Professional Documents

Culture Documents

Storage Tank Design Calculation

Storage Tank Design Calculation

Uploaded by

naseemtycheOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Storage Tank Design Calculation

Storage Tank Design Calculation

Uploaded by

naseemtycheCopyright:

Available Formats

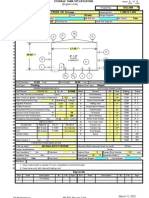

DESIGN CALCULATIONS OF STORAGE TANKS

According to API 650 Code, Edition Sept. 2003

Designed by : Eng. Abdel Halim Galala, Design General Manager

Page : 23 of 34

REV. : 0

Project

Job Name

Service

Capacity

Date : 26.9.2008

Location : Port Said

Client : PETROBEL

Item : TK-01A

: Design & procurement of storage tanks

: El-Gamil Plant Storage Facilities

: Crude Oil Storage Tank

: 5000 M3

A. Cylindrical Tank, Fixed-Roof with Rafter & Column (cont.)

9. Seismic Design.

[APPENDIX E, API 650]

9.1. Overturning Moment due to Seismic forces applied to bottom of tank shell,

M = Z I (C1 Ws Xs + C1 Wr Ht + C1 W1 X1 + C2 W2 X2)

10488643 Ft-lb

where,

Z = Seismic force factor, depends on seismic zone [Table E-2]

Seismic zone of site

I = Importance factor

C1 = Lateral earthquake force coefficient

C2 = Lateral earthquake force coefficient

= 0.75 S / T

when T <= 4.5

= 3.375 S / T2

when T > 4.5

[Para. E.3.3.3]

[Para. E.3.3.3]

Kg-M

0.15

2A

1

0.6

0.203019

0.164867

S = Site coefficient

[Table E-3]

T = Natural period of the 1st sloshing mode = k (D0.5)

k = Factor depends on ratio D/H

[Figure E-4]

D = Nominal tank dia.

H = Max. design liquid level

Ratio D/H

Since T > 4.5 seconds, Use C2

1.5

5.541355 Sec.

0.625

78.60892 Ft

40.28858 Ft

1.951147

0.164867

Ws = Total weight of tank shell

Xs = Height from bottom of tank shell to shell's center of gravity

Wr = Total weight of tank roof (fixed or floating) + portion of the

snow load, if any, specified by the purchaser

Ht = Total height of tank shell

180760.5 lb

15.6939 Ft

106077.9 lb

81.9917 Ton

4.7835 M

48.1162 Ton

40.28858 Ft

12.28

W1 & W2 = Weight of effective mass of tank contents that move

in unison with tank shell [Para. E.3.2.1 & Figure E-2]

D/H

- Find ratio W 1 / W T by knowing D/H

[Figure E-2]

- Find ratio W 2 / W T by knowing D/H

[Figure E-2]

W T = Total weight of tank contents = Tank volume x specific gr.

23.96

12.28

M

M

1.951147

0.38

0.52

12206584 lb

5536.82 Ton

3

5.99E+12 Ft

4638502 lb

3

5536.82 M

Kg

(specific gravity of the product to be specified by the purchaser)

Tank volume

W 1 = Ratio ( W 1 / W T ) . W T

W 2 = Ratio ( W 2 / W T ) . W T

6347424

lb

Kg

DESIGN CALCULATIONS OF STORAGE TANKS

According to API 650 Code, Edition Sept. 2003

Designed by : Eng. Abdel Halim Galala, Design General Manager

Page : 24 of 34

REV. : 0

Project

Job Name

Service

Capacity

Date : 26.9.2008

Location : Port Said

Client : PETROBEL

Item : TK-01A

: Design & procurement of storage tanks

: El-Gamil Plant Storage Facilities

: Crude Oil Storage Tank

: 5000 M3

9. Seismic Design. (cont.)

[APPENDIX E, API 650]

X1 = Height from bottom of tank shell to the centroid of lateral

seismic force applied to W 1

Ft

[E.3.3.2 & Figure E-3]

X2 = Height from bottom of tank shell to the centroid of lateral

seismic force applied to W 2

Ft

[E.3.3.2 & Figure E-3]

D/H

- Find ratio X1 / H by knowing D/H

[Figure E-3]

1.951147

0.375

- Find ratio X2 / H by knowing D/H

[Figure E-3]

0.56

X1 = Ratio ( X1 / H ) . H

15.10822 Ft

4.60498 M

X2 = Ratio ( X2 / H ) . H

22.5616

6.87678 M

9.2. Resistance to Overturning Moment at bottom of tank shell, WL

Ft

[Para. E-4]

Resistance to the overturning moment at the bottom of the shell

may be provided by the weight of the tank shell and by the anchorage

of the tank shell,

or, for unanchored tanks, the weight of a portion of the tank contents

adjacent to the shell.

For unanchored tanks, the portion of the contents that may be

used to resist overturning depends on the width of the bottom

plate under the shell that lifts off the foundation and may be

determined as follows :

wL = 7.9 tb ( Fby G H )0.5

lb/Ft

However, wL shall not exceed 1.25 G H D

lb/Ft

Where, wL = max. weight of the tank contents that may be used

to resist the shell overturning moment,

wL1 = 7.9 tb ( Fby G H )0.5

wL2 = 1.25 G H D

Use

wL = Min ( wL1 , wL2 )

5470.978 lb/Ft

3958.802 lb/Ft

3958.802 lb/Ft

tb = Thickness of the bottom plate under the shell

0.629921 INCH

Fby = Min. specified yield strength of the bottom plate under the shell

G = Design specific gravity of the liquid to be stored

30000

1

PSI

MM

DESIGN CALCULATIONS OF STORAGE TANKS

According to API 650 Code, Edition Sept. 2003

Designed by : Eng. Abdel Halim Galala, Design General Manager

Page : 25 of 34

REV. : 0

Project

Job Name

Service

Capacity

Date : 26.9.2008

Location : Port Said

Client : PETROBEL

Item : TK-01A

: Design & procurement of storage tanks

: El-Gamil Plant Storage Facilities

: Crude Oil Storage Tank

: 5000 M3

9. Seismic Design. (cont.)

[APPENDIX E, API 650]

9.3. Shell Compression .

[Para. E-5]

9.3.a. Unanchored Tanks

[Para. E.5.1]

Value of M / [ D2 (wt + wL)]

where,

b = max. longitudinal compressive force at the bottom of the shell

lb/Ft

(lb/Ft of shell circumference)

wt = weight of tank shell and the portion of the fixed roof

supported by the shell (lb/Ft of shell circumference) = wt / 3.14 D

I. When

M / [ D2 (wt + wL )] <= 0.785

0.361854

b = wt + 1.273 M / D2

II. When

2892.698 lb/Ft

0.785 < M / [ D2 (wt + wL )] <= 1.5

b may be computed from the value of (b + wL )/ (wt + wL )

obtained from Figure E-5.

Value obtained from Figure E-5

b = ( wt + wL ) . Value from Figure E-5 - wL

III. When

1.5 < M / [ D (wt + wL )] <= 1.57

b=

VI. For

1490

.

(w t + wL )

0.637 M

1 2

D

(w t + w L

731.9506 lb/Ft

0 .5

wL

M / [ D2 (wt + wL )] > 1.57

or when b / 12 t > Fa

Value b / 12 t

Value Fa

In case b/12 t > Fa, the tank is structurally unstable.

It is necessary to take one of the following measures :

a. Increase the thickness of the bottom plate under the shell,

tb, to increase wL without exceeding the limitations of

E.4.1 and E.4.2.

b. Increase the shell thickness, t (see Item 9.5 for shell courses).

c. Change the proportions of the tank to increase the dia.

and reduce the height.

d. Anchor the tank in accordance with E.6.

0.361854

2

5422.703 lb/Ft

0.361854

6415.053 lb/Ft

0.361854

478.3498 PSI

6410.684 PSI

< Fa

OK

DESIGN CALCULATIONS OF STORAGE TANKS

According to API 650 Code, Edition Sept. 2003

Designed by : Eng. Abdel Halim Galala, Design General Manager

Page : 26 of 34

REV. : 0

Project

Job Name

Service

Capacity

Date : 26.9.2008

Location : Port Said

Client : PETROBEL

Item : TK-01A

: Design & procurement of storage tanks

: El-Gamil Plant Storage Facilities

: Crude Oil Storage Tank

: 5000 M3

9. Seismic Design. (cont.)

[APPENDIX E, API 650]

9.3.b. Anchored Tanks

[Para. E.5.2]

For anchored tanks, the max. longitudinal compressive force at

2

the bottom of shell,

b = wt + 1.273 M / D

9.4. Max. Allowable Shell Compression

2892.698 lb/Ft

[Para. E.5.3]

The max. longitudinal compressive stress in the shell, b / 12 t,

shall not exceed the max. allowable stress, Fa determined by

the following formulas for Fa, which take into account the effect

of internal pressure due to the liquid contents.

G H D2 / t2

2

2

6

6

- When G H D / t >= 10 , Fa = 10 t / D

2

2

6

6

0.5

- When G H D / t < 10 , Fa = 10 t / 2.5 D + 600 (G H )

However, Fa shall not be greater than 0.5 Fty

0.5 Fty

where, t = thickness of the bottom shell course, excl. any corr. allow.

Fa = Max. allowable longit. compressive stress in the shell

Fty = Min. specified yield strength of the bottom shell course

980331.9 > 106

6410.684 PSI

6372.671 PSI

15000

PSI

0.503937 INCH

6410.684 PSI

30000

PSI

9.5. Upper Shell Course

[Para. E.5.4]

If the thickness of the lower shell course calculated to resist the

seismic overturning moment is greater than the thickness required

for hydrostatic pressure, both excluding any corrosion allowance,

then the calculated thickness of each upper shell course for

hydrostatic pressure shall be increased in the same proportion,

unless a special analysis is made to determine the seismic overturning

moment and corresponding stresses at the bottom of each upper

shell course.

9.6. Anchorage of Tanks

[Para. E.6]

When anchorage is provided, it shall be designed to provide the

following min. anchorage resistance in lb/Ft of shell circumference :

Min. anchorage resistance = 1.273 M / D2 - wt

1428.797 lb/Ft

OK

DESIGN CALCULATIONS OF STORAGE TANKS

According to API 650 Code, Edition Sept. 2003

Designed by : Eng. Abdel Halim Galala, Design General Manager

Page : 27 of 34

REV. : 0

Project

Job Name

Service

Capacity

Date : 26.9.2008

Location : Port Said

Client : PETROBEL

Item : TK-01A

: Design & procurement of storage tanks

: El-Gamil Plant Storage Facilities

: Crude Oil Storage Tank

: 5000 M3

9. Seismic Design. (cont.)

[APPENDIX E, API 650]

DESIGN CALCULATIONS OF STORAGE TANKS

According to API 650 Code, Edition Sept. 2003

Designed by : Eng. Abdel Halim Galala, Design General Manager

Page : 28 of 34

REV. : 0

Project

Job Name

Service

Capacity

Date : 26.9.2008

Location : Port Said

Client : PETROBEL

Item : TK-01A

: Design & procurement of storage tanks

: El-Gamil Plant Storage Facilities

: Crude Oil Storage Tank

: 5000 M3

A. Cylindrical Tank, Fixed-Roof with Rafter & Column (cont.)

10. Overturning Moment due to Wind, Mw.

Mw1 = P (Ar Xr + As Xs)

Where, P = Wind pressure

Ar = Projected area over roof = 0.5 Do (Ht - H)

Xr = Height from bottom of tank shell to center of gravity

of roof = H + 0.3 (Ht - H)

As = Projected area of shell = Do H

Xs = Height from bottom of tank shell to shell's center of gravity

= (H1+H2)/2 + (H2+H3)/2 + x

where x (see next page)

Do = D + 2 t1

( Up- lift for wind ) = 4 Mw / 3.14 D2

549994.2 lb-ft

PSI

INCH2

Ft

INCH2

Ft

113.3247 lb/ft

Total load, W (operating: full liq. p = 1+ wind)

( Dead Load ) = W / 3.14 D

where W = weight of tank exc. weight of floating roof & bottom

76089.4

50

8.994

12.5049

2

294.621 M

4.7835 M

-0.0165 M

23.992 M

168.757 Kg/M

116.672 Ton

lb/ft

2098.53 Kg/M

157.962 Ton

Ratio of Up-lift load / Dead load

0.080417 < 1

Since Up-lift (128 Kg/M) < Dead load (2838 Kg/M)

Not necessary of Anchor Bolts.

11. Anchor Bolt Strength.

11.1. Wind Load,

Pw = 0.7 x P x Do x H

Where, P = Wind Pressure

Do = Tank diameter

H = Tank Height

Wt = Total Tank Weight (excluding corrosion allowance)

Wt' = Tank Weight except Bottom Plate (excl. corr. allow.)

Design pressure

Kg-M

2

Kg/M

2

M

M

lb

10311.7

50

23.992

12.28

151746

126369

Kg

Kg/M2

M

M

Kg

Kg

atmospheric

11.2. Overturning Moment,

Mw2 = Pw . Xs

Overturning moment, Mw = Max. (Mw1 , Mw2)

356542.5 lb-ft

549994.2 lb-ft

49326.2 Kg-M

76089.4 Kg-M

11.3. Anti-Overturning Moment,

10957504 lb-ft

1515925 Kg-M

Rw = Wt' . D/2

Ratio of Mw / Rw

Since Mw < Rw

0.050193 < 1

Anchor Bolts are not required.

DESIGN CALCULATIONS OF STORAGE TANKS

According to API 650 Code, Edition Sept. 2003

Designed by : Eng. Abdel Halim Galala, Design General Manager

Page : 29 of 34

REV. : 0

Project

Job Name

Service

Capacity

Date : 26.9.2008

Location : Port Said

Client : PETROBEL

Item : TK-01A

: Design & procurement of storage tanks

: El-Gamil Plant Storage Facilities

: Crude Oil Storage Tank

: 5000 M3

A. Cylindrical Tank, Fixed-Roof with Rafter & Column (cont.)

To find tank shell's CG : Take Moment about CG :

W1 [(H1+H2)/2 + (H2+H3)/2 + x] + W2 [(H2+H3)/2 + x] + W3 [x]

= W4 [(H3+H4)/2 - x]

+ W5 [(H3+H4)/2 - x + (H4+H5)/2]

+ W6 [(H3+H4)/2 - x + (H4+H5)/2 + (H5+H6)/2]

+ W7 [(H3+H4)/2 - x + (H4+H5)/2 + (H5+H6)/2 + (H6+H7)/2]

+ W8 [(H3+H4)/2 - x + (H4+H5)/2 + (H5+H6)/2 + (H6+H7)/2 + (H7+H8)/2]

W1 [(H1+H2)/2 + (H2+H3)/2] + W1 x + W2 [(H2+H3)/2] + W2 x + W3 x

= W4 [(H3+H4)/2] - W4 x

+ W5 [(H3+H4)/2 + (H4+H5)/2] - W5 x

+ W6 [(H3+H4)/2 + (H4+H5)/2 + (H5+H6)/2] - W6 x

+ W7 [(H3+H4)/2 + (H4+H5)/2 + (H5+H6)/2 + (H6+H7)/2] - W7 x

+ W8 [(H3+H4)/2 + (H4+H5)/2 + (H5+H6)/2 + (H6+H7)/2 + (H7+H8)/2] - W8 x

x (W1 + W2 + W3) + W1 [(H1+H2)/2 + (H2+H3)/2]

= W4 [(H3+H4)/2]

+ W5 [(H3+H4)/2 + (H4+H5)/2]

+ W6 [(H3+H4)/2 + (H4+H5)/2 + (H5+H6)/2]

+ W7 [(H3+H4)/2 + (H4+H5)/2 + (H5+H6)/2 + (H6+H7)/2]

+ W8 [(H3+H4)/2 + (H4+H5)/2 + (H5+H6)/2 + (H6+H7)/2 + (H7+H8)/2]

- x (W4 + W5 + W6 + W7 + W8)

Figure (13)

x (W1 + W2 + W3) + x (W4 + W5 + W6 + W7 + W8)

+ W1 [(H1+H2)/2 + (H2+H3)/2]

+ W2 [(H2+H3)/2]

= W4 [(H3+H4)/2]

+ W5 [(H3+H4)/2 + (H4+H5)/2]

+ W6 [(H3+H4)/2 + (H4+H5)/2 + (H5+H6)/2]

+ W7 [(H3+H4)/2 + (H4+H5)/2 + (H5+H6)/2 + (H6+H7)/2]

+ W8 [(H3+H4)/2 + (H4+H5)/2 + (H5+H6)/2 + (H6+H7)/2 + (H7+H8)/2]

x =[W4 [(H3+H4)/2]

+ W5 [(H3+H4)/2 + (H4+H5)/2]

+ W6 [(H3+H4)/2 + (H4+H5)/2 + (H5+H6)/2]

+ W7 [(H3+H4)/2 + (H4+H5)/2 + (H5+H6)/2 + (H6+H7)/2]

+ W8 [(H3+H4)/2 + (H4+H5)/2 + (H5+H6)/2 + (H6+H7)/2 + (H7+H8)/2]

- W1 [(H1+H2)/2 + (H2+H3)/2]

- W2 [(H2+H3)/2]]

/ (W1+W2+W3+W4+W5+W6+W7+W8)

-0.054127 Ft

-0.0165

DESIGN CALCULATIONS OF STORAGE TANKS

According to API 650 Code, Edition Sept. 2003

Designed by : Eng. Abdel Halim Galala, Design General Manager

Page : 30 of 34

REV. : 0

Project

Job Name

Service

Capacity

Date : 26.9.2008

Location : Port Said

Client : PETROBEL

Item : TK-01A

: Design & procurement of storage tanks

: El-Gamil Plant Storage Facilities

: Crude Oil Storage Tank

: 5000 M3

A. Cylindrical Tank, Fixed-Roof with Rafter & Column (cont.)

11.4. Sliding.

Sliding force by wind, Ps = 0.7 x P x D x H

lb

10311.7 Kg

Frictional Resistance Force by wind, Rs = 0.3 Wt

lb

45523.9 Kg

Ratio Ps / Rs

Since Ps < Rs

11.5. Anchor Bolts Provided.

Number of anchor bolts, n

Size of anchor bolts (UNC)

Anchor bolt sectional area, A

Allowable load (for 3/4" bolt) :

- Tensile, fat

- Shearing, fas

0.226512 < 1

Anchor bolts are not required.

12

0.75

INCH

4299.009 lb

2976.237 lb

2.36

MM

CM2

1950

1350

Kg

Kg

11.6. Anchor Bolt Load.

Tensile load per each bolt, ft = (4 Mw / n D) - Wt' / n

Since ft < fat

-9845.45 Kg/Bolt

The anchor bolt is sufficient

Shearing load per each bolt, fs = (Ps - Rs)/n

Since fs < fas

-2934.35 Kg/Bolt

The anchor bolt is sufficient

12. Fixed-Roof Inspection Hatches.

[API-650, Appendix H.65.3]

Inspection hatches shall be located on tank fixed roof to permit

visual inspection of the seal region.

- Max. spacing of inspection hatches per code

- Min. spacing of inspection hatches per code

75

4

Ft

Ft

Circle dia. of inspection hatches = D - 6, Ft

Calculated No. of inspection hatches = 3.14(D-6)/75

72.60892 Ft

3.041435

Assume actual No. of inspection hatches

Actual spacing of inspection hatches

6

38.01794 Ft

< 75 Ft

OK

> 4 Ft

OK

22.86

1.2192

M

M

22.1312 M

11.5879 M

DESIGN CALCULATIONS OF STORAGE TANKS

According to API 650 Code, Edition Sept. 2003

Designed by : Eng. Abdel Halim Galala, Design General Manager

Page : 31 of 34

REV. : 0

Project

Job Name

Service

Capacity

Date : 26.9.2008

Location : Port Said

Client : PETROBEL

Item : TK-01A

: Design & procurement of storage tanks

: El-Gamil Plant Storage Facilities

: Crude Oil Storage Tank

: 5000 M3

A. Cylindrical Tank, Fixed-Roof with Rafter & Column (cont.)

13. Total Weight of Tank.

a. Weight of Shell

180760.5 lb

22.6902

19.8539

15.5995

12.7632

9.92695

1.15797

0

0

81.9917

Ton

Ton

Ton

Ton

Ton

Ton

Ton

Ton

Ton

69933.98 lb

11.366

1.82917

11.3291

404.096

31.7216

M

M

M

M2

Ton

c. Weight of Annular Bottom Plate

9593.336 lb

4.35147 Ton

d. Weight of Roof Plate = Roof area * t p

Roof conical area = 3.14 * (D/2) * sq. root ((D/2)2 + h2)

'where, h = Ht - H = Cone height = Rafter Slope * Do/2

Rafter slope = 1/16

[see Figure (2)]

62546.89 lb

28.3708 Ton

2

451.765 M

0.74975 M

1st Course, W1 = 3.14 D t H p

2nd Course, W2

3rd Course, W3

4th Course, W4

5th Course, W5

6th Course, W6

7th Course, W7

8th Course, W8

Sub-Total (a)

b. Weight of Bottom Plate, R1 = D/2 - Annular width, Rw

L1 = 2 R1 Sin (O/2)

h1 = L1 / 2 R1 Tan (O/2)

Total Bottom plate Area, A = 0.5 L1 . h1 . n

Total bottom Plate Weight, W = A. ta . p

Sub-Total (b)

Figure (14)

01:30

DESIGN CALCULATIONS OF STORAGE TANKS

According to API 650 Code, Edition Sept. 2003

Designed by : Eng. Abdel Halim Galala, Design General Manager

Page : 32 of 34

REV. : 0

Project

Job Name

Service

Capacity

Date : 26.9.2008

Location : Port Said

Client : PETROBEL

Item : TK-01A

: Design & procurement of storage tanks

: El-Gamil Plant Storage Facilities

: Crude Oil Storage Tank

: 5000 M3

A. Cylindrical Tank, Fixed-Roof with Rafter & Column (cont.)

e. Weight of Rafters

Total length of rafters (H beam 250x125x6/9)

Weight of one meter of beam

13.3577 Ton

467.22 M

28.5897 Kg

f. Weight of Column, Pipe 20" NPS, Sch. 40

4.46457 Ton

g. Weight of Top Wind Girder

Circumferential length of 2 angles 6x4x3/8" (160x100x10mm)

Weight of one meter of angle

Total area of top wind girder, A

Weight of top wind girder, W = A * P * t

3.07263

150.545

20.41

60.7712

3.02929

Ton

M

Kg

M2

Ton

h. Weight of Intermediate Wind Girder

Wind Girder ID

Wind Girder OD

Ton

M

M

i. Weight of Manholes, Cleanout Doors & Nozzles

Ton

j. Weight of Ladders & Platforms

Ton

k. Weight of brackets (cooling system supports)

No. of brackets per level = 3.14 D / 4000

Total brackets for two levels of cooling system + level for foam

Bracket dimensions 400x850x100x8

Weight of one bracket

3.32338 Ton

20

Support

84

Support

600x850x8

39.564 Kg

l. Weight of Inspection Hatches.

No. of inspection hatches, Nih

Weight of nozzle

Weight of flange (or loose cover)

m. Weight of Manways (for fixed-roof tanks).

At least one manhole, min 24" ID shall be provided for access to

the tank interior.

[API-650, Appendix H.6.5.1]

No. of manholes located at fixed roof, 24" NPS

Weight of nozzle

Weight of flange

Total Tank Weight

Ton

6

Ton

189.683 Ton

You might also like

- Design of Cone Roof Type Storage Tanks ForDocument51 pagesDesign of Cone Roof Type Storage Tanks ForPraveen Mallya86% (7)

- Storage Tanks CalculationsDocument21 pagesStorage Tanks Calculationsjimallen21288% (26)

- API 650 Design TanksDocument34 pagesAPI 650 Design TanksSyedZainAli100% (13)

- API 650 Tank Design 1foot MethodDocument4 pagesAPI 650 Tank Design 1foot Methodjakjak67% (3)

- API 650 Tank DesignDocument29 pagesAPI 650 Tank DesignBerk Koç100% (11)

- Storage Tank Design CalculationDocument12 pagesStorage Tank Design Calculationhtutswe80% (15)

- API 650 Tank Design 5Document44 pagesAPI 650 Tank Design 5Inamullah Khan93% (14)

- Tank CalculationsDocument1 pageTank CalculationsJp Rao67% (3)

- Storage Tanks PresentationDocument107 pagesStorage Tanks Presentationsinner123100% (12)

- Storage TanksDocument304 pagesStorage Tanksmohamedyoussef1100% (30)

- Storage Tank DesignDocument43 pagesStorage Tank DesignsamvendanNo ratings yet

- Ldo Storage Tank CalculationDocument7 pagesLdo Storage Tank CalculationchetanmaleNo ratings yet

- API 650 Load CombinationsDocument10 pagesAPI 650 Load Combinationsศุภกฤต รักในหลวงNo ratings yet

- API Storage Tank DesignDocument21 pagesAPI Storage Tank DesignIndunil Prasanna Bandara Warnasooriya100% (2)

- B ABJ 5000 2 API 650 Calculation ReportDocument46 pagesB ABJ 5000 2 API 650 Calculation ReportSalamaNo ratings yet

- Calculation API 650Document78 pagesCalculation API 650jamil93% (14)

- API Tank DesignDocument189 pagesAPI Tank DesignDD3NZ91% (11)

- Storage Tank CALC Api 650Document10 pagesStorage Tank CALC Api 650kuselanml100% (3)

- API 650 Seismic Design SampleDocument8 pagesAPI 650 Seismic Design SampleOmer Eker100% (1)

- Orica Tank Design Calculation AWWADocument8 pagesOrica Tank Design Calculation AWWAmohanuma100% (2)

- Tank Anchorage (Overturning Stability)Document3 pagesTank Anchorage (Overturning Stability)robertantoreni100% (2)

- Outrigger Ships With Traditional Hull ShapeDocument8 pagesOutrigger Ships With Traditional Hull ShapegksahaNo ratings yet

- Transmission Tower Foundation DesignDocument26 pagesTransmission Tower Foundation Design14pcash100% (1)

- Design Calculation R1 PDFDocument14 pagesDesign Calculation R1 PDFJagankumarNo ratings yet

- (A) Time Periods and Seismic Coefficients: 11. Stability For Seismic Design LoadDocument4 pages(A) Time Periods and Seismic Coefficients: 11. Stability For Seismic Design Loadkpsahu100% (1)

- Stability Report For Bentonite TankDocument11 pagesStability Report For Bentonite TankDong-Yong KimNo ratings yet

- Frangible Roof To Shell JointDocument1 pageFrangible Roof To Shell JointSAGARNo ratings yet

- Abutment Check DetailDocument79 pagesAbutment Check DetailHimal KafleNo ratings yet

- Study of Seismic Analysis of Non-Conventional Shapes of Elevated Water TankDocument13 pagesStudy of Seismic Analysis of Non-Conventional Shapes of Elevated Water TankIJRASETPublications100% (2)

- Upheval Bukling CalculationDocument2 pagesUpheval Bukling Calculationbaghelrohit100% (7)

- Calculation of T-100Document14 pagesCalculation of T-100b4suki100% (1)

- Transmission Tower Foundation DesignDocument26 pagesTransmission Tower Foundation DesignSara Nuon86% (7)

- API 650 Tank Design CalculationsDocument8 pagesAPI 650 Tank Design Calculationsツ ツNo ratings yet

- Oil Storage Tank Foundation DesignDocument5 pagesOil Storage Tank Foundation Designsugianto100% (2)

- Tinh Dong Dat Va Gio Cho Tank-Full - Outer Tank123Document51 pagesTinh Dong Dat Va Gio Cho Tank-Full - Outer Tank123Thinh Vipro100% (1)

- LOAD CALC - Concord UnitedDocument95 pagesLOAD CALC - Concord UnitedRakesh CivilianNo ratings yet

- 1000MT Cap DesignDocument5 pages1000MT Cap Designrbalmodal100% (1)

- Oil Storage Tank Foundation Design Spreadsheet 1Document2 pagesOil Storage Tank Foundation Design Spreadsheet 1ronyNo ratings yet

- 2.TankSurge Plate FOundationDocument2 pages2.TankSurge Plate FOundationdanjidNo ratings yet

- Crane UbDocument20 pagesCrane UbBobor Emmanuel OfovweNo ratings yet

- Chapter 6 eDocument22 pagesChapter 6 eVoora GowthamNo ratings yet

- Supported Cone Roof (CS) Add.4Document21 pagesSupported Cone Roof (CS) Add.4skhurramq100% (2)

- API 650 Design TanksDocument39 pagesAPI 650 Design TanksAhmedAli25% (4)

- Silo Cement CalculationDocument11 pagesSilo Cement CalculationFikriaraz AfifNo ratings yet

- API 650 Tank Design CalculationsDocument8 pagesAPI 650 Tank Design CalculationsMohammed EljammalNo ratings yet

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Pressure Vessel and Stacks Field Repair ManualFrom EverandPressure Vessel and Stacks Field Repair ManualRating: 4 out of 5 stars4/5 (4)

- Supplementary Paper SP 2 4 HydratesDocument25 pagesSupplementary Paper SP 2 4 Hydrates1234abcdNo ratings yet

- Flare Stack Mechanical Design Calculations by Abdel Halim GalalaDocument24 pagesFlare Stack Mechanical Design Calculations by Abdel Halim Galalamarkfgt100% (2)

- Sample Biography 1Document1 pageSample Biography 1markfgtNo ratings yet

- Storage Tank Design Calculations - Seismic Design & Overturning Moment - by Abdel Halim GalalaDocument10 pagesStorage Tank Design Calculations - Seismic Design & Overturning Moment - by Abdel Halim Galalamarkfgt57% (7)

- ETank 2000Document47 pagesETank 2000markfgtNo ratings yet

- Ambiguity of MathematicsDocument10 pagesAmbiguity of MathematicsDeimante BlikertaiteNo ratings yet

- How Is PPM Related To Concentration - Sequoia ScientificSequoia ScientificDocument1 pageHow Is PPM Related To Concentration - Sequoia ScientificSequoia ScientificTg TarroNo ratings yet

- Improvement of A Francis Runner Design: Nicola VISCANTIDocument8 pagesImprovement of A Francis Runner Design: Nicola VISCANTIFolpoNo ratings yet

- Thread CompoundDocument5 pagesThread CompoundJas SumNo ratings yet

- 1 s2.0 S0098135422001570 MainDocument13 pages1 s2.0 S0098135422001570 MainjanurangNo ratings yet

- A General Cuboidal Element For Three-Dimensional Thermal ModellingDocument4 pagesA General Cuboidal Element For Three-Dimensional Thermal ModellingAlejandro Antonio Ferrada JaraNo ratings yet

- Cosmolubric HF-130: Description Features/ BenefitsDocument1 pageCosmolubric HF-130: Description Features/ BenefitsLuHa1No ratings yet

- Axicom RelayDocument3 pagesAxicom RelayHarry RamzaNo ratings yet

- 1.8M Pedestal C Manual PDFDocument1 page1.8M Pedestal C Manual PDFEdwin Valiente ZavaletaNo ratings yet

- Material Model Calibration by Indentation, Imprint Mapping and Inverse AnalysisDocument19 pagesMaterial Model Calibration by Indentation, Imprint Mapping and Inverse AnalysisangelNo ratings yet

- Completion - Reservoir Drill in FluidsDocument45 pagesCompletion - Reservoir Drill in FluidsFauzan Rahman Haq100% (1)

- Test Pattern ResonanceDocument50 pagesTest Pattern ResonanceAnupam KushwahaNo ratings yet

- Ultimate Lateral Load of Slope-Stabilising Piles: Géotechnique Letters September 2017Document9 pagesUltimate Lateral Load of Slope-Stabilising Piles: Géotechnique Letters September 2017ValerioNo ratings yet

- HW3 Selected SolutionsDocument5 pagesHW3 Selected Solutionsgari_teroNo ratings yet

- 1 ElectronicsDocument6 pages1 ElectronicsMrzaiboNo ratings yet

- Astm d638 99 CompressDocument7 pagesAstm d638 99 CompressJonel UrbonaNo ratings yet

- Process Control in Wet ProcessingDocument23 pagesProcess Control in Wet ProcessingKirti Nagda75% (4)

- Eklavya Motion ForceDocument114 pagesEklavya Motion Forcembbk5783No ratings yet

- Charlez Rock Mechanics V1Document339 pagesCharlez Rock Mechanics V1Yehimy Cambas100% (4)

- Digital Filters For Offset Removal: Digital High Pass FilterDocument9 pagesDigital Filters For Offset Removal: Digital High Pass FilterPrince BlissfulNo ratings yet

- DTS-Short Questions and AnswerDocument7 pagesDTS-Short Questions and AnswerAlfred Franklin V100% (1)

- UT (A) - CoE (XI) - Test-05 - Paper-2 - (Code-B) - (2022-24) - Compile (13-10-2022) - (2020-P-2) - (Only Que.)Document13 pagesUT (A) - CoE (XI) - Test-05 - Paper-2 - (Code-B) - (2022-24) - Compile (13-10-2022) - (2020-P-2) - (Only Que.)darling deanNo ratings yet

- Solutions For Homework Set 7: X Z X I (K X+K Z)Document3 pagesSolutions For Homework Set 7: X Z X I (K X+K Z)rahul krNo ratings yet

- CE162P MODULE 1 LECTURE 5 Analysis & Design of Isolated Rectangular FootingDocument15 pagesCE162P MODULE 1 LECTURE 5 Analysis & Design of Isolated Rectangular FootingPROSPEROUS LUCKILYNo ratings yet

- UHMW-PE Tivar 1000Document2 pagesUHMW-PE Tivar 1000centurion2988No ratings yet

- Exam 12 P PDFDocument4 pagesExam 12 P PDFAnonymous RRTcbwUNo ratings yet

- EggDocument2 pagesEggapi-320549212No ratings yet

- Final Presentation - Corrected (1) .PPTX RaviDocument15 pagesFinal Presentation - Corrected (1) .PPTX RavisudamNo ratings yet

- GED Chemistry Note2 (Compounds and Solutions)Document4 pagesGED Chemistry Note2 (Compounds and Solutions)Shahadat Hussain Parvez100% (1)

- Dindigul Bypass To Samyanallore On NH 7 in The State of Tamil Nadu Vol - Iii PDFDocument29 pagesDindigul Bypass To Samyanallore On NH 7 in The State of Tamil Nadu Vol - Iii PDFVinay YadavNo ratings yet