Professional Documents

Culture Documents

Itp 0003

Itp 0003

Uploaded by

Giancarlo Puma0 ratings0% found this document useful (0 votes)

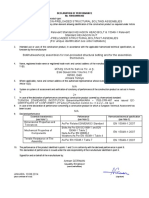

4 views1 pageThis document provides an inspection test plan for safety relief valves for a project for customer SAMSON CONTROLS S.A. It outlines 4 main check points - receipt of goods control, shell test, valve setting and testing, and final inspection. Each check point contains specific test procedures and performance responsibilities to ensure the valves meet standards such as ASME, API, and DIN. Tests include dimensional checks, visual inspections, shell tightness, hydrostatic testing, non-destructive testing, material identification, seat tightness, back seat tightness, operability, and cold differential pressure. Responsibilities are assigned as manufacturer, third party inspector, or customer reviews.

Original Description:

Original Title

ITP-0003

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides an inspection test plan for safety relief valves for a project for customer SAMSON CONTROLS S.A. It outlines 4 main check points - receipt of goods control, shell test, valve setting and testing, and final inspection. Each check point contains specific test procedures and performance responsibilities to ensure the valves meet standards such as ASME, API, and DIN. Tests include dimensional checks, visual inspections, shell tightness, hydrostatic testing, non-destructive testing, material identification, seat tightness, back seat tightness, operability, and cold differential pressure. Responsibilities are assigned as manufacturer, third party inspector, or customer reviews.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pageItp 0003

Itp 0003

Uploaded by

Giancarlo PumaThis document provides an inspection test plan for safety relief valves for a project for customer SAMSON CONTROLS S.A. It outlines 4 main check points - receipt of goods control, shell test, valve setting and testing, and final inspection. Each check point contains specific test procedures and performance responsibilities to ensure the valves meet standards such as ASME, API, and DIN. Tests include dimensional checks, visual inspections, shell tightness, hydrostatic testing, non-destructive testing, material identification, seat tightness, back seat tightness, operability, and cold differential pressure. Responsibilities are assigned as manufacturer, third party inspector, or customer reviews.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Inspection Test Plan

Custumer: SAMSON CONTROLS S.A.

Project: Quellaveco Project

LESER - Safety Relief Valve Performance Resp.

Nro check / process step Test Procedure LESER Estándar Pro H T K

1 Receipt of goods control

1.1 dimensional and visual control of valve Drawing W

1.2 visual inspection of flaw in casting W

2 Shell Test

2.1 Shell tightness test DIN EN 12266 Teil 1 4.4 LGS 0201-E 3.1 W

2.2 Hydrostatic testing ASME Sec.VIII Div. 1 UG 136(d)(2) LGS 0209-E 3.1 W R

LGS 0203-E

W

2.3 Nondestructive testing ASME Sec.VIII Div. 1 UG 136(f) LGS 0206-E

Material identification check for alloyed

W

2.4 materials AD2000 Merkblatt A4 6.1.(6) LGS 0207-E

3 Valve Setting and Testting

ASME Sec.VIII Div. 1 UG 136(d)(5)

3.1 W

3.1 Seat tightness API 527 2/3/4 LGS 0201-E

3.2 Back seat tightness ASME Sec.VIII Div. 1 UG 136(d)(3) LGS 0201-E 3.1 W

3.3 Operability DIN EN 12266 Teil 2 4. (F20) LGS 0217-E 3.1 W

ASME Sec.VIII Div. 1 UG 136(d)(4)

W R

3.4 Cold differential test pressure API 527 2/3/4 LDeS 1001.69

4 Final Inspection

4.1 Marking ASME Sec.VIII Div. 1 UG 77 LGS 0218-E W

4.2 Check for dimensional accuracy LGS 0216-E W

Pro= Report/level acc. To DIN EN 10204

H= Manufacturer

T= Third party inspector

K= Customer

W= Witness

R= Review

H= Hold

The realization of the test took place through: LESER GmbH & Co.KG

You might also like

- Tested by M/S Siemens Organized by M/S Emc Witnessed by M/S Pgcil Name G Ramesh Designation SignatureDocument2 pagesTested by M/S Siemens Organized by M/S Emc Witnessed by M/S Pgcil Name G Ramesh Designation SignatureRK KNo ratings yet

- Box Culvert Design As Per AASHTO LRFDDocument18 pagesBox Culvert Design As Per AASHTO LRFDshish0iitr0% (1)

