Professional Documents

Culture Documents

50-QAIP-00030 R2 Reinforced Concrete and Corrugated HDPE Piping Inspection and Test Plan

Uploaded by

michael98765Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

50-QAIP-00030 R2 Reinforced Concrete and Corrugated HDPE Piping Inspection and Test Plan

Uploaded by

michael98765Copyright:

Available Formats

Reinforced Concrete and Corrugated

HDPE Piping Inspection and Test Plan

Golden Triangle Polymers Project

Project No. 116058

Revision 2

07-13-2023

50-QAIP-00030

Issued for Construction (IFC)

50-QAIP-00030 Page 1 of 8 Revision 2

REVISION CONTROL

REV Date Issued For Prepared By Reviewed By Approved By

AA 02-02-2023 Review B. Ensign J. Black D. Rogers

BB 03-16-2023 Review B. Ensign J. Black D. Rogers

0 04-04-2023 IFC B. Ensign J. Black D. Rogers

1 05-10-2023 IFC B. Ensign J. Black D. Rogers

2 07-13-2023 IFC B. Ensign J. Black D. Rogers

REVISION HISTORY

REV Brief Description of Reason for Changes

2 Top left key code matrix was revised adding Exhibit W items, and added items 1.2 through 1.5 for

MOC, QSR, calibration, and storage control. Removed old 2.1 for duplicate Build it Clean storage

inspection now on 1.5.

1 Section 2.5 revised ITR naming removing testing. Section 3.4 added new testing ITR.

0 Added additional supporting specifications to 2.5. Issued for Construction

BB Corrected grammar 2.4, corrected verbiage in 3.2, changed client inspection code on 3.6.

AA Initial draft, review and issue.

50-QAIP-00030 Page 2 of 8 Revision 2

Reinforced Concrete and

Corrugated HDPE Piping

Inspection and Test Plan

prepared for

Golden Triangle Polymers Project

Orange, Texas

Project No. 116058

Revision 2

07-13-2023

prepared by

Burns & McDonnell/Zachry

Kansas City, Missouri

50-QAIP-00030 Page 3 of 8 Revision 2

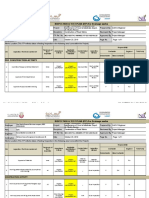

Inspection Codes: H = Hold, W = Witness, I = Inspect Work, R = Review, M = Monitor, AU = Audit, NA = Not Applicable

Hold (H): 24-hour notification to next responsible Party; signature required on ITR by all parties. The work shall not proceed without inspection presence.

Witness (W): 24-hour notification to next responsible party Quality Control and Company; signature required on ITR when the inspection is witnessed. The work may proceed without

BMZ FLS responsible for

Company QC Inspection

inspection presence. Reinforced Concrete and Corrugated

Inspect Work (I) Company Inspection requirement per Exhibit “W” Responsibility Matrix. Notification is not required, signature is required. Company signature not required for contractor to

meeting requirement

HDPE Piping Inspection and Test

BMZ QC Inspection

continue work and go to the next step, only Contractor signature is required to proceed.

Review (R): A review of documentation (auditing of data, drawings, procedures, or field installation). Signature not required.

Monitor (M): Verifying work and testing activities on an ongoing random basis. Owner signature not required. Plan

Other (AI, etc.)

Audit (AU): A review of documentation (auditing of data, drawings, procedures, field installation and third party reports).

Requirement

Front Line Supervisor (FLS): Foreman (F), General Foreman (GF), Superintendent (SUP), Subcontract Manager (SCM), Project Quality Manager (PQM), Field Quality Manager (FQC),

or any designated employee that has been trained to oversee the installation or signoff of work activities.

Comments and Inspection Frequencies

Acceptance Criteria (Code, Standard, ITR Required

Activity ID No. / Activity Description

Specification, SOP, Drawing, etc.) See Note 2

1.0 Pre-Construction Meeting:

Project

The ITP shall be reviewed prior to the commencement of

1.1 Facilitate an ITP review meeting. Field Quality Control Plan Attendance Sheet Quality H M N/A

first of the kind work activities or as needed thereafter.

