Professional Documents

Culture Documents

Acceptance Action Tracking - Rig ST-1 Closed Out

Uploaded by

Mn AnaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acceptance Action Tracking - Rig ST-1 Closed Out

Uploaded by

Mn AnaCopyright:

Available Formats

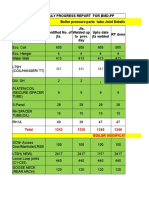

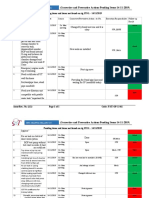

Acceptance Action Tracking - Rig ST-1

CO-MAN AUDIT

Category Open Closed

Statistics of the total Items

Critical 0 0

Major 0 0 Open 24 28.57

Minor 0 0 Closed 60 71.43

Total 24 60 Total 84 100%

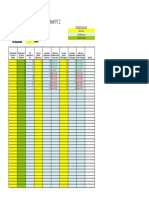

S\N Category Non-Conformance Description Corrective/Preventive Action Status Target Closing Date Action Party photos Closing Evidence

H ad shortage in 5' ' DP's grade G (available on

1 location 12 joints only), ne ed 340 Jts more as will be available next well open

per rig contract.

H ad shortage in 5' ' HWDP's grade (available rig contract 25 joints will be a vailable

2 on location 18 joints only), ne ed 12 Jts more tommorrow 8 joints (total will be 26 closed

a s per rig contract. joints)

Ha d shorta ge in 3 1/2'' DP's grade S

3 (available on location 143 joints only), need will be available next well open

49 Jts more a s per rig contract.

H ad shortage in 3 1/2' ' DP's grade G (no

4 a vailable on location any joints), need 192 Jts will be available next well open

more as pe r rig c ontrac t.

H ad shortage in 4 3/4" D/Cs, (available on

5 location 22 joints only), ne ed 2 Jts more as available 29 joints closed

per rig contract.

H ad shortage in 8 1/4' ' D/Cs (available on

6 location 3 joints only), need 21 Jts more as will be available next well open

per rig contract.

Ha d shorta ge in shale shaker and mud

c leane rs screens siz es 50, 70, 80, 100, 120,

140, 170, 200 me sh, so ne ed 19 E A X 50

7 mesh, 10 E A X 70 mesh, 6 EA X 80 mesh, 15 available closed

E A X 100 mesh, 6 EA X 120 mesh, 10 E A X

140 mesh, 19 EA X 170 me sh, 8 EA X 200

mesh

H ad shortage in cellar pumps (available on

8 location 1 pump only), nee d one more as per open

rig contract.

H ad shortage in 5" pup joint (available on

9 location 10' only), need 5' , 15' pup joints as available closed

per rig contract.

H ad shortage in 3 1/2" pup joint (available on

10 location 5',15' only), need 10' pup joint as per available closed

rig contract.

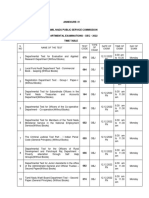

11- Had shortage in both 6" and 20" bit rings

11 open

needs both as per rig contra ct.

12- Had camera available on monkey board

but not w orking yet also had voic e

12 c ommunication system betw een driller and closed

derrick man but not working yet also there is

no a ny came ra available on mud system.

13- Poor lighting on rig floor, mud syste m,

13 closed

mixing area, well head area and c atwalk area .

14- Had no communication available (public

14 a ddress) betwee n driller console cabin a nd rig closed

c rew, ok done

15- Mud cle aner, desande r and dega sser

15 Replaced with new one open

gauge s are not calibrated ye t.

16- Sha le shaker supports c onnec ted by

16 screwed bolts should be replac ed by ce rtified closed

pins.

17 17- Degasser vent line need to be extended closed

18 18- Mud pumps need to be tested ready for test closed

19 19- Hopper No. ( 2,3) Moderate jetting ready for test closed

20- Need Sha kers spare parts, more screens,

20 springs, rubber, Vibra tion, G -Force check by closed

M anufacturer T ech.

