Professional Documents

Culture Documents

Cytec Solutions 2013 21

Uploaded by

aktivrudarpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cytec Solutions 2013 21

Uploaded by

aktivrudarpCopyright:

Available Formats

Solvent Extraction, Mineral Processing and Alumina Processing

AERO®7260 HFP: Novel, Safe and Sustainable Alternative to Traditional Hazardous Modifiers

– NaSH, Nokes, Na2S, and Cyanide

20

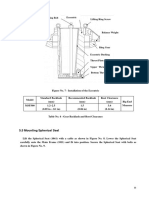

% Difference between control and with AERO 7260 HFP (%)

Fe Cu Mo

-20

-40

FIGURE 6:

Three consecutive days of plant

-60

data using AERO®7260 HFP in an

on/off cycle in the cleaner

-80

circuit. The % difference in Fe, Cu,

and Mo grades between control

(off cycle) and with AERO®7260 HFP

-100 (on cycle) is shown

Day 1 Day 2 Day 3

General Guidelines for Application

• The typical dosages to test AERO®7260 HFP is around • AERO 7260 HFP should be added along with NaSH

250-1500 g/T, and needs to be adjusted depending on (or Nokes/Na2S).

the ore mineralogy and other process conditions. Higher

• Recommended conditioning times are 5 to 15 minutes.

dosages may be evaluated as needed. Optimization should

Longer conditioning times, e.g. 30 min or longer are not

be based upon Cu and pyrite depression, Mo selectivity,

required.

and economics.

• AERO 7260 HFP can be added in the roughers, scavenger

• The performance of AERO 7260 HFP is best when air is

or cleaner stage, as needed. Usually, if the dosages are

used. Note: N2 can be used, however the performance

optimized, stage addition is not required.

advantages and benefits of AERO 7260 HFP may not be

fully realized. • AERO 7260 HFP can be added as-is, or may be diluted as

needed.

• Pretreatments are not required with AERO 7260 HFP.

Other Applications for AERO 7260 HFP

AERO 7260 HFP is an excellent depressant for a variety of b) Depression of penalty/toxic elements in Cu and complex

sulfide minerals, selectivity being dictated by dosage of sulfide ores.

AERO 7260 HFP and process conditions. Products based on c) Enhancement of selectivity in Cu-Pb, Pb-Zn, Cu-Zn

AERO 7260 HFP have a wide range of applications including: separations.

a) Rejection of gangue from sulfide concentrates: d) Depression of iron sulfides in Cu-pyrite and Zn-pyrite

Depression of all sulfide minerals while floating Non separations.

Sulfide Gangue E.g. Ni-talc separation. e) Depression of Cu sulfides and pyrite in Cu-Mo,

Cu-graphite, Cu-F, Cu-Talc separations.

21

IN PROCESS SEPARATION

You might also like

- 14 - SCRsystemInstallationGuideLineDNOx2 - V7.3Document103 pages14 - SCRsystemInstallationGuideLineDNOx2 - V7.3George Huarcaya Diaz100% (1)

- COE-110.06, Corrosion FailuresDocument90 pagesCOE-110.06, Corrosion Failuresامين100% (1)

- Qatar Petroleum Ngl-1 Operating ManualDocument50 pagesQatar Petroleum Ngl-1 Operating Manualvaratharajan g rNo ratings yet

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- DIN 1681 Chemical CompositionDocument12 pagesDIN 1681 Chemical CompositionAshish Kesharwani100% (1)

- ACI ATI Integration of SAF Report BnmzjuDocument33 pagesACI ATI Integration of SAF Report BnmzjuyoNo ratings yet

- Ipac 9220 PDS 7JB171 PDFDocument1 pageIpac 9220 PDS 7JB171 PDFJorge Zegarra67% (3)

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- p91, p92, p11, p22, p9 Chemical CompositionDocument1 pagep91, p92, p11, p22, p9 Chemical CompositionYogesh Wadhwa100% (1)

- Geology and Metallogeny of Copper DepositsDocument602 pagesGeology and Metallogeny of Copper Depositsze costaNo ratings yet