Manager

50-QAGN-00006

Quality

Any changes to ITPs or ITRs after they are IFC must

Management of

Project follow the Management of Change Procedure and tracked

50-QAPR-00032 Quality Management Change Form and

1.2 Changes to this ITP or ITRs after IFC. Quality H M N/A on the Management of Change Log. Review and approval

of Change Procedure 50-QALS-00022

Manager are required per the MOC and are needed before

Quality

changes are to be incorporated.

Management of

Change Log

50-QALS-00018

50-QAPR-00009 Inspection Project

All test equipment shall be verified, calibrated, and

1.3 Verify the equipment calibration of test equipment. Control of Inspection Measuring and Measuring Test Quality R M N/A

captured on the IMTE Log prior to testing activities.

Testing Equipment Equipment Manager

Calibration Log

50-QAAR-00003

Quality Surveillance The QSR may serve to document an acceptance or a

Project

50-QAPR-00008 Quality Surveillance Report and 50- potential Nonconformance to the project specifications or

1.4 Quality Surveillance Reporting. Quality H M N/A

Report Procedure QALS-00015 other project acceptance criteria for work. It is applicable

Manager

Quality Surveillance to self-performed, supplier, or subcontractor work scope.

Report Log

Applicable

50-QAPR-00033 Build It Clean Cleanliness ITR(s) This ITR(s) shall be completed for in-process or final

& & cleanliness requirements per project specifications as

QC

1.5 Verify all materials are stored properly. Manufactures Storage 50-QAIR-00017 M M N/A applicable.

Inspector

Requirements/Site Storage Storage Control

Requirements Inspection Test This is to be filled out per tag item as applicable.

Report

2.0 Pipe Installation Activities:

Project See: 50-QAIP-00002 Earthworks Inspection and Test

2.1 Ensure installation of bedding is per the project 50-QAIP-00002 Earthworks Inspection

N/A Quality H M N/A Plan for hold points and the required Inspection and Test

specifications. and Test Plan

Manager Reports

Project

2.2 Orientation and elevation of piping per project

Per Project drawings & specifications N/A Quality H M N/A See: Project drawings & specifications

specifications.

Manager

50-QAIP-00030 Page 4 of 8 Revision 2

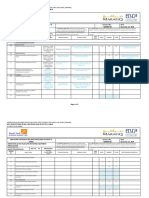

Inspection Codes: H = Hold, W = Witness, I = Inspect Work, R = Review, M = Monitor, AU = Audit, NA = Not Applicable

Hold (H): 24-hour notification to next responsible Party; signature required on ITR by all parties. The work shall not proceed without inspection presence.

Witness (W): 24-hour notification to next responsible party Quality Control and Company; signature required on ITR when the inspection is witnessed. The work may proceed without

BMZ FLS responsible for

Company QC Inspection

inspection presence. Reinforced Concrete and Corrugated

Inspect Work (I) Company Inspection requirement per Exhibit “W” Responsibility Matrix. Notification is not required, signature is required. Company signature not required for contractor to

meeting requirement

HDPE Piping Inspection and Test

BMZ QC Inspection

continue work and go to the next step, only Contractor signature is required to proceed.

Review (R): A review of documentation (auditing of data, drawings, procedures, or field installation). Signature not required.

Monitor (M): Verifying work and testing activities on an ongoing random basis. Owner signature not required. Plan

Other (AI, etc.)

Audit (AU): A review of documentation (auditing of data, drawings, procedures, field installation and third party reports).

Requirement

Front Line Supervisor (FLS): Foreman (F), General Foreman (GF), Superintendent (SUP), Subcontract Manager (SCM), Project Quality Manager (PQM), Field Quality Manager (FQC),

or any designated employee that has been trained to oversee the installation or signoff of work activities.

