Professional Documents

Culture Documents

R&R Seremban - Suction Pump

Uploaded by

JeghiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R&R Seremban - Suction Pump

Uploaded by

JeghiCopyright:

Available Formats

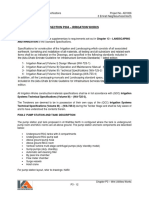

PROPOSED REJUNEVATION PROJECT AT SEREMBAN RSA SOUTH BOUND

DESIGN PUMP BOOSTER PUMP (SUCTION TANK TO ELEVATED WATER TANK)

LOCATION R&R SEREMBAN

Node 1 to 1 Pipe Losses (meters) = 0.9578

Flow Q 1.0364 MLD Given total water demand by C&S = 345,455 Ltr

43.1819 m3/hr *Pumping rate = 8 hrs

720 Ltr/min Q = Total Water Demand/Pumping Rate

Add 10% safety factor ≈ 800 Ltr/min

Note : Min. pumping rate for a commercial building must

be 8 hours as per SPAN guideline (refer attachment)

Pipe Diameter D 150 mm

6 in

0.15 m

Pipe Area A 0.018 m2 A = πd2/4

Fluid Velocity V 0.679 m/s V = Q/A

Pipe constant C 120 Pipe type : Mild Steel

Equivalent Pipe Length & Straight Pipe =70 m

Fittings Elbow 6nos. X 4.3 =25.8m

Check valve 1no. X 48.79 =48.79m

Gate valve 3no. x 1.13 =3.4m

Strainer 1no. X 35.88 =35.88m

Total , L = 183.87 m

Pipe Losses Pf = {(6.05 x 105) (L) (Q1.85)} / {(C1.85) (D4.87)} where Q = flow rate in Ltr/min

D = pipe dia. in mm

Pf = 0.0940 bar C = pipe constant

L = Equivalent pipe

Pf = 0.9578 m length and fittings in m

TOTAL PIPE FRICTION LOSSES IN METERS = 0.9578

Thus, Pump Head calculation = Static Head + Total Pipe Friction Losses + Pressure Required at Outlet

Static Head =26.75 m

Total Pipe Friction Losses = 0.96 m

Pressure at outlet = 7.5 m

Pump Head = 26.75 + 0.96 + 7.5

Pump Head = 35.21 m

Add 5% Safety Factor 37 m Pump Head

RSA SEREMBAN SP-1 PERUNDING AZFAR

Pump Horse Power

Assume

Pump Efficiency 80 %

Motor Efficiency 95 %

Pump Break Required, P 6.05 kw [P = 9810QH/Pump Effeciency]

Power of Motor , Pm 6.37 kw [Pm = P/Motor Effeciency]

≈ 6.5 kw

PUMP SELECTION 800 Ltr/min @ 37 meter Motor 6.5 kw

RSA SEREMBAN SP-2 PERUNDING AZFAR

Uniform Technical Guidelines

c. Water for non potable purposes

i. The pressure of water supplied for non-potable use, e.g. for

industrial process, cooling, washing, etc., shall conform with

equipment manufacturer specifications.

ii. If pressures of more than 30m head are required, piping and fittings

of a higher pressure rating to suit the specific requirement of a

manufacturer shall be provided. If required, a separate localized

pressure boosting pump set shall be employed to meet the required

pressure levels.

C.3.5 Pumping System

a. Before commencement of any design work for a pumping system, the WDL

shall be consulted on the minimum water pressure available at the identified

tapping point along an existing public main. In this context application for a

water pressure test may be made to the WDL to determine the pressure

available at the proposed tapping point. Should the available pressure be

inadequate to supply water to the elevated storage cistern; a pumping

system shall be provided.

b. Duty and standby hydro-pneumatic pump sets, or variable speed pump sets,

shall be provided to raise the pressure of water supply to the top two floors

of high rise residential and commercial buildings. The pumps shall be fed

with water from the elevated storage cistern.

c. Separate pumping systems shall be provided for non-potable distribution

water systems.

d. Buildings of more than 70m (measured from the ground floor to the top of

the last occupied floor) shall require multi-stage pumping. Similarly each

stage of an intermediate pumping system shall be limited to 70m (physical

height) measured from the base of the suction cistern to the delivery point of

the break cistern.

e. The capacity of suction cistern should be from 30% to 70% of the total daily

storage capacity required. The balance of the storage volume shall be

provided at the elevated (roof top) cistern.

f. The capacity of the break cistern shall be equivalent to sustaining 1 hour of

pumping of the transfer pump, or 11.5m3, whichever is greater.

g. Minimum pumping rate for a duty pump shall be adequate to fill a

commercial or office building elevated storage cistern in eight (8) hours; and

a residential building storage cistern in sixteen(16) hours.

h. Pumping system operation shall be automated with the assistance of

stainless steel electrodes located within both the suction cistern and storage

cistern.

i. Selector switches shall be provided at the starter panel in order for pumps to

be operated manually.