- IPAC 745 PDS V 2.0 PDFDocument1 pageIPAC 745 PDS V 2.0 PDFJorge Zegarra100% (1)

- High Vacuum UnitDocument75 pagesHigh Vacuum UnitKurnia AthiefNo ratings yet

- High Temperature Physicochemical Properties of High Alumina Blast Furnace SlagDocument200 pagesHigh Temperature Physicochemical Properties of High Alumina Blast Furnace SlagBernardo Loureiro PattoNo ratings yet

- Predict MIddle Distillate PropertiesDocument8 pagesPredict MIddle Distillate PropertiesKumarNo ratings yet

- ASTM Codes For SteelDocument1 pageASTM Codes For SteelRaktim DasNo ratings yet

- Cytec Solutions 2013 17Document1 pageCytec Solutions 2013 17aktivrudarpNo ratings yet

- Cytec Solutions 2013 20Document1 pageCytec Solutions 2013 20aktivrudarpNo ratings yet

- Flotacion Ppt-Flotación 2018 - Alexis CamposDocument23 pagesFlotacion Ppt-Flotación 2018 - Alexis CamposLuis Katsumoto Huere AnayaNo ratings yet

- Cytec Solutions 2013 16Document1 pageCytec Solutions 2013 16aktivrudarpNo ratings yet

- Refrigerant Transition Under F-Gas Regulation 517-2014Document4 pagesRefrigerant Transition Under F-Gas Regulation 517-2014daniel.hinczewskiNo ratings yet

- Cytec Solutions 2013 28Document1 pageCytec Solutions 2013 28aktivrudarpNo ratings yet

- Service Manual: PUHZ-P100VHA - UK PUHZ-P125VHA - UK PUHZ-P140VHA - UKDocument110 pagesService Manual: PUHZ-P100VHA - UK PUHZ-P125VHA - UK PUHZ-P140VHA - UKPepePlatanoNo ratings yet

- Freon 404A enDocument12 pagesFreon 404A enisturmanNo ratings yet

- Compresor DoosanDocument73 pagesCompresor DoosanMartin MartinezNo ratings yet

- Truck, Forklift: Adverse Terrain, 10,000 LB CAPACITY, M544E (NSN 3930-01-301-8250)Document17 pagesTruck, Forklift: Adverse Terrain, 10,000 LB CAPACITY, M544E (NSN 3930-01-301-8250)Хелфор УкраинаNo ratings yet

- Cytec Solutions 2013 22Document1 pageCytec Solutions 2013 22aktivrudarpNo ratings yet

- Service Manual: MU-A07YV - MU-A09YV - MU-A12YVDocument28 pagesService Manual: MU-A07YV - MU-A09YV - MU-A12YValessandroNo ratings yet

- Dupont Improve Reliability Efficiency Centrifugal Pumps PTQ 0613Document3 pagesDupont Improve Reliability Efficiency Centrifugal Pumps PTQ 0613duhaimNo ratings yet

- Mitsubishi Service Manual MU-A09 12WA CondensadorDocument28 pagesMitsubishi Service Manual MU-A09 12WA CondensadortorqueuNo ratings yet

- Advanced Strategies For Selecting Oil Analysis AlarmsDocument6 pagesAdvanced Strategies For Selecting Oil Analysis AlarmsDANIEL ZORRONo ratings yet

- Ord 5774 Norsok, Iso, and APIDocument3 pagesOrd 5774 Norsok, Iso, and APIRoo FaNo ratings yet

- TULUX T300 CF-4 Diesel Engine OilDocument3 pagesTULUX T300 CF-4 Diesel Engine OilYoong TanNo ratings yet

- Mxz-2a20na & Mxz-3a30na Ob444aDocument77 pagesMxz-2a20na & Mxz-3a30na Ob444aSLAMET PAMBUDINo ratings yet

- Cosmolubric HF-122 Data SheetDocument1 pageCosmolubric HF-122 Data Sheetsiddharth srinivasanNo ratings yet

