Professional Documents

Culture Documents

Analysis of Wear Particles

Uploaded by

tribo technicalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analysis of Wear Particles

Uploaded by

tribo technicalCopyright:

Available Formats

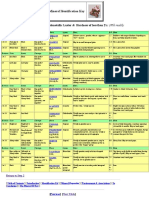

ANALYSIS OF WEAR PARTICES

Rubbing wear

wear due to rubbing, and is

typically considered normal.

Parallel, thin lines at the

beginning of ferrogram.

Contaminants

Dirt, sand and other silica

particulate.

SPHERE

A relatively smooth spherical

particle.

ANALYSIS OF WEAR PARTICES

BLACK OXIDE

Black oxides are

generated during metal-to-

metal contact where

micro-welding occurs and

are indicative of boundary

lubrication. Contaminants

are created by welding,

grinding, arcing, and blast

COPPER

Copper particles appear

golden orange, brass

appears golden yellow and

bronze appears a darker

yellow/orange when viewed

carbon

Black in color irregular

shape.

ANALYSIS OF WEAR PARTICES

Fibre

Fibers are thread-like

material made of

asbestos, paper, glass or a

synthetic material.

Cutting Wear

Shaved metal particles

that look like wood

shavings from a lathe.

Seen in sleeve bearings

and shaft couples.

HIGHE STEEL ALLOY

Gray before and after

heating pink in colour.

Ferrous and appears in

strings.

ANALYSIS OF WEAR PARTICES

BEARINGS

Flat particles with irregular

and smooth edges that have

holes in them.

LOW STEEL ALLOY

• Gray before heating, blue after heating (can also be

pink or red after heating). Ferrous and found in strings

ANALYSIS OF WEAR PARTICES

Corrosive wear

Fine particles at the exit of

ferrogram.

Sliding wear

Flat particles with parallel

striations on it at the entry

of ferrogram.

Molybdenum Disulphide

Grayish-purple in color with

many shear planes, non-

ferrous, semi-metallic, does

not change after heat

treatment.

You might also like

- Metal Lecture NotesDocument8 pagesMetal Lecture Notesbsnow5325No ratings yet

- Metal and Non MetalsDocument7 pagesMetal and Non Metalschhabra navdeep100% (1)

- Metal and Non MetalsDocument7 pagesMetal and Non Metalschhabra navdeep100% (1)

- Mark B. Dahay BSCRIM 2C Activity 4: Metals, Metalloids and Non-MetalsDocument3 pagesMark B. Dahay BSCRIM 2C Activity 4: Metals, Metalloids and Non-MetalsLa LieNo ratings yet

- GEO101 HW1M1 - Group EDocument20 pagesGEO101 HW1M1 - Group EDE GUIA, ENRICO GABRIEL F.No ratings yet

- 2.3 Non-Metals G6Document8 pages2.3 Non-Metals G6Ala'No ratings yet

- Metal Non MetalDocument19 pagesMetal Non MetalFatima M KhalifehNo ratings yet

- Caie Checkpoint Science Chemistry v4Document19 pagesCaie Checkpoint Science Chemistry v4Shame BopeNo ratings yet

- Megascopic Identification of Minerals: Physical Properties Quartz Talc Bauxite Biotite Mica Muscovite MicaDocument3 pagesMegascopic Identification of Minerals: Physical Properties Quartz Talc Bauxite Biotite Mica Muscovite MicaKannanGovindarajanNo ratings yet

- Metals and Non MetalsDocument23 pagesMetals and Non Metalsshaunchinu patilNo ratings yet

- Workshop Note1Document16 pagesWorkshop Note1ashanNo ratings yet

- Find The Symbols of The Following Metals in The Periodic TableDocument38 pagesFind The Symbols of The Following Metals in The Periodic Tablemenaga ilangkovanNo ratings yet

- Metals and Non-Metals: Grade 7Document15 pagesMetals and Non-Metals: Grade 7hihelloNo ratings yet

- Describe The Differences in Properties Between A Wooden Spoon and A Spoon Made of SilverDocument1 pageDescribe The Differences in Properties Between A Wooden Spoon and A Spoon Made of SilverMedo O. EzzatNo ratings yet