21- Mud Saver Bucket Highly Ruste d, Need

21 closed

Rubber c heck or replacement

22- Desande r pressure gauge need to be

22 closed

replaced

23 23- Mud cleaner gauge need to be replaced closed

24- Premix 3 Agitator fixing, small long arms

24 closed

of Reserve 2 Agitators

25- Need to E xtend both MGS vent line and

25 open

vacuum degasser

26 26- Need to connect flare line for choke closed

manifold

27 27- No back up available on location for available under rerquest in Badr yard closed

a nnula r element

28 28- Had se veral flange s on mud system closed

missed bolts

29 29- No c austic soda/soda ash mixer available closed

on location

30 30- Need to install e arthling for choke closed

manifold

31 31- 7" circ. head not available on location closed

32- Rig re corder 8 pins not available on

32 available in drill watch unit closed

location

33 33- Found TOTCO survey not working closed

34- Had shortage in both vac cine s for snakes

34 a nd sc orpion ( a vailable on location only 1 closed

For Snakes & 2 for Sc orpion)

35- Almost wire s and slings in bad c ondition

35 open

a nd not certified

36- No ta nks volumes signs or scales

36 will be closed tommorrow open

a vailable for mud system

37 37- Found mud box rubbe r in bad condition changed closed

need to be cha nged

38 38- No pest control available on location open

39 39- Some of rig gauges not calibrated yet a ll gauge ca librated e xept new gauge s closed

for mud cle aner and de gasser .

40 40- No BOP locking device available on open

location

41- There is not any secondary re tention for

41 available now closed

the pulsation dampener

42- No mud gun in flow line if flow line

42 closed

plugged

43- There is not digital gauges for casing

43 equipped with analoge gauge. closed

pre ssure and drill pipe pressure on swaco

44 44- No safety signs at mud mixing area closed

45- Attende d accumulator test (from remote

c ontrol panel) found the following: charged

unite from ze ro to 3000 in 7 minutes,

pneumatic pump stopped a t 2700 psi and

e lectric pump c ontinued to inc rease pressure

to 3000 psi, shut off and isolated the

pneumatic and ele ctric pumps, func tion tested

a nnula r ram (close and open pressure dropped

to 2200 psi), function tested top pipe ram

(close d and opened pressure dropped to 1800

psi), func tion teste d bottom pip ram (closed

45 a nd opened, pressure dropped to 1700 psi), test done closed

c losed and opened bottom pipe ram again

instead of share ram (pressure dropped at

1500 psi), function tested kill line HCR

(pressure droppe d at 1400 psi), function

te ste d chock line H CR (pre ssure dropped to

1350), checked the accumulator gauge at the

a ccumulator unit found 1000 psi instead of

1350 on the remote pa nel (350 psi

discre pancy), turn on the pumps and

recharged the acc umula tor to 3000 psi in 7

minutes.

46 46- 9 5/8" ram not available on location available closed

47- Usable fluid in hydra ulic control unit not

47 will be available tommorrow open

e nough

48 48- Chart for rig test pump not tested yet closed

49- Protrac tor cla mp nee d to be insta lle d on

49 damaged spots of outside protection on choc k closed

manifold coflex

50 50- All chicksans are not available on loca tion closed

51 a vailable 2'' hoses with c ertificates 5K

51- 10k psi. 2" hose not ava ilable on location closed

Psi

52 52- Not e nough diverter vent line (only four will be available next well open

JT s available on loc ation)

53- 7" casing shooting nipple not ava ila ble on

53 open

location

54- 2 DSA s are missed, 13 5/8'' 10k psi x 13

54 closed

5/8'' 5k psi and 13 5/8" 10k psi x 11'' 5k psi

55- No platform and ladde r for pulsation there is movable ladder a vailable on rig

55 closed

dampe ner safe acce ss site

56- No record for 10 ye arly hydro test of mud a vialble wall thickness and CAT-4

56 closed

pump pulsation dampene rs c ertific ates for overhauling

57- No record for ye arly w all thickness

57 readings for mud pump a nd the entire high closed

pre ssure mud system

58- No record for ye arly recertifica tion of

58 available closed

mud pump pressure re lie f va lve

59- Rig has no N 2 purity meter on location to no c hargring done for N2 botte ls on rig

59 c hec k N2 purity before cha rging pulsation site ,tra nsfe rred from badr yard with closed

dampe ner c ertific ate.