- O&M of WTP Metering PumpsDocument58 pagesO&M of WTP Metering Pumpssidehustle.abduNo ratings yet

- Getriebele Auf Polyglykolbasis - e PDFDocument11 pagesGetriebele Auf Polyglykolbasis - e PDFbernardohbgNo ratings yet

- Contactor Vol 3 No 1Document2 pagesContactor Vol 3 No 1sushant0261No ratings yet

- PDFDocument8 pagesPDFmsmsoft90No ratings yet

- 108SE-Selected Answers To The 2010 NPRA QADocument7 pages108SE-Selected Answers To The 2010 NPRA QAJay LawsonNo ratings yet

- Yap1 Aaaa00 Jepr Depr 1003 D03Document13 pagesYap1 Aaaa00 Jepr Depr 1003 D03Amir JalaliNo ratings yet

- 102 - Not 200 9010 enDocument13 pages102 - Not 200 9010 enKhurram ShahzadNo ratings yet

- Appendices C DDocument15 pagesAppendices C Dnaser shamsNo ratings yet

- Soft Natural Rubber Lining: Technical Data SheetDocument2 pagesSoft Natural Rubber Lining: Technical Data SheetArmanda SiryogiawanNo ratings yet

- M.F. Menoufy, H.S. Ahmed, M.A. Betiha, M.A. Sayed: Highlights GraphicalDocument5 pagesM.F. Menoufy, H.S. Ahmed, M.A. Betiha, M.A. Sayed: Highlights GraphicalTya ArisandiNo ratings yet

- Estequiometria PU DOWDocument2 pagesEstequiometria PU DOWRenan Rovani100% (1)

- Brochure Re-Refinery Thermopac PDFDocument3 pagesBrochure Re-Refinery Thermopac PDFPan Jun KimNo ratings yet

- Lubrication Order L05 4320-258-12 20 JULY 1977 (Supersedes L05-4320-258-12, 30 July 1971)Document5 pagesLubrication Order L05 4320-258-12 20 JULY 1977 (Supersedes L05-4320-258-12, 30 July 1971)SteveNo ratings yet

- Valvulas Gemu DB C60 67HPS GBDocument9 pagesValvulas Gemu DB C60 67HPS GBejrfjxhjtntauuwtfcNo ratings yet

- Dokumen - Tips - Registered Trademark of Basf Se Magnafloc Magnafloc 155 Is A High Molecular WeightDocument2 pagesDokumen - Tips - Registered Trademark of Basf Se Magnafloc Magnafloc 155 Is A High Molecular WeightMahmoud HakimNo ratings yet

- Sir - Tds .Siropol 7440 LV. No3Document3 pagesSir - Tds .Siropol 7440 LV. No3Yousef LotfyNo ratings yet

- Muz A18 26yv (OB346E)Document52 pagesMuz A18 26yv (OB346E)Selçuk özkutluNo ratings yet

- Worksheets - ENAP Bio Bio Refineria Par-Isom HAZOP PDFDocument192 pagesWorksheets - ENAP Bio Bio Refineria Par-Isom HAZOP PDFFrancisco SanchezNo ratings yet

- Ciclo Di Verniciatura: Proprietà TecnicheDocument9 pagesCiclo Di Verniciatura: Proprietà TecnicheMaffone NumerounoNo ratings yet

- Labor VariancesDocument4 pagesLabor VariancesMeghan Kaye LiwenNo ratings yet

- Advantage 3000 Series Instruction ManualDocument32 pagesAdvantage 3000 Series Instruction ManualGabriel GriNo ratings yet

- Spe Distinguished Lecturer Series Spe FoundationDocument39 pagesSpe Distinguished Lecturer Series Spe FoundationYajaira Nicole Coca SilesNo ratings yet

- DMO Diesel Motor OilsDocument9 pagesDMO Diesel Motor OilssrcattozziNo ratings yet

- Safety Valve's Noise LevelDocument2 pagesSafety Valve's Noise Levelaravind grandhiNo ratings yet

- HGM-740 T5 BIO: Heavy Range Open SkidDocument7 pagesHGM-740 T5 BIO: Heavy Range Open SkidghostshotNo ratings yet

