vendor drawing.

4 Check the following

- Flanges and the RF pads of the nozzles are not

fouling

- Nozzles are not fouling and adequate clearance is

provided with weld seam, reinforcing ring/ stiffner

ring

- Nozzles are not fouling with the internals

Check clearances on the sides

as well as the top of the vessel

- Nozzles are not fouling with external structural

- Adequate clearance for the opening of manholes

- Orientation of supports, lifting lug, tailing lug, name

plate, earthing boss, anchor chairs, all nozzles are

shown

- Elevation of Bottom T/L & Height of skirt, Under

side elevation of support lug/ring & its distance from

Bottom T/L is shown for vertical vessel.

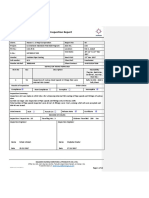

SHEET 2 OF 2

CHECK LIST FOR NOZZLE AND CLEAT ORIENTATION

Document No.

DRAWING

IOTDE-PIP-CL-004

Rev - 0

CHECK LIST YES NO N/A COMMENTS

- Table indicating the elevation of all the nozzles from

a Common reference line(Bottom Tan line for

Vertical and Centrelline of Fixed saddle for horizontal

vessel), the projection of nozzles,the size, rating and

orientation of nozzles.

- Centre line elevation of horizontal vessel & Distance

of underside of saddle with centre line vessel is

shown. Also show fixed and sliding saddle.

- Orientation, elevation, extent of platform, ladder,

Staircase, column devit, lightening arrestor is shown.

- Scope of supply of the platform i.e. by the purchaser

or by vendor

- Internals are not located infront of manhole to block

the entry in the vessel

- Cathodic protection requirement & incorporate the

requirements. (Applicable for Vertical storage tanks

and buried vessels)

- Pipe support cleats along with loading in a tabular

format

- Cleats required for instrument/Electrical cables

- Provide loads if lines are supported on the platform.

- Check Slope of bottom plate and orientation of the

drain / cleanout nozzle for vertical tanks checked.

- Check the extent of spiral staircase, intermediate

platforms,number of steps. Check manholes are

accessible from intermediate landings (For large

vertical storage tanks)

5 QA / QC Review / Clients Comments

5.1 - SDC / IDC comments incorporated

5.2 - Clients comments incorporated

You might also like

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Nozzle OrientationDocument2 pagesNozzle OrientationArindom KunduNo ratings yet

- Piping Field Inspection ChecklistDocument2 pagesPiping Field Inspection Checklistanwarhas0583% (6)

- TSH Ip 53.0056 - 01Document6 pagesTSH Ip 53.0056 - 01Cong BuiNo ratings yet

- 835-Pre-Commissioning of Vessels, Columns, Tanks and Heat ExcDocument3 pages835-Pre-Commissioning of Vessels, Columns, Tanks and Heat ExcFolarin AyodejiNo ratings yet

- WI-INSP-02 R1 Work Instruction - Heat Exchanger InspectionDocument5 pagesWI-INSP-02 R1 Work Instruction - Heat Exchanger InspectionRakesh MishraNo ratings yet

- Vendor drawing checklist for valvesDocument2 pagesVendor drawing checklist for valvesArindom KunduNo ratings yet

- IOTDE-PIP-CL-002 Rev 0 Check List For Piping GADocument3 pagesIOTDE-PIP-CL-002 Rev 0 Check List For Piping GAArindom KunduNo ratings yet

- API 653 Storage Tank Inspection ChecklistDocument16 pagesAPI 653 Storage Tank Inspection Checklistkevin RichNo ratings yet

- Checklist for Isometric DrawingsDocument2 pagesChecklist for Isometric DrawingsArindom KunduNo ratings yet

- Material Take OffDocument5 pagesMaterial Take OffArindom KunduNo ratings yet

- 5 de 5) VÁLVULA DE RETENCIÓN Marca TYCO (Inglés)Document6 pages5 de 5) VÁLVULA DE RETENCIÓN Marca TYCO (Inglés)Maximiliano StaitiNo ratings yet

- Checklist For Drum Nozzle DrawingDocument2 pagesChecklist For Drum Nozzle DrawingRamalingam PrabhakaranNo ratings yet

- RAPID PROJECT REFINERY TANK FARM CABLE CHECKLISTDocument1 pageRAPID PROJECT REFINERY TANK FARM CABLE CHECKLISTnayumNo ratings yet