60 60- Mud pump-1 w ithout any lock w ire for open

mud pump pulley also misse d bolts

61 61- Mud pump-1 motor blower screen is open

damaged and loose

62 62- PMS for Mud pumps belts not available open

63 63- Mud hoppers va lve flanges missing bolts will be closed tommorrow open

64 64- Water tank No. 3 missing bolts will be closed tommorrow open

te ste d OK without any leak and miss

65- Line betw een settling a nd intermediate

65 a llignment due to bad leve lling from closed

ta nk need alignment

the ground .

66 66- Walk way supports missing safety pins closed

not a pplicable as rig design de signates

67- No instrume ntation for monitoring drill

67 gauge s on swac o and remote control closed

pipe pressure for choke manifold

panel

68- Almost studs for BO P in different sizes

68 closed

a nd lengths and poor studs cleanness

69- No record for OEM certificates for

69 open

a ccumulator control hoses

70 70- No record for accumulator drawn down closed

te st

71- No a n emergency backup system

c onsisting of either an air pressure vesse l

71 w hich is isolated from rig air system with a open

non-return valve/N2 bottles should be

installed to supply the remote control system

of air

72 72- Accumulator unit no re cord for pre ssure closed

relieve valve 2 yearly ca libra tion

73 73- No record for ye arly w all thickness closed

inspe ction for mud gas sepa rator

74- No record that mud gas separator is H2S

74 open

trimmed

75- Pressure gauge for M ud gas separator not

75 open

c alibrated

76- There is not any RPM gauge for rotary

c onve rter chart from ampere to ft.ib

76 ta ble also T Q by ampere ne ed to calibrate to closed

poste d on driller ca bin

ft.ib

77- No record that draw w orks PM system is

77 update d and no major maintenance had be en closed

schedule d for the upcoming drilling period

78- No record that all draww orks caliper

CAT -4 overhauling for draww ork done

78 frames were inspected for crac ks within the closed

a t ja nuary 2020.

la st six months

79- No record to verify if the drawworks

79 springs of the safety ca lipers w ere rene wed closed

w ithin last year

80- No O EM or API recommenda tions for the

80 minimum numbe r of line wraps rema ining on closed

the drum with top drive at drill floor position

81 81- Drilling line ree ving diagram and closed

recommendations require d from OEM

82 82- No trace that groove s for the drum and closed

bra ke disc are ND T inspected

83 83- Hopper No. 3 valve missing handle closed

84 84- No je tting line available at end of flow closed

line to prevent flow line from plugging

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

Date: 09/04/2021 1/3

You might also like

- S - Curve MTR 119 OSDocument22 pagesS - Curve MTR 119 OSLuiz Haryst SuarezNo ratings yet

- Vertical Development Well Mud ReportDocument12 pagesVertical Development Well Mud ReportBOUBAKER LOGBINo ratings yet

- Installation and maintenance instructions for Speck Buffel and Pumpmeister pumpsDocument3 pagesInstallation and maintenance instructions for Speck Buffel and Pumpmeister pumpsSergei Kurpish0% (1)

- 7kN JackDocument2 pages7kN JackNguyen Quoc KhanhNo ratings yet

- SCPL civil and mechanical site works status updateDocument5 pagesSCPL civil and mechanical site works status updateJagadeesh rNo ratings yet

- POB BOGORO Location-Based Checklist-Mil Camps INDORDBDocument40 pagesPOB BOGORO Location-Based Checklist-Mil Camps INDORDBazzalea.marten88No ratings yet