- Hydrogen Peroxide Attitude Control SystemsDocument10 pagesHydrogen Peroxide Attitude Control SystemsDarius MaximusNo ratings yet

- Downloads - 2020-01 - InBrief May 2018Document20 pagesDownloads - 2020-01 - InBrief May 2018Rambo khanNo ratings yet

- Wat'S Going On With Vlsfos?Document3 pagesWat'S Going On With Vlsfos?Руслан КостюкNo ratings yet

- M60eh44 Man 001Document40 pagesM60eh44 Man 001Riski KurniawanNo ratings yet

- 3 - Approval Universal Trans LZ9990A Performance Summary1Document10 pages3 - Approval Universal Trans LZ9990A Performance Summary1Adam KaczmarekNo ratings yet

- Starting Up Hydrotreating Units With Cracked FeedsDocument5 pagesStarting Up Hydrotreating Units With Cracked FeedsAle SanzNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-61Document1 page612431362-200928-MSP300-0078-CONICA-61aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-67Document1 page612431362-200928-MSP300-0078-CONICA-67aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-65Document1 page612431362-200928-MSP300-0078-CONICA-65aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-40Document1 page612431362-200928-MSP300-0078-CONICA-40aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-36Document1 page612431362-200928-MSP300-0078-CONICA-36aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-52Document1 page612431362-200928-MSP300-0078-CONICA-52aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-45Document1 page612431362-200928-MSP300-0078-CONICA-45aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-48Document1 page612431362-200928-MSP300-0078-CONICA-48aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-49Document1 page612431362-200928-MSP300-0078-CONICA-49aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-39Document1 page612431362-200928-MSP300-0078-CONICA-39aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-43Document1 page612431362-200928-MSP300-0078-CONICA-43aktivrudarpNo ratings yet

- MSP300 0078 Conica 23Document1 pageMSP300 0078 Conica 23aktivrudarpNo ratings yet

- 612431362-200928-MSP300-0078-CONICA-50Document1 page612431362-200928-MSP300-0078-CONICA-50aktivrudarpNo ratings yet

- MSP300 0078 Conica 4Document1 pageMSP300 0078 Conica 4aktivrudarpNo ratings yet

- MSP300 0078 Conica 19Document1 pageMSP300 0078 Conica 19aktivrudarpNo ratings yet

- MSP300 0078 Conica 21Document1 pageMSP300 0078 Conica 21aktivrudarpNo ratings yet

- MSP300 0078 Conica 2Document1 pageMSP300 0078 Conica 2aktivrudarpNo ratings yet

- Cytec Solutions 2013 50Document1 pageCytec Solutions 2013 50aktivrudarpNo ratings yet

- MSP300 0078 Conica 5Document1 pageMSP300 0078 Conica 5aktivrudarpNo ratings yet

- MSP300 0078 Conica 3Document1 pageMSP300 0078 Conica 3aktivrudarpNo ratings yet

- Cytec Solutions 2013 45Document1 pageCytec Solutions 2013 45aktivrudarpNo ratings yet

- Cytec Solutions 2013 39Document1 pageCytec Solutions 2013 39aktivrudarpNo ratings yet

- Cytec Solutions 2013 46Document1 pageCytec Solutions 2013 46aktivrudarpNo ratings yet

- Cytec Solutions 2013 18Document1 pageCytec Solutions 2013 18aktivrudarpNo ratings yet

- Cytec Solutions 2013 42Document1 pageCytec Solutions 2013 42aktivrudarpNo ratings yet

- Cytec Solutions 2013 34Document1 pageCytec Solutions 2013 34aktivrudarpNo ratings yet

- Cytec Solutions 2013 35Document1 pageCytec Solutions 2013 35aktivrudarpNo ratings yet

- Cytec Solutions 2013 23Document1 pageCytec Solutions 2013 23aktivrudarpNo ratings yet

- Cytec Solutions 2013 31Document1 pageCytec Solutions 2013 31aktivrudarpNo ratings yet