- Chemistry 8Document3 pagesChemistry 8joannavera2020No ratings yet

- Properties of Non Ferrous Metal Uses of Ferrous Metal: School of Civil Engineering and SurveyingDocument1 pageProperties of Non Ferrous Metal Uses of Ferrous Metal: School of Civil Engineering and SurveyingHadhi Hassan KhanNo ratings yet

- Combined Science (Chemistry) : METALS: Metal Properties UsesDocument2 pagesCombined Science (Chemistry) : METALS: Metal Properties UsesHn HMSNo ratings yet

- Name of Elements Properties Use/S 1. ZinkDocument13 pagesName of Elements Properties Use/S 1. ZinkNora Alfaro BalsakiNo ratings yet

- Degradation of Materials Nov 07Document29 pagesDegradation of Materials Nov 07vinguyNo ratings yet

- Materialscience Slide Chapter 5Document38 pagesMaterialscience Slide Chapter 5Kaizer UltimateNo ratings yet

- Common Metal Shapes and Terminology - Metalworking - Tractor Supply Co.Document4 pagesCommon Metal Shapes and Terminology - Metalworking - Tractor Supply Co.FredNo ratings yet

- l-27 Metals and Non-MetalsDocument2 pagesl-27 Metals and Non-MetalsMostafa ElngarNo ratings yet

- Aluminum: Type of Metal Color Properties Attacked By: Other InfoDocument2 pagesAluminum: Type of Metal Color Properties Attacked By: Other InfoVin Yaoshua de CastroNo ratings yet

- Alloys - ChemDocument1 pageAlloys - ChempotholemaryNo ratings yet

- Chemistry: Properties of MetalsDocument12 pagesChemistry: Properties of Metalsakiv shettyNo ratings yet

- Ferrous Metals: Ar1402 Building Materials and Construction - IiiDocument87 pagesFerrous Metals: Ar1402 Building Materials and Construction - IiiDevika Hemalatha DeviNo ratings yet

- Klarifikasi MaterialDocument7 pagesKlarifikasi MaterialBidin AgathaNo ratings yet

- Chapter 1 (A) Corrosion SlideDocument26 pagesChapter 1 (A) Corrosion SlideNasyitah TarmiziNo ratings yet

- Crop Production & ManagementDocument14 pagesCrop Production & ManagementAnkit PatelNo ratings yet

- Learn PracticallyDocument79 pagesLearn Practicallyprincethakan9No ratings yet

- Metals and Non-MetalsDocument11 pagesMetals and Non-MetalsdhandanikitaNo ratings yet

- Metals Non Metals Class 8 PDFDocument11 pagesMetals Non Metals Class 8 PDFTechnical AkshayNo ratings yet

- Experiment 5B Types of Chemical ReactionsDocument8 pagesExperiment 5B Types of Chemical ReactionsNicole ZhangNo ratings yet

- Metals and Non-Metals: Second Year ScienceDocument25 pagesMetals and Non-Metals: Second Year Scienceapi-406307933No ratings yet

- Case Study On MdisDocument16 pagesCase Study On MdisDing HangNo ratings yet

- Ferrography AnalysisDocument34 pagesFerrography Analysistribo technicalNo ratings yet

- Ferrous & Non-FerrousDocument1 pageFerrous & Non-Ferrousriain2008100% (3)

- Solid State Class 1 (4th May 2022) Handout and Home WorkDocument89 pagesSolid State Class 1 (4th May 2022) Handout and Home WorkShivacharan HollaNo ratings yet

- Engg Materials1Document3 pagesEngg Materials1Kallu KatiyarNo ratings yet

- INTRODUCTION TO STEEL - Part 1Document85 pagesINTRODUCTION TO STEEL - Part 1ragulNo ratings yet

- Defect-TrainingDocument16 pagesDefect-TrainingSubhash100% (1)

- Minerals: ColorDocument17 pagesMinerals: ColorsylNo ratings yet

- Materials and Construction - Iii: Lecture No. Iv Dated: 08/10/2018Document14 pagesMaterials and Construction - Iii: Lecture No. Iv Dated: 08/10/2018arooj anjumNo ratings yet