- Aashto M288-17 Product Selection GuideDocument1 pageAashto M288-17 Product Selection GuideDem DemNo ratings yet

- ITP-P-001 ITP For Above Ground Piping Rev. ADocument9 pagesITP-P-001 ITP For Above Ground Piping Rev. APhong Đỗ100% (1)

- FIDIC and The Standard Form ContractsDocument108 pagesFIDIC and The Standard Form ContractsAhmedSalemNo ratings yet

- MS Mexico Conformity To UL1741&IEEE1547Document4 pagesMS Mexico Conformity To UL1741&IEEE1547carlosNo ratings yet

- Certificación UL 1741 Serie D-NSDocument4 pagesCertificación UL 1741 Serie D-NSJesus Alonso Camacho CastilloNo ratings yet

- On Site Water Tightness Testing For Curtain WallingDocument4 pagesOn Site Water Tightness Testing For Curtain WallingManojkumar kondaveetiNo ratings yet

- Nozzle Neck CalculationDocument4 pagesNozzle Neck CalculationAkshat JainNo ratings yet

- SAIC-U-7009 - Floating Cranes and Floating Derricks-2023Document7 pagesSAIC-U-7009 - Floating Cranes and Floating Derricks-2023محمد ممدوحNo ratings yet

- Plot PlanDocument5 pagesPlot PlandasubhaiNo ratings yet

- Sample QAPDocument3 pagesSample QAPsniperiNo ratings yet

- ITP ManifoldDocument7 pagesITP ManifoldvinothNo ratings yet

- Fabrication Quality Dossier IndexDocument22 pagesFabrication Quality Dossier IndexAli KayaNo ratings yet

- ACC Actuator Capacity Control Manual: m-ROY, Maxroy, Milroyal, Primeroyal and Primeroy Product Family PumpsDocument33 pagesACC Actuator Capacity Control Manual: m-ROY, Maxroy, Milroyal, Primeroyal and Primeroy Product Family Pumpsbondsivamani100% (1)

- IPE Home Assignment 4: Instrumentation StandardsDocument4 pagesIPE Home Assignment 4: Instrumentation StandardsAmeya DalviNo ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Reference (Woodside - Standards)Document23 pagesReference (Woodside - Standards)shankarmech04@gmail.com100% (1)

- ITP-format For VesselsDocument5 pagesITP-format For VesselsHanuman RaoNo ratings yet

- Checklist de NFPA 59A PDFDocument2 pagesChecklist de NFPA 59A PDFKurt StanburyNo ratings yet

- 5.1 - (ANX-1) Inspection Test Plan (ITP) ListDocument3 pages5.1 - (ANX-1) Inspection Test Plan (ITP) ListWinston BoxNo ratings yet

- Inspection Test Plan: Amadeus ProjectDocument3 pagesInspection Test Plan: Amadeus ProjectErikikoNo ratings yet

- 16-20-PSS-2101 - Busbar Ir&crmDocument2 pages16-20-PSS-2101 - Busbar Ir&crmirshadchukkan1No ratings yet

- Uniform Mechanical Code - 2009 Chapter 17Document22 pagesUniform Mechanical Code - 2009 Chapter 17memosplumbingNo ratings yet

- Omtech Tubes QAPDocument1 pageOmtech Tubes QAPPrathamesh OmtechNo ratings yet

- IN-QD-5531-21005-AIS-001-R1 Circuit Breaker Inspection Report-GulDocument13 pagesIN-QD-5531-21005-AIS-001-R1 Circuit Breaker Inspection Report-GulSikandar MasoodNo ratings yet

- QCR W 2007Document4 pagesQCR W 2007Madhan KannanNo ratings yet

- BCBC 2018dbp1s13r2 PDFDocument32 pagesBCBC 2018dbp1s13r2 PDFdomcristiniNo ratings yet

- V 2155 508 A 600 - 0 - ITP - CodeBDocument13 pagesV 2155 508 A 600 - 0 - ITP - CodeBHanh BuiminhNo ratings yet

- TS Merged PgcilDocument422 pagesTS Merged PgcilsankhaginNo ratings yet

- Itp For Piping Fabrication and InstallationDocument10 pagesItp For Piping Fabrication and InstallationwidiNo ratings yet

- Basic Design & Fabrication of Pressure VesselDocument30 pagesBasic Design & Fabrication of Pressure VesselannisNo ratings yet

- 1.0 Equipment DetailsDocument2 pages1.0 Equipment Detailsjalaj bisenNo ratings yet