Comments and Inspection Frequencies

Acceptance Criteria (Code, Standard, ITR Required

Activity ID No. / Activity Description

Specification, SOP, Drawing, etc.) See Note 2

50-QAIR-00003 Set

Reference the following ITP for

Pre-Cast Concrete

inspection details and required ITRs: Craft

2.3 Installation of precast concrete structures. Structures W M N/A This ITR is to be filled out per tag item.

Earthworks Inspection and Test Plan Foreman

Inspection Test

50-QAIP-00002

Report

50-QAIR-000041

Infiltration &

Exfiltration

Installation

Inspection Test

Manufactures Specifications, 50-STES- Project

Report This is to be filled out by Craft, either per work package

2.4 Joint assembly per manufacturer requirements. 00003, PIP STS03001, PIP STS03600 Quality M M N/A

Or as applicable.

& PIP STS03601 Manager

50-QAIR-00048

HDPE Corrugated

Pipe Installation

Inspection Test

Report

Project See: 50-QAIP-00002 Earthworks Inspection and Test

2.5 Ensure installation of flowfill is per the Project 50-QAIP-00002 Earthworks Inspection

N/A Quality H M N/A Plan for hold points and the required Inspection and Test

specifications. and Test Plan

Manager Reports

3.0 Pipe Joint Testing Activities:

Concrete or cement components will absorb water, so the

Supplier shall fill the system and let it stand for a

minimum of 4 hours to a maximum 72 hours before

topping off and testing. All couplings, bells, joints, etc.,

shall remain exposed (for observation during exfiltration

2.6 Testing of process and sanitary sewers, catch basins and Infiltration & Exfiltration Testing Piping Test Project testing).

sumps shall be in accordance with the project per ASTM C969 Package Quality H W N/A

specification(s). Manager Measure the leakage loss over a timed test period. The

minimum test period shall be 4 hours and the maximum

shall not exceed 24 hours. If the measured rate of

leakage is less than or equal to the allowable leakage in

accordance with 8.2 of ASTM C969, the section of sewer

tested is acceptable.

50-QAIP-00030 Page 5 of 8 Revision 2

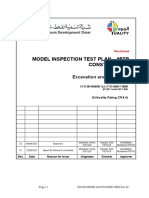

Inspection Codes: H = Hold, W = Witness, I = Inspect Work, R = Review, M = Monitor, AU = Audit, NA = Not Applicable

Hold (H): 24-hour notification to next responsible Party; signature required on ITR by all parties. The work shall not proceed without inspection presence.

Witness (W): 24-hour notification to next responsible party Quality Control and Company; signature required on ITR when the inspection is witnessed. The work may proceed without

BMZ FLS responsible for

Company QC Inspection

inspection presence. Reinforced Concrete and Corrugated

Inspect Work (I) Company Inspection requirement per Exhibit “W” Responsibility Matrix. Notification is not required, signature is required. Company signature not required for contractor to

meeting requirement

HDPE Piping Inspection and Test

BMZ QC Inspection

continue work and go to the next step, only Contractor signature is required to proceed.

Review (R): A review of documentation (auditing of data, drawings, procedures, or field installation). Signature not required.

Monitor (M): Verifying work and testing activities on an ongoing random basis. Owner signature not required. Plan

Other (AI, etc.)

Audit (AU): A review of documentation (auditing of data, drawings, procedures, field installation and third party reports).

Requirement

Front Line Supervisor (FLS): Foreman (F), General Foreman (GF), Superintendent (SUP), Subcontract Manager (SCM), Project Quality Manager (PQM), Field Quality Manager (FQC),

or any designated employee that has been trained to oversee the installation or signoff of work activities.

Comments and Inspection Frequencies

Acceptance Criteria (Code, Standard, ITR Required

Activity ID No. / Activity Description

Specification, SOP, Drawing, etc.) See Note 2

Concrete or cement components will absorb water, so the

BMZ shall fill the system and let it stand for 12 to 24, with

a minimum of 4 hours to a maximum of 72 hours before

topping off and testing. All couplings, bells, joints, etc.,

shall remain exposed (for observation during testing).

Project

3.1 Testing of storm sewers and catch basins. Quality H W N/A

Measure the leakage loss over a timed test period. The

Manager

minimum test period shall be 4 hours and the maximum

shall not exceed 24 hours. If the measured rate of

leakage is less than or equal to the allowable leakage in

accordance with 8.2 of ASTM C969, the section of sewer

test is acceptable.