- MetalsDocument31 pagesMetalsChetan Raj PandeyNo ratings yet

- Metals.: Exercise 1: Make A List of All The Different Metals That You Know AboutDocument29 pagesMetals.: Exercise 1: Make A List of All The Different Metals That You Know AboutDurgesh Patil100% (1)

- CorrosionDocument4 pagesCorrosionMaria Α.No ratings yet

- Chemistry Notes (Metals)Document4 pagesChemistry Notes (Metals)Teo Jia Ming Nickolas67% (3)

- D&D 5E - Metals - Dungeon Master AssistanceDocument25 pagesD&D 5E - Metals - Dungeon Master AssistanceSamuel JouveNo ratings yet

- Reviewer Chapter 3-4Document2 pagesReviewer Chapter 3-4Kyle BullandayNo ratings yet

- Nature Guide Rocks and Minerals-2 - 51-100Document1 pageNature Guide Rocks and Minerals-2 - 51-100Jean PeutpuNo ratings yet

- Alloys: by MazlanDocument13 pagesAlloys: by MazlanAlia IzyanNo ratings yet

- Consmat Reviewer 1 2Document3 pagesConsmat Reviewer 1 2AicelleNo ratings yet

- Mineral Identification KeyDocument15 pagesMineral Identification KeyElla Mari ComiaNo ratings yet

- Form 1 Science Chapter 6Document10 pagesForm 1 Science Chapter 6Koo SengleeNo ratings yet

- Universal Self Scorer Errorless - "Solid State"Document10 pagesUniversal Self Scorer Errorless - "Solid State"100 RishabhNo ratings yet

- Metals and Non MetalsDocument28 pagesMetals and Non MetalsALEENANo ratings yet

- Mineral Project 2Document10 pagesMineral Project 2Hansel UngartNo ratings yet

- Chapter 5Document13 pagesChapter 5DUIN 1o1 VlogsNo ratings yet

- Major Lead Zinc DepositDocument20 pagesMajor Lead Zinc Depositzeeshan269No ratings yet

- SOPof Flash Point (ASTM D93 &D92)Document1 pageSOPof Flash Point (ASTM D93 &D92)tribo technicalNo ratings yet

- SOP of Total Acid NumberDocument2 pagesSOP of Total Acid Numbertribo technicalNo ratings yet

- Sop Wear Debris Analysis (Astm D-7690)Document2 pagesSop Wear Debris Analysis (Astm D-7690)tribo technicalNo ratings yet

- TN05 BasecatalystsDocument2 pagesTN05 Basecatalyststribo technicalNo ratings yet

- 5989 5924enDocument4 pages5989 5924entribo technicalNo ratings yet

- ViscosityDocument8 pagesViscositytribo technicalNo ratings yet

- Metals IdentificationDocument11 pagesMetals Identificationtribo technicalNo ratings yet

- Direct Reading Ferograh-5: Determination of Wear Particle Concentration in Oil 1.0 SCOPEDocument3 pagesDirect Reading Ferograh-5: Determination of Wear Particle Concentration in Oil 1.0 SCOPEtribo technicalNo ratings yet

- SOP of FerrographyDocument2 pagesSOP of Ferrographytribo technicalNo ratings yet

- Astm D-2244-ColorimeterDocument11 pagesAstm D-2244-Colorimetertribo technicalNo ratings yet

- Trace Nitrogen in Liquid Petroleum Hydrocarbons by Syringe/Inlet Oxidative Combustion and Chemiluminescence DetectionDocument5 pagesTrace Nitrogen in Liquid Petroleum Hydrocarbons by Syringe/Inlet Oxidative Combustion and Chemiluminescence Detectiontribo technicalNo ratings yet

- SOP For ViscosityDocument7 pagesSOP For Viscositytribo technicalNo ratings yet

- Ferrography AnalysisDocument34 pagesFerrography Analysistribo technicalNo ratings yet

- MAP V6.3: Reference ManualDocument106 pagesMAP V6.3: Reference ManualGkou DojkuNo ratings yet

- Plaquette - PRECASEM - CIMEC 2019 English VersionDocument18 pagesPlaquette - PRECASEM - CIMEC 2019 English VersionFranck BertrandNo ratings yet