60

You might also like

- Reciprocating Pump Test RigDocument7 pagesReciprocating Pump Test RigPurtain MENo ratings yet

- Determination of Friction Factor of Pipe Lines: Al Habeeb College of Engineering & TechnologyDocument3 pagesDetermination of Friction Factor of Pipe Lines: Al Habeeb College of Engineering & TechnologyAsrar UddinNo ratings yet

- Fire Pump Head CalculationDocument7 pagesFire Pump Head CalculationM.Jabar ali100% (12)

- Pump by BoseDocument26 pagesPump by BoseSonu SinghNo ratings yet

- Fluid Mechanics-II AssignmentDocument7 pagesFluid Mechanics-II AssignmentMuntaha AnjumNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Fire Pump Schedule and Head CalculationsDocument7 pagesFire Pump Schedule and Head CalculationsAry TubagusNo ratings yet

- Lecture 5 - Transport of FluidsDocument24 pagesLecture 5 - Transport of FluidsLouie GresulaNo ratings yet

- 3 B3 ArcuriDocument28 pages3 B3 ArcurijoesuhreNo ratings yet

- Hot Water Circulation Pump CalculationDocument2 pagesHot Water Circulation Pump Calculationvictor.s67% (3)

- Pumps PDFDocument15 pagesPumps PDFHarshil ChangelaNo ratings yet

- ENCH607-ENPE625 Assignment-04 - 28 Fall 2020Document3 pagesENCH607-ENPE625 Assignment-04 - 28 Fall 2020Ghost RiderNo ratings yet

- HI Pump Intake Design - 1998Document4 pagesHI Pump Intake Design - 1998Anonymous YcAZv5qF67No ratings yet

- REPORTDocument31 pagesREPORTMiralles MariellaNo ratings yet

- PumpDocument3 pagesPumpfazila fauziNo ratings yet

- Pumps PDFDocument31 pagesPumps PDFYURI G. MELLIZANo ratings yet

- CalculationsDocument4 pagesCalculationsVinish HARIDAS NAIRNo ratings yet

- PLATE 2 HydraulicsDocument8 pagesPLATE 2 HydraulicsMarrian AlamagNo ratings yet

- Example Fire Fighting Calculation ReportDocument14 pagesExample Fire Fighting Calculation Reportkhairuddin shamsudin100% (1)

- Ejercicos Ec de Conserv WhiteDocument8 pagesEjercicos Ec de Conserv WhiteLuz RodriguezNo ratings yet

- Closed Circuit Pipe Friction ManualDocument4 pagesClosed Circuit Pipe Friction Manualrohit kumarNo ratings yet

- Chapter 8 McCabeDocument65 pagesChapter 8 McCabeConrad MonterolaNo ratings yet

- Pump sizing spreadsheet calculates performanceDocument26 pagesPump sizing spreadsheet calculates performancesterling100% (1)

- Sizing Calculations RW CW HD ADDocument27 pagesSizing Calculations RW CW HD ADBhavesh Panchal100% (1)

- Fluid Machinery - Eng - Pump - Part2 (Compatibility Mode)Document65 pagesFluid Machinery - Eng - Pump - Part2 (Compatibility Mode)ณัฐวัศ มั่นบุญสมNo ratings yet

- Name of Project Sample 2. Location 2.1. RMC Sample 2.2. Ward No: 2,3 3. District Kaski 4. Total Demand 2345 5. Total Rvts 2Document15 pagesName of Project Sample 2. Location 2.1. RMC Sample 2.2. Ward No: 2,3 3. District Kaski 4. Total Demand 2345 5. Total Rvts 2Rajendra K KarkiNo ratings yet

- 4.2 Water PumpDocument8 pages4.2 Water PumpPRATIKNo ratings yet

- 5th Week LecturesDocument40 pages5th Week LecturesMohamed RamadanNo ratings yet