BMZ Craft will notify and BMZ Quality will generate this

documentation to be completed prior to the

Project commencement of head testing of any piping test

3.2 Systems requiring head testing. Quality H W N/A package.

Manager

This is to be filled out either by test package or as

applicable.

50-QAIR-00116 BMZ Craft will notify and BMZ Quality will generate this

Infiltration & documentation to be completed during infiltration,

Exfiltration Testing exfiltration, and head testing in the testing section of the

Inspection Test ITR.

Per Manufactures recommendations Report Project

3.3 Test results. & Or Quality H W N/A The Infiltration & Exfiltration Testing Inspection Test

ASTM C969 50-QAIR-00048 Manager Report shall be used to capture testing activities if testing

HDPE Corrugated occurs later than the installation inspection activities.

Pipe Installation

Inspection Test This is to be filled out either by test package or as

Report applicable.

50-QAIR-00019 BMZ Craft will notify and BMZ Quality will witness this

Project

Pipe Cleanliness documentation assuring the system is completed after

3.4 Piping cleanliness verification. Project BIC program Quality H W N/A

Inspection Test testing has been performed. This is to be filled out either

Manager

Report by test package, work package or as applicable.

BMZ Quality will witness and generate the documentation

50-QAIR-00050

once completed and after testing is complete and the test

Post Pipe Re- Project

package is reinstalled according to P&IDs.

3.5 Piping reinstatement post-testing. Per Project Drawings instatement Quality H W N/A

Inspection Test Manager

This is to be filled out either by test package or as

Report

applicable.

50-QAIP-00030 Page 6 of 8 Revision 2

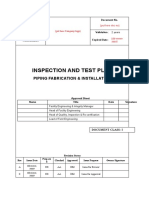

Inspection Codes: H = Hold, W = Witness, I = Inspect Work, R = Review, M = Monitor, AU = Audit, NA = Not Applicable

Hold (H): 24-hour notification to next responsible Party; signature required on ITR by all parties. The work shall not proceed without inspection presence.

Witness (W): 24-hour notification to next responsible party Quality Control and Company; signature required on ITR when the inspection is witnessed. The work may proceed without

BMZ FLS responsible for

Company QC Inspection

inspection presence. Reinforced Concrete and Corrugated

Inspect Work (I) Company Inspection requirement per Exhibit “W” Responsibility Matrix. Notification is not required, signature is required. Company signature not required for contractor to

meeting requirement

HDPE Piping Inspection and Test

BMZ QC Inspection

continue work and go to the next step, only Contractor signature is required to proceed.

Review (R): A review of documentation (auditing of data, drawings, procedures, or field installation). Signature not required.

Monitor (M): Verifying work and testing activities on an ongoing random basis. Owner signature not required. Plan

Other (AI, etc.)

Audit (AU): A review of documentation (auditing of data, drawings, procedures, field installation and third party reports).

Requirement

Front Line Supervisor (FLS): Foreman (F), General Foreman (GF), Superintendent (SUP), Subcontract Manager (SCM), Project Quality Manager (PQM), Field Quality Manager (FQC),

or any designated employee that has been trained to oversee the installation or signoff of work activities.

Comments and Inspection Frequencies

Acceptance Criteria (Code, Standard, ITR Required

Activity ID No. / Activity Description

Specification, SOP, Drawing, etc.) See Note 2

4.0 Non-Conformances Identified:

BMZ Craft General Foreman to ensure required

corrective action is taken.

50-QAAR-00002

4.1 Non-Conforming items are to be identified, documented, Craft

50-QAPR-00001 Nonconformance Construction BMZ Quality to verify corrective action has been

and dispositioned per the Non-Conformance Reporting General H M N/A

Reporting (SOP) Nonconformance completed.

Procedure. Foreman

Report

Non-Conforming items dispositioned as “Repair or

Replace”.

BMZ Craft General Foreman to ensure required

corrective action is taken.

