Professional Documents

Culture Documents

Isolated Foundation - 5

Isolated Foundation - 5

Uploaded by

Saravanan SOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Isolated Foundation - 5

Isolated Foundation - 5

Uploaded by

Saravanan SCopyright:

Available Formats

Print Calculation Sheet

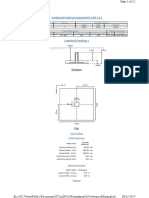

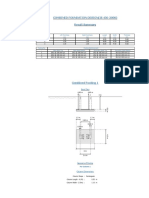

Isolated Footing Design(ACI 318-14) - Metric

Footing No. Group ID Foundation Geometry

- - Length Width Thickness

55 5 3.00m 3.00m 0.50m

Footing No. Footing Reinforcement Pedestal Reinforcement

- Bottom Reinforcement(Mz) Bottom Reinforcement(Mx) Top Reinforcement(Mz) Top Reinforcement(Mx) Main Steel Trans Steel

55 25 - 13 mm 25 - 13 mm 21 - 13 mm 21 - 13 mm N/A

Isolated Footing 55

1m

0.5 m

Elevation

X 1.5 m

0.5 m

0.7 m

3m

1.5 m

3m

Plan

Input Values

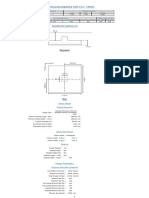

Footing Geometry

Design Type : Set Dimension

Minimum Footing Length - X(Fl) : 3000.00 mm

Minimum Footing Width - Z (Fw) : 3000.00 mm

Footing Thickness (Ft) : 500.00 mm

Eccentricity along X (Oxd) : 0.00 mm

Eccentricity along Z (Ozd) : 0.00 mm

Column Dimensions

Column Shape : Rectangular

Typesetting math: 35%

28-04-2024 12:50:35 1/18

Column Length - X (Dcol) : 0.50 m

Column Width - Z (Bcol) : 0.70 m

Pedestal

Include Pedestal : No

Pedestal Shape : N/A

Design Parameters

Concrete and Rebar Properties

Unit Weight of Concrete : 25.00 kN/m3

Strength of Concrete : 32.00 N/mm2

Yield Strength of Steel : 420.00 N/mm2

Minimum Bar Size : 13 mm

Maximum Bar Size : 25 mm

Top Footing Minimum Bar Size : 13 mm

Top Footing Maximum Bar Size : 25 mm

Pedestal Minimum Bar Size : 19 mm

Pedestal Maximum Bar Size : 32 mm

Minimum Bar Spacing : 80.00 mm

Maximum Bar Spacing : 300.00 mm

Pedestal Clear Cover (P, CL) : 50.00 mm

Bottom Footing Clear Cover (F, CL) : 75.00 mm

Soil Properties

Unit Weight : 18.00kN/m3

Base Value of Soil Bearing Capacity : 236.00kPa

Multiplying factor for soil bearing capacity for ultimate

: 2.00

loads

Soil Bearing Capacity Type : Gross Bearing Capacity

Soil Surcharge : 0.00kN/m2

Height of Soil above Footing : 1000.00mm

Type of Depth : Fixed Top

Bearing Capacity Input Method : Fixed Bearing Capacity

Minimum Percentage of Slab area in Contact for Service

: 0.00

Loads

Minimum Percentage of Slab area in Contact for Ultimate

: 0.00

Loads

Sliding and Overturning

Coefficient of Friction : 0.40

Factor of Safety Against Sliding : 1.50

Factor of Safety Against Overturning : 1.50

Global Settings

Top Reinforcement Option : Calculate only when foundation is subjected to uplift forces

Concrete Design Option : Net Pressure(Gross Pressure - Self Weight Pressure)

Top Reinforcement Factor : 1.00

------------------------------------------------------

Design Calculations

Typesetting math: 35%

28-04-2024 12:50:35 2/18

Footing Size

Initial Length (Lo) = 3.00 m

Initial Width (Wo) = 3.00 m

Load Combinations

Load Combination/s- Service Stress Level

Load Load Case Soil Self

Combination Load Combination Title Multiplier Bearing Weight Code

Number (a) Factor (b) Factor (c)