- Materials Required For Stressing Prestressed Girders or SlabsDocument1 pageMaterials Required For Stressing Prestressed Girders or Slabshariom singh chaudharyNo ratings yet

- Persentasi DrillingDocument9 pagesPersentasi DrillingNova ArifienNo ratings yet

- PQC Report - Email, Turn OverDocument32 pagesPQC Report - Email, Turn OverDave GianganNo ratings yet

- Midwesco QA Base Fahud Semiannual Inspection ReportDocument3 pagesMidwesco QA Base Fahud Semiannual Inspection ReportNasser AL AzryNo ratings yet

- Aramco Balance Material Site IssuesDocument12 pagesAramco Balance Material Site IssuesVinay Yadav100% (1)

- Data Sheet Slot Breather ValveDocument4 pagesData Sheet Slot Breather ValveAzis Irfan Azis IrfansyahNo ratings yet

- Industry Academia Workshop on Design of Refinery Distillation ColumnsDocument70 pagesIndustry Academia Workshop on Design of Refinery Distillation ColumnsRADHE GRAPHICSNo ratings yet

- Motl DDR 59 PLT-12 2022-8-12Document3 pagesMotl DDR 59 PLT-12 2022-8-12Hando MiskuNo ratings yet

- Imd Todo List PDFDocument6 pagesImd Todo List PDFAnonymous qT80dF24dNo ratings yet

- Pressure Safety Valves DatasheetDocument1 pagePressure Safety Valves DatasheetUmer KhanNo ratings yet

- Safety PPE Status SwroDocument25 pagesSafety PPE Status Swroprasenjit ghatakNo ratings yet

- 24 Inch Casing Cementing ProgramDocument24 pages24 Inch Casing Cementing ProgramMarvin OmañaNo ratings yet

- DPR - Steel Pipeline Laying CGS To MS Dindugal GADocument5 pagesDPR - Steel Pipeline Laying CGS To MS Dindugal GAJk KarthikNo ratings yet

- VL10 Service Installation Ver2c SN 001-012Document62 pagesVL10 Service Installation Ver2c SN 001-012andrea772No ratings yet

- Westinghouse Lighting Price List Outdoor Lighting 10-73Document12 pagesWestinghouse Lighting Price List Outdoor Lighting 10-73Alan MastersNo ratings yet

- Rig:50 Diesel / Hydraulic Crane Weekly and Monthly ChecksDocument1 pageRig:50 Diesel / Hydraulic Crane Weekly and Monthly Checksvikrant911No ratings yet

- Mom Day 33Document65 pagesMom Day 33NSB-2018 PGDMNo ratings yet

- Bbattachment 1049Document3 pagesBbattachment 1049Harsh ChawdaNo ratings yet

- RCD Inspection ChecklistDocument8 pagesRCD Inspection ChecklistPrabhaker AllampallyNo ratings yet

- Smoke Detector Checklist August-2021Document1 pageSmoke Detector Checklist August-2021phitoNo ratings yet

- 6000 Spa PDFDocument51 pages6000 Spa PDFLmf DanielNo ratings yet

- Sewer SymbolsDocument12 pagesSewer SymbolsAlaa' MowafiNo ratings yet

- A320 Walkaround ChecklistDocument105 pagesA320 Walkaround ChecklistJaroslav Navrkal100% (1)

- Cement Mills Inspection ReportDocument4 pagesCement Mills Inspection Reportzain140No ratings yet

- Expresions 02Document24 pagesExpresions 02Dr.Amir SadeghiNo ratings yet

- TASKDocument6 pagesTASKMartin ArizaNo ratings yet

- 880GS-005-Jack-up Rig GlossaryDocument23 pages880GS-005-Jack-up Rig Glossarycaptainamerica1284No ratings yet

- Daily machine reportsDocument4 pagesDaily machine reportssatishNo ratings yet

- Level Glass Gauge Tightening ProcedureDocument2 pagesLevel Glass Gauge Tightening ProcedureUsman Aslam100% (1)