50-QAAR-00002

4.2 Non-Conforming items are to be identified, documented, Craft

50-QAPR-00001 Nonconformance Construction

and dispositioned per the Non-Conformance Reporting General H H N/A BMZ Quality to verify corrective action has been

Reporting (SOP) Nonconformance

Procedure. Foreman completed.

Report

Non-Conforming items dispositioned as “Use-As-IS”.

5.0 This Section Reserved for Future Use:

5.1 This Section Reserved for Future Use This Section Reserved for Future Use ------ ------ ------ ------ This Section Reserved for Future Use

Note 1 This Inspection & Test Plan is only to be used as a guideline for establishing the “HOLD” and “WITNESS” points for inspection and testing, supplementing the construction activities of the project. This ITP is not

intended to replace any contractual engineering documents such as specifications, drawings, or Owner/Manufacturer installation instructions. Always review the contract documents in their entirety before executing

the installation of any construction activity.

Note 2 If frequencies are prescribed or are previously agreed to by the individual activity items, the Inspection & Test Record (ITR) shall be completed by installation work package (IWP).

50-QAIP-00030 Page 7 of 8 Revision 2

Burns & McDonnell Engineering Company, Inc./Zachry Industrial, Inc.

9201 State Line

Kansas City, MO 64114

O 816-333-9400

F 816-823-7028

50-QAIP-00030 Page 8 of 8 Revision 2

You might also like

- Drainage Work - Inspection Test Plan - ITPDocument4 pagesDrainage Work - Inspection Test Plan - ITPAlaa Ali67% (3)

- ADM3346 Fall 2019 Assignment 9 Revised Nov 22Document2 pagesADM3346 Fall 2019 Assignment 9 Revised Nov 22Sam Fish100% (1)

- Fiberglass and Foster - Inspection Test Plan - ITPDocument4 pagesFiberglass and Foster - Inspection Test Plan - ITPAlaa Ali100% (1)

- Itp For Fitp For Hdpe Pipes InstallationDocument3 pagesItp For Fitp For Hdpe Pipes InstallationBleep NewsNo ratings yet

- Field Quality Plan (FQP)Document2 pagesField Quality Plan (FQP)Ranjit Singh100% (3)

- Itp For For Excavation, Backfilling & Compaction For Building WorksDocument4 pagesItp For For Excavation, Backfilling & Compaction For Building WorksBleep NewsNo ratings yet

- ITP FormatDocument3 pagesITP FormatyousifNo ratings yet

- Coursework 1: Module: Business Communication Module Code: Sbl-105 Module Leader: Patience ConlonDocument13 pagesCoursework 1: Module: Business Communication Module Code: Sbl-105 Module Leader: Patience ConlonLame JoelNo ratings yet

- Pressure Testing ProcedureDocument4 pagesPressure Testing Proceduredavideristix100% (1)

- PTO Application FormDocument3 pagesPTO Application FormElisa MaeNo ratings yet

- A New Way Shop, Meet Rise: To andDocument8 pagesA New Way Shop, Meet Rise: To andAmit GolaNo ratings yet

- MOS-Civil-102 Structural ConcreteDocument12 pagesMOS-Civil-102 Structural ConcreteAdib SalahNo ratings yet

- DD-QC-XK-ITP-23-004 - El DaBaa NPP Unit 3 - R6Document5 pagesDD-QC-XK-ITP-23-004 - El DaBaa NPP Unit 3 - R6Minh NguyễnNo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282: Right of Way Procedure B-CON-PRO-210-39151-ADocument12 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282: Right of Way Procedure B-CON-PRO-210-39151-AZaidiNo ratings yet

- PMT Machines LTD Inspection and Test Plan For Bogie Frame FabricationDocument6 pagesPMT Machines LTD Inspection and Test Plan For Bogie Frame FabricationAMIT SHAHNo ratings yet

- Attachment 10 - ITP-Earth WorksDocument11 pagesAttachment 10 - ITP-Earth WorksHayder JNo ratings yet

- NEW PUMP STATION PS-56A INSTALLATIONDocument3 pagesNEW PUMP STATION PS-56A INSTALLATIONJaseelKanhirathinkal100% (1)