- SOP - 04 - Erection ProcedureDocument45 pagesSOP - 04 - Erection ProcedureSuci YatiningtiyasNo ratings yet

- Inspection Test Record jacket pre-loadoutDocument1 pageInspection Test Record jacket pre-loadoutMomo ItachiNo ratings yet

- Columns and DrumsDocument8 pagesColumns and DrumsaliNo ratings yet

- Piping Inspection Seminar GuideDocument35 pagesPiping Inspection Seminar GuideMorg ActusNo ratings yet

- P&ID Check List For EM-PEDocument14 pagesP&ID Check List For EM-PEsajjadyasin100% (1)

- Shop Drawing Submittal Review Comments: Action Code KeyDocument18 pagesShop Drawing Submittal Review Comments: Action Code KeyalostooraNo ratings yet

- IOTDE-PIP-CL-001 Rev 0 Check List For Plot PlanDocument3 pagesIOTDE-PIP-CL-001 Rev 0 Check List For Plot PlanArindom KunduNo ratings yet

- SSE-QC-ELE-510 - CT & PT Installation ChecklistDocument2 pagesSSE-QC-ELE-510 - CT & PT Installation ChecklistBhalsingh JangraNo ratings yet

- Overhead Crane Inspection ProceduresDocument5 pagesOverhead Crane Inspection ProceduresRonniNo ratings yet

- Construction Check Sheet Control & Relay Panel E-025A: ElectricalDocument1 pageConstruction Check Sheet Control & Relay Panel E-025A: ElectricalhrimklimNo ratings yet

- Construction Check Sheet Orifice Plate Pre-Installation Check I-005ADocument1 pageConstruction Check Sheet Orifice Plate Pre-Installation Check I-005AKailash PandeyNo ratings yet

- Mechanical Integrity Inspection ExchangerDocument7 pagesMechanical Integrity Inspection ExchangerSyed Faraz RazaNo ratings yet

- Piping Inspector QuestionsDocument7 pagesPiping Inspector Questionsnike_y2k100% (1)

- Q.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteDocument5 pagesQ.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteAws Mohamed100% (1)

- Written Scheme of Examination (Pressure Vessel) : Part 1-Scope, Examination, Repairs and ModificationsDocument3 pagesWritten Scheme of Examination (Pressure Vessel) : Part 1-Scope, Examination, Repairs and Modificationsahmed sobhy50% (2)

- T-K-Y Presentation 16-12-13Document31 pagesT-K-Y Presentation 16-12-13mukeshayoor100% (1)

- Tank Erection ProcedureDocument15 pagesTank Erection ProcedureJOSHUA SULLEGUENo ratings yet

- API 510 PV Inspection ChecklistDocument9 pagesAPI 510 PV Inspection ChecklistSreekumar SNo ratings yet

- Of in Service Storage Tank Inspection and Verification ChecklistDocument14 pagesOf in Service Storage Tank Inspection and Verification Checklistkevin RichNo ratings yet

- SOP Mobile Crane-Rev.1Document7 pagesSOP Mobile Crane-Rev.1RonniNo ratings yet

- 242694634-Itp-for-Tank-Fabrication-Installation-Work1-rev02Document22 pages242694634-Itp-for-Tank-Fabrication-Installation-Work1-rev02au9t5teyrNo ratings yet

- TSH Ip 53.0060 - 02Document5 pagesTSH Ip 53.0060 - 02Cong BuiNo ratings yet

- Verabar V500 and V510: 1.0 ScopeDocument4 pagesVerabar V500 and V510: 1.0 ScopemacflirtyNo ratings yet

- Technical Specification For Supply of Valves Table - 1: Manuf'S OfferDocument11 pagesTechnical Specification For Supply of Valves Table - 1: Manuf'S OfferRadhakrishnan SreerekhaNo ratings yet

- Inspection Test Record (Itr) - A Jacket Pre-Loadout ST08-ADocument1 pageInspection Test Record (Itr) - A Jacket Pre-Loadout ST08-AMomo ItachiNo ratings yet

- Cable Tray and Conduit Field Inspection ReportDocument1 pageCable Tray and Conduit Field Inspection ReportTreesa Archnana100% (1)

- Check List For Installation and Incoming Materials For Pipe Sleeves (Sanitary & Plumbing Works)Document2 pagesCheck List For Installation and Incoming Materials For Pipe Sleeves (Sanitary & Plumbing Works)Imho TepNo ratings yet