a - Value specified in the Load Multiplier table

b - Value specified in the Pile/Soil Bearing Capacity Factors table

c - Value specified in the Apply Self Weight and Dead Weight Factor table

101 1.0 DL 1.00 1.00 1.00 -

102 1.0 DL + 1 L 1.00 1.00 1.00 -

103 1.0 DL + 1 L 1.00 1.00 1.00 -

104 1.0 DL + 1.0 LR 1.00 1.00 1.00 -

105 1.0 DL + 0.75 L + 0.75 LR 1.00 1.00 1.00 -

106 1.0 DL + 0.75 L + 0.75 LR 1.00 1.00 1.00 -

107 1.0 DL + 0.6 W+X (+GCPI) 1.00 1.00 1.00 -

108 1.0 DL + 0.6 W+X (-GCPI) 1.00 1.00 1.00 -

109 1.0 DL + 0.6 W-X (+GCPI) 1.00 1.00 1.00 -

110 1.0 DL + 0.6 W-X (-GCPI) 1.00 1.00 1.00 -

111 1.0 DL + 0.6 W+Z (+GCPI) 1.00 1.00 1.00 -

112 1.0 DL + 0.6 W+Z (-GCPI) 1.00 1.00 1.00 -

113 1.0 DL + 0.6 W-Z (+GCPI) 1.00 1.00 1.00 -

114 1.0 DL + 0.6 W-Z (-GCPI) 1.00 1.00 1.00 -

115 1.05 DL + 0.7 E+X 1.00 1.00 1.00 -

116 1.05 DL + 0.7 E-X 1.00 1.00 1.00 -

117 1.05 DL + 0.7 E+Z 1.00 1.00 1.00 -

118 1.05 DL + 0.7 E-Z 1.00 1.00 1.00 -

119 1.0 DL + 0.45 W+X (+GCPI) + 0.75 L + 0.75 LR 1.00 1.00 1.00 -

120 1.0 DL + 0.45 W+X (-GCPI) + 0.75 L + 0.75 LR 1.00 1.00 1.00 -

121 1.0 DL + 0.45 W-X (+GCPI) + 0.75 L + 0.75 LR 1.00 1.00 1.00 -

122 1.0 DL + 0.45 W-X (-GCPI) + 0.75 L + 0.75 LR 1.00 1.00 1.00 -

123 1.0 DL + 0.45 W+Z (+GCPI) + 0.75 L + 0.75 LR 1.00 1.00 1.00 -

124 1.0 DL + 0.45 W+Z (-GCPI) + 0.75 L + 0.75 LR 1.00 1.00 1.00 -

125 1.0 DL + 0.45 W-Z (+GCPI) + 0.75 L + 0.75 LR 1.00 1.00 1.00 -

126 1.0 DL + 0.45 W-Z (-GCPI) + 0.75 L + 0.75 LR 1.00 1.00 1.00 -

127 1.026 DL + 0.525 E+X + 0.75 L + 0.75 LR 1.00 1.00 1.00 -

128 1.026 DL + 0.525 E-X + 0.75 L + 0.75 LR 1.00 1.00 1.00 -

129 1.026 DL + 0.525 E+Z + 0.75 L + 0.75 LR 1.00 1.00 1.00 -

130 1.026 DL + 0.525 E-Z + 0.75 L + 0.75 LR 1.00 1.00 1.00 -

131 0.6 DL + 0.6 W+X (+GCPI) 1.00 1.00 1.00 -

132 0.6 DL + 0.6 W+X (-GCPI) 1.00 1.00 1.00 -

133 0.6 DL + 0.6 W-X (+GCPI) 1.00 1.00 1.00 -

134 0.6 DL + 0.6 W-X (-GCPI) 1.00 1.00 1.00 -

135 0.6 DL + 0.6 W+Z (+GCPI) 1.00 1.00 1.00 -

136 0.6 DL + 0.6 W+Z (-GCPI) 1.00 1.00 1.00 -

137 0.6 DL + 0.6 W-Z (+GCPI) 1.00 1.00 1.00 -

138 0.6 DL + 0.6 W-Z (-GCPI) 1.00 1.00 1.00 -

139 0.55 DL + 0.7 E+X 1.00 1.00 1.00 -

140 0.55 DL + 0.7 E-X 1.00 1.00 1.00 -

141 0.55 DL + 0.7 E+Z 1.00 1.00 1.00 -

142 0.55 DL + 0.7 E-Z 1.00 1.00 1.00 -

143 1.0 DL + TLSS (+) 1.00 1.00 1.00 -

144 1.0 DL + TLSS (-) 1.00 1.00 1.00 -

145 1.0 DL + 1 L + TLSS (+) 1.00 1.00 1.00 -

146 1.0 DL + 1 L + TLSS (-) 1.00 1.00 1.00 -

147 1.0 DL + 1.0 LR + TLSS (+) 1.00 1.00 1.00 -

148 1.0 DL + 1.0 LR + TLSS (-) 1.00 1.00 1.00 -

149 1.0 DL + 0.75 L + 0.75 LR + TLSS (+) 1.00 1.00 1.00 -

150 1.0 DL + 0.75 L + 0.75 LR + TLSS (-) 1.00 1.00 1.00 -

151 1.0 DL + 0.5 L + 1.0 BL 1.00 1.00 1.00 -

152

Typesetting math: 35% 0.9 DL + 1.0 BL 1.00 1.00 1.00 -

28-04-2024 12:50:35 3/18

Load Combination/s- Strength Level

Load Load Case Soil Self

Combination Load Combination Title Multiplier Bearing Weight Code

Number (a) Factor (b) Factor (c)

a - Value specified in the Load Multiplier table

b - Value specified in the Pile/Soil Bearing Capacity Factors table

c - Value specified in the Apply Self Weight and Dead Weight Factor table

201 1.4 DL 1.00 1.00 1.00 -

202 1.2 DL + 1.6 L + 0.5 LR 1.00 1.00 1.00 -

203 1.2 DL + 1.6 L + 0.5 LR 1.00 1.00 1.00 -

204 1.2 DL + 1.0 L + 1.6 LR 1.00 1.00 1.00 -

205 1.2 DL + 1.6 LR + 0.5 W+X (+GCPI) 1.00 1.00 1.00 -

206 1.2 DL + 1.6 LR + 0.5 W+X (-GCPI) 1.00 1.00 1.00 -

207 1.2 DL + 1.6 LR + 0.5 W-X (+GCPI) 1.00 1.00 1.00 -

208 1.2 DL + 1.6 LR + 0.5 W-X (-GCPI) 1.00 1.00 1.00 -

209 1.2 DL + 1.6 LR + 0.5 W+Z (+GCPI) 1.00 1.00 1.00 -

210 1.2 DL + 1.6 LR + 0.5 W+Z (-GCPI) 1.00 1.00 1.00 -

211 1.2 DL + 1.6 LR + 0.5 W-Z (+GCPI) 1.00 1.00 1.00 -

212 1.2 DL + 1.6 LR + 0.5 W-Z (-GCPI) 1.00 1.00 1.00 -

213 1.2 DL + 1.0 L + 0.5 LR + 1.0 W+X (+GCPI) 1.00 1.00 1.00 -

214 1.2 DL + 1.0 L + 0.5 LR + 1.0 W+X (-GCPI) 1.00 1.00 1.00 -

215 1.2 DL + 1.0 L + 0.5 LR + 1.0 W-X (+GCPI) 1.00 1.00 1.00 -

216 1.2 DL + 1.0 L + 0.5 LR + 1.0 W-X (-GCPI) 1.00 1.00 1.00 -

217 1.2 DL + 1.0 L + 0.5 LR + 1.0 W+Z (+GCPI) 1.00 1.00 1.00 -

218 1.2 DL + 1.0 L + 0.5 LR + 1.0 W+Z (-GCPI) 1.00 1.00 1.00 -

219 1.2 DL + 1.0 L + 0.5 LR + 1.0 W-Z (+GCPI) 1.00 1.00 1.00 -

220 1.2 DL + 1.0 L + 0.5 LR + 1.0 W-Z (-GCPI) 1.00 1.00 1.00 -

221 1.25 DL + 1.0 L + 1.0 E+X 1.00 1.00 1.00 -

222 1.25 DL + 1.0 L + 1.0 E-X 1.00 1.00 1.00 -

223 1.25 DL + 1.0 L + 1.0 E+Z 1.00 1.00 1.00 -

224 1.25 DL + 1.0 L + 1.0 E-Z 1.00 1.00 1.00 -

225 0.9 DL + 1.0 W+X (+GCPI) 1.00 1.00 1.00 -

226 0.9 DL + 1.0 W+X (-GCPI) 1.00 1.00 1.00 -

227 0.9 DL + 1.0 W-X (+GCPI) 1.00 1.00 1.00 -

228 0.9 DL + 1.0 W-X (-GCPI) 1.00 1.00 1.00 -

229 0.9 DL + 1.0 W+Z (+GCPI) 1.00 1.00 1.00 -

230 0.9 DL + 1.0 W+Z (-GCPI) 1.00 1.00 1.00 -

231 0.9 DL + 1.0 W-Z (+GCPI) 1.00 1.00 1.00 -

232 0.9 DL + 1.0 W-Z (-GCPI) 1.00 1.00 1.00 -

233 0.85 DL + 1.0 E+X 1.00 1.00 1.00 -

234 0.85 DL + 1.0 E-X 1.00 1.00 1.00 -

235 0.85 DL + 1.0 E+Z 1.00 1.00 1.00 -

236 0.85 DL + 1.0 E-Z 1.00 1.00 1.00 -

237 1.2 DL + 0.5 W+X (+GCPI) 1.00 1.00 1.00 -

238 1.2 DL + 0.5 W+X (-GCPI) 1.00 1.00 1.00 -

239 1.2 DL + 0.5 W-X (+GCPI) 1.00 1.00 1.00 -

240 1.2 DL + 0.5 W-X (-GCPI) 1.00 1.00 1.00 -

241 1.2 DL + 0.5 W+Z (+GCPI) 1.00 1.00 1.00 -

242 1.2 DL + 0.5 W+Z (-GCPI) 1.00 1.00 1.00 -

243 1.2 DL + 0.5 W-Z (+GCPI) 1.00 1.00 1.00 -

244 1.2 DL + 0.5 W-Z (-GCPI) 1.00 1.00 1.00 -

245 1.4 DL + 1.2 TLSS (+) 1.00 1.00 1.00 -

246 1.4 DL + 1.2 TLSS (-) 1.00 1.00 1.00 -

247 1.2 DL + 1.6 L + 0.5 LR + 1.2 TLSS (+) 1.00 1.00 1.00 -

248 1.2 DL + 1.6 L + 0.5 LR + 1.2 TLSS (-) 1.00 1.00 1.00 -

249 1.2 DL + 1.0 L + 1.6 LR + 1.2 TLSS (+) 1.00 1.00 1.00 -

250 1.2 DL + 1.0 L + 1.6 LR + 1.2 TLSS (-) 1.00 1.00 1.00 -

251 1.2 DL + 0.5 L + 1.0 BL 1.00 1.00 1.00 -

252 0.9 DL + 1.0 BL 1.00 1.00 1.00 -

Applied Loads on Top of Pedestal

Before consideration of self weight and load multiplier table

Moments are about the center of Column / Pedestal (does not include moments caused by lateral loads)

For the loads shown in this table, the sign convention is the same as that for JOINT LOADS in STAAD.Pro when global Y is the vertical axis.