- C-QAC-PLN-000-38152-A PaintingDocument20 pagesC-QAC-PLN-000-38152-A PaintingahmedNo ratings yet

- 25045-A1000-18-ITP-E-004r004 - ITP For Underfloor RacewayDocument8 pages25045-A1000-18-ITP-E-004r004 - ITP For Underfloor RacewaymsmkhanNo ratings yet

- Ain Tsila Road and Pavement Works ITPDocument23 pagesAin Tsila Road and Pavement Works ITPAslaouiNo ratings yet

- Inspection and Testing Plan: (Insert Project Name)Document10 pagesInspection and Testing Plan: (Insert Project Name)vin ssNo ratings yet

- Itp PipingDocument15 pagesItp PipingEkhy Transmisi100% (1)

- Inspection and Test Plan for Site Preparation and Earth WorksDocument26 pagesInspection and Test Plan for Site Preparation and Earth WorksZaidi100% (1)

- BK91 1310 CPF 000 CIV RFI 0013 Visual Inspection of Incoming Pre Cast Piles & Check Piling EquipmentDocument1 pageBK91 1310 CPF 000 CIV RFI 0013 Visual Inspection of Incoming Pre Cast Piles & Check Piling EquipmentPanneer SelvamNo ratings yet

- Site Supervision PlanDocument113 pagesSite Supervision PlanChan Chee YongNo ratings yet

- Shic A 0009Document1 pageShic A 000901095902062ahmedNo ratings yet

- Fabrication of Steel Structure and Steel Equipmentitp PDF FreeDocument4 pagesFabrication of Steel Structure and Steel Equipmentitp PDF FreeAhmed GhareebNo ratings yet

- MITP For Excavation and Backfilling ApprovedDocument7 pagesMITP For Excavation and Backfilling ApprovedMogu MohanNo ratings yet

- Audit Plan 审核计划: To be completed by theDocument3 pagesAudit Plan 审核计划: To be completed by thegeorge liuNo ratings yet

- 60-00-Qm-Itp-00039 - 0001 - 0 ITP PipingDocument109 pages60-00-Qm-Itp-00039 - 0001 - 0 ITP PipingTauqeer SalimNo ratings yet

- MicDocument434 pagesMicray cheungNo ratings yet

- S-000-1676-0001V - 11 - ITP For Piping WorkDocument47 pagesS-000-1676-0001V - 11 - ITP For Piping WorkVO DINH TRI100% (2)

- Qality Assurance Inspection and Test Plan: Piping Fabrication & InstallationDocument16 pagesQality Assurance Inspection and Test Plan: Piping Fabrication & Installationmanoj thakkarNo ratings yet

- Installation of Irrigation System ITPDocument2 pagesInstallation of Irrigation System ITPBleep NewsNo ratings yet

- Inspection & Test Plan for Survey Instrument StationsDocument2 pagesInspection & Test Plan for Survey Instrument StationsDoni TriatmojoNo ratings yet

- Itp For Fabn. & Erection of Structural WorksDocument4 pagesItp For Fabn. & Erection of Structural Workscrm 2No ratings yet

- Afi SC03 QRBN Ci 00233Document1 pageAfi SC03 QRBN Ci 00233حسن كاظم ريسان B-4No ratings yet

- 0000100324/17-Civil Inspection and Test Plan: 0000100324/17 03-100000-0000100324 - FTC-CIV-ITP-xxxxxxDocument1 page0000100324/17-Civil Inspection and Test Plan: 0000100324/17 03-100000-0000100324 - FTC-CIV-ITP-xxxxxxMeshaal ALBalharithNo ratings yet

- Corrective Action Request: Contract NoDocument1 pageCorrective Action Request: Contract NoTanmay VegadNo ratings yet

- Shic A 0008Document3 pagesShic A 000801095902062ahmedNo ratings yet

- ITP ErectionDocument3 pagesITP Erectionjanpaul2481No ratings yet

- Request For Inspection (RFI) : Material Verification Prior Test To LaboratoriumDocument1 pageRequest For Inspection (RFI) : Material Verification Prior Test To Laboratoriumalfad maulaNo ratings yet