- FLM3B0S Tutorial 2a TurbomachinesDocument3 pagesFLM3B0S Tutorial 2a TurbomachinesFabrizio NEBESSENo ratings yet

- Calculation ReportDocument29 pagesCalculation Reportvictor.sNo ratings yet

- Pipe Flow Problems-III: Example 1Document10 pagesPipe Flow Problems-III: Example 1Chaithanya Kumar DanduNo ratings yet

- Design of Pumps For BS1Document8 pagesDesign of Pumps For BS1Miko AbiNo ratings yet

- Classify & Analyze Reciprocating PumpsDocument16 pagesClassify & Analyze Reciprocating PumpsRICHARD VALIENTENo ratings yet

- Gear Pump TMcDocument5 pagesGear Pump TMcbottomfragger993No ratings yet

- Pump Practice ProblemsDocument16 pagesPump Practice ProblemsKhaled SolimanNo ratings yet

- Pumps and Pumping Systems ExplainedDocument32 pagesPumps and Pumping Systems ExplainedAngela Paul PeterNo ratings yet

- Pipe - Friction ManualDocument6 pagesPipe - Friction ManualSrinivas ParvatiniNo ratings yet

- Project Spec-Irrigation PumpDocument14 pagesProject Spec-Irrigation PumpKoshy MathewNo ratings yet

- 1 - Fluid Mechanics Takehome Project AssignmentDocument4 pages1 - Fluid Mechanics Takehome Project Assignmentazeem sheikhNo ratings yet

- 04 150 MM Borewell Submersible PumpsetDocument23 pages04 150 MM Borewell Submersible PumpsetN ANITHANo ratings yet

- 150 MM Borewell Submersible Pumpset Performance Chart: Texmo IndustriesDocument23 pages150 MM Borewell Submersible Pumpset Performance Chart: Texmo IndustriesKovarthanan ElumalaiNo ratings yet

- H. Reel Hotel BentongDocument3 pagesH. Reel Hotel BentongJeghi100% (1)

- FLUID MACHINERY Sessional GalibDocument14 pagesFLUID MACHINERY Sessional Galibnehar shubheschaNo ratings yet

- External Pumping StationDocument10 pagesExternal Pumping Stationabdullah sahibNo ratings yet

- Pump DesigningDocument12 pagesPump DesigningFaizal MohammedNo ratings yet

- Axial Flow Fan Test Rig PDFDocument7 pagesAxial Flow Fan Test Rig PDFsunil kumarNo ratings yet

- Automatic Fire Sprinkler CalcualtionDocument2 pagesAutomatic Fire Sprinkler CalcualtionKyaw HtayNo ratings yet

- Vedant Rate BOQ WiseDocument22 pagesVedant Rate BOQ Wiserkpatel40No ratings yet

- BITS Pilani: Module 2: Flowsheet Synthesis Lecture-7Document16 pagesBITS Pilani: Module 2: Flowsheet Synthesis Lecture-7pulkitNo ratings yet

- Book 1Document1 pageBook 1Manju NaikNo ratings yet

- Calibrate Venturi & Orifice MetersDocument7 pagesCalibrate Venturi & Orifice Metersrohit kumarNo ratings yet

- Pump Hydralics TrainingDocument81 pagesPump Hydralics TrainingNai Bale100% (1)

- Chapter 6 Pump StationDocument22 pagesChapter 6 Pump StationAce Thunder100% (2)

- Hydraulic Machines ChapterDocument15 pagesHydraulic Machines Chapterحيدر محمدNo ratings yet

- Fluid Mechanics Lab ManualDocument33 pagesFluid Mechanics Lab Manualkannan_kcetNo ratings yet

- 05 - CoolingLoad Estimator - Imtiaz - Admin - GRD - BLK PengetuaDocument2 pages05 - CoolingLoad Estimator - Imtiaz - Admin - GRD - BLK PengetuaJeghiNo ratings yet

- Detail Pipe JointDocument1 pageDetail Pipe JointJeghiNo ratings yet

- How To Calculate Fire Alarm Standby Battery SizeDocument1 pageHow To Calculate Fire Alarm Standby Battery Sizebogdan darcaciu100% (1)

- Low Power Compact Clean Room Fan SolutionDocument1 pageLow Power Compact Clean Room Fan SolutionJeghiNo ratings yet

- 03 - CoolingLoad Estimator - Imtiaz - Admin - GRD - BLK KesihatanDocument2 pages03 - CoolingLoad Estimator - Imtiaz - Admin - GRD - BLK KesihatanJeghiNo ratings yet