Typesetting math: 35%

28-04-2024 12:50:35 4/18

Applied Loads from Column - Service Stress Level

Fy

(kN)

Fx Fz Mx Mz

Load Case Downwards is

(kN) (kN) (kNm) (kNm)

negative Upwards

is positive

101 -11.27 -861.60 -9.33 -12.28 5.48

102 -12.50 -1041.27 -36.58 -44.31 7.16

103 -12.50 -1041.27 -36.58 -44.31 7.16

104 -11.39 -918.52 -7.27 -9.98 5.60

105 -12.28 -1039.04 -28.22 -34.58 6.83

106 -12.28 -1039.04 -28.22 -34.58 6.83

107 -2.68 -771.41 -13.27 -15.47 -5.49

108 -6.14 -888.42 -11.22 -14.17 -1.21

109 -18.66 -779.92 -13.97 -17.03 15.25

110 -18.59 -895.04 -11.77 -15.38 14.95

111 -9.85 -749.50 16.31 46.73 3.93

112 -11.09 -874.20 11.12 29.79 5.26

113 -9.32 -800.93 -35.32 -70.41 2.93

114 -10.74 -908.12 -22.94 -47.50 4.60

115 108.45 -831.07 -6.09 -4.28 -150.73

116 -132.13 -978.29 -13.50 -21.52 162.23

117 -9.16 -757.16 88.71 228.34 3.32

118 -14.51 -1052.19 -108.30 -254.14 8.18

119 -5.84 -971.41 -31.18 -36.96 -1.40

120 -8.43 -1059.16 -29.64 -35.99 1.81

121 -17.82 -977.78 -31.70 -38.13 14.16

122 -17.77 -1064.13 -30.05 -36.90 13.93

123 -11.21 -954.97 -9.00 9.69 5.67

124 -12.14 -1048.49 -12.89 -3.02 6.67

125 -10.82 -993.54 -47.72 -78.17 4.92

126 -11.88 -1073.94 -38.43 -60.98 6.17

127 77.64 -1006.24 -25.69 -28.43 -110.39

128 -102.79 -1116.66 -31.24 -41.36 124.34

129 -10.57 -950.81 45.41 146.03 5.15

130 -14.58 -1172.08 -102.34 -215.82 8.80

131 1.83 -426.78 -9.54 -10.55 -7.68

132 -1.63 -543.78 -7.49 -9.26 -3.40

133 -14.15 -435.28 -10.24 -12.11 13.06

134 -14.08 -550.40 -8.04 -10.46 12.76

135 -5.34 -404.86 20.04 51.65 1.74

136 -6.58 -529.56 14.85 34.71 3.07

137 -4.81 -456.29 -31.59 -65.49 0.74

138 -6.23 -563.48 -19.21 -42.58 2.41

139 114.09 -400.27 -1.43 1.87 -153.47

140 -126.49 -547.49 -8.83 -15.38 159.50

141 -3.53 -326.36 93.37 234.48 0.58

142 -8.87 -621.39 -103.63 -248.00 5.44

143 -11.27 -861.60 -9.33 -12.28 5.48

144 -11.27 -861.60 -9.33 -12.28 5.48

145 -12.50 -1041.27 -36.58 -44.31 7.16

146 -12.50 -1041.27 -36.58 -44.31 7.16

147 -11.39 -918.52 -7.27 -9.98 5.60

148 -11.39 -918.52 -7.27 -9.98 5.60

149 -12.28 -1039.04 -28.22 -34.58 6.83

150 -12.28 -1039.04 -28.22 -34.58 6.83

151 -11.65 -928.78 -31.14 -39.49 6.13

152 -9.91 -752.79 -16.58 -22.25 4.74

Applied Loads from Column - Strength Level

Fy

(kN)

Fx Fz Mx Mz

Load Case Downwards is

(kN) (kN) (kNm) (kNm)

negative Upwards

is positive

201 -15.78 -1206.24 -13.06 -17.20 7.67

202 -15.55 -1349.86 -53.77 -64.83 9.33

203 -15.55 -1349.86 -53.77 -64.83 9.33

Typesetting math: 35%

28-04-2024 12:50:35 5/18

Applied Loads from Column - Strength Level

Fy

(kN)

Fx Fz Mx Mz

Load Case Downwards is

(kN) (kN) (kNm) (kNm)

negative Upwards

is positive

204 -14.94 -1304.66 -35.15 -43.08 8.45

205 -6.55 -1049.84 -11.18 -13.71 -2.38

206 -9.43 -1147.34 -9.48 -12.63 1.19

207 -19.87 -1056.92 -11.77 -15.00 14.91

208 -19.81 -1152.86 -9.93 -13.63 14.66

209 -12.53 -1031.58 13.46 38.13 5.47

210 -13.55 -1135.49 9.14 24.01 6.58

211 -12.08 -1074.43 -29.56 -59.49 4.64

212 -13.26 -1163.76 -19.24 -40.40 6.03

213 -0.50 -1091.75 -43.98 -50.92 -9.97

214 -6.26 -1286.75 -40.58 -48.76 -2.83

215 -27.13 -1105.92 -45.15 -53.52 24.61

216 -27.01 -1297.79 -41.48 -50.77 24.10

217 -12.45 -1055.23 5.31 52.74 5.73

218 -14.50 -1263.05 -3.33 24.51 7.95

219 -11.56 -1140.93 -80.73 -142.49 4.08

220 -13.92 -1319.60 -60.10 -104.30 6.86

221 156.52 -1151.51 -33.62 -35.06 -215.01

222 -187.16 -1361.83 -44.20 -59.70 232.08

223 -11.50 -1045.94 101.81 297.24 5.06

224 -19.14 -1467.41 -179.63 -392.01 12.00

225 4.17 -625.13 -14.96 -16.36 -13.35

226 -1.59 -820.14 -11.55 -14.20 -6.22

227 -22.46 -639.31 -16.13 -18.96 21.22

228 -22.34 -831.17 -12.46 -16.21 20.71

229 -7.78 -588.61 34.33 87.31 2.34

230 -9.84 -796.43 25.69 59.07 4.56

231 -6.89 -674.32 -51.71 -107.93 0.69

232 -9.25 -852.98 -31.08 -69.74 3.47

233 162.26 -627.20 -2.64 1.88 -218.89

234 -181.42 -837.52 -13.22 -22.76 228.20

235 -5.76 -521.62 132.79 334.19 1.19

236 -13.40 -943.09 -148.65 -355.07 8.13

237 -6.37 -958.76 -14.48 -17.39 -2.57

238 -9.25 -1056.27 -12.77 -16.31 1.00

239 -19.69 -965.85 -15.06 -18.69 14.72

240 -19.62 -1061.79 -13.23 -17.32 14.47

241 -12.34 -940.51 10.17 34.44 5.28

242 -13.37 -1044.42 5.85 20.32 6.39

243 -11.90 -983.36 -32.85 -63.18 4.45

244 -13.08 -1072.69 -22.54 -44.08 5.84

245 -15.78 -1206.24 -13.06 -17.20 7.67

246 -15.78 -1206.24 -13.06 -17.20 7.67

247 -15.55 -1349.86 -53.77 -64.83 9.33

248 -15.55 -1349.86 -53.77 -64.83 9.33

249 -14.94 -1304.66 -35.15 -43.08 8.45

250 -14.94 -1304.66 -35.15 -43.08 8.45

251 -13.91 -1101.10 -33.00 -41.95 7.22

252 -9.91 -752.79 -16.58 -22.25 4.74

Reduction of force due to buoyancy = 44.11 kN

Effect due to adhesion = 0.00 kN

2

Area from initial length and width, Ao = Lo X W o = 9.00 m

Min. area required from bearing pressure, Amin = 8.50 m2

Note: Amin is an initial estimation considering self-weight, axial load and moment against factored bearing capacity.

Typesetting math: 35%

28-04-2024 12:50:35 6/18

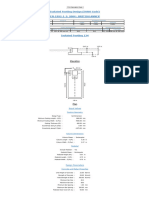

Final Footing Size

Length (L2) = 3.00 m Governing Load Case : # 101

Width (W2) = 3.00 m Governing Load Case : # 101

Depth (D2) = 0.50 m

Depth is governed by Ultimate Load Case

(Service check is performed with footing thickness requirements from concrete check)

Area (A2) = 9.00 m2

Final Soil Height = 1.00 m

Weight of the footing + pedestal (if any) = 112.50 kN

Soil Weight On Top Of Footing = 155.69 kN

Gross Pressures at 4 Corners

Pressure Pressure Area of

Pressure Pressure Gross

at top at bottom

Load Case / at top left at bottom footing in Bearing

right right uplift (Au)

Combination corner left corner Capacity

corner corner 2

(kN/m2) (kN/m2) (m ) (kN/m2)

(kN/m2) (kN/m2)

130 222.9381 215.7889 97.1224 104.2716 0.00 236.0000

130 222.9381 215.7889 97.1224 104.2716 0.00 236.0000

117 55.0849 51.5722 172.7716 176.2843 0.00 236.0000

116 195.5137 94.0468 81.4823 182.9492 0.00 236.0000

If Au is zero, there is no uplift and no pressure adjustment is necessary. Otherwise, to account for uplift, areas of negative pressure will be set to zero and the pressure

will be redistributed to remaining corners.

Summary of Adjusted Gross Pressures at four Corners

Pressure at Pressure at Pressure at Pressure at Gross

top left top right bottom right bottom left Bearing

Load Case / corner corner corner corner Capacity

Combination (kN/m2) (kN/m2) (kN/m2) (kN/m2) (kN/m2)

130 222.9381 215.7889 97.1224 104.2716 236.0000

130 222.9381 215.7889 97.1224 104.2716 236.0000

117 55.0849 51.5722 172.7716 176.2843 236.0000

116 195.5137 94.0468 81.4823 182.9492 236.0000

Stability Check

Typesetting math: 35%

28-04-2024 12:50:35 7/18

1m

OTM

Sliding Force

.

Frictional Force 0.5 m

Factor of safety against

- Factor of safety against sliding

overturning

Load

Along X- Along Z- Required About X- About Z- Required

Case Resultant

Direction Direction FOS Direction Direction FOS

No.

101 38.53 46.56 29.68 1.50 96.09 146.52 1.50

102 40.49 13.84 13.09 1.50 30.32 141.49 1.50

103 40.49 13.84 13.09 1.50 30.32 141.49 1.50

104 40.14 62.88 33.83 1.50 125.89 151.80 1.50

105 41.14 17.90 16.42 1.50 38.91 146.06 1.50

106 41.14 17.90 16.42 1.50 38.91 146.06 1.50

107 148.39 30.01 29.42 1.50 67.56 359.76 1.50

108 72.46 39.65 34.78 1.50 84.35 896.97 1.50

109 21.52 28.74 17.23 1.50 62.72 61.25 1.50

110 24.08 38.04 20.35 1.50 78.95 69.25 1.50

111 39.53 23.88 20.44 1.50 26.61 164.96 1.50

112 39.63 39.50 27.98 1.50 46.60 152.52 1.50

113 43.98 11.61 11.22 1.50 17.46 202.47 1.50

114 42.18 19.74 17.88 1.50 28.80 170.34 1.50

115 3.89 69.29 3.89 1.50 216.18 7.72 1.50

116 3.64 35.63 3.62 1.50 63.80 7.90 1.50

117 42.84 4.42 4.40 1.50 5.40 186.23 1.50

118 35.19 4.71 4.67 1.50 6.21 124.01 1.50

119 81.90 15.34 15.08 1.50 34.12 1177.80 1.50

120 60.87 17.32 16.65 1.50 37.88 319.17 1.50

121 26.97 15.16 13.22 1.50 33.39 78.13 1.50

122 29.00 17.15 14.76 1.50 37.21 84.69 1.50

123 42.05 52.43 32.80 1.50 340.86 156.86 1.50

124 41.93 39.51 28.75 1.50 201.75 149.87 1.50

125 45.02 10.21 9.95 1.50 17.90 176.80 1.50

126 43.71 13.51 12.91 1.50 24.28 160.73 1.50

127 6.34 19.16 6.02 1.50 44.71 12.37 1.50

128 5.22 17.17 4.99 1.50 35.29 11.44 1.50

129 44.47 10.35 10.08 1.50 10.44 168.88 1.50

130 38.31 5.46 5.40 1.50 7.84 130.19 1.50

131 142.63 27.30 26.81 1.50 63.72 113.57 1.50

132 188.10 40.99 40.05 1.50 88.56 445.49 1.50

133 18.63 25.76 15.10 1.50 57.39 49.11 1.50

134 22.00 38.55 19.11 1.50 80.22 58.68 1.50

Typesetting math: 35%

135 47.09 12.55 12.13 1.50 15.30 214.08 1.50

28-04-2024 12:50:35 8/18

Factor of safety against

- Factor of safety against sliding

overturning

Load

Along X- Along Z- Required About X- About Z- Required

Case Resultant

Direction Direction FOS Direction Direction FOS

No.

136 45.83 20.30 18.56 1.50 26.83 177.88 1.50

137 56.55 8.62 8.52 1.50 12.55 324.22 1.50

138 50.58 16.40 15.60 1.50 22.64 213.84 1.50

139 2.19 174.98 2.19 1.50 812.34 4.45 1.50

140 2.44 34.94 2.43 1.50 58.46 5.20 1.50

141 62.45 2.36 2.36 1.50 2.94 351.91 1.50

142 38.11 3.26 3.25 1.50 4.23 128.36 1.50

143 38.53 46.56 29.68 1.50 96.09 146.52 1.50

144 38.53 46.56 29.68 1.50 96.09 146.52 1.50

145 40.49 13.84 13.09 1.50 30.32 141.49 1.50

146 40.49 13.84 13.09 1.50 30.32 141.49 1.50

147 40.14 62.88 33.83 1.50 125.89 151.80 1.50

148 40.14 62.88 33.83 1.50 125.89 151.80 1.50

149 41.14 17.90 16.42 1.50 38.91 146.06 1.50

150 41.14 17.90 16.42 1.50 38.91 146.06 1.50

151 39.58 14.81 13.87 1.50 31.41 144.69 1.50

152 39.43 23.57 20.23 1.50 47.98 151.21 1.50

Critical Load Case And The Governing Factor Of Safety For Overturning And Sliding - X Direction

Critical Load Case for Sliding along X-Direction : 139

Governing Disturbing Force : 114.09 kN

Governing Restoring Force : 249.74 kN

Minimum Sliding Ratio for the Critical Load Case : 2.19

Critical Load Case for Overturning about X-Direction : 141

Governing Overturning Moment : 281.17 kNm

Governing Resisting Moment : 825.65 kNm

Minimum Overturning Ratio for the Critical Load Case : 2.94

Critical Load Case And The Governing Factor Of Safety For Overturning And Sliding - Z Direction

Critical Load Case for Sliding along Z-Direction : 141

Governing Disturbing Force : 93.37 kN

Governing Restoring Force : 220.18 kN

Minimum Sliding Ratio for the Critical Load Case : 2.36

Critical Load Case for Overturning about Z-Direction : 139

Governing Overturning Moment : -210.51 kNm

Governing Resisting Moment : 936.50 kNm

Minimum Overturning Ratio for the Critical Load Case : 4.45

Critical Load Case And The Governing Factor Of Safety For Sliding Along Resultant Direction

Critical Load Case for Sliding along Resultant Direction : 139

Governing Disturbing Force : 114.10 kN

Governing Restoring Force : 249.74 kN

Minimum Sliding Ratio for the Critical Load Case : 2.19

Ultimate Gross Pressures

The base pressures reported in this table and the area of footing in contact include the effect of buoyancy (if any).

Load Case / Pressure at Pressure at Pressure at Pressure at Gross Area of

Load top left top right bottom bottom left Factored footing in

Typesetting math: 35% Combination Bearing Contact

28-04-2024 12:50:35 9/18

ID corner corner right corner corner Capacity with soil

(kN/m2) (kN/m2) (kN/m2) (kN/m2) For (Au)

2

Ultimate (m )

Load Case

(kN/m2)

201 167.6549 160.7391 150.1935 157.1093 472.0000 9.00

202 199.0650 191.4624 150.6992 158.3018 472.0000 9.00

203 199.0650 191.4624 150.6992 158.3018 472.0000 9.00

204 186.8774 179.8024 152.8437 159.9187 472.0000 9.00

205 146.0339 145.6350 137.0586 137.4575 472.0000 9.00

206 157.5518 154.9266 147.2081 149.8333 472.0000 9.00

207 152.4969 141.4546 132.1704 143.2128 472.0000 9.00

208 162.5832 151.6684 143.4028 154.3177 472.0000 9.00

209 132.1561 126.9411 146.8789 152.0939 472.0000 9.00

210 147.6797 141.7431 154.4463 160.3829 472.0000 9.00

211 163.1574 158.4088 125.4004 130.1490 472.0000 9.00

212 168.1341 162.5052 140.2749 145.9038 472.0000 9.00

213 160.2466 164.5651 132.1595 127.8409 472.0000 9.00

214 183.2824 183.1482 152.4584 152.5926 472.0000 9.00

215 173.1726 156.2043 122.3831 139.3514 472.0000 9.00

216 193.3452 176.6318 144.8478 161.5612 472.0000 9.00

217 132.4910 127.1773 151.7999 157.1136 472.0000 9.00

218 163.5381 156.7812 166.9348 173.6917 472.0000 9.00

219 194.4936 190.1126 108.8429 113.2239 472.0000 9.00

220 204.4471 198.3056 138.5920 144.7335 472.0000 9.00

221 99.1987 229.5445 206.4885 76.1427 472.0000 9.00

222 266.7613 122.0212 85.6643 230.4044 472.0000 9.00

223 66.1487 61.3432 216.0777 220.8832 472.0000 9.00

224 299.8113 290.2225 76.0751 85.6639 472.0000 9.00

225 96.2241 103.0859 92.4898 85.6279 472.0000 9.00

226 119.2599 121.6691 112.7887 110.3796 472.0000 9.00

227 109.1502 94.7251 82.7134 97.1384 472.0000 9.00

228 129.3228 115.1526 105.1781 119.3483 472.0000 9.00

229 68.4685 65.6981 112.1302 114.9006 472.0000 9.00

230 99.5156 95.3020 127.2651 131.4787 472.0000 9.00

231 130.4711 128.6334 69.1732 71.0109 472.0000 9.00

232 140.4246 136.8264 98.9223 102.5205 472.0000 9.00

233 27.7905 161.1345 161.3823 28.0382 472.0000 9.00

234 195.3531 53.6112 40.5581 182.2999 472.0000 9.00

235 0.0000 0.0000 171.1764 173.0535 472.0000 8.66

236 228.4031 221.8125 30.9689 37.5594 472.0000 9.00

237 137.0380 136.7640 125.8165 126.0905 472.0000 9.00

238 148.5559 146.0556 135.9660 138.4663 472.0000 9.00

239 143.5010 132.5836 120.9283 131.8457 472.0000 9.00

240 153.5873 142.7973 132.1607 142.9506 472.0000 9.00

241 123.1602 118.0701 135.6367 140.7268 472.0000 9.00

242 138.6838 132.8721 143.2042 149.0159 472.0000 9.00

243 154.1615 149.5378 114.1582 118.7820 472.0000 9.00

244 159.1382 153.6342 129.0328 134.5368 472.0000 9.00

245 167.6549 160.7391 150.1935 157.1093 472.0000 9.00

246 167.6549 160.7391 150.1935 157.1093 472.0000 9.00

Typesetting math: 35% 247 199.0650 191.4624 150.6992 158.3018 472.0000 9.00

28-04-2024 12:50:35 10/18

248 199.0650 191.4624 150.6992 158.3018 472.0000 9.00

249 186.8774 179.8024 152.8437 159.9187 472.0000 9.00

250 186.8774 179.8024 152.8437 159.9187 472.0000 9.00

251 163.3816 157.0816 131.1036 137.4035 472.0000 9.00

252 117.4805 113.1737 99.6008 103.9076 472.0000 9.00

Minimum Required Contact Area for Ultimate Loads : 0.00 m2

Actual Area in Contact for all ultimate load cases exceeds the minimum required. Hence Safe

Gross Bearing Capacity for Ultimate Loads : 472.00 kN/m2

Maximum Corner Pressure from all ultimate load cases is less than the allowable. Hence Safe

Shear Calculation

Punching Shear Check

X 1.5 m

Z

0.205 m

1.5 m

Plan

Total Footing Depth, D = 0.50m

Calculated Effective Depth, d = D - Ccover - 1 * db = 0.41 m

For rectangular column, β = Bcol / Dcol = 1.40

Effective depth, d, increased until 0.75XVc ≥ Punching Shear Force

Punching Shear Force, Vu = 1886.65kN, Load Case # 224

From ACI Cl. 22.6.5.2, bo for column= 2 ×(BCOL+DCOL+2 ×d) = 4.05 m

Table 22.6.5.2, (b), Vc1 = 0.17×1+2β×λ×fc'×b0×d = 3899.03 kN

Table 22.6.5.2, (c), Vc2 = 0.083×as×db0+2×λ×fc'×b0×d = 4760.27 kN

Table 22.6.5.2, (a), Vc3 = 0.33×λ× fc'×b0×d = 3116.53 kN

Punching shear strength, Vc = 0.75 X minimum of (Vc1, Vc2, Vc3) = 2337.40 kN

0.75 X Vc > Vu hence, OK

One-Way Shear in XY Plane

(Shear Plane Parallel to Global X Axis)

Typesetting math: 35%

28-04-2024 12:50:35 11/18

X 1.5 m

0.74 m

Z

1.5 m

0.74 m

Plan

From ACI Cl. 22.5.5.1, Vc = 0.17×λ × bw× d × fc' = 1171.16 kN

Distance of critical section from top left corner

along Z, DZ = 0.5 × L ± Dcol-d+ Ozd = 0.74 m

Check that 0.75 X Vc > Vux where Vux is the shear force for the critical load cases at a distance d from the face of the column caused by bending about the X axis.

From above calculations, 0.75 X Vc = 878.37 kN

Critical load case for Vux is # 224 Vux= Vux | z=Dx = 543.38 kN

0.75 X Vc > Vux hence, OK

One-Way Shear in YZ Plane

(Shear Plane Parallel to Global Z Axis)

X 1.5 m

0.84 m 0.84 m

1.5 m

Plan

From ACI Cl. 22.5.5.1, Vc = 0.17×λ × bw× d × fc' = 1171.16 kN

Distance of critical section from top left corner along

X, DX = 0.5 × L ± Bcol-d+ Oxd = 0.84 m

Check that 0.75 X Vc > Vuz where Vuz is the shear force for the critical load cases at a distance d from the face of the column caused by bending about the Z axis.

From above calculations, 0.75 X Vc = 878.37 kN

Critical load case for Vuz is # 222 Vuz= Vuz | x=Dz = 515.65 kN

0.75 X Vc > Vuz hence, OK

Flexure About Z-Axis

Design For Bottom Reinforcement Parallel to X Axis

Typesetting math: 35%

28-04-2024 12:50:35 12/18

X

25 - 13 mm

Calculate the flexural reinforcement along the X direction of the footing. Find the area of steel required.

Critical Load Case # 222

The strength values of steel and concrete used in the formulae are in Mpa

Bars parallel to X Direction are placed at bottom

Effective Depth d = 0.41 m

Factor β1 from ACI Cl. 22.2.2.4.3 =

= 0.82

From ACI318-2011 Appendix B 8.4.2, ρbal = 0.85 × β1 × fc'fy ×(600600+ fy) = 0.03116

Maximum Reinforcement Ratio corresponding to εt

= 0.01986

= 0.005 = ρmax =

From ACI Cl. 7.6.1.1, ρmin = = 0.00180

From Ref.1, Eq. 3.8.4a, constant m = fy0.85×fc' = 15.44

Calculate reinforcement ratio ρ for critical load case

Design for flexure about Z axis is performed at the face

of the column at a distance from top left corner of 0.5 × L ± Bcol+ Oxd = 1.25 m

footing, Dx =

Ultimate moment = Mu|z = Dz = 477.12 kNm

Nominal moment capacity required, Mn = MuΦ = 530.14 kNm

(Based on effective depth) Required ρ = 1m 1- 1-2×m×Mnfy× bw×d2 = 0.00261

(Based on gross depth)ρ x d / Depth = 0.00212

Since ρmin < ρ < ρmax OK

Area of Steel Required, As = ρ × bw × d = 3173.21 mm2

Note - "Area of Steel required" reported here is the larger value between the calculated area of steel and minimum steel required as per code stipulations

Selected bar Size = 13 mm

Minimum spacing allowed (Smin) = 80.00mm

Selected spacing (S) = 118.22mm

Smin<= S <= Smax and selected bar size < selected maximum bar size

The reinforcement is accepted.

According to ACI 318 Clause No- 24.3.2

Max spacing for Cracking Consideration = 192.39mm

Safe for Cracking Aspect.

Based on spacing reinforcement increment; provided reinforcement is

13 mm @ 115mm o.c.

Required development length for bars = db × fy2.1 ×λ×fc' = 0.45 m

Typesetting math: 35%

28-04-2024 12:50:35 13/18

Available development length for bars,DL = 0.5 × L- Dcol- Ccover = 1.18 m

Size of bar Used as

Reinforcement 13 mm Area of one bar = 129.00 mm2

Number of bars required, Nbar = AsAbar = 25

Because the number of bars is rounded up, make sure new reinforcement ratio < ρmax

Total reinforcement area, As_total = Nbar X (Area of one bar) = 3224.99 mm2

d= D - Ccover - 0.5 X (dia. of = 0.41 m

one bar)

Reinforcement ratio, ρ = As_totald × bw = 0.00265

From ACI Cl. 25.2.1, minimum req'd clear distance between bars

Cd = max (Diameter of one bar, 1.0" (25.4mm), Min. User Spacing) = 80.00mm

Provided Steel Area / Required Steel Area = 1.02

Design For Top Reinforcement Parallel to X Axis

First load case to be in pure/partial uplift # 235

Calculate the flexural reinforcement for Mz. Find the area of steel required

The strength values of steel and concrete used in the formulae are in ksi

Bars parallel to X Direction are placed at bottom

Effective Depth d = 15.98 m

Factor β1 from ACI Cl. 22.2.2.4.3 = 0.82

=

From ACI318-2011 Appendix B 8.4.2, ρbal = = 0.03116

Maximum Reinforcement Ratio corresponding to εt = 0.005

= 0.01986

= ρmax =

From ACI Cl. 7.6.1.1, ρmin = = 0.00180

From Ref. 1, Eq. 3.8.4a, constant m = fy0.85 × fc' = 15.44

Calculate reinforcement ratio ρ for critical load case

Design for flexure about Z axis is performed at the

face of the column at a distance from top left corner 0.5 × L ± Bcol+ Oxd = 1.75 m

of footing, Dx =

Ultimate moment = Mu|x = Dx = 71.48 kNm

Nominal moment capacity required, Mn = MuΦ = 79.42 kNm

(Based on effective depth)Required ρ = 1m 1- 1-2×m×Mnfy× bw×d2 = 0.000384

(Based on gross depth)ρ x d / Depth =

Since ρ < ρmin, select ρ= ρmin ρmin Governs

Area of Steel Required, As = ρ × bw × d = 2699.96 mm2

Note - "Area of Steel required" reported here is the

larger value between the calculated area of steel and

minimum steel required as per code stipulations

Total reinforcement area, As_total = Nbar X (Area of one bar) = 2708.99 mm2

Provided Steel Area / Required Steel Area = 1.00

Selected bar Size = mm

Minimum spacing allowed (Smin) =

Selected spacing (S) =

Smin<= S <= Smax and selected bar size < selected maximum bar size

The reinforcement is accepted.

According to ACI 318 Clause No- 24.3.2

Max spacing for Cracking Consideration = 192.39mm

Safe for Cracking Aspect.

Based on spacing reinforcement increment; provided reinforcement is

mm @ o.c.

Typesetting math: 35%

28-04-2024 12:50:35 14/18

Flexure About X-Axis

Design For Bottom Reinforcement Parallel to Z Axis

25 - 13 mm

Calculate the flexural reinforcement along the Z direction of the footing. Find the area of steel required.

Critical Load Case # 224

The strength values of steel and concrete used in the formulae are in Mpa

Bars parallel to X Direction are placed at bottom

Effective Depth d = 0.41 m

Factor β1 from ACI Cl. 22.2.2.4.3 =

= 0.82

From ACI318-2011 Appendix B 8.4.2, ρbal = 0.85 × β1 × fc'fy ×(600600+ fy) = 0.03116

Maximum Reinforcement Ratio corresponding to εt

= 0.01986

= 0.005 = ρmax =

From ACI Cl. 7.6.1.1, ρmin = = 0.00180

From Ref.1, Eq. 3.8.4a, constant m = fy0.85 × fc' = 15.44

Calculate reinforcement ratio ρ for critical load case

Design for flexure about X axis is performed

at the face of the column at a distance from 0.5 ×L ±0.5 × Bcol+Ozd = 1.15 m

top left corner of footing, Dz =

Ultimate moment = Mu|x = Dx = 481.54 kNm

Nominal moment capacity required, Mn = MuΦ = 535.05 kNm

(Based on effective depth) Required ρ = 1m 1- 1-2×m×Mnfy× bw×d2 = 0.00263

(Based on gross depth) ρ x d / Depth = 0.00214

Since ρmin < ρ < ρmax OK

Area of Steel Required, As = ρ × bw × d = 3203.23 mm2

Note - "Area of Steel required" reported here is the larger value between the calculated area of steel and minimum steel required as per code stipulations

Selected Bar Size = 13 mm

Minimum spacing allowed (Smin) = 80.00mm

Selected spacing (S) = 118.22mm

Smin<= S <= Smax and selected bar size < selected maximum bar size

The reinforcement is accepted.

Max spacing for Cracking Consideration = 192.39mm

Safe for Cracking Aspect.

Based on spacing reinforcement increment; provided reinforcement is

Typesetting math: 35%

28-04-2024 12:50:35 15/18

13 mm @ 115mm o.c.

Required development length for bars = db × fy2.1 ×λ×fc' = 0.45 m

Available development length for bars, DL

0.5 × L- Dcol- Ccover = 1.08 m

=

Size of bar Used as

=

Reinforcement 13 mm Area of one bar 129.00 mm2

Number of bars required, Nbar= AsAbar = 25

Because the number of bars is rounded up, make sure new reinforcement ratio < ρmax

Total reinforcement area, As_total = Nbar X (Area of one bar) = 3224.99 mm2

d= D - Ccover - 1.5 X (dia. of 0.41 m

=

one bar)

Reinforcement ratio, ρ = As_totald × bw = 0.00265

From ACI Cl. 25.2.1, minimum req'd clear distance between bars

Cd = max (Diameter of one bar, 1.0" (25.4mm), Min. User Spacing) = 80.00mm

Provided Steel Area / Required Steel Area = 1.01

Bending moment for uplift cases will be calculated based solely on selfweight, soil depth and surcharge loading.

As the footing size has already been determined based on all servicebility load cases, and design moment calculation is based on selfweight, soil depth and surcharge

only, top reinforcement value for all pure uplift load cases will be the same.

Design For Top Reinforcement Parallel to Z Axis

Top reinforcement is calculated based on self weight of footing and soil

Calculate the flexural reinforcement for Mx. Find the area of steel required

The strength values of steel and concrete used in the formulae are in ksi

Bars parallel to X Direction are placed at bottom

Effective Depth d = 15.98 m

Factor β1 from ACI Cl. 22.2.2.4.3 = = 0.82

From ACI318-2011 Appendix B 8.4.2, ρbal = = 0.03116

Maximum Reinforcement Ratio corresponding to εt = 0.005

= 0.01986

= ρmax =

From ACI Cl. 7.6.1.1, ρmin = = 0.00180

From Ref. 1, Eq. 3.8.4a, constant m = fy0.85 × fc' = 15.44

Calculate reinforcement ratio ρ for critical load case

Design for flexure about X axis is performed at the face of

the column at a distance from top left corner of footing, = 0.5 × L ± Bcol+ Oxd = 1.85 m

Dx

Ultimate moment, = Mu|z = Dz = 60.50 kNm

Nominal moment capacity required, Mn = MuΦ = 67.22 kNm

(Based on effective depth) Required ρ = 1m 1- 1-2×m×Mnfy× bw×d2 = 0.00032

(Based on gross depth)ρ x d / Depth = 0.00032

Since ρ < ρmin, select ρ= ρmin ρmin Governs

Area of Steel Required, As = ρ × bw × d = 2699.96 mm2

Note - "Area of Steel required" reported here is the larger

value between the calculated area of steel and minimum

steel required as per code stipulations

Total reinforcement area, As_total = Nbar X (Area of one bar) = 2708.99 mm2

Provided Steel Area / Required Steel Area = 1.00

Selected bar Size = 13 mm

Minimum spacing allowed (Smin) = mm

Selected spacing (S) = 141.87mm

Smin<= S <= Smax and selected bar size < selected maximum bar size

The reinforcement is accepted.

Typesetting math: 35% According to ACI 318 Clause No- 24.3.2

28-04-2024 12:50:35 16/18

Max spacing for Cracking Consideration = 192.39mm

Safe for Cracking Aspect.

Based on spacing reinforcement increment; provided reinforcement is

13 mm @ 140mm o.c.

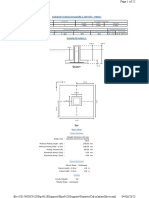

Material Take Off

Footing Reinforcement

Direction Size Number Total Length (m) Weight (kg)

Along Z on Bottom

13 mm 25 71.25 70.83

Face

Along X on Bottom

13 mm 25 71.25 70.83

Face

Along Z on Top

13 mm 21 59.85 59.50

Face

Along X on Top

13 mm 21 59.85 59.50

Face

Total Reinforcement Weight : 260.65 kg

Concrete

3

- Length (m) Width (m) Thickness (m) Volume (m )

Footing 3.00 3.00 0.50 4.50

Pedestal 0.00 0.00 0.00 0.00

Total Concrete Volume : 4.50 m3

Formwork

Footing : 6.00 m2

Pedestal : 0.00 m2

Total : 6.00 m2

Soil Excavation

Pit Depth : 1.50 m

Pit Slope (a : b) : 1 : 1 (Assumed)

Side Distance, s : 0 (Assumed)

Excavation Volume : 31.50 m3

Backfill Volume : 27.00 m3

X X

Z Z

21 - 13 mm

21 - 13 mm

Typesetting math: 35%

28-04-2024 12:50:35 17/18

18/18

X 1.5 m

Z

1m

0.5 m

0.7 m

3m

1.5 m

3m

0.5 m

28-04-2024 12:50:35

Plan

1.5 m

Elevation

BOTTOM 25 - 13 mm

TOP 21 - 13 mm

Dimensions (m) Reinforcement

L B D AstX(T) AstZ(T) AstX(B) AstZ(B)

Foundation

1.5 m

3m 3m 0.5 m 21 - 13 mm 21 - 13 mm 25 - 13 mm 25 - 13 mm

l b h Main Reinforcement Trans Reinforcement

TOP 21 - 13 mm Pedestal

N/A N/A N/A N/A N/A

BOTTOM 25 - 13 mm

Plan

Typesetting math: 35%

You might also like

- Isolated Footing Design (ACI 318-11) : ElevationDocument12 pagesIsolated Footing Design (ACI 318-11) : ElevationAhmed Ben HmidaNo ratings yet

- Isolated Footing Design (ACI 318-14) - Metric: Footing No. Group ID Foundation Geometry - Length Width ThicknessDocument48 pagesIsolated Footing Design (ACI 318-14) - Metric: Footing No. Group ID Foundation Geometry - Length Width ThicknessRoberto BautistaNo ratings yet

- Isolated Footing Design (BS 8110-97) : Footing No. Group ID Foundation Geometry - Length Width ThicknessDocument10 pagesIsolated Footing Design (BS 8110-97) : Footing No. Group ID Foundation Geometry - Length Width ThicknessAnonymous mWTB5TaMANNo ratings yet

- Construction Innovation: Article InformationDocument21 pagesConstruction Innovation: Article InformationMohamed-amineAkaabouneNo ratings yet

- Isolated Footing Design (ACI 318-14) - Metric: ElevationDocument14 pagesIsolated Footing Design (ACI 318-14) - Metric: Elevationrehjk85No ratings yet

- Isolated Footing Design (ACI 318-11) - Metric: ElevationDocument12 pagesIsolated Footing Design (ACI 318-11) - Metric: ElevationOsas Asemota-OsagieNo ratings yet

- Isolated Footing Design (ACI 318-14) - Metric: ElevationDocument12 pagesIsolated Footing Design (ACI 318-14) - Metric: ElevationkhuNo ratings yet

- F1 F2 F3 F4 MergedDocument48 pagesF1 F2 F3 F4 MergedkhuNo ratings yet

- Design of Footing F1: ElevationDocument12 pagesDesign of Footing F1: Elevationcyrus juanezaNo ratings yet

- 5 Design of Isolated FTG 1Document10 pages5 Design of Isolated FTG 1Wilkenn TuazonNo ratings yet

- MBV FTG 15 CalcDocument11 pagesMBV FTG 15 CalcjssrycbrNo ratings yet

- Design of Footing F1: ElevationDocument12 pagesDesign of Footing F1: Elevationcyrus juanezaNo ratings yet

- FootingDocument16 pagesFootingClaude ReyesNo ratings yet

- Iso Slope FT 2Document12 pagesIso Slope FT 2Bhavya PatelNo ratings yet

- Design of FootingDocument17 pagesDesign of FootingJezley SalemNo ratings yet

- Isolated Footing Design (ACI 318-11) - Metric: ElevationDocument12 pagesIsolated Footing Design (ACI 318-11) - Metric: ElevationOsas Asemota-OsagieNo ratings yet

- Isolated Footing Design (ACI 318-11) - Metric: ElevationDocument12 pagesIsolated Footing Design (ACI 318-11) - Metric: ElevationOsas Asemota-OsagieNo ratings yet

- F7 CalculationsDocument14 pagesF7 CalculationsRaviraj ThoratNo ratings yet

- Isolated Footing Design (ACI 318-11) - Metric: ElevationDocument13 pagesIsolated Footing Design (ACI 318-11) - Metric: ElevationHenry TuganoNo ratings yet

- Isolated Footing Design (IS 456-2000) : ElevationDocument11 pagesIsolated Footing Design (IS 456-2000) : ElevationVandhiyan RNo ratings yet

- F2 (Isolated)Document13 pagesF2 (Isolated)mojako freaksNo ratings yet

- COMBIIDocument16 pagesCOMBIINefer PitouNo ratings yet

- Iso Slope Ft1Document12 pagesIso Slope Ft1Bhavya PatelNo ratings yet

- TrussDocument11 pagesTrussPravin GadlingNo ratings yet

- Isolated Foundation - 12Document12 pagesIsolated Foundation - 12Saravanan SNo ratings yet

- Du2 Soil Type IDocument14 pagesDu2 Soil Type ILokzmanNo ratings yet

- Pipe Support Analysis Report (Isolated Footing)Document12 pagesPipe Support Analysis Report (Isolated Footing)ahmedNo ratings yet

- Fo PDFDocument15 pagesFo PDFإسماعيل مظفرNo ratings yet

- STAADDocument13 pagesSTAADIan Adrianne BongcayaoNo ratings yet

- Result Summary: Combined Foundation Design (Aci 318-11)Document10 pagesResult Summary: Combined Foundation Design (Aci 318-11)clarkgaguiNo ratings yet

- Isolated Footing Design (IS 456-2000) : ElevationDocument11 pagesIsolated Footing Design (IS 456-2000) : ElevationVandhiyan RNo ratings yet

- Kalkulasi Pondasi Tiang 25 MeterDocument14 pagesKalkulasi Pondasi Tiang 25 MeterMuhammad FauzanNo ratings yet

- Kalkulasi Pondasi Tiang 30 MeterDocument13 pagesKalkulasi Pondasi Tiang 30 MeterMuhammad FauzanNo ratings yet

- 7762.isolated Footing OutputDocument14 pages7762.isolated Footing Outputmichael murakamiNo ratings yet

- Isolated Part1Document1 pageIsolated Part1arghyaNo ratings yet

- Zap T2 PDFDocument12 pagesZap T2 PDFOscar EspinosaNo ratings yet

- Result Summary: Combined Foundation Design (Aci 318-05)Document12 pagesResult Summary: Combined Foundation Design (Aci 318-05)Oscar EspinosaNo ratings yet

- Isolated FootingDocument15 pagesIsolated FootingMark Christian Esguerra100% (1)

- Combined Foundation Design (Is 456-2000) Result SummaryDocument28 pagesCombined Foundation Design (Is 456-2000) Result Summaryarchetype designNo ratings yet

- Isolated Footing Design (ACI 318-05) - Metric: ElevationDocument12 pagesIsolated Footing Design (ACI 318-05) - Metric: Elevationoscar angNo ratings yet

- Zap T1 PDFDocument16 pagesZap T1 PDFOscar EspinosaNo ratings yet

- Zap T1 PDFDocument16 pagesZap T1 PDFOscar EspinosaNo ratings yet

- Zap T3 PDFDocument12 pagesZap T3 PDFOscar EspinosaNo ratings yet

- Combined Foundation Design (Is 456-2000) Result SummaryDocument10 pagesCombined Foundation Design (Is 456-2000) Result Summaryarchetype designNo ratings yet

- Ewt Footing Column DesignDocument64 pagesEwt Footing Column DesignMark Roger Huberit IINo ratings yet

- Footing Staad Test 1Document10 pagesFooting Staad Test 1Kem RaiNo ratings yet

- Footing of Mits ChimneyDocument12 pagesFooting of Mits ChimneyPradeep Kumar RajNo ratings yet

- Tisl SCNL DRW 0008 TNK Sht1 Rev 1 Footing Design CalculationDocument33 pagesTisl SCNL DRW 0008 TNK Sht1 Rev 1 Footing Design Calculationtimothy ogbechieNo ratings yet

- Centre Column Foundation ReportDocument16 pagesCentre Column Foundation Reportokechukwu1benjaminNo ratings yet

- Isolated FTNG DesignDocument48 pagesIsolated FTNG DesignclarkgaguiNo ratings yet

- Combined Foundation Design (Is 456-2000) Result SummaryDocument19 pagesCombined Foundation Design (Is 456-2000) Result Summaryarchetype designNo ratings yet

- Salida Sap2000 PSUB-69KVDocument14 pagesSalida Sap2000 PSUB-69KVCesar HernandezNo ratings yet

- Isolated Footing Design (ACI 318-05) : Footing No. Group ID Foundation Geometry - Length Width ThicknessDocument13 pagesIsolated Footing Design (ACI 318-05) : Footing No. Group ID Foundation Geometry - Length Width ThicknessRaah E SulookNo ratings yet

- Isolated Footing Design (ACI 318-11) : Input ValuesDocument9 pagesIsolated Footing Design (ACI 318-11) : Input ValuesMohammed FarhanNo ratings yet

- Foundation 2Document17 pagesFoundation 2farha zoheb imranNo ratings yet

- Result Summary: Combined Foundation Design (Aci 318-11)Document32 pagesResult Summary: Combined Foundation Design (Aci 318-11)Napoleon CarinoNo ratings yet

- F1 CombinedDocument15 pagesF1 Combinedmojako freaksNo ratings yet

- Isolated FootingDocument1 pageIsolated FootingPre SheetNo ratings yet

- Boundary FootingDocument46 pagesBoundary FootingANKESH SHRIVASTAVANo ratings yet

- Combined Foundation Design (Is 456-2000) Result SummaryDocument30 pagesCombined Foundation Design (Is 456-2000) Result Summaryarchetype designNo ratings yet

- D G 4.3.2 MEP D M: ScopeDocument6 pagesD G 4.3.2 MEP D M: ScopeViraj GhatgeNo ratings yet

- NU MEP Design Standards (PDFDrive)Document393 pagesNU MEP Design Standards (PDFDrive)Viraj GhatgeNo ratings yet

- (Page Name Not Set) Audit: Say Goodbye To Paper Checklists!Document2 pages(Page Name Not Set) Audit: Say Goodbye To Paper Checklists!Viraj GhatgeNo ratings yet

- Say Goodbye To Paper Checklists!: CompanyDocument3 pagesSay Goodbye To Paper Checklists!: CompanyViraj GhatgeNo ratings yet

- Nabers Rules - Conducting A Portfolio Rating v1.5Document31 pagesNabers Rules - Conducting A Portfolio Rating v1.5Viraj GhatgeNo ratings yet

- 5th DR Victor Demello Goa Lecture BrochureDocument2 pages5th DR Victor Demello Goa Lecture BrochureViraj GhatgeNo ratings yet

- ICACI MCT Seminar V2 FormsDocument2 pagesICACI MCT Seminar V2 FormsViraj GhatgeNo ratings yet

- National Institute of Construction Management and Research: Instructions To CandidateDocument7 pagesNational Institute of Construction Management and Research: Instructions To CandidateViraj GhatgeNo ratings yet

- 20200506olp PMWPDocument1 page20200506olp PMWPViraj GhatgeNo ratings yet

- 6060 Dump Cylinder PartsDocument2 pages6060 Dump Cylinder PartsAlexsander EustáquioNo ratings yet

- Portals and Trussed Frame StructuresDocument5 pagesPortals and Trussed Frame StructuresMichael SandersNo ratings yet

- Asco 4000 Manual Transfer Switch PDFDocument12 pagesAsco 4000 Manual Transfer Switch PDFblancoNo ratings yet

- Nift ChennaiDocument2 pagesNift ChennaiShreejith GowdaNo ratings yet

- Assignment Solutions 2Document4 pagesAssignment Solutions 22020CEM029 MUJEEBUL100% (1)

- 03.GuardMagic - Fuel Level SensorsDocument4 pages03.GuardMagic - Fuel Level SensorsvkmsNo ratings yet

- Horizontal Distance Measurement: Tape Odometer Subtense Bar Stadia EDMDocument33 pagesHorizontal Distance Measurement: Tape Odometer Subtense Bar Stadia EDMAhmad ZakyNo ratings yet

- Injection Cheat Sheet Non SQLDocument1 pageInjection Cheat Sheet Non SQLKahJin MartinezNo ratings yet

- IBS Caixa de Vapor Transphase Results Pulp Dec 2019Document2 pagesIBS Caixa de Vapor Transphase Results Pulp Dec 2019Clayer PaperNo ratings yet

- Adsorption of Betacyanin On YarnsDocument11 pagesAdsorption of Betacyanin On YarnsNurul Ain IbrahimNo ratings yet

- Tower Crane ChecklistDocument10 pagesTower Crane ChecklistalizafareeerNo ratings yet

- 001.17056.000028-AK008-01 1st Stage PreheaterDocument5 pages001.17056.000028-AK008-01 1st Stage PreheaterQuy RomNo ratings yet

- Hartzell Propeller Inc.: Remove Pages: Insert PagesDocument740 pagesHartzell Propeller Inc.: Remove Pages: Insert PagesJoel AlbuquerqueNo ratings yet

- Code of Practice BS 7072 1989Document16 pagesCode of Practice BS 7072 1989Adel Jeddi100% (1)

- RADWIN System DescriptionDocument28 pagesRADWIN System Descriptiontho2007100% (1)

- A Scalable Verification Solution For BlockchainsDocument50 pagesA Scalable Verification Solution For BlockchainsJosé IgnacioNo ratings yet

- Chapter 05Document49 pagesChapter 05HassanKMNo ratings yet

- CPF2023LS Parts ListDocument87 pagesCPF2023LS Parts ListcuongNo ratings yet

- SAP SOlution ManagerDocument67 pagesSAP SOlution ManagervyomakeshNo ratings yet

- SL500Document13 pagesSL500Thu Thủy Đào ThịNo ratings yet

- G7M-1210-00 - Approved Voltage Testers ForDocument4 pagesG7M-1210-00 - Approved Voltage Testers ForMohammad QureshiNo ratings yet

- Sae2 DiscvalveDocument64 pagesSae2 DiscvalveMechanical2022No ratings yet

- GAPS Guidelines: Transformers - Arrangement and Fixed Fire ProtectionDocument7 pagesGAPS Guidelines: Transformers - Arrangement and Fixed Fire ProtectionAsad KhanNo ratings yet

- Omega T TutorialDocument3 pagesOmega T TutorialErick TrilloNo ratings yet

- Wind System CalibrationDocument16 pagesWind System CalibrationAmit NainNo ratings yet

- Apex Variable Speed Single Stage Base-Mounted and Tank Mounted CompressorsDocument71 pagesApex Variable Speed Single Stage Base-Mounted and Tank Mounted CompressorsDan GillaspyNo ratings yet

- Haptic TechnologyDocument13 pagesHaptic TechnologyBandaru Purna0% (1)

- Example of Trip DistributionDocument9 pagesExample of Trip DistributionGuianne Carlo BustamanteNo ratings yet