- Camouflage Lesson PlanDocument4 pagesCamouflage Lesson Planapi-344569443No ratings yet

- Product Specifications: MB3F-PSA4-19DEDocument2 pagesProduct Specifications: MB3F-PSA4-19DEВадим ЧеховскийNo ratings yet

- SweetenersDocument23 pagesSweetenersNur AfifahNo ratings yet

- Inverse Curve Trip Time Calculation: Enter Values in White CellDocument3 pagesInverse Curve Trip Time Calculation: Enter Values in White CellVijay FxNo ratings yet

- Onitsuka Tiger PDFDocument67 pagesOnitsuka Tiger PDFAhmad Bilal MawardiNo ratings yet

- Bitsat Paper 5Document19 pagesBitsat Paper 5pranka5240100% (1)

- Aci 522R-06 PDFDocument25 pagesAci 522R-06 PDFaldi raimon100% (2)

- Science: The Menstrual CycleDocument4 pagesScience: The Menstrual CycleLena Beth Tapawan YapNo ratings yet

- Frequency Converter English ManualDocument33 pagesFrequency Converter English Manualproduccion multipack100% (2)

- Design of Cycle Rickshaw For School ChildrenDocument23 pagesDesign of Cycle Rickshaw For School ChildrenAditya GuptaNo ratings yet

- Soccer Training DiaryDocument1 pageSoccer Training DiaryMark DeaconNo ratings yet

- Lecture 1 - Reinforced Concrete - IntroductionDocument62 pagesLecture 1 - Reinforced Concrete - IntroductionChristopher PaladioNo ratings yet

- JMO 2023 (7, 8) Question PaperDocument2 pagesJMO 2023 (7, 8) Question PaperSuryanshu BhardwajNo ratings yet

- EMV Card Reader Upgrade Kit Instructions - 05162016Document6 pagesEMV Card Reader Upgrade Kit Instructions - 05162016Shashi K KumarNo ratings yet

- Book 2 - Koning (COMPLETO)Document100 pagesBook 2 - Koning (COMPLETO)Kevin VianaNo ratings yet

- Notice - Appeal Process List of Appeal Panel (Final 12.1.24)Document13 pagesNotice - Appeal Process List of Appeal Panel (Final 12.1.24)FyBerri InkNo ratings yet

- Accessories 162-USDocument20 pagesAccessories 162-USعايد التعزيNo ratings yet

- Design of CEB BuildingDocument20 pagesDesign of CEB BuildingVishalya Nipuni Lankeshi100% (1)

- Original Sandeha NivariniDocument117 pagesOriginal Sandeha NivariniHmis BlrNo ratings yet

- Editor: Lalsangliana Jt. Ed.: H.Document4 pagesEditor: Lalsangliana Jt. Ed.: H.bawihpuiapaNo ratings yet

- Lesson Notes Lecture 14Document5 pagesLesson Notes Lecture 14Quantum SaudiNo ratings yet

- Pelton2014 Para-Equilibrium Phase DiagramsDocument7 pagesPelton2014 Para-Equilibrium Phase DiagramsAbraham Becerra AranedaNo ratings yet

- Nissan 720 L4-2.0-Z20 1983-86 Manual PDFDocument641 pagesNissan 720 L4-2.0-Z20 1983-86 Manual PDFEduardo Ariel JuarezNo ratings yet

- Unit 3 InfiltrationDocument5 pagesUnit 3 InfiltrationHRIDYA MGNo ratings yet

- 11 - Morphology AlgorithmsDocument60 pages11 - Morphology AlgorithmsFahad MattooNo ratings yet

- A Collection of Ideas For The Chemistry Classroom by Jeff HepburnDocument14 pagesA Collection of Ideas For The Chemistry Classroom by Jeff HepburnPaul SchumannNo ratings yet

- CM Bu9000 Eng Bushings 3Document36 pagesCM Bu9000 Eng Bushings 3ing.dmanriq27100% (1)

- Instructor: DR - Ashok Kaushal: Orthogonal ViewsDocument49 pagesInstructor: DR - Ashok Kaushal: Orthogonal ViewsKristi GjokaNo ratings yet