- Ei Mech Proton City 2B #2 - 18.1.2023Document1 pageEi Mech Proton City 2B #2 - 18.1.2023JeghiNo ratings yet

- Polyethylene InsulationDocument2 pagesPolyethylene InsulationJeghi100% (1)

- SPAN-HB (30june2023)Document2 pagesSPAN-HB (30june2023)JeghiNo ratings yet

- Workshop ER Compliance - Mech ServicesDocument5 pagesWorkshop ER Compliance - Mech ServicesJeghiNo ratings yet

- Katalog-Ceiling Conceal Inverter R32-1Document1 pageKatalog-Ceiling Conceal Inverter R32-1JeghiNo ratings yet

- Architectural finishes and door specificationsDocument7 pagesArchitectural finishes and door specificationsJeghiNo ratings yet

- Design Brief Aircond PHQ For GBIDocument2 pagesDesign Brief Aircond PHQ For GBIJeghiNo ratings yet

- Sound Reinforcement Equipment Rack LayoutDocument1 pageSound Reinforcement Equipment Rack LayoutJeghiNo ratings yet

- Istana Negara Desiccant Dehumidifier Technical RequirementsDocument1 pageIstana Negara Desiccant Dehumidifier Technical RequirementsJeghiNo ratings yet

- BMS Rev.1 - Reengineering - 13.12.2018Document2 pagesBMS Rev.1 - Reengineering - 13.12.2018JeghiNo ratings yet

- List of Mech Equipment PHQ - 11.11.2021Document1 pageList of Mech Equipment PHQ - 11.11.2021JeghiNo ratings yet

- PTS As Per ContractDocument2 pagesPTS As Per ContractJeghiNo ratings yet

- Trans Resources Corporation Sdn Bhd project discussion notes for Prasarana Malaysia Berhad headquarters building automation systemDocument1 pageTrans Resources Corporation Sdn Bhd project discussion notes for Prasarana Malaysia Berhad headquarters building automation systemJeghiNo ratings yet

- Wcpu Table Flow Rate 1Document2 pagesWcpu Table Flow Rate 1JeghiNo ratings yet

- List of Mech DWG PHQ - 19.2.2019Document3 pagesList of Mech DWG PHQ - 19.2.2019JeghiNo ratings yet

- Tank Calculation LatestDocument2 pagesTank Calculation LatestJeghiNo ratings yet

- Cat Adb - A5db 1802 PDFDocument24 pagesCat Adb - A5db 1802 PDFDương Tiến TháiNo ratings yet

- Air System Sizing Summary For AHU-01Document29 pagesAir System Sizing Summary For AHU-01JeghiNo ratings yet

- Pusat Darah Wilayah Utara, Sungai Petani, Kedah (Reka & Bina)Document3 pagesPusat Darah Wilayah Utara, Sungai Petani, Kedah (Reka & Bina)JeghiNo ratings yet

- 02 - Heat Load DataDocument29 pages02 - Heat Load DataJeghiNo ratings yet

- 03 - Cooling Tower Make Up Water CalculationDocument1 page03 - Cooling Tower Make Up Water CalculationJeghiNo ratings yet

- Mechanical Works SummaryDocument4 pagesMechanical Works SummaryJeghiNo ratings yet

- Jpbasic-Pt: Auto Pressure UnitsDocument1 pageJpbasic-Pt: Auto Pressure UnitsJeghiNo ratings yet

- Mech - Costing Bank Rakyat - ApartmentDocument1 pageMech - Costing Bank Rakyat - ApartmentJeghiNo ratings yet

- Efficient Solutions For Important Environments: Multi-DENCODocument12 pagesEfficient Solutions For Important Environments: Multi-DENCOJeghiNo ratings yet

- Xplore Orld Iping: Ymbols SometricsDocument4 pagesXplore Orld Iping: Ymbols SometricsHafiz RahmanNo ratings yet

- Petrom OMV Norm B 2001 Rom Eng Rev.1 2006-12-21Document72 pagesPetrom OMV Norm B 2001 Rom Eng Rev.1 2006-12-21lucianduNo ratings yet

- Welding F22 To F91 (09MAR2018)Document2 pagesWelding F22 To F91 (09MAR2018)Juan Shuna100% (2)

- Asme B31.3 Process Piping - Asme B31.3 Process Piping - Allowable Design Pressureallowable Design PressureDocument1 pageAsme B31.3 Process Piping - Asme B31.3 Process Piping - Allowable Design Pressureallowable Design PressureRicardo LanderNo ratings yet