- Accede PR-162 1-2Document1 pageAccede PR-162 1-2Massimo FumarolaNo ratings yet

- SB1345Document7 pagesSB1345Yarisa VangeNo ratings yet

- Itp For Tank Fabrication Installation Work1 Rev02 PDFDocument22 pagesItp For Tank Fabrication Installation Work1 Rev02 PDFMichelNo ratings yet

- GM 4L80-E, 4L85-E Vacuum Test Plate Kit: Part NumberDocument8 pagesGM 4L80-E, 4L85-E Vacuum Test Plate Kit: Part NumberДенис ЕфрахимNo ratings yet

- TSH Ip 53.0050 - 02Document6 pagesTSH Ip 53.0050 - 02Cong BuiNo ratings yet

- Fabrication of Pressure 32-68Document38 pagesFabrication of Pressure 32-68DIPAK VINAYAK SHIRBHATE100% (1)

- Sawant Rupesh C.: B. Tech. (PRODUCTION) (D-050729) Under Guidance ofDocument33 pagesSawant Rupesh C.: B. Tech. (PRODUCTION) (D-050729) Under Guidance ofDIPAK VINAYAK SHIRBHATENo ratings yet

- RYCO Hydraulics Product Technical Manual RHY-RHC0707AUSDocument444 pagesRYCO Hydraulics Product Technical Manual RHY-RHC0707AUSAdiya PurevjavNo ratings yet

- QA/Qc - Checklist Sewer LineDocument2 pagesQA/Qc - Checklist Sewer Lineyash shah100% (2)

- Safety and Relief Valve Test ProgramDocument47 pagesSafety and Relief Valve Test ProgramRomul KNo ratings yet

- Scope of Work Between Instrumentation & Operation For Distributed Control SystemDocument7 pagesScope of Work Between Instrumentation & Operation For Distributed Control SystemGobi HaiNo ratings yet

- Aot Om2700aDocument9 pagesAot Om2700aModestyNo ratings yet

- Asa-146 NSH Apco Ir 040Document10 pagesAsa-146 NSH Apco Ir 040Fahad AhmadNo ratings yet

- Underground Drainage Pipes - Installation & TestingDocument1 pageUnderground Drainage Pipes - Installation & TestingBharathraj RajNo ratings yet

- Valvula Piloto 1.5 inDocument10 pagesValvula Piloto 1.5 inDurvis Joel Romero LopezNo ratings yet

- 513-Mechanical Installation of Shop Fabricated TanksDocument3 pages513-Mechanical Installation of Shop Fabricated TanksFolarin AyodejiNo ratings yet

- Checklist for Isometric DrawingsDocument2 pagesChecklist for Isometric DrawingsArindom KunduNo ratings yet

- IOTDE-PIP-CL-002 Rev 0 Check List For Piping GADocument3 pagesIOTDE-PIP-CL-002 Rev 0 Check List For Piping GAArindom KunduNo ratings yet

- Material Take OffDocument5 pagesMaterial Take OffArindom KunduNo ratings yet

- Vendor drawing checklist for valvesDocument2 pagesVendor drawing checklist for valvesArindom KunduNo ratings yet

- IOTDE-PIP-CL-006 Rev 0 Check List For Stress AnalysisDocument4 pagesIOTDE-PIP-CL-006 Rev 0 Check List For Stress AnalysisArindom KunduNo ratings yet

- IOTDE-PIP-CL-001 Rev 0 Check List For Plot PlanDocument3 pagesIOTDE-PIP-CL-001 Rev 0 Check List For Plot PlanArindom KunduNo ratings yet

- Rotary GurgaonDocument1 pageRotary GurgaonArindom KunduNo ratings yet

- Biology Lab Manual LabelDocument1 pageBiology Lab Manual LabelArindom KunduNo ratings yet

- CONTROL DOCUMENTS - PROCESS (Composite)Document2 pagesCONTROL DOCUMENTS - PROCESS (Composite)Arindom KunduNo ratings yet

- Abstract & Concrete NounsDocument2 pagesAbstract & Concrete NounsSitifatimah92No ratings yet

- Lauren Tarshis - (I Survived 05) - I Survived The San Francisco Earthquake, 1906Document66 pagesLauren Tarshis - (I Survived 05) - I Survived The San Francisco Earthquake, 1906Olga de Ramos100% (1)

- Owner'S Manual: Dell Poweredge T110 Ii SystemsDocument130 pagesOwner'S Manual: Dell Poweredge T110 Ii SystemsDonNo ratings yet