- Name of Company/Firm: National Highways Authority of IndiaDocument2 pagesName of Company/Firm: National Highways Authority of IndiapiuhyderabadNo ratings yet

- Model Silverstitcher: Box StitcherDocument32 pagesModel Silverstitcher: Box StitcherEnrique DelgadoNo ratings yet

- Office Building SI Location and Device ListDocument10 pagesOffice Building SI Location and Device ListEmmanuel ToretaNo ratings yet

- Ship equipment defect report and office commentsDocument1 pageShip equipment defect report and office commentsChowdhury MithilaNo ratings yet

- U1 Coh em Gen Bar ChartDocument1 pageU1 Coh em Gen Bar ChartSHITESH KUMARNo ratings yet

- DPR 25042013 1of2Document1 pageDPR 25042013 1of2Afiawan MaleekNo ratings yet

- Gate valve technical specificationDocument1 pageGate valve technical specificationkoraina2015No ratings yet

- Rig:50 Diesel / Hydraulic Crane Weekly and Monthly ChecksDocument1 pageRig:50 Diesel / Hydraulic Crane Weekly and Monthly Checksvikrant911No ratings yet

- 13 No - WAREHOUSE (Alread Submitted) : S.No Bill Description Total CostDocument5 pages13 No - WAREHOUSE (Alread Submitted) : S.No Bill Description Total CostMohammed AzharNo ratings yet

- Multicore Cable Schedule 15-9-01Document16 pagesMulticore Cable Schedule 15-9-01Archiford NdhlovuNo ratings yet

- Drill Collar Inspection ProcedureDocument1 pageDrill Collar Inspection ProcedureEdwin MPNo ratings yet

- Blowout Preventers:: Types of (Bops)Document3 pagesBlowout Preventers:: Types of (Bops)Mohamed Abd El-MoniemNo ratings yet

- Ac 7 PDFDocument146 pagesAc 7 PDFMohammed Al-hewaimel100% (1)

- CN Rexroth变量轴向柱塞泵A10VGDocument46 pagesCN Rexroth变量轴向柱塞泵A10VGcunvip163.comNo ratings yet

- Variable Flow PICV - Case StudyDocument19 pagesVariable Flow PICV - Case StudySikander AahilNo ratings yet

- SMPM Divider Valve - A compact progressive divider valve suitable until to eighteen outlets in a single blockDocument2 pagesSMPM Divider Valve - A compact progressive divider valve suitable until to eighteen outlets in a single blockPetru AncaNo ratings yet

- Rear Wipermasher: - ) Wreen I LtooDocument21 pagesRear Wipermasher: - ) Wreen I LtooDante amezquitaNo ratings yet

- Geotechnical Investigation QuotationDocument2 pagesGeotechnical Investigation QuotationMin KhantNo ratings yet

- Group 12 Brake Supply Valve: 1. StructureDocument2 pagesGroup 12 Brake Supply Valve: 1. StructureTaha RdmanNo ratings yet

- Group 12 Brake Supply Valve: 1. StructureDocument2 pagesGroup 12 Brake Supply Valve: 1. StructureTaha RdmanNo ratings yet

- Megguer Report 25-07-2020 Panel AlarmDocument2 pagesMegguer Report 25-07-2020 Panel AlarmMario Roberto Rodríguez RangelNo ratings yet

- 33kV Line BOQ R1Document1 page33kV Line BOQ R1Tukaram PawarNo ratings yet

- Joint Water Pressure ReportDocument2 pagesJoint Water Pressure Reporttarlok chandNo ratings yet

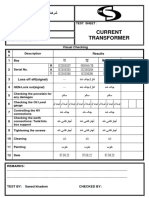

- Current Transformer: Visual Checking N o Results 1Document2 pagesCurrent Transformer: Visual Checking N o Results 1Ghorbani SaeidNo ratings yet