- Inspection and Test Plan for Piping Fabrication and InstallationDocument16 pagesInspection and Test Plan for Piping Fabrication and InstallationEyoh EffiongNo ratings yet

- Unnecessary Regulatory Burdens in Dealing With Construction Permits Ar Ezumi Harzani IsmailDocument43 pagesUnnecessary Regulatory Burdens in Dealing With Construction Permits Ar Ezumi Harzani IsmailCindy LiewNo ratings yet

- BTC003-B020-CM-PRJ-00015 C02 Qualiti Control PlansDocument11 pagesBTC003-B020-CM-PRJ-00015 C02 Qualiti Control PlansLevan JaparidzeNo ratings yet

- 14C. 2082-PM-ITP-7017 Rev.0 - SITE ITP PaintingDocument6 pages14C. 2082-PM-ITP-7017 Rev.0 - SITE ITP PaintingAmarKumarNo ratings yet

- Fire & Safety Lab and HPL Generator Building Modon-3 Dammam, KsaDocument5 pagesFire & Safety Lab and HPL Generator Building Modon-3 Dammam, KsaMiqdadNo ratings yet

- Bv Pspc Pres 03122012Document31 pagesBv Pspc Pres 03122012Ahmed Algunaid احمد الجنيدNo ratings yet

- Work Method Statement For: Concrete Coring WorksDocument14 pagesWork Method Statement For: Concrete Coring WorksAbdul AbbasNo ratings yet

- 1TB03300 300C04 STC Wir Me 0002Document19 pages1TB03300 300C04 STC Wir Me 0002heerkhanheerkhan435No ratings yet

- ITP For Pipeline Welding ProcedureDocument15 pagesITP For Pipeline Welding ProcedureNYO100% (2)

- QAQC Section PresentationDocument17 pagesQAQC Section PresentationWildan Al BaihaqiNo ratings yet

- Right of Way Construction ITPDocument12 pagesRight of Way Construction ITPZaidiNo ratings yet

- IVASDocument12 pagesIVASCommunication GuyNo ratings yet

- CDP RDC Ar Mal Qac 0001Document5 pagesCDP RDC Ar Mal Qac 0001ElvinNo ratings yet

- m1439 GHD MCL Mss 053 Modification For LV PanelDocument84 pagesm1439 GHD MCL Mss 053 Modification For LV PanelAnandu AshokanNo ratings yet

- Inspection and Test PlanDocument6 pagesInspection and Test PlanMadison ChanNo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282: Site Itp For Fiber Optic Installation B-QAC-PLN-210-39267Document19 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282: Site Itp For Fiber Optic Installation B-QAC-PLN-210-39267ZaidiNo ratings yet

- Cathodic Protection ITPDocument25 pagesCathodic Protection ITPZaidiNo ratings yet

- 15.5 GPSPE CC Turnover from civil construction to erectionDocument2 pages15.5 GPSPE CC Turnover from civil construction to erectionH2gen ProjectNo ratings yet

- @email: Mohd Zaky Bin RosnanDocument18 pages@email: Mohd Zaky Bin RosnanINSTECH PremierNo ratings yet

- HFY 3800 0000 CIV ITP 0002 - 0 Inspection and Test Plan For Piling Works - Code - ADocument17 pagesHFY 3800 0000 CIV ITP 0002 - 0 Inspection and Test Plan For Piling Works - Code - ANashaat DhyaaNo ratings yet

- ITP Box Setting On CHB or Macro WallDocument3 pagesITP Box Setting On CHB or Macro WallRitchie OcampoNo ratings yet

- Gabions ITPDocument6 pagesGabions ITPVishnudas MgNo ratings yet

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsFrom EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsNo ratings yet

- Statement of Axis Account No:918010022379745 For The Period (From: 01-01-2022 To: 31-12-2022)Document75 pagesStatement of Axis Account No:918010022379745 For The Period (From: 01-01-2022 To: 31-12-2022)Murugesh SalemNo ratings yet