- Cytec Solutions 2013 6Document1 pageCytec Solutions 2013 6aktivrudarpNo ratings yet

- Hindalco Production & Operations DepartmentDocument7 pagesHindalco Production & Operations DepartmentJaydeep SolankiNo ratings yet

- Ore of Punta Gorda (N. Moreno B.)Document22 pagesOre of Punta Gorda (N. Moreno B.)Willy ApryantoNo ratings yet

- The Performance of Stainless Steels in Concentrated Sulphuric AcidDocument4 pagesThe Performance of Stainless Steels in Concentrated Sulphuric AcidAlvaro JaraNo ratings yet

- Clark Forklift Oh 339 c500 Overhaul ManualDocument22 pagesClark Forklift Oh 339 c500 Overhaul Manualsarahlucero080795jcr97% (38)

- Dae AnnDocument290 pagesDae AnnTICKER PORTNo ratings yet

- Principle:-: Analysis of Metals by Atomic Absorption SpectrophotometryDocument2 pagesPrinciple:-: Analysis of Metals by Atomic Absorption SpectrophotometryThambidurai KNo ratings yet

- Unit I Foundry TechnologyDocument151 pagesUnit I Foundry TechnologyAkash akNo ratings yet

- Several Thiospinels Proposed As High Temperature Superconductors - Bi2ZnO4Document16 pagesSeveral Thiospinels Proposed As High Temperature Superconductors - Bi2ZnO4Sai VandanaNo ratings yet

- Enhancing The Efficiency of Manganese Recovery From Pyrolusite Ore Through Hydrometallurgical Techniques Utilizing Nitric Acid and Distilled WaterDocument13 pagesEnhancing The Efficiency of Manganese Recovery From Pyrolusite Ore Through Hydrometallurgical Techniques Utilizing Nitric Acid and Distilled WaterInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Compounds of MetalsDocument15 pagesCompounds of MetalsMycovich Myco100% (1)

- GCSE ChemistryDocument22 pagesGCSE ChemistryAmeerul HazeeqNo ratings yet

- General Principles and Processes of Isolation of ElementsDocument12 pagesGeneral Principles and Processes of Isolation of ElementsBhavesh KNo ratings yet

- Aporte HandbookDocument2 pagesAporte HandbookJulio Vergara CruzNo ratings yet

- Earth Science Q1 Presentation 4 (Important Minerals in Society)Document13 pagesEarth Science Q1 Presentation 4 (Important Minerals in Society)Janine AsiertoNo ratings yet

- Materials Selection: Lecturer: Muhammad SulaimanDocument15 pagesMaterials Selection: Lecturer: Muhammad SulaimanHussain AliNo ratings yet

- Checkpoint Revision (Part 2) : Plants Need To Absorb Water and Transport It To All of Their Living PartsDocument15 pagesCheckpoint Revision (Part 2) : Plants Need To Absorb Water and Transport It To All of Their Living PartsMark ZuckerburgNo ratings yet

- Golongan I A - Iv A - Kelompok 1 - Xii Ipa 1Document42 pagesGolongan I A - Iv A - Kelompok 1 - Xii Ipa 1Anisa AyuNo ratings yet

- Ree ImpurityDocument40 pagesRee Impuritynabil FarhaanNo ratings yet

- Periodic TableDocument1 pagePeriodic Tablemusa sanyangNo ratings yet

- Unit15 Minerals and CeramicsDocument11 pagesUnit15 Minerals and Ceramicsjohão BagrielNo ratings yet

- Casting Clinic-How To Produce DI PDFDocument14 pagesCasting Clinic-How To Produce DI PDFsachinguptachdNo ratings yet

- Turner Question and Answer Bank 2014Document88 pagesTurner Question and Answer Bank 2014bijukumarg93% (30)

- How Minerals Are Mined and Processed For Human UseDocument24 pagesHow Minerals Are Mined and Processed For Human UseBea Dacillo BautistaNo ratings yet

- Presentation EnorDocument23 pagesPresentation EnorLaraba MohamedNo ratings yet