- LFP12100D With ApplicationsDocument1 pageLFP12100D With ApplicationsPower WhereverNo ratings yet

- Mechanics of Solids by Sadhu Singhpdf Ebook and Ma PDFDocument1 pageMechanics of Solids by Sadhu Singhpdf Ebook and Ma PDFNeeraj Janghu0% (2)

- A-PDF Watermark DEMO Purchase RemoveDocument4 pagesA-PDF Watermark DEMO Purchase RemoveGaurav JoshiNo ratings yet

- Dead Reckoning and Estimated PositionsDocument20 pagesDead Reckoning and Estimated Positionscarteani100% (1)

- Aquilion ONE GENESIS Edition Transforming CTDocument40 pagesAquilion ONE GENESIS Edition Transforming CTSemeeeJuniorNo ratings yet

- Customer Status Update Report 27th January 2015 ColourDocument20 pagesCustomer Status Update Report 27th January 2015 ColourmaryNo ratings yet

- KORT RENZO C. BESARIO BS NURSING LESSON REVIEWDocument3 pagesKORT RENZO C. BESARIO BS NURSING LESSON REVIEWDummy AccountNo ratings yet

- LESSON PLAN On PancreasDocument4 pagesLESSON PLAN On PancreasShweta Pal100% (1)

- LLM Thesis On Human RightsDocument7 pagesLLM Thesis On Human Rightswssotgvcf100% (2)

- UX5HPDocument2 pagesUX5HPNazih ArifNo ratings yet

- Supply Chain Management A Logistics Perspective 10th Edition Coyle Test BankDocument24 pagesSupply Chain Management A Logistics Perspective 10th Edition Coyle Test BankWilliamLewisiscy100% (38)

- Resume Dianne Ostrander 4-27-06-09Document2 pagesResume Dianne Ostrander 4-27-06-09api-12400587No ratings yet

- Solution Map For Mining ppt3952 PDFDocument29 pagesSolution Map For Mining ppt3952 PDFHans AcainNo ratings yet

- Kindergarten Quarter 4 Standards For Lesson PlansDocument2 pagesKindergarten Quarter 4 Standards For Lesson PlansLydiaDietschNo ratings yet

- The Principles Taj MahalDocument2 pagesThe Principles Taj MahalVishnuMohanNo ratings yet

- Past Simple Past ContinuousDocument2 pagesPast Simple Past ContinuousEsmeralda Gonzalez80% (5)

- Cucs 016 13 PDFDocument16 pagesCucs 016 13 PDFAnonymous SlyvspdBNo ratings yet

- Arnold Jacobs: His Global Influence: Midwest Clinic, Thursday, December 17 12:00-1:00pmDocument17 pagesArnold Jacobs: His Global Influence: Midwest Clinic, Thursday, December 17 12:00-1:00pmAlex MoralesNo ratings yet

- Electric Potential and CapacitanceDocument30 pagesElectric Potential and CapacitanceRachita PatangiNo ratings yet

- GYROSCOPE ManualDocument8 pagesGYROSCOPE ManualAman BansalNo ratings yet

- Basic Encaustic Manual Author R&FDocument16 pagesBasic Encaustic Manual Author R&Fagustin arellanoNo ratings yet

- Criminal VIIIDocument31 pagesCriminal VIIIAnantHimanshuEkkaNo ratings yet

- (Oxford Studies in Digital Politics) Jack Parkin - Money Code Space - Hidden Power in Bitcoin, Blockchain, and Decentralisation-Oxford University Press (2020)Document297 pages(Oxford Studies in Digital Politics) Jack Parkin - Money Code Space - Hidden Power in Bitcoin, Blockchain, and Decentralisation-Oxford University Press (2020)berpub0% (1)

- Program Pakan Budidaya Lele: Farm Pond Code AREA (m2) Stocking Date Stocking Amount DensityDocument6 pagesProgram Pakan Budidaya Lele: Farm Pond Code AREA (m2) Stocking Date Stocking Amount DensityChevienrenaldy SamsuNo ratings yet

- Oxidation of CopperDocument21 pagesOxidation of CopperAmeen ShahidNo ratings yet

- Literature Review On OscilloscopeDocument5 pagesLiterature Review On Oscilloscopedhjiiorif100% (1)

- Elah'Im CultureDocument60 pagesElah'Im CultureRichard David DellermanNo ratings yet