- From (Jayakanth.M (Jayakanthlegend - Gmail@naukri - Com) ) - ID (5763 - 2) - Resume 1Document5 pagesFrom (Jayakanth.M (Jayakanthlegend - Gmail@naukri - Com) ) - ID (5763 - 2) - Resume 1Ram JiNo ratings yet

- Nudge Theory - Janki Solanki - 1813051Document7 pagesNudge Theory - Janki Solanki - 1813051Janki SolankiNo ratings yet

- Capital Structure ProjectDocument56 pagesCapital Structure ProjectHarshita chauhanNo ratings yet

- Unit 7 - Review QuestionsDocument3 pagesUnit 7 - Review Questionslinhnhp.workNo ratings yet

- Lecture One: The Pay Model: Course Name: Compensation ManagementDocument25 pagesLecture One: The Pay Model: Course Name: Compensation ManagementInzamamul HaqueNo ratings yet

- J910 DT03 P0ZEN 040001 SQCP 0010 (Quality Control Procedure Index) - Rev.0Document3 pagesJ910 DT03 P0ZEN 040001 SQCP 0010 (Quality Control Procedure Index) - Rev.0Budi SetiawanNo ratings yet

- Diya GDocument45 pagesDiya GDiya goyalNo ratings yet

- Peregrine Exam Study QuestionsDocument228 pagesPeregrine Exam Study QuestionsKristina100% (1)

- Metro Laundry Services Vs Commission Proper, Commission On Audit, and City of Manila, G.R. No. 252411, February 15, 2022Document2 pagesMetro Laundry Services Vs Commission Proper, Commission On Audit, and City of Manila, G.R. No. 252411, February 15, 2022Gi NoNo ratings yet

- C243340 SalarySlipIncludeDocument1 pageC243340 SalarySlipIncludebenq78786No ratings yet

- Final E-Government Strategy Implementation Report v1.12-26th FebDocument362 pagesFinal E-Government Strategy Implementation Report v1.12-26th FebRo ManNo ratings yet

- Circumstances Allowing Piercing of Corporate VeilDocument8 pagesCircumstances Allowing Piercing of Corporate VeilSipho NdlovuNo ratings yet

- BCA-3rd-Sem-2022-23 (1) - 231123 - 060059Document12 pagesBCA-3rd-Sem-2022-23 (1) - 231123 - 060059satya.bhatia123456No ratings yet

- College Accounting Chapters 1-27-22nd Edition Heintz Solutions ManualDocument35 pagesCollege Accounting Chapters 1-27-22nd Edition Heintz Solutions Manualengildhebraism.he3o100% (22)

- Ingersoll RandDocument14 pagesIngersoll Randakadityakapoor100% (1)

- Msme NdaDocument3 pagesMsme NdaXuena ouNo ratings yet

- Taxguru - in-GST Audit GSTR-9C Practical Checklist Alongwith Audit ProcessDocument3 pagesTaxguru - in-GST Audit GSTR-9C Practical Checklist Alongwith Audit ProcesschetudaveNo ratings yet

- Market Analysis of Footwear Industry in India With Ref To LakhaniDocument74 pagesMarket Analysis of Footwear Industry in India With Ref To LakhaniVinod Upadhyay100% (7)

- GX About Deloitte Global Report Full Version 2022Document94 pagesGX About Deloitte Global Report Full Version 2022Riza AlatasNo ratings yet

- Chap 6-Supply, Demand & Government PoliciesDocument30 pagesChap 6-Supply, Demand & Government PoliciesKhánh AnNo ratings yet

- Tech Mahindra Talent Management Practices SummaryDocument3 pagesTech Mahindra Talent Management Practices SummarySAYANTH SUDHEERNo ratings yet

- TQCSI-Audit-Plan-IMS-Gmmostech Marine & Technical Services LLCDocument2 pagesTQCSI-Audit-Plan-IMS-Gmmostech Marine & Technical Services LLCHamid HussainNo ratings yet

- Airbnb Team Assignement AMDocument26 pagesAirbnb Team Assignement AMMadoz MGNo ratings yet

- Kristine Mae v. Panes CVDocument2 pagesKristine Mae v. Panes CVKristine mae PanesNo ratings yet