- Mahmoud Alaa El-Din: CC From Subject DateDocument1 pageMahmoud Alaa El-Din: CC From Subject DateMn AnaNo ratings yet

- Fire Fighting TeamDocument1 pageFire Fighting TeamMn AnaNo ratings yet

- Corrective and Preventive Actions Pending Items 14-11-2019Document4 pagesCorrective and Preventive Actions Pending Items 14-11-2019Mn AnaNo ratings yet

- Muhammad Al-BadriDocument14 pagesMuhammad Al-BadriMn AnaNo ratings yet

- Medic & First Aid Team: Crew A ID Course DateDocument1 pageMedic & First Aid Team: Crew A ID Course DateMn AnaNo ratings yet

- Mahmoud Alaa El-Din Islam Ahmed Hany Helal Ahmed Heikal ST-23 Breaking Sino Tharwa Policy 22/9/2021Document2 pagesMahmoud Alaa El-Din Islam Ahmed Hany Helal Ahmed Heikal ST-23 Breaking Sino Tharwa Policy 22/9/2021Mn AnaNo ratings yet

- OP-13-02 - CorrectiveDocument1 pageOP-13-02 - CorrectiveMn AnaNo ratings yet

- A. Kommy UnitDocument13 pagesA. Kommy UnitMn AnaNo ratings yet

- Math 4Document10 pagesMath 4Mn AnaNo ratings yet

- Saleh Mohammed: Date of Birth Gender Marital Status Driving LicenseDocument2 pagesSaleh Mohammed: Date of Birth Gender Marital Status Driving LicenseMn AnaNo ratings yet

- رياضDocument12 pagesرياضMn AnaNo ratings yet

- رياضDocument12 pagesرياضMn AnaNo ratings yet

- ItemsDocument2 pagesItemsMn AnaNo ratings yet

- Main Camp InspectionDocument17 pagesMain Camp InspectionMn AnaNo ratings yet

- MatDocument10 pagesMatMn AnaNo ratings yet

- Acceptance Action Tracking - Rig ST-1 Closed OutDocument2 pagesAcceptance Action Tracking - Rig ST-1 Closed OutMn AnaNo ratings yet

- Dy DX F (X+y) XF (XDocument3 pagesDy DX F (X+y) XF (XMn AnaNo ratings yet

- FDocument1 pageFMn AnaNo ratings yet

- FDocument6 pagesFMn AnaNo ratings yet

- رياضDocument12 pagesرياضMn AnaNo ratings yet

- FDocument5 pagesFMn AnaNo ratings yet

- FDocument4 pagesFMn AnaNo ratings yet

- FDocument1 pageFMn AnaNo ratings yet

- Dy DX F (X+y) XF (XDocument3 pagesDy DX F (X+y) XF (XMn AnaNo ratings yet

- FDocument5 pagesFMn AnaNo ratings yet

- Section 2. Calculation Formula.: Drilling - English Metric (Constant 10.2) Formula SheetDocument4 pagesSection 2. Calculation Formula.: Drilling - English Metric (Constant 10.2) Formula SheetMn AnaNo ratings yet

- FDocument5 pagesFMn AnaNo ratings yet

- 33 Trip SheetV1.2Document1 page33 Trip SheetV1.2Mn AnaNo ratings yet

- ةداملا مسا (Subject) ثحبلا ناونع (Research Title) Graphs and its importanceDocument18 pagesةداملا مسا (Subject) ثحبلا ناونع (Research Title) Graphs and its importanceMn AnaNo ratings yet

- Đáp Án K Năng NóiDocument6 pagesĐáp Án K Năng NóiSói ConNo ratings yet

- CENELEC RA STANDARDS CATALOGUEDocument17 pagesCENELEC RA STANDARDS CATALOGUEHamed AhmadnejadNo ratings yet

- Confidentiality Agreement With Undertaking and WaiverDocument1 pageConfidentiality Agreement With Undertaking and WaiverreddNo ratings yet

- TC-21FJ30LA: Service ManualDocument33 pagesTC-21FJ30LA: Service ManualRajo Peto alamNo ratings yet

- Fraud Ebook Latest - Databricks PDFDocument14 pagesFraud Ebook Latest - Databricks PDFmohitbguptaNo ratings yet

- Quiz Chapter 1 Business Combinations Part 1Document6 pagesQuiz Chapter 1 Business Combinations Part 1Kaye L. Dela CruzNo ratings yet

- English 3 PDFDocument177 pagesEnglish 3 PDFÇèrela ĆlavəcillasNo ratings yet

- ANNEXURE IV Dec 2022 enDocument17 pagesANNEXURE IV Dec 2022 enadvocacyindyaNo ratings yet

- Pertanyaan Dan Jawaban Interview Dengan Bahasa InggrisDocument2 pagesPertanyaan Dan Jawaban Interview Dengan Bahasa Inggrissan_idrus_sip99No ratings yet

- NIJ Sawmark Analysis Manual for Criminal MutilationDocument49 pagesNIJ Sawmark Analysis Manual for Criminal MutilationAntonio jose Garrido carvajalinoNo ratings yet

- Python operators and data types quizDocument34 pagesPython operators and data types quizATUL SHARMANo ratings yet

- Chengdu Bus GroupDocument2 pagesChengdu Bus GroupMohammad LabbanNo ratings yet

- NView NNM (V5) Operation Guide PDFDocument436 pagesNView NNM (V5) Operation Guide PDFAgoez100% (1)

- FINANCIAL REPORTSDocument34 pagesFINANCIAL REPORTSToni111123No ratings yet

- FLG 212 Study GuideDocument19 pagesFLG 212 Study GuidecynthiaNo ratings yet

- 1 MergedDocument93 pages1 MergedAditiNo ratings yet

- Water Booster Pump Calculations - Plumbing Engineering - Eng-TipsDocument3 pagesWater Booster Pump Calculations - Plumbing Engineering - Eng-TipsNeal JohnsonNo ratings yet

- Test Bank For Pediatric Nursing The Critical Components of Nursing Care 2nd Edition Kathryn Rudd Diane KociskoDocument36 pagesTest Bank For Pediatric Nursing The Critical Components of Nursing Care 2nd Edition Kathryn Rudd Diane Kociskolaurencelittlehdcj100% (25)

- Since 1977 Bonds Payable SolutionsDocument3 pagesSince 1977 Bonds Payable SolutionsNah HamzaNo ratings yet

- Teaching Methods in The PhilippinesDocument2 pagesTeaching Methods in The PhilippinesTonee Marie Gabriel60% (5)

- Key Differences Between Natural Sciences and Social SciencesDocument6 pagesKey Differences Between Natural Sciences and Social SciencesAshenPerera60% (5)

- Chapter 2 Research and DesignDocument24 pagesChapter 2 Research and Designalvin salesNo ratings yet

- Operational Readiness Guide - 2017Document36 pagesOperational Readiness Guide - 2017albertocm18100% (2)

- Indigo Vision CatalogDocument117 pagesIndigo Vision CatalogWAEL50% (2)

- The Essential Guide To Data in The Cloud:: A Handbook For DbasDocument20 pagesThe Essential Guide To Data in The Cloud:: A Handbook For DbasInes PlantakNo ratings yet

- Decision Flow Chart: For Suspicious PackagesDocument2 pagesDecision Flow Chart: For Suspicious PackagesHervian LanangNo ratings yet

- Steve Jobs MarketingDocument1 pageSteve Jobs MarketingAnurag DoshiNo ratings yet

- Ic T7HDocument36 pagesIc T7HCarlos GaiarinNo ratings yet

- 2020-Effect of Biopolymers On Permeability of Sand-Bentonite MixturesDocument10 pages2020-Effect of Biopolymers On Permeability of Sand-Bentonite MixturesSaswati DattaNo ratings yet

- English 9Document26 pagesEnglish 9Joann Gaan YanocNo ratings yet