- STR-1377-Tech. Spec. App.1 TestsDocument3 pagesSTR-1377-Tech. Spec. App.1 TestsAbdul AzimNo ratings yet

- Physics and Chemistry PDFDocument1 pagePhysics and Chemistry PDFKishore KumarNo ratings yet

- Qaswa - 100 ABFV 17.06.21Document1 pageQaswa - 100 ABFV 17.06.21FLOW VALVE AUTOMATIONNo ratings yet

- CSA C22 No.131Document1 pageCSA C22 No.131metin yurtseverNo ratings yet

- NS2-DH01-P0ZEN-740009 - ITP For Crane & Hoist Installation - REV.DDocument12 pagesNS2-DH01-P0ZEN-740009 - ITP For Crane & Hoist Installation - REV.DAnh VàngNo ratings yet

- Mechanical Metigurical DimensionalDocument4 pagesMechanical Metigurical DimensionalPaviter SinghNo ratings yet

- ItpDocument5 pagesItpMuhammad Fajar100% (1)

- Sample WorkDocument135 pagesSample WorkmirceaNo ratings yet

- Service Co. Ltd. Inspection and Test Record: Bistable Relay-Rxmvb-4Document2 pagesService Co. Ltd. Inspection and Test Record: Bistable Relay-Rxmvb-4GANESH KNo ratings yet

- Water Supplies Department: E-11-01 Feb. 2017Document37 pagesWater Supplies Department: E-11-01 Feb. 2017Jothimanikkam SomasundaramNo ratings yet

- 15522HE0253 Rev 0Document7 pages15522HE0253 Rev 0Fernando Ramírez CéspedesNo ratings yet

- Attachment-2.4A - PSV - Datasheet (Hot Water HPT)Document6 pagesAttachment-2.4A - PSV - Datasheet (Hot Water HPT)mohamed salahNo ratings yet

- STR-1356-Tech. Spec. App.1 Tests PDFDocument3 pagesSTR-1356-Tech. Spec. App.1 Tests PDFIm MustakimNo ratings yet

- Va2-Dn04-p0ab-140011 Inspection and Test Plan For Manufacturing of Power and Control Cable For 500kv Ais - Rev.cDocument3 pagesVa2-Dn04-p0ab-140011 Inspection and Test Plan For Manufacturing of Power and Control Cable For 500kv Ais - Rev.cAnh Ngọc NguyễnNo ratings yet

- Reference Nondestructive TestingDocument3 pagesReference Nondestructive TestingRino SutrisnoNo ratings yet

- P Q R - 005Document2 pagesP Q R - 005Courtney Duke100% (1)

- Astor Accreditation Certificate 2022 (Id 1361648)Document6 pagesAstor Accreditation Certificate 2022 (Id 1361648)Dalibor84No ratings yet

- Tender - Volume 2 Watershed 132kV Line Diversion - r1Document21 pagesTender - Volume 2 Watershed 132kV Line Diversion - r1Phathutshedzo Given ThaboNo ratings yet

- Part-2-July21 A P P E N D I X 1 Tests Required For Materials, and Responsibility For VerifyingDocument8 pagesPart-2-July21 A P P E N D I X 1 Tests Required For Materials, and Responsibility For VerifyingSergio AlejandroNo ratings yet

- Harness Structural Test Report - LTF: V V V V V VDocument9 pagesHarness Structural Test Report - LTF: V V V V V Vparasailing jakartaNo ratings yet

- Prepared (Also Subject Responsible If Other) No.: With Adhesive TapeDocument4 pagesPrepared (Also Subject Responsible If Other) No.: With Adhesive TapePauloNo ratings yet

- Astm E1975 - 1 (En)Document17 pagesAstm E1975 - 1 (En)Dinesh Sai100% (1)

- Specification For T&Y Strainer: 0 27.08.2015 First Issue NV US SVKDocument20 pagesSpecification For T&Y Strainer: 0 27.08.2015 First Issue NV US SVKvishal bhamreNo ratings yet

- QCR W 2032Document3 pagesQCR W 2032Madhan KannanNo ratings yet

- 2 - V-P055AZOR-00-30-4-V78048 ManualDocument91 pages2 - V-P055AZOR-00-30-4-V78048 ManualDion Alfred EucogcoNo ratings yet

- QIP TT 307 PIPING WORK - RevisedDocument2 pagesQIP TT 307 PIPING WORK - Revisedsuria qaqcNo ratings yet

- LA 2001 0233 D - 3 Approved Signatory LetterDocument3 pagesLA 2001 0233 D - 3 Approved Signatory LetterEswaranNo ratings yet

- R18!01!03 - QSil 250 Post - Prototype Test ReportDocument22 pagesR18!01!03 - QSil 250 Post - Prototype Test ReportGlenys MuñozNo ratings yet

- ASTM F519 Standard Test Method For Mechanical Hydrogen Embrittlement Evaluation of Plating Processes and Service Environments1Document12 pagesASTM F519 Standard Test Method For Mechanical Hydrogen Embrittlement Evaluation of Plating Processes and Service Environments1David VegaNo ratings yet

- Rules: For The Classification and Construction of Subsea PipelinesDocument170 pagesRules: For The Classification and Construction of Subsea Pipelinesjosmery cabrera gonzalezNo ratings yet

- Wak CV (Updated)Document10 pagesWak CV (Updated)Waheed AhmadNo ratings yet

- CE Homework 4Document3 pagesCE Homework 4eg4034No ratings yet

- Lightning ArresterDocument25 pagesLightning ArresterGITAM UNIVERISTYNo ratings yet

- Material 11373Document1 pageMaterial 11373Deepak MadnaikNo ratings yet

- 3D Printing Group 7 ReportDocument19 pages3D Printing Group 7 ReportMark CrisostomoNo ratings yet

- Marksheet InventoryDocument25 pagesMarksheet InventoryShravani SalunkheNo ratings yet

- Declaration of Performance No. 15048-0000-002: (Name and Function)Document1 pageDeclaration of Performance No. 15048-0000-002: (Name and Function)John LiaromatisNo ratings yet

- Resume ShortDocument8 pagesResume ShortNeetu BehalNo ratings yet

- Sawc/Fte El Calafate, Argentina: Bokuk MotnoDocument18 pagesSawc/Fte El Calafate, Argentina: Bokuk MotnoLeonardo LimaNo ratings yet

- SEM 2 2016/2017 BETA 3573 Vehicle Powertrain Management System Tutorial 2Document5 pagesSEM 2 2016/2017 BETA 3573 Vehicle Powertrain Management System Tutorial 2uoyonoNo ratings yet

- Transmission Line Conductors, AssignmentDocument9 pagesTransmission Line Conductors, Assignmentmuhammad_sarwar_27No ratings yet

- s3 HandoutDocument160 pagess3 HandoutSunilkumarNo ratings yet

- Profile of Surveying and MappingDocument12 pagesProfile of Surveying and MappingVaibhav GuptaNo ratings yet

- Course PlanDocument2 pagesCourse PlanPethurajNo ratings yet

- Design of Edge Beams in Slim Floors Using Precast Hollow Core SlabsDocument9 pagesDesign of Edge Beams in Slim Floors Using Precast Hollow Core SlabsPaloma ValeNo ratings yet

- Material ConcreteDocument6 pagesMaterial ConcreteA.Subin DasNo ratings yet

- Surveying Problems and Solutions PDF Wordpresscom - 59c51eef1723dd2b1c9e659b PDFDocument2 pagesSurveying Problems and Solutions PDF Wordpresscom - 59c51eef1723dd2b1c9e659b PDFRaymart Ruben100% (1)

- Forming and Shoring CatalogDocument54 pagesForming and Shoring Cataloglucnewarchi100% (1)

- DSI-DYWIDAG Geotechnical Product Range enDocument44 pagesDSI-DYWIDAG Geotechnical Product Range enzuccoloNo ratings yet

- The Third Narmada Extrados Bridge in India: Bridge Designer™: Case Study #3Document12 pagesThe Third Narmada Extrados Bridge in India: Bridge Designer™: Case Study #3ShaileshRastogi100% (1)

- Resume - Jacob BandenburgDocument1 pageResume - Jacob Bandenburgapi-545268426No ratings yet

- JD - FAE or Test EngineerDocument2 pagesJD - FAE or Test EngineerChanti KumpatlaNo ratings yet

- Classified2020 3 14476666.Document1 pageClassified2020 3 14476666.udmanNo ratings yet

- CEG PMVGHHDocument29 pagesCEG PMVGHHVasantharajan 5naNo ratings yet

- VEDA Poster For Paid Training Program - FinalDocument1 pageVEDA Poster For Paid Training Program - FinalPriyanka GNo ratings yet