- Vol II KuchamanDocument556 pagesVol II Kuchamanrasun krNo ratings yet

- Thomafluid Complete Programme (English)Document1,197 pagesThomafluid Complete Programme (English)Reichelt ChemietechnikNo ratings yet

- Important SLK Calculation SheetDocument65 pagesImportant SLK Calculation SheetYermi ParabangNo ratings yet

- List of ISO Standards, 2016Document31 pagesList of ISO Standards, 2016Nulls NoughsNo ratings yet

- BERMAD Ordering Guide: Hydraulic Control Valves 700-ES Series 700-EN SeriesDocument4 pagesBERMAD Ordering Guide: Hydraulic Control Valves 700-ES Series 700-EN SeriesRuben SoteloNo ratings yet

- Master Plumbing Reviewer 1Document17 pagesMaster Plumbing Reviewer 1mcpayod40% (5)

- Pipeline Design For PiggingDocument19 pagesPipeline Design For PiggingSK. Sazzad HossainNo ratings yet

- Chapter 8Document200 pagesChapter 8ماقوريNo ratings yet

- 630 KV DG SetDocument18 pages630 KV DG SetKEYSTONE INFRA PVT LTDNo ratings yet

- Rotary Actuators HelacDocument20 pagesRotary Actuators HelacIanNo ratings yet

- AH-type Instruction ManualDocument39 pagesAH-type Instruction Manualcraponzel100% (1)

- Paper-Milling Windows With A Single Trip System - FinalDocument17 pagesPaper-Milling Windows With A Single Trip System - FinalGrigore BalanNo ratings yet

- Ficha TecnicaDocument4 pagesFicha TecnicaFabian AriasNo ratings yet

- Project Guide CAT C9.3Document44 pagesProject Guide CAT C9.3Ngurah WidhiNo ratings yet

- Reinforcement CheckDocument2 pagesReinforcement Checkviv0102No ratings yet

- TSSA-DLB-2020-Feb-09-2021-Biogas ProjectDocument9 pagesTSSA-DLB-2020-Feb-09-2021-Biogas ProjectNazrul IslamNo ratings yet

- Lusail SpecificationDocument80 pagesLusail SpecificationAhmed Reda100% (1)

- Maharashtra Government Handbook for Pipe Distribution NetworksDocument254 pagesMaharashtra Government Handbook for Pipe Distribution NetworksVikram DesaiNo ratings yet

- PHMSA - Form - 5 - Gas Pipeline - and - Compressor - Station - Construction - 2011Document9 pagesPHMSA - Form - 5 - Gas Pipeline - and - Compressor - Station - Construction - 2011dakidofdaboomNo ratings yet

- Applicability of Caesar II For Stress Analysis of Lines Having DT Ratio More Than 100 PDFDocument2 pagesApplicability of Caesar II For Stress Analysis of Lines Having DT Ratio More Than 100 PDFBogdan ChivulescuNo ratings yet

- Lesson 3Document20 pagesLesson 3Jazmin RamosNo ratings yet

- Aircraft Fuel SystemsDocument36 pagesAircraft Fuel SystemsShaddy Gitau100% (2)

- CSA W47.1 and CSA W59 Exam questions study guideDocument5 pagesCSA W47.1 and CSA W59 Exam questions study guideAlex Alex100% (2)

- Komatsu PC200 6 Shop Manual PDFDocument711 pagesKomatsu PC200 6 Shop Manual PDFMelpi Norawati Simarmata100% (6)

- Fencing SpecificationDocument6 pagesFencing Specificationkanji yamashitaNo ratings yet

- Catalog Duct Seal Panduit PDFDocument1 pageCatalog Duct Seal Panduit PDFedy yusufNo ratings yet

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (241)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Building Construction Technology: A Useful Guide - Part 2From EverandBuilding Construction Technology: A Useful Guide - Part 2Rating: 5 out of 5 stars5/5 (1)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- An Architect's Guide to Construction: Tales from the Trenches Book 1From EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1No ratings yet

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftFrom EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftRating: 5 out of 5 stars5/5 (5)

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsFrom EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsRating: 4.5 out of 5 stars4.5/5 (6)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- Field Guide for Construction Management: Management by Walking AroundFrom EverandField Guide for Construction Management: Management by Walking AroundRating: 4.5 out of 5 stars4.5/